TTBIO TTcare 100+ User manual

Thank you for purchasing the TTcae 100+, a dental handpiece maintenance unit.

The TTcae 100+ lubricates and internally cleans dental handpieces easily and effectively.

For optimum safety and performance, read this manual thoroughly before using the unit and pay close attention to the warnings and notes.

Keep this manual in a handy place for future reference.

感謝您購買TTcae100+牙科手機自動保養機。

TTcae100+ 能有效的清潔與潤滑牙科手機的內部結構。

為了獲得最佳的安全性和性能,使用本機前請閱讀本手冊,並密切注意所有的警告符號和意義。�

請將本手冊放在一個方便拿取的地方,以利隨時參考。

感謝您購買TTcae100+牙科手機自動保養機。

TTcae100+ 能有效的清潔與潤滑牙科手機的內部結構。

為了獲得最佳的安全性和性能,使用本機前請閱讀本手冊,並密切注意所有的警告符號和意義。�

請將本手冊放在一個方便拿取的地方,以利隨時參考。

Instruction Manual

雷虎生技股份有限公司

Manufactured by

TTBIO CORP.

台中巿40755工業區六路7號2F

2F.,NO.7, 6TH ROAD INDUSTRY PARK

TAICHUNG. TAIWAN 40755

TEL:886-4-23595958

FAX:886-4-23596893

E-mail:[email protected]

Website:www.ttbio.com

許可證字號:衛署醫器製壹字第004431號

售后服務:上海漢瑞祥貿易有限公司

地址:上海市延安西路1358號4B-1室

電話:021-32231198

傳真:021-32231196

生產商:雷虎生技股份有限公司

註冊地址:台中市西屯區協和里

工業區六路七號2F

生產地址:台中市西屯區工業六路七號2F

電話:886-4-23595958

傳真:886-4-23596893

網址:www.tbio.com

EC REP

CMC MEDICAL DEVICES & DRUGS S.L.

C/ Horacio Lengo N18.

CP29006,Málaga Spain

Content are subject to change without prior notice. 0JL0138V2

Automatic Handpiece Maintenance Unit

手機自動保養機操作說明書

2016.12

01

CONTENTS

PRECAUTIONS

DISCLAIMER

1. Warnings, Cautions and Notes

2. Specifications

3. Parts Identification

4. Setup

5. Operation

6. Maintenance and Replacement Parts

7. Maintenance and Inspection

8. Trouble shooting and Error Code

9. Tools and Consumables

10. Service Contacts

11. Information on Electromagnetic Compatibility

01

02

02

03

06

08

10

13

16

17

19

20

21

PRECAUTIONS

Most operation and maintenance problems result from insufficient attention being paid to basic safety

precautions and not being able to foresee the possibilities of accidents. Problems and accidents are

best avoided by foreseeing the possibility of danger and operating the unit in accordance with the

manufacturer’s recommendations. First thoroughly read all precautions and instructions pertaining to

safety and accident prevention; then, operate the equipment with the utmost caution to prevent either

damaging the equipment itself or causing injury.

Note the meaning of the following symbols and expressions:

■Note

This alerts the user of important points concerning operation.

The user (i.e. clinic, hospital etc.) is responsible for the management, maintenance and use of

medical devices. Also this equipment must not be used by anyone except legally qualified dentist or

doctors.

■Caution:

Federal law restricts this device to sale by or on the order of a dentist (for U.S.A.).

WARNINGS

CAUTIONS

NOTES

This warns the user of danger of death, serious injury or total equipment

damage and failure or fire.

This identifies methods not to be used or purposes which the instrument

is not suited for.

This alerts the user to the risk of light to medium injury or equipment

damage.

Do not use this equipment for anything other than its specified purpose.

English

02 03

• Explosion Hazard. Do not use near open flames or other ignition sources.

• Health Hazard. The area must be well ventilated. Breathing fumes could damage your health.

• The equipment must be properly grounded.

• Make sure the ground is properly connected.

• To prevent the spread of grave, life-threatening diseases like HIV and hepatitis B, autoclave

handpieces after performing regular maintenance using the TTcare 100+.

• Avoid the risks of electrical shock, equipment damage and fire during an electrical storm: Turn the

TTcare 100+ off and do not touch it or its cord.

• Wear surgical gloves, mask and protective eyewear to operate and clean the TTcare 100+.

WARNINGS

Electromagnetic wave interference caused by cellular phones, transceivers, remote controls and

similar transmission devices could cause the equipment to operate randomly. All devices which

transmit electromagnetic waves located near the work area should be turned off.

CAUTIONS

• Set the TTcare 100+ on a level and stable surface.

• Depending on the type of handpiece and coupling, there could be a release of oil mist. In this

case, lower the pressure to 4 bar.

• Oil will leak or spray out if the cans are not properly installed.

• Make sure the head is flat against the nozzle guide. If it is tilted, the nozzle might be bent or oil

might spray out.

• Oil will spray out of the chuck nozzle if the handpiece is removed too soon (before the beep).

NOTES

ATTENTION

TTBIO CORP. will not be responsible for accidents, instrument damage, or

(1) repairs made by personnel not authorized by TTBIO CORP.

(2) any changes, modifications, or alterations of its products.

(3) maintenance or repairs using parts or components other than those specified by TTBIO CORP. and

other than in their original condition

(4) operating the instrument in ways other than the operating procedures described in this manual or

resulting from the safety precautions and warnings in this manual not being observed

(5) workplace conditions and environment or installation conditions which do not conform to those

stated in this manual such as improper electrical power supply

(6) fires, earthquakes, floods, lightning, natural disasters, or acts of God.

1. Warnings, Cautions and Notes

• For some handpieces, an oil mist may be released if a burr is not inserted.

• Do not damage the o-ring on the coupling when attaching a handpiece. This could result in oil

spraying out or poor performance.

• Do not select a coupling that does not have a handpiece attached to it. This would result in oil

spraying out when the Start Switch is pressed.

• If the unit will not be used for a while, unplug it and close the main air valve.

• Please insure you use the correct adaptor for the instrument.

• Do not use couplings made for maintenance equipment other than the TTcare 100+. This could

result in release of oil mist or poor handpiece maintenance.

• Dispose of used oil pads according to regulations for medical waste.

• Do not fail to push the tray all the way in. Otherwise, oil could leak out or oil mist might be

released.

2. Specifications

Name TTcare 100+

AC 100-240 V 50/60 Hz

60VA max.

