TTI 1705 User manual

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 1

THURLBY THANDAR INSTRUMENTS

PROGRAMMABLE TRUE RMS MULTIMETER

Model 1705

INSTRUCTION MANUAL

Table of Contents

Introduction 2

Specifications 3

Safety 8

EMC 9

Installation 10

General Operation 12

Making Basic Measurements 16

Dual Measurement Mode 19

Advanced Features 21

DataLogging and Printing 25

Calibration 27

Maintenance 28

Remote Operation 29

Remote Commands 34

General Commands 34

Main Display Commands 35

Dual Measurement Mode Commands 37

First Level Modifier Commands 37

Second Level Modifier Commands 38

DataLogging Commands 39

Calibration Commands 40

Default Settings 41

1

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 2

Introduction

This programmable true RMS multimeter has dual measurement capability and a dual display †

which can show either two independent measurements, a measurement together with its range or

a measurement with one of the many calculated functions available.

The key features are:

• Large, high contrast, liquid crystal dual display.

• 0.04% basic accuracy, 12000 counts.

• Manual or autoranging.

• DC and AC Volts, DC and AC current, Resistance, Capacitance, and Frequency measurement;

Continuity and Diode checks.

• True RMS AC and AC+DC measurement.

• Display nulling and Ohms null.

• Touch hold mode - holds onto a stable reading until updated.

• 100 point data logger.

• Measurement post-processing to give:

dB and power measurement with settable reference impedance

percentage deviation from a user-entered reference

linear scaling with offset

limits comparison for go/no go testing

automatic storage of minimum and maximum readings.

• Remote control via addressable RS232 (standard) or GPIB (factory-fit option) interfaces.

• Closed case software calibration.

• Fully compliant with EN61010-1 Safety and EN61326 EMC standards.

† Licensed under U.S. Pat. 4,825,392

2

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 3

Specifications

ACCURACY

Accuracies apply for 1 year 19°C to 25°C. Temperature coefficient outside these limits is <0.1 x

quoted range accuracy per °C.

DC Volts

Ran

g

eAccurac

y

Resolution

100mV 0.06% ± 3 di

g

.*10uV *after null

1000mV 0.04% ± 2 di

g

.100uV

10V 0.06% ± 2di

g

. 1mV

100V 0.06% ± 2 di

g

. 10mV

1000V 0.06% ± 2 di

g

. 100mV

Input Impedance: 10MΩ//<100pF, except for Vdc plus Vac measurement when the

1MΩac attenuator is in parallel with the 10MΩdc attenuator.

Maximum Input: 1kV DC or AC peak, any range.

NMR: >60dB at 50/60Hz.

1kΩUnbalanced CMR: >90dB at DC/50Hz/60Hz.

Maximum Allowable AC Voltage While Measuring DC Voltage

Range Max AC Range Max AC The table shows the maximum AC voltage

100mV, 1000mV 6V 10V 80V (45Hz-50kHz) that can be applied without

100V 200V 1000V 1000V affecting the accuracy of the DC measurement.

AC Volts (True RMS)

Range Accuracy Resolution

45Hz - 10kHz 10kHz - 20kHz 20kHz - 50kHz

100mV 1% ± 20 dig. - 10µV

1000mV 1% ± 50 dig 100µV

10V 0.2% ± 20 dig 0.2% ± 20 dig 1% ± 80 dig 1mV

100V 1% ± 80 dig 10mV

750V - 100mV

Accuracy specifications apply for readings between 1,000 and 12,000 counts. Additional error at

crest factor = 3 typically 0.2%.

Extended frequency performance

(typical):

100mV range <-1dB at 50kHz; 1000mV,10V and

100V ranges <-1dB at 100kHz.

Input Impedance: 1MΩ//<100pF

Maximum Input: 750V rms, 1000V peak; any range.

1kΩUnbalanced CMR: >60dB at DC/50Hz/60Hz

3

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 4

(AC + DC) Voltage Accuracy

Total measurement error will not exceed the sum of the separate ac and dc accuracy

specifications plus 1 display count.

