2 |Section

Table of Contents

1. Introduction...................................................................................................................................................................................................................4

1.1 Warranty...............................................................................................................................................................................................................4

1.2 Safety Information..................................................................................................................................................................................4

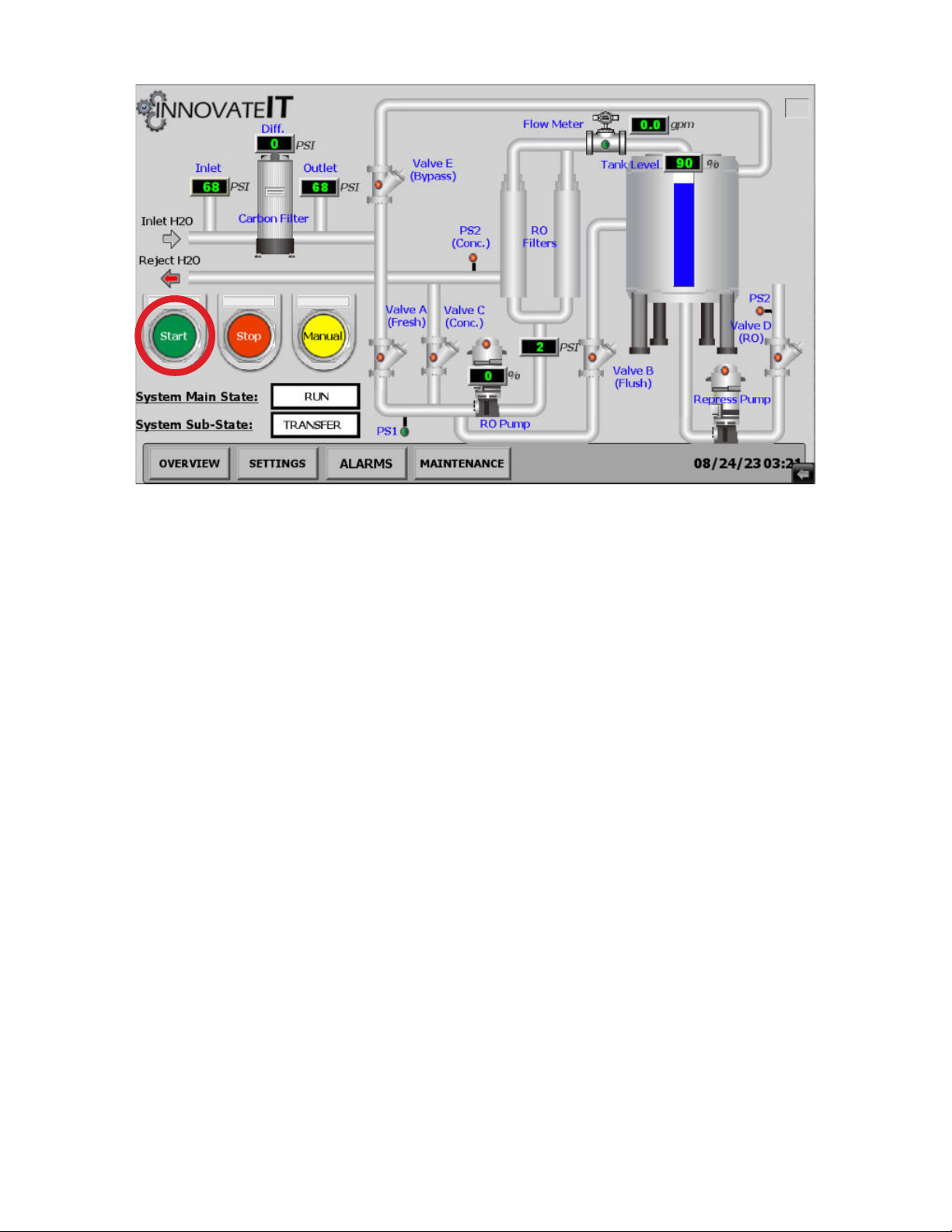

2. System Overview...................................................................................................................................................................................................5

2.1 Principles of Operations.................................................................................................................................................................7

2.2 System Operation...................................................................................................................................................................................7

2.2.1 Pump Inlet Pressure Switch (PS1)....................................................................................................................7

2.2.2 RO Pump Pressure Switch (PS2)........................................................................................................................8

2.2.3 RO Product Flow Sensor (ROFLO)...................................................................................................................8

2.2.4 Tank Level Sensor..................................................................................................................................................................8

2.2.5 Recirculation Flow Switch...........................................................................................................................................8

2.2.6 Re-Pressurization Pump Flow Switch........................................................................................................9

2.3 System Functions ....................................................................................................................................................................................9

2.3.1 Stop Mode.........................................................................................................................................................................................9

2.3.2 Start Mode.........................................................................................................................................................................................9

2.4 Tunnel Signal Command for RO Water Delivery to Tunnel.....................................................10

2.5 RO Storage Tank...................................................................................................................................................................................10