250V 2A Slow Blow Type

4~6 bar

4 bar

40 NL/ min

Approx. 9 kg

Width 295 × Height 385 × Depth 295 mm

Rating

Power Consumption

Fuse

Air Pressure

Recommended Air Pressure

Air Flow Rate

Weight

Size (including regulator)

Protection category (Dust-proof;

water-proof) IP20

Operating environment

Permitted in interior rooms

15 to 40°C (59 to 104°F)

25 to 90 %

2000 m (6560 feet)

Ambient temperature

Temperature

Humidity

Max. altitude

Transportation and storage conditions

-20 to 70°C (-4 to 158°F)

5 to 95 %

700 to 1060 hPa

Temperature

Humidity

Atmospheric pressure

English

04 05

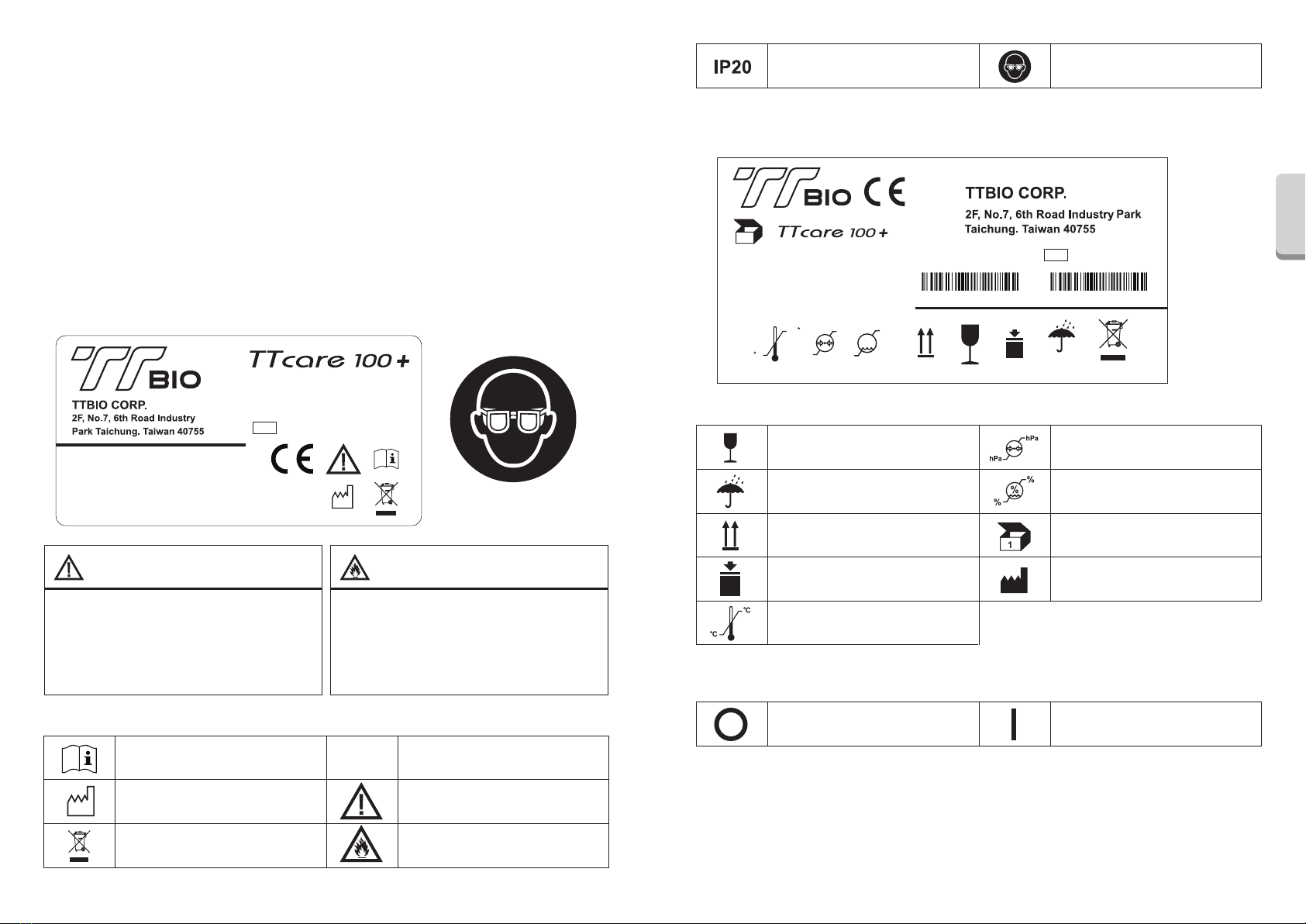

■Meaning of the Symbols

• Device Label

WARNING

• The blister can be cleaned with 30˚C±5˚C tap

water or 60% to 70% alcohol,

non-high-temperature cleaning.

• The blister can be used repeatedly, but

should be changed once broken.

FLAMMABLE

• Spray cans will explode if they get too hot.

• Do not expose the spray cans to heat.

• Only use approved spray can.

*PREVENT EXPLOSION AND

IGNITION OF SPRAY CANS!

• Appearing on the device

Observe operator’s manual

Date of manufacture

Disposal information, see

important information “ Disposal”

Serial Number

Warning

Flammable

SN

■Product Description

Used to maintain optimum performance and prolong working life of dental handpieces.

Delivers oil and air automatically to handpiece.

Used after dental treatment and before autoclaving.

■Disposal

The wastes incurred are to be recycled or disposed of in a way that is harmless for human beings

and the environment; in doing so, the national valid regulations are to be observed.

Disposal of equipment and accessories at the end of their service lives:

On the basis of EC Directive 2002/96/EC on Waste Electrical and Electronic Equipment, we would

like to point out that this product is currently in compliance with the labelling requirements but is not

yet subject to the disposal requirements of this Directive. However, the unit may be disposed of in

Europe in special waste management centers. Additional information can be obtained from the

manufacturer or your dental supplier.

Automatic Handpiece

Maintenance Unit

Product code : 08090012XXX

XXXXXXXXXXX

SN

INPUT :AC 100~240V 50/60 Hz

60VA max.

AIR PRESSURE: 4~6 bar

FUSE: 250V 2A Slow Blow Type YYYY-MM

IP20

Protection category

Dust-proof; water-proof Eye protection must be worn

• Appearing on the packaging

Fragile

Keep dry

Transport upright

Air pressure

Humidity

Quantity

Manufacturer

Stacking restrictions

Temperature range

■Main Switch

OFF ON

• Carton Label

20 kg

95%

5%

%

700

1060

hPa

hPa

70 C

-20 C

0473

Temperature range Air Pressure Humidity Fragile Keep dry

Transport

upright

Stacking

restriction

Waste

Disposal

Storage and transport requirements

1

Automatic Handpiece

Maintenance Unit

Product Code:

08090012

XXXXXXXXXXX

SN

English

06 07

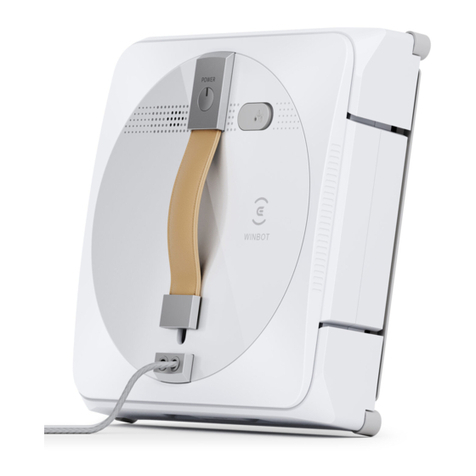

3. Parts Identification

■Introduction

Front Door

Tray

Absorption pad

Operation Panel

Side Door Air Regulator

Power Swtich

Power Cord Connection

Air Connection

Fuse Holder

Selector Lamps Empty Spray Can Indication

Start / Set /

Chuck Maintenance Switch

LCD Display

Selector Switches

Blister

Front door

Connection Nut

Chuck Nozzle

Side door

See Chapter2

See Chapter2

■Components

Main Unit Blister

(CODE No. 0PL0350)

Absorption pads

(CODE No. 0PL0351)

Oil Tray

(CODE No. 0PL0359)

Air Tube

(CODE No. 0PL0360)

*TTcare 100+ contains above standard components.