Resistance

Range Accuracy Resolution

100Ω0.1% ± 3 dig. 10mΩ

1000Ω0.08% ± 2 dig. 100mΩ

10kΩ0.09% ± 2 dig. 1Ω

100kΩ0.09% ± 2 dig. 10Ω

1000kΩ0.12% ± 2 dig. 100Ω

10MΩ0.5% ± 2 dig. 1kΩ

20MΩ0.5% ± 2 dig. 10kΩ

Maximum Input: 300V DC or AC rms, any range.

Maximum Open Circuit Voltage: 4V

DC Current

Range Accuracy Resolution

1mA 0.1% ± 3 dig. 100nA

100mA 0.1% ± 3 dig. 10uA

10A 0.3% ± 3 dig. to 1A 1mA

10A 1.0% ±3 dig. to 5A 1mA

10A 3% ± 10 dig to 10A 1mA

Maximum Input: mA ranges - 500mA DC or AC rms, 250V, fuse protected.

10A range - 10A DC or AC rms, 250V, fuse protected.

Typical Voltage Burden: mA ranges - <250mV

10A range - <500mV

AC Current (True RMS)

Range Accuracy (45Hz - 10kHz) Resolution

1mA 0.35% ± 20dig. 100nA

100mA 0.35% ± 20 dig. 10uA

10A 0.5% ± 20 dig. to 1A 1mA

10A 1.2% ± 20 dig to 5A 1mA

10A 3% ± 20 dig. to 10A 1mA

Accuracy specifications apply for readings between 1,000 and 12,000 counts. Additional error at

crest factory = 3 typically 0.2%.

Maximum Input: mA ranges - 500mA DC or AC rms, 250V, fuse protected.

10A range - 10A DC or AC rms, 250V, fuse protected.

Typical Voltage Burden: mA ranges - <250mV

10A range - <500mV

4

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 5

Frequency

Range Accuracy Resolution

100Hz 0.01Hz

1000Hz 0.01% ± 1 dig. 0.1Hz

10kHz 1Hz

100kHz 10Hz

Range: 10Hz to 100kHz

Input sensitivity: Better than 30m Vrms (100mV range); better than 10% of range

for all other Vac and Iac ranges.

Capacitance

Range Accuracy Resolution

10nF 10pF

100nF 100pF

1uF 2% ± 5 dig. 1nF

10uF 10nF

100uF 5% ± 5 dig. 100nF

Continuity and Diode Test

Continuity: 1000Ωrange selected; audible tone sounds for impedance <10Ω.

Diode Test: Test current approximately 0.5mA; displays voltages up to 1.2V.

Maximum Open Circuit

Voltage:

4V

Maximum Input: 300V DC or AC rms, any range.

DISPLAY

Display Type: High contrast LCD. Main display 4½ digits17mm high, secondary

display 5 digits10mm high.

Scale Length: 4¼ digits(12000 counts) in most modes.

Annunciators: LCD annunciators for all ranges, functions and program modes.

Reading Rate: Varies with function, maximum 4/sec.

Overrange: Display flashes 12000 if input too great for range.

Overflow: Displays -Or- if calculated result overflows display.

COMPUTING FUNCTIONS

Null (Relative) Stores current reading and subtracts it from future readings.

Ω Null: Additional non-volatile function for nulling test lead resistance.

Hold: Reading is frozen

T-Hold (Touch & Hold): Reading is frozen when stable.

dB: Displays measurement in dBm relative to 600Ω or other user-entered

impedance.

5

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 6

AC plus DC: The RMS value of the ac plus dc parts of the signal is calculated and

displayed.

% Deviation: Displays % deviation from entered reference value.

Ax+B: Linear scaling of results, with offset.

Limits: Reading displayed with HI, LO, or PASS with respect to user-defined

high and low limits.

Min/Max: Minimum and maximum reading stored.

Power: Calculates V2/R and displays in Watts with respect to a user-defined

impedance.