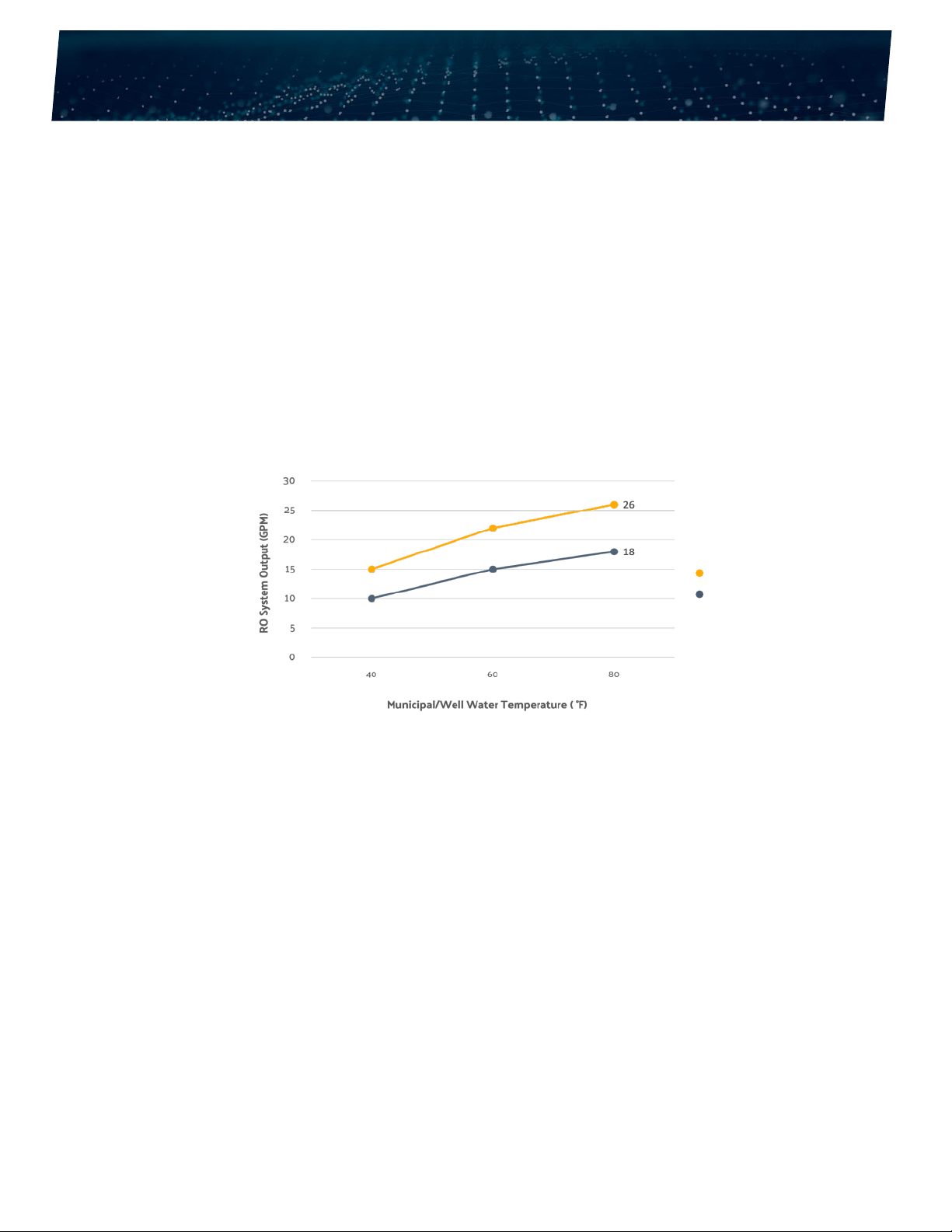

2.6 System Performance ........................................................................................................................................................................11

3. Installation Requirements......................................................................................................................................................................13

3.1 Pre-Treatment Solutions.............................................................................................................................................................13

3.1.1 Carbon Block for Chlorine and Chloramine Removal.......................................................13

3.1.2 Additional Feed Water Pre-Treatment...................................................................................................14

3.1.3 System Requirements...................................................................................................................................................14

3.2 Installation Preparation................................................................................................................................................................14

3.2.1 Water Supply.............................................................................................................................................................................15

3.2.2 Floor Drain.....................................................................................................................................................................................15

3.2.3 Compressed Air Supply...............................................................................................................................................15

3.2.4 Unit Placement.......................................................................................................................................................................15

3.4 ReverseOsmosisSystemIdenti cation...............................................................................................................16

4. Installation....................................................................................................................................................................................................................17

4.1 System Installation.............................................................................................................................................................................17

4.1.1 RO Membrane Installation......................................................................................................................................19

4.1.2 Electrical Installation......................................................................................................................................................20

5. System Startup......................................................................................................................................................................................................23

6. Maintenance.............................................................................................................................................................................................................28