*Optional components see chapter 9.

English

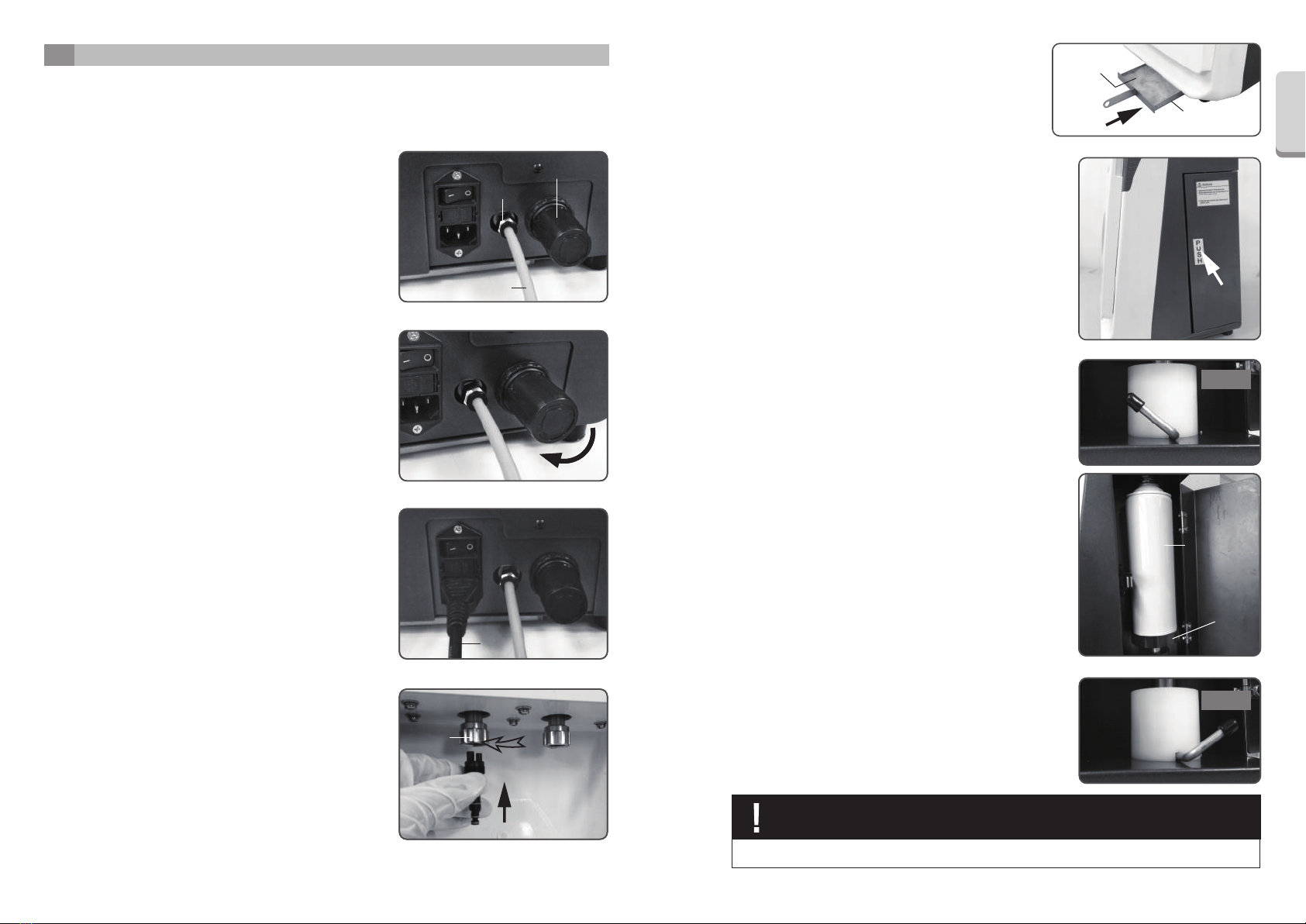

(2) Power Cord

Connect one end of the power cord to the main unit

and plug the other end into the electrical supply.

Power Cord

08 09

4. Setup

■Note

Leave at least 5 cm (2 in) of free and open space around the TTcare 100+.

(1) Air Connection

1. Connect the air tube to the air connection

and the main air supply.

Turn on the valve for the main air supply.

■Note

The main air supply must be clean and oil-free.

Make sure the tube is securely connected.

2. Set the air regulator dial between 4 and 6 bar.

Recommended Air Pressure is 4 bar.

■Note

Less than 4 bar or higher than 6 bar will result in an

error code.

(3) Adapter

Fit the adapter into the nozzle and fasten the nut.

Nut

■Note

Make sure the nut is securely tightened. Otherwise oil

and air will escape and cause incorrect maintenance.

2. Ensure the lock lever is on the left, place the spray

can on the stand shown in the photo.

Spray can

Stand

Unlock

3. Shift the lock lever to the right to secure the spray can.

Lock

■Note

Ensure the nozzle is properly connected.

Make sure the lock lever is all the way to the right,

otherwise the oil will not come out.

Gently pull the spray can to ensure it is secured.

Oil will leak or disperse if the cans are not properly installed.

NOTE

(5) Spray Cans

1. Open the side door.

Press the PUSH sign indicated in the photo to open the

door.

PRESS

■Note

Do not use Acidity Cleaner which is used for air

bearing handpieces only. It could damage both the

TTcare 100+ and the handpiece.

(4) Tray

Place two Absorption pads in the tray and slide it into

place.

Absorption

pad

Tray

■Note

Slide the tray all the way in; otherwise, it might leak.

Air Connection

Air Tube

Air Regulator

English

10 11

Spray can

stand

Adjust screw

5. Use a hex wrench to adjust the screw on the spray can

stand, if necessary.

■Note

This can make up for a difference in height of 5mm.