VA: Calculates and displays Volts x Amps.

DataLogger: Manual or automatic storage of 100 measurements. Storage interval

1s to 9999s, manually from keyboard, or by remote contact closure.

INTERFACES

Full remote control facilities are available through the RS232 (all models) or GPIB (alternative

mains-only version) interfaces.

RS232: Baud rates 2400, 9600 or 19200. Complies fully with the ARC

(Addressable RS232 Chain) interface standard. Address selectable

from the front panel. Operational only when the meter is powered from

the AC input.

GPIB (IEEE-488): The meter can be specified with an IEEE-488 interface. This is an

alternative version which operates only from AC mains; IEEE-488 is

not a retrofittable option. Address selectable from the front panel.

POWER REQUIREMENTS

AC Input: 220V-240V or 110-120V AC ±10%, 50/60Hz, by internal adjustment;

5VAmax. Installation Category II.

Batteries: 6 x C cells, disposable or rechargeable.

Battery Life: >150 hours from alkaline cells; typically 70 hours from rechargeable

cells.

GENERAL

Operating Range: +5°C to + 40°C, 20% to 80% RH

Storage Range: −20°C to + 60°C

Environmental: Indoor use at altitudes up to 2000m, Pollution Degree 1.

Safety: Complies with EN61010-1.

EMC: Complies with EN61326.

Size: 260(W) x 88(H) x 235(D)mm, excl. handle and feet.

Weight: 2.0kg.

6

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 7

EC Declaration of Conformity

We Thurlby Thandar Instruments Ltd

Glebe Road

Huntingdon

Cambridgeshire PE29 7DR

England

declare that the

Model 1705 True RMS Programmable Multimeter and

Model 1705GP True RMS Programmable Multimeter with GPIB

meet the intent of the EMC Directive 89/336/EEC and the Low Voltage Directive 73/23/EEC.

Compliance was demonstrated by conformance to the following specifications which have been

listed in the Official Journal of the European Communities.

EMC

Emissions: a) EN61326 (1998) Radiated, Class B

b) EN61326 (1998) Conducted, Class B

c) EN61326 (1998) Harmonics, referring to EN61000-3-2 (2000)

Immunity: EN61326 (1998) Immunity Table 1, Performance B, referring to:

a) EN61000-4-2 (1995) Electrostatic Discharge

b) EN61000-4-3 (1997) Electromagnetic Field

c) EN61000-4-11(1994) Voltage Interrupt

d) EN61000-4-4 (1995) Fast Transient

e) EN61000-4-5 (1995) Surge

f) EN61000-4-6 (1996) Conducted RF

Safety

Multimeter: EN61010-1

Installation Category I measurements to 1000V,

Installation Category II measurements to 600V,

Pollution Degree 1.

Probes: IEC1010-2-031

Rated to 1000V, Installation Category III.

CHRIS WILDING

TECHNICAL DIRECTOR

2 July 2004

7

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 8

Safety

This multimeter is a Safety Class I instrument according to IEC classification and has been

designed to meet the requirements of EN61010-1 (Safety Requirements for Electrical Equipment for

Measurement, Control and Laboratory Use). It is an Installation Category II instrument intended for

operation from a normal single phase supply.

WARNING! THIS INSTRUMENT MUST BE EARTHED WHEN OPERATED FROM AMAINS SUPPLY

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When operated from the internal batteries the multimeter meets the safety requirements for a Safety

Class II (reinforced insulation) product and does not require grounding for safety.

The test leads supplied with this instrument meet the requirements of IEC1010-2-031 and are rated

to 1000V Cat III; use only these test leads with the meter or a set of equivalent performance.

This instrument has been tested in accordance with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 1 environment (no pollution,

or only dry non-conductive pollution) in the temperature range 5°C to 40°C, 20% - 80% RH (non-

condensing). It may occasionally be subjected to temperatures between +5° and −10°C without

degradation of its safety. It has been designed for Installation Category II measurement use to

600VDC/ACrms. and Installation Category I measurement use to 1000VDC/750VACrms. The full

definitions of Categories I and II can be found in IEC664, but the following can be taken as a guide:

Installation Category I is signal level e.g. telecommunication, electronic equipment, with smaller

transient overvoltages than Installation Category II.

Installation Category II is local domestic supply level, e.g. portable equipment and appliances. In

particular, Category II does not include distribution level supplies, e.g. three phase installations

which are classified as Installation Category III.

For this equipment 2500V is the maximum peak transient overvoltage that can be tolerated by any

terminal with respect to earth ground without impairing safety.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range. In particular excessive moisture may impair safety.

When the instrument is connected to its supply or its inputs are connected to live voltages, terminals

may be live and opening the covers or removal of parts (except those to which access can be

gained by hand) is likely to expose live parts. The apparatus shall be disconnected from all voltage

sources before it is opened for any adjustment, replacement, maintenance or repair. Any

adjustment, maintenance and repair of the opened instrument under voltage shall be avoided as far

as possible and, if inevitable, shall be carried out only by a skilled person who is aware of the

hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protection may be impaired and the apparatus should be withdrawn

from use and returned for checking and repair. Make sure that only fuses with the required rated

current and of the specified type are used for replacement. The use of makeshift fuses and the

short-circuiting of fuse holders is prohibited.

Do not wet the instrument when cleaning it and in particular use only a softdry cloth to clean the

display window. The following symbols are used on the instrument and in this manual:

WARNING - risk of electric shock.

mains earth (ground)

CAUTION - refer to accompanying documentation;

incorrect operation may damage the meter. direct current

alternating current

8

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 9

EMC

This instrument has been designed to meet the requirements of the EMC Directive 89/336/EEC.

Compliance was demonstrated by meeting the test limits of the following standards:

Emissions

EN61326 (1998) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use. Test limits used were:

a) Radiated: Class B

b) Conducted: Class B

c) Harmonics: EN61000-3-2 (2000) Class A; the instrument is Class Aby product category.

Immunity

EN61326 (1998) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use.

Test methods, limits and performance achieved were:

a) EN61000-4-2 (1995) Electrostatic Discharge : 4kV air,4kV contact, Performance B.

b) EN61000-4-3 (1997) Electromagnetic Field, 3V/m, 80% AM at 1kHz, Performance B.

c) EN61000-4-11(1994) Voltage Interrupt, 1 cycle, 100%, Performance A.

d) EN61000-4-4 (1995) Fast Transient, 1kV peak (AC line), 0.5kV peak (DC Outputs),

Performance B.

e) EN61000-4-5 (1995) Surge, 0.5kV (line to line), 1kV (line to ground), Performance A.

f) EN61000-4-6 (1996) Conducted RF, 3V, 80% AM at 1kHz (AC line only; DC Output

connections <3m not tested), Performance A.

According to EN61326 the definitions of performance criteria are:

Performance criterion A: ‘During test normal performance within the specification limits.’

Performance criterion B: ‘During test, temporary degradation, or loss of function or

performance which is self-recovering’.

Performance criterion C: ‘During test, temporary degradation, or loss of function or

performance which requires operator intervention or system reset occurs.’

Where Performance B is stated the multimeter will continue to function but accuracy may deviate

from Specification under the test conditions. However,the possible deviations are small and

infrequent and are unlikely to be a problem in practice.

Cautions

To ensure continued compliance with the EMC directive the following precautions should be

observed:

a) only use screened cables and connectors to connect between the multimeter’s RS232

interface and other equipment.

b) after opening the case for any reason ensure that all signal and ground connections are

remade correctly before replacing the cover. Always ensure all case screws are correctly

refitted and tightened.

c) In the event of part replacement becoming necessary, only use components of an identical

type, see the Service Manual.

9

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 10

Installation

Mains Operating Voltage

Check that the instrument operating voltage marked on the rear panel is suitable for the local

supply.Should it be necessary to change the operating voltage, proceed as follows:

1) Disconnect the instrument from all voltage sources.