6. Close the side door.

4. Gently lift the spray can and ensure the nozzle is secured.

OK NG

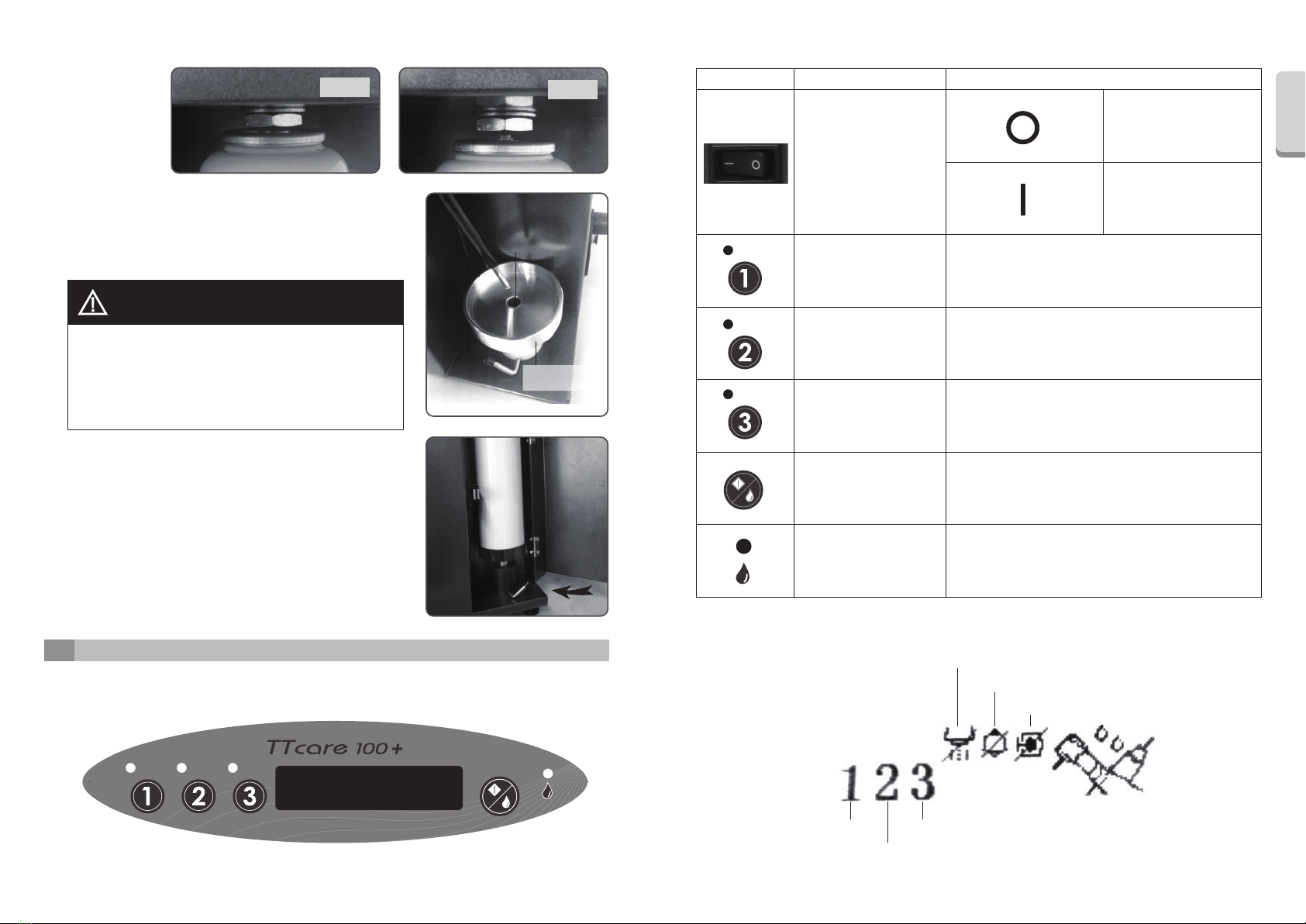

5. Operation

■Panel display:

■Operating instruction:

■Operating instruction:

Icons Functions Illustration

Power On/Off

Selection of handpiece 1

Selection of handpiece 2

Selection of handpiece 3

Handpiece 1 is selected when the lamp lights up.

Handpiece 2 is selected when the lamp lights up.

Handpiece 3 is selected when the lamp lights up.

Replace spray can when lamp lights up

1. Handpiece maintenance when door is closed

2. Chuck maintenance when door is open

3. Function setting by long press and wait for the beep

Start / Set / Chuck

maintenance switch

Spray can change

OFF

ON

Handpiece 1

Handpiece 2

Handpiece 3

Turn compressed air off

Turn buzzer sound off

Turn auxiliary motor off

• It is recommended to use TTBIO of TTlube spray can

for the TTcare 100+.

•The spray can nozzle and spray can stand are

designed to offer compatibility with other spray can

brands but dose not mean all applicable.

NOTE

English

12 13

■Operation maintenance:

■Note

● Air Turbine and Contra Angle :

Remove the test bur from the handpiece.

● Straight Handpiece :

Insert the supplied test bur into the handpiece and locking. (5) will show on LCD Display by pressing shortly. Press / /

to select handpieces which are connected to run optional auxiliary rotation.

(6) will show on LCD Display by pressing shortly.

■Compressed air setting:

Adjust air pressure by turning between 4.0-6.0 bars. Recommend to set air pressure at

4.0bars for TTcare 100+. Save and leave functional setting mode by pressing shortly.

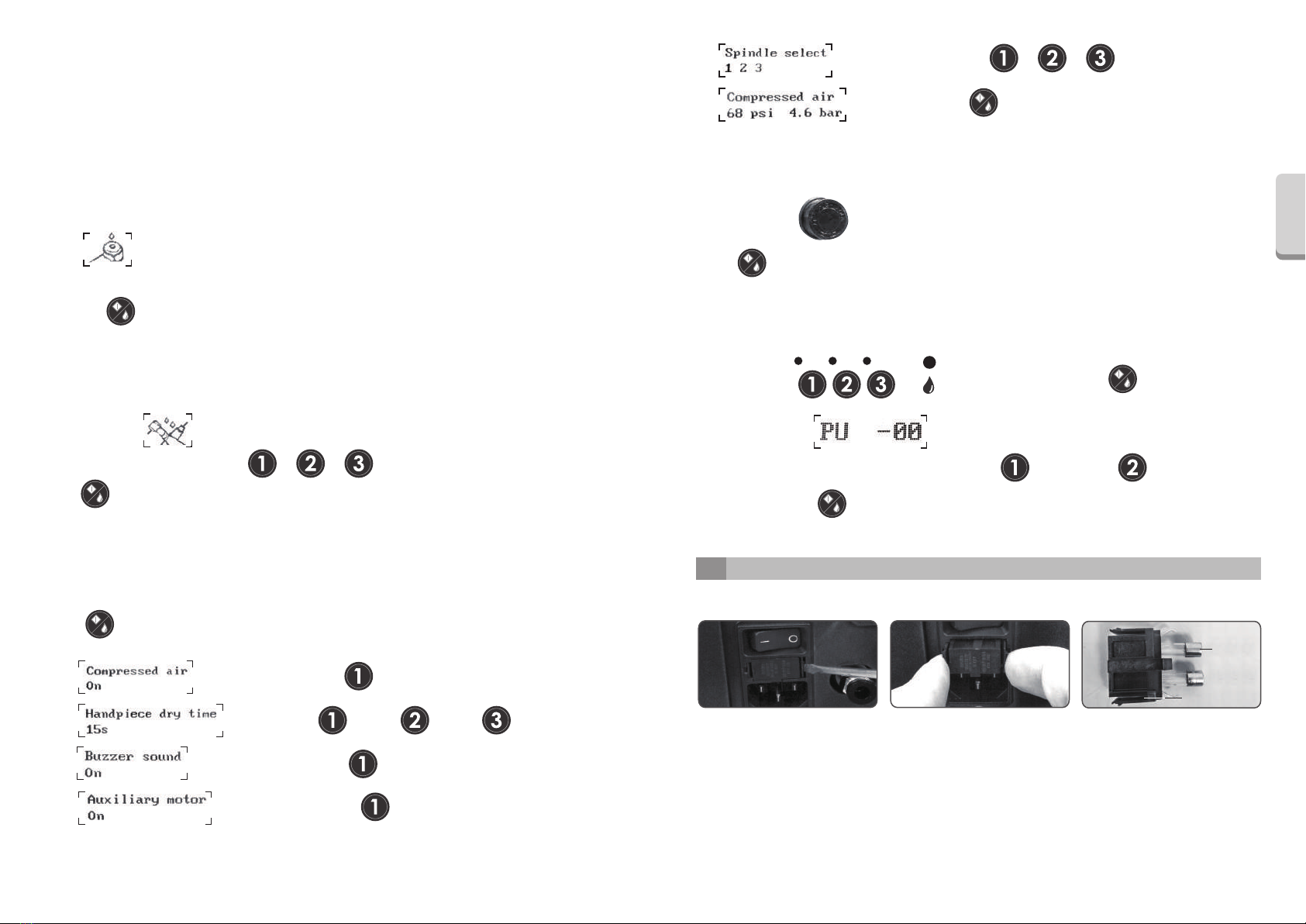

6. Maintenance and Replacement Parts

■Replace Fuse

(1) Press fuse holder by slotted wrench to loose the holder.

(2) Remove fuse holder.

(3) Replace new fuse (250V2A Slow-Blow type) into fuse holder

(4) Insert fuse holder.

Fuse

Fuse holder

■Oil amount adjustment :

(1) Indicator lights and are on when the Lubrication Unit is turned on. Press

for three seconds until it enters Oil amount adjustment mode, LCD will display:

(2) There are 11 adjustable oil amount from PU-00 to PU-10. Press for increasing or for

decreasing. PU-00 is the default setting, PU-10 has the largest oil amount.

Choose the PU value required, press button to complete setup. Lubrication unit will

automatically reboot after setting adjustments.

(1) Chuck maintenance:

Turn on the power switch. Open the front door.

will show on LCD Display during process.

Place the chuck side of head to the chuck nozzle.

Press to begin cleaning and lubricating the chuck .

A beep sound meaning the procedure is completed.

(2) Handpiece maintenance:

Turn on the power switch.

Open the front door.

Connect the handpiece to its coupling with the chuck facing back.

Make sure the handpieces are connected to the adapter until it clicks into place.

Close the front door.

will show on LCD Display during process.

Press / / to select handpieces which are connected.

Press to lubricate the handpieces in sequence order.

A beep sound meaning the procedure is completed.

(1) will show on LCD Display meaning compressed air is on.

Turn compressed air On/Off by pressing .

(2) will show on LCD Display by pressing shortly.

Maintenance time setting:

Select 15 sec by pressing /Select 20 sec by pressing / Select 30 sec by pressing .

(3) will show on LCD Display meaning buzzer sound is on by pressing shortly.

Select buzzer sound On/Off by pressing .

■Note

Pressing any button or opening the front door will immediately stop the maintenance procedure.

■Functional setting:

Select functional setting mode by pressing for approx 2 sec.

(4) will show on LCD Display meaning auxiliary motor is on by pressing

shortly. Select Auxiliary motor On/Off by pressing .

14

■Remove and Clean Front Door:

(1) Push left pivot upward and inward.

(2) Push right pivot upward and inward.

Left Pivot

Front Door

Front Pin

(3) Pull front pin in the direction of arrow shown in the

photo.

(4) Remove front door.

The front door can be cleaned with 30 ° ± 5 ° C tap water or 60% to

70% alcohol, non-high-temperature cleaning.

Nut

15

■Cleaning Couplings :

Loosen the nut and take the coupling off.

Clean it with ethanol 60 to 70 vol%

■Note

(1) Remove it carefully without damaging the o-ring.

(2) Couplings cannot be autoclaved.

■Note

Do not connect handpiece to the coupling when

o-ring is not properly fitted in its groove. Possible

damages to the o-ring and stuck in the coupling

may make it difficult for disassembling handpiece.

An o-ring could slip out of its groove.

Make sure all o-rings are properly seated in their

grooves before attaching a handpiece.

NG

OK

Upward

Blister

• The blister can be cleaned with 30˚C±5˚C tap water or 60% to 70% alcohol,

non-high-temperature cleaning.

• The blister can be used repeatedly, but should be changed once broken.

WARNING

■Remove and Clean Blister

Remove it upward.

Tray

■Cleaning the Tray:

(1) Take the tray out in the direction of arrow shown in the photo.

(2) Clean and replace new absorption pad.

• The tray cannot be autoclaved.

• Autoclaving will cause it to rust.

• Do not use disinfectants that contain

chlorine-based cleaners or benzalkonium

chloride or chlorinated aromatics.

• If this tray is not cleaned, oil will overflow

from the tray.

CAUTION

• Dispose of used absorption pad according to

regulations for medical waste.

• Push the tray all the way in, otherwise, oil

may leak and oil mist might be dispersed.

NOTE

16 17

7. Maintenance and Inspection 8. Trouble Shooting and Error Code

■Trouble Shooting

Breakdown Reason Solution

Main power lamp does not light up

Does not start when Start Switch is

pressed.

(1) Double beep sound

(2) Spray can Empty Lamp is

blinking

Unusual odor.

Surfaces are unusually dirty.

Cannot install spray can.

Oil leaks from spray can.

Power supply cord not properly

plugged into supply socket

Power supply cord not properly

plugged into TTcare100+

Front door may be open

Empty can

Can is not properly installed

Compressor air is not connected

Air regulator is not set properly

Close front door

Replace can

Properly install the can

Connect air

Set regulator properly

Use without connecting handpiece

Absorption pads is saturated

Can is not properly installed

Air regulator is not set properly

Select only couplings that have a

handpiece connected

Clean TTcare100+ and replace

filter

Properly install the can

Set regulator properly

Bent spray can nozzle pin

Wrong stand for spray can

Replace can

Use proper stand for can

Air pressure too high Reduce air pressure, but not less

than 4 bar

No burr inserted in straight

attachment.

Refer to the user instructions for

the handpiece. For some

handpieces, an oil mist may be

released if a burr is not inserted

Oil mist is released.

Equipment surfaces get oily

Type of handpiece or coupling

Depending on the type of

handpiece and coupling, there

could be a release of oil mist. In

this case, lower the pressure to 4

bar

Plug in properly

*Send the product every 2 years for a service check.

The safety checks in different countries can vary in compliance with country specific

regulations and requirements for medical devices. The national valid regulations are to be

observed.

*Repair and maintenance work- part from the activities described in these operating

instructions-may be performed only by qualified technical staff.

*Expected service life 5 years.

• In the event of modification by third parties, existing medical device licences become null and

void.

• Only use original parts and spare parts.

• The user( i.e. clinic, hospital etc.) is responsible for the management, maintenance and use of

medical devices.

■Regular Inspection

*Maintenance and inspection are generally considered to be the duty and obligation of the user, but

if, for some reason, the user is unable to carry out these duties, they may rely on a qualified

medical device serviceman. Contact your local dealer or the TTIBO CORP. for details.

• Regularly Required Replacement Parts

Fuse

• Other Replacement Parts

Absorption pads, Blister

(1) Power Supply Cord

Inspect visually for wear and broken wires.

(2) Main and Operation Switches

Turn on main switch and ensure main lamp lights up.

Check that the unit operates correctly.

(3) Absorption pads

Replace absorption pads(when the tray is filled by oil)..

English

18 19

9. Tools and consumables

■Error Code

Presentation Material summary Part No.

KaVo service adapter

W&H service adapter

NSK service adapter

Bien-Air service adapter

SIRONA service adapter

E-Type adapter

Spray can

Blister

Absorption pads

0PL0345

0PL0346

0PL0344

0PL0348

0PL0347

0PL0349

08090011

0PL0350

0PL0351

Error Code ReasonDescription Exclusion

Error 01

Error 02

Error 03

Error 04

Error 05

Error 06

Error 07

Error 08

Error 09

Error 10

Keyboard Error

Oil supply motor Error

Pressure input too low

Pressure input too high

Oil empty

Circuit is over temperature

Circuit detect Error

Auxiliary rotation motor

Error

Function Memory Access

Error

Electromagnetic valve Error

Faulty Motor

or internal circuit

Function keypad Error

Faulty Motor or internal

circuit

Air pressure lower than

preset

Air pressure higher than

preset

Faulty Main IC

Oil empty

Faulty Electromagnetic

valve

Faulty Motor or internal

circuit

Faulty Main IC

Contact your dealer

Contact your dealer

Contact your dealer

Increase air pressure

renew air setting(refer to

chapter 4)

Decrease air pressure

renew air setting(refer to

chapter 4)

Contact your dealer

Replace a new can of oil or

Contact your dealer

Contact your dealer

Contact your dealer

Contact your dealer

English

10. Service Contacts

■For repair or other types of service contact your local dealer or TTBIO CORP.

■Disposal of Medical Devices

Any medical devices which could possibly be contaminated must be first decontaminated by the

responsible doctor or medical institution and then be disposed by an agent licensed and qualified to

handle medical and industrial waste.

11. Information on Electromagnetic Compatibility

Emission Test Compliance

Group 1

Group B

Group A

Compliance

Electromagnetic environment-guidance

The TTcare 100+ is intended for use in the electromagnetic environment specified below.

The customer or the user of the TTcare 100+ should assure that it is used in such an environment.

Guidance and manufacturer’s declaration-electromagnetic emissions

RF emissions

CISPR 11

RF emissions

CISPR 11

Harmonic emissions

IEC 61000-3-2

Voltage fluctuations

/flicker emissions

IEC 61000-3-3

The TTcare 100+ uses RF energy only for its internal

function. Therefore, its RF emissions are very low and

are not likely to cause any interference in nearby

electronic equipment.

The TTcare 100+ is suitable for use in all

establishments, including domestic establishments

and those directly connected to the public low-voltage

power supply network that supplies buildings used for

domestic purposes.

20 21

English

22 23

English

Immunity test IEC 60601

test level

Compliance level

Electromagnetic

environment-guidance

The TTcare 100+ is intended for use in the electromagnetic environment specified below.

The customer or the user of the TTcare 100+ should assure that it is used in such an environment.

Guidance and manufacturer’s declaration-electromagnetic immunity

Electrostatic

discharge(ESD)

IEC 61000-4-2

Floors should be wood, concrete or

eramic tile. If floors are covered

with synthetic material, the relative

humidity should be at least 30%

± 6 kV contact

± 8 kV air

± 6 kV contact

± 8 kV air

Electrical fast

transient/burst

IEC 61000-4-4

Mains power quality should be that

of a typical commercial or hospital

environment.

± 2kV for power

supply lines

Not applicable

± 2kV for power

supply lines

± 1kV for

input/output lines

Surge IEC 61000-4-5

Mains power quality should be that

of a typical commercial or hospital

environment.

± 1kV differential

mode

Not applicable

± 1kV line(s) to

line(s)

± 2kV line(s) to

earth

The TTcare 100+ power frequency

magnetic fields should be at levels

characteristic of a typical location

in a typical commercial or hospital

environment.

3 A/m

3 A/m

Power frequency

(50/60 Hz)

magnetic field IEC

61000-4-8

Mains power quality should be that

of a typical commercial or hospital

environment. If the user of the

TTcare 100+ requires continued

operation during power mains

interruptions, it is recommended

that the TTcare 100+ be powered

from an uninterruptible power

supply or a battery.

<5% UT(>95%

dip in UT) for 0,5

cycle 40%

UT(60% dip in

UT) for 5 cycles

70% UT(30% dip

in UT) for 25

cycles <5%

UT(>95% dip in

UT) for 5 s

<5% UT(>95% dip

in UT) for 0,5 cycle

40% UT(60% dip

in UT) for 5 cycles

70% UT(30% dip

in UT) for 25

cycles <5%

UT(>95% dip in

UT) for 5 s

Voltage Dips, short

interruptions and

voltage variations

on power supply

input lines IEC

61000-4-11

■Note: UT is the a.c. mains voltage prior to application of the test level.

Immunity test IEC 60601

test level

Compliance

level

Electromagnetic

environment-guidance

The TTcare 100+ is intended for use in the electromagnetic environment specified below.

The customer or the user of the TTcare 100+ should assure that is used in such and environment.

Guidance and manufacturer’s declaration-electromagnetic immunity

Portable and mobile RF communications

equipment should be used no closer to any

part of the TTcare 100+ including cables,

than the recommended separation distance

calculated from the equation applicable to

the frequency of the transmitter.

Recommended separation distance:

d = 1,2 √P

d = 1,2 √P 80MHz to 800 MHz

d = 2,3 √P 800MHz to 2,5 GHz

Where P is the maximum output power

rating of the transmitter in watts (W)

according to the transmitter manufacturer

and d is the recommended separation

distance in metres (m).

Field strengths from fixed RF transmitters,

as determined by an electromagnetic site

survey, ashould be less than the compliance

level in each

frequency range.b

Interference may occur in the vicinity of

equipment marked with the following

symbol:

Conducted RF

IEC 61000-4-6 3 Vrms

3 Vrms

150 KHz to 80 MHz

Radiated RF

IEC 61000-4-3 3 V/m

3 V/m

80MHz to 2,5 GHz

■a: Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless)

telephones and land mobile radios, amateur radio, AM and FM radio broadcast and TV

broadcast cannot be predicted theoretically with accuracy. To assess the electromagnetic

environment due to fixed RF transmitters, an electromagnetic site survey should be

considered. If the measured field strength in the location in which the TTcare 100+ is used

exceeds the applicable RF compliance level above, the TTcare 100+ should be observed to

verify normal operation. If abnormal performance is observed, additional measures my be

necessary, such as re-orienting or relocating the TTcare 100+.

■b: Over the frequency range 150 kHz to 80 MHz, field strengths should be les than 3 V/m.

■Note1: At 80 MHz and 800 MHz, the higher frequency range applies.

■Note2: These guidelines may not apply in all situations. Electromagnetic propagation is affected

by absorption and reflection from structures, objects and people.

24 25

Rated maximum output

power of transmitter

W

Separation distance according

to frequency of transmitter

M

150 kHz to 80 MHz

d =1,2√P

80 MHz to 800 MHz

d =1,2√P

800 MHz to 2,5 GHz

d =2,3√P

The TTcare 100+ is intended for use in an electromagnetic environment in which radiated RF

disturbances are controlled. The customer or the user of the TTcare 100+ can help prevent

electromagnetic interference by maintaining a minimum distance between portable and mobile RF

communications equipment (transmitters) and the TTcare 100+ as recommended below, according

to the maximum output power of the communications equipment.

Recommended separation distance between

portable and mobile RF communications equipment and the TTcare 100+

0.01

0.1

1

10

100

0.02

0.38

1.2

3.8

12

0.12

0.38

1.2

3.8

12

0.23

0.73

2.3

7.3

23

For transmitters rated at a maximum output power not listed above, the recommended separation

distance d in metres (m) can be estimated using the equation applicable to the frequency of the

transmitter, where p is the maximum output power rating of the transmitter in watts (W) according to

the transmitter manufacturer.

■Note1: At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

■Note2: These guidelines may not apply in all situations. Electromagnetic propagation is affected

by absorption and reflection from structures, objects and people.

注意事項

免責聲明

1. 警告,注意和提醒

2. 規格

3. 零件說明

4. 設定

5. 操作

6. 維修和更換零件

7. 保養和檢查

8. 異常排除和故障碼

9. 工具和消耗品

10. 服務聯繫

11. 電磁相容性資訊

25

26

26

27

30

32

34

37

40

41

43

44

45

注意事項

大多數操作和維護問題都是因為忽略最基本的安全預防措施,並且沒有能夠預見到事故的問題和事故的

可能性。要避免問題產生與危險的可能性請按照製造商的建議操作。首先仔細閱讀所有有關安全和事故

預防和注意事項;然後在操作上需謹慎,以防止設備損壞或造成人身傷害。

注意下列符號和用語的含義:

■提醒:

此提醒用戶相關的操作要點。

用戶(即診所,醫院等)負責管理,維護和使用此保養設備。除非具有專業資格的牙醫或護士,其餘人

都不適合操作此設備。

■注意:

美國聯邦法律規定,此設備只能出售於有合格專業證書的牙醫。

警 告

注 意

提 醒

嚴重受傷或設備損壞或故障或引起火災的危險

使用不適當的方法或工具來操作設備

設備損壞或中等傷害

切勿把此設備用於非預期用途。

目 錄 繁體中文

26

注 意

TTBIO對於從事下面事項而造成設備損壞,將不負責任

(1) 由未經TTBIO授權的人員進行維修。

(2) 任何變更,修改或改變此產品。

(3) 維護或修理使用非TTBIO生產的零件或部件,而導致原始設定條件失效。

(4) 使用非此手冊提到的操作程序或沒有遵守本手冊中提到安全注意事項和警告。

(5) 工作場所的條件和環境,或安裝條件不符合本手冊中所規定的條件。

(6) 火災,地震,洪水,雷電,自然災害,或不可抗力之因素。

• 爆炸危害。使用時不要靠近火源或其他點火源。

• 健康危害。通風必須保持良好。因為吸入過多的煙霧可能會損害您的健康。

• 設備電源必須正確的連接。

• 電源接地需正確且妥善的連接與建立。

• 為了防止危及生命的疾病或病菌蔓延,如愛滋病和B型肝炎,在使用TTcare100+後,牙科手機需進

行高溫滅菌消毒。

• 避免觸電的風險。設備損壞和火災與雷電期間:關閉TTcare100+電源,且不要觸摸它或電源線。

• 操作或清潔TTcare100+時,請戴上手套,口罩和防護眼鏡。

警 告

手機,收發器,遙控器和類似的裝置有可能會引起電磁波干擾,造成設備錯誤。在靠近工作區會發射

電磁波的相關裝置都必須被關閉。

注意

• 不同的牙科手機和快速接頭,所釋放的油霧會不一樣。減少油霧的產生可調降壓力為最低的設定值

4bar。

• 保養油罐安裝不正確,會導致保養油洩漏或是無法順利出油。

• 筒夾保養時需確定牙科手機的筒夾有對準噴噴嘴。如果傾斜,會導致保養油噴射出來。

• 在保養未完成(蜂鳴聲)前,就把牙科手機從接頭拆下,會導致保養油從接頭噴射而出。

提醒

1. 警告,注意和提醒

繁體中文

27

• 對於某些牙科手機,在鑽針沒有安裝的情況下,油霧可能會被散出。

• 將牙科手機安裝到設備的接頭時,請不要損壞上面的O型環。這會導致保養油洩漏而使保

養效果不佳。

• 不要選擇一個跟手機不相配的的快速接頭,這會導致在按下啟動開關後保養油洩出。

• 如果一段時間不使用此設備,請將連接此設備,診所內的主空氣閥關閉。

• 請確認您使用正確的電源供應於TTcare100+。

• 不要使用非TTBIO生產的快速接頭於TTcare100+,這可能會導致釋放油霧過多 或牙科手機保養不

佳。

• 根據當地醫療廢棄物法規處置用過的吸油墊。

• 請將集油盤完全推入,否則過多的油與油霧可能洩漏。

2. 規格

產品名稱 TTcare 100+

AC 100-240 V 50/60 Hz

60VA max.

250V 2A Slow Blow Type

4~6 bar

4 bar

40 NL/ min

9 kg

295 ×385 ×295 mm

電壓與頻率

電力消耗

保險絲

壓力需求

建議壓力

空氣流量

重量

尺寸(寬/高/深)

保護等級(防塵防水) IP20

工作環境要求

只允許在室內使用

15 to 40°C (59 to 104°F)

25 to 90 %

2000 m (6560 feet)

位置

環境溫度

相對溼度

最大海拔高度

儲存及運輸環境

-20 to 70°C (-4 to 158°F)

5 to 95 %

700 to 1060 hPa

環境溫度

相對溼度

大氣壓力

繁體中文

28

■符號的意義

• 設備標籤

WARNING

• The blister can be cleaned with 30˚C±5˚C tap

water or 60% to 70% alcohol,

non-high-temperature cleaning.

• The blister can be used repeatedly, but

should be changed once broken.

FLAMMABLE

• Spray cans will explode if they get too hot.

• Do not expose the spray cans to heat.

• Only use approved spray can.

*PREVENT EXPLOSION AND

IGNITION OF SPRAY CANS!

• 設備上的符號

注意操作手冊

生產日期

廢棄資訊

參照重要資訊”廢棄物處置”

產品序號

注意

易燃

SN

■產品說明

用於保持牙科手機最佳性能和延長工作壽命。

自動提供保養油和空氣於潤滑清潔牙科手機。

用於牙科治療後,滅菌前。

■廢棄物處置

廢棄物必須在不傷害人類和環境的方法下回收處理;請遵照當地國家的法規進行。

到了壽命使用期限時,設備和配件的處置:

根據2002/96/EC的廢電氣電子設備指令,指出本產品標籤目前遵守其規定,但未受限於此指令處置要

求,然而,本產品可能由歐洲特殊廢棄物管理中心處理,其他的資訊可透過製造商或牙科供應商取得。

Automatic Handpiece

Maintenance Unit

Product code : 08090012XXX

XXXXXXXXXXX

SN

INPUT :AC 100~240V 50/60 Hz

60VA max.

AIR PRESSURE: 4~6 bar

FUSE: 250V 2A Slow Blow Type YYYY-MM

IP20

29

保護等級(防塵防水) 護目鏡佩戴

• 包裝上的符號

易碎

保持乾燥

垂直運輸

氣壓

溼度

數量

製造商

疊放規定

溫度範圍

■主電源開關

關 開

• 外箱標籤

20 kg

95%

5%

%

700

1060

hPa

hPa

70 C

-20 C

0473

Temperature range Air Pressure Humidity Fragile Keep dry

Transport

upright

Stacking

restriction

Waste

Disposal

Storage and transport requirements

1

Automatic Handpiece

Maintenance Unit

Product Code:

08090012

XXXXXXXXXXX

SN

繁體中文

30

3. 零件說明

■介紹

前門

集油盤

吸油棉

操作介面

油罐側門 氣壓調整閥

電源開關

電源接口

氣壓連接孔

保險絲座

手機選擇燈號 保養罐無油

啟動/設定/

筒夾保養

顯示屏

手機選擇鍵

31

泡殼

前門

手機連接頭

筒夾接嘴

油罐側門

見第2章

見第2章

■內容物

保養機 泡殼

料號:0PL0350

吸油棉

料號:0PL0351

集油盤

料號:0PL0359

氣壓管

料號:0PL0360

*TTcare 100+ 包含上述標準配備。

* 選購配件,請參閱第9章。

繁體中文

(2) 電源連接

將電源線的一端插入主機,另一端插入電源插座。

電源線

32

4. 設定

■注意

TTcare100 + 安置至少要離牆面5公分(2英吋)的距離,不可緊貼牆面。

(1) 氣壓連接

1. 將氣壓管連接到氣壓連接孔。打開診所內的供氣閥。

■注意

供給的氣必須是清潔不含油的。

請確保牢固地連接氣壓管。

2. 調整氣壓調整閥,將氣源設定4~6 bar。推薦的氣壓

為4 bar。

■注意

氣壓小於4bar或高於6 bar將會發生錯誤,會產生錯誤

代碼並顯示於顯示屏。

螺帽

■注意

確保螺帽是有旋緊的。否則,油和空氣會洩漏,而導致

保養不完全。

氣壓連接孔

氣壓管

氣壓調整閥

33

2. 確定如左圖中所示的固定桿,它是往左邊的,然後放

入保養油罐。

保養油罐

油罐座

未鎖固

3. 將固定桿往右邊推,使得油罐被固定,如右圖所示。

已鎖固

■注意

確定油罐噴嘴與保養罐是對正的。

確定固定桿如右圖所示,是往右的,否則油會出不來。

可輕輕拉一拉噴霧罐,確定它是穩固不會晃動的。

若是油罐沒被正確的安裝,它將會造成洩漏。

注 意

(5) 噴罐

1. 打開油罐側門。

按下PUSH標誌,如右圖所示。

壓

■注意

不要使用含有酸性或鹼性的清潔劑,它會損壞

TTcare100+和牙科手機。

(4) 集油盤

放入兩個吸油墊並往後推到底。

吸油棉

集油盤

■注意

集油盤需正確放入,否則,它會導致洩漏。

繁體中文

34

油罐座

調整螺絲

5. 如果油罐是鬆動的,可使用六角板手調整如右圖所示的

螺絲。

■注意

可調整的高度距離約5mm.。

6. 關上油罐側門。

4. 輕輕抬起噴霧罐,確認油罐噴嘴是否被固定,如下圖所示。

OK NG

5. 操作

■面板顯示

• 建議使用TTBIO生產的 TTlube保養罐。

• 油罐噴嘴和油罐座的設計可相容於某些品牌的保養油罐,

但不代表所有的保養油罐都可用。

注 意

35

■操作指令

■操作顯示說明

圖示 功能 操作指令

電源開關

1號手機

2號手機

3號手機

當選擇1號時燈會亮起

當選擇2號時燈會亮起

當選擇3號時燈會亮起

當燈號亮起代表油罐無油請更換

1.門關閉時,進行牙科手機保養

2.門打開時,進行筒夾保養

3.無任何燈號亮起時,長按進入功能設定

開始 / 設定 / 筒夾保養

保養油耗盡

關

開

1號手機

2號手機

3號手機

氣源 開/關

蜂鳴器 開/關

輔助馬達 開/關

繁體中文

36

■保養操作

■注意

● 高速手機與彎手機

保養時移除手機上的鑽針

● 直手機

保養時手機上插入鑽針並鎖上

(1) 筒夾保養:

打開電源,打開前門。

此符號將會顯示於顯示屏上。

將筒夾對準於設備噴嘴的出口。

按下 進行保養,發出”嗶”聲代表完成保養。

(2) 手機保養:

打開電源,打開前門。

將手機連接到設備的保養接頭上,請確認連接是有牢固的。

關上前門, 此符號將會顯示於顯示屏上。

選擇有接手機的位置,並按下 / / 進行保養,

發出”嗶”聲代表完成保養。

■注意

保養過程中,按下任意鍵或打開前門,保養將馬上停止。

■功能設定:

長按 鍵約2秒,進入設定功能。

(1) 氣源輸入 ON/OFF ,按下 可做切換。

(2) 保養吹氣時間, :15秒, :20秒, :30秒。

(3) 蜂鳴器響聲ON/OFF ,按下 可做切換。

(4) 輔助馬達 ON/OFF ,按下 可做切換。

37

6. 保養和更換零件

■更換保險絲

(1) 使用一字起子壓住保險絲座。

(2) 拉起保險絲座。

(3) 更換保險絲 (規格:250V 2A Slow-Blow type)

(4) 將更換完畢的保險絲座插回。

保險絲

保險絲座

■氣源輸入調整:

拉起壓力調整閥 然後轉動,調整壓力在4.0~6.0 bars。建議壓力為4.0 bars。

按下 鍵確定。

■保養油量調整:

(1) 開機後,在 和 的指示燈號一起全亮時,按下 鍵,

直到螢幕出現 。

(2) 總共有PU-00到PU-10共11段油量可供調整。按下 為增加,按下 為減少,選擇你所需

的油量後,按下 鍵確定儲存便會自動回到主畫面。

(5) 輔助馬達運轉選擇 ,按下 / / 來各別選擇需要啟動的手機。

(6) 氣源輸入顯示,按下 確定。

Table of contents