2) Unclip the front bezel by gently pulling the centre of each long edge up and forward.

The case halves are held together by 4 plastic push-rivets. Use the blade of a small

screwdriver in the slot beside each rivet to first ease out the rivet head and then fully remove

the rivet body. Separate the case halves. Visit www.tti-test.com for further details.

3) Change the transformer connections following the diagrams below:

4) Reassemble in the reverse order.

5) To comply with safety standard requirements the operating voltage marked on the rear panel

must be changed to clearly show the new voltage setting.

Mains Lead

When a three core mains lead with bare ends is provided it should be connected as follows:-

Brown - Mains Live

Blue - Mains Neutral

Green / Yellow - Mains Earth

WARNING! THIS INSTRUMENT MUST BE EARTHED WHEN OPERATED FROM AN AC LINE SUPPLY

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

Battery Operation

To fit or replace the six ‘C’ cells, slide off the battery cover at the rear of the instrument and

remove the battery tray. For safety reasons the battery cover can only be slid off after first

removing the security screw with a screwdriver. Always refit the security screw after changing the

batteries.

10

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 11

Either rechargeable or disposable cells may be used; fit into the battery tray observing the polarity

marked in the tray. Suitable cells are as follows:

Rechargeable:2 Amp hour, e.g. NCC200, AN220, VR2C, RSH1.8, P-180C.

Disposable: Alkaline, e.g. MN1400.

Zinc Carbon, e.g. R14B, R14S.

If batteries are fitted it is essential that the disposable/rechargeable selector switch on the rear

panel is positioned correctly before applying external power via the AC socket.

WARNING! If disposable batteries are fitted and the selector is set in the rechargeable

position, there is a risk of explosion if the meter is connected to an AC supply.

The Rechargeable batteries are charged at a ‘trickle’ rate of C/20; the time to fully charge from

completely discharged is approximately 28 hours.

Low battery condition is indicated by showing the battery symbol in the top left-hand corner of the

display; when this symbol shows, approximately 5% of battery life remains.

Handle

Adjust the handle position by pulling out the ends and rotating the handle to the desired position.

There are sixteen possible positions including five facing forward which provide upward tilts for

the most convenient bench operation. The handle may be swung out of the way to the back or

front of the instrument if no tilt is required. The natural spring in the handle will lock it into position

when the handle is released.

11

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 12

General Operation

This section is a general introduction to the features and organisation of the multimeter intended

to be read before using the instrument for the first time. Detailed operation is covered in later

sections, starting with Making Basic Measurements.

Connections

Input Sockets

The input socketsare 4mm safety socketson a 19mm pitch designed to accept 4mm safety plugs

with fixed or retractable shrouds. The socketsare all rated to 1000V (Cat I)/600V (Cat II) with

respect to earth ground.

The input impedance between V/Ωand COM is nominally 10MΩon dc ranges and 1MΩon ac

ranges. The black COM socket is considered less positive than the red socket.

The mA/10A current socketsare low impedance; the voltage burden between mA/10A and COM

at full scale is <250mV for the mA ranges and <500mV for the 10A range. The black COM socket

is considered less positive than the white mA/10A sockets.

Multimeter Test Leads

The test leads supplied meet the requirements of IEC1010-2-031 and are rated to 1000V Cat III.

Use only the test leads provided, or a set of similar performance, to ensure safe operation.

Alternative test leads should be rated to at least 1000V (Cat I), 600V (Cat II) and 10A current

capability.

RS232

The RS232 interface only operates when the instrument is run from an ac supply; RS232 signal

ground is then connected to the safety ground. The interface is fully isolated from the

measurement system.

9-pin D-connector compatible with the Thurlby Thandar ARC (Addressable RS232 Chain) system.

The pin connections are shows below:

Pin Name Description

1 - Power to optional PC-02

2 TXD Transmitted data from instrument

3 RXD Received data to instrument

4 - No internal connection

5 GND Signal ground

6 - No internal connection

7 RXD2 Secondary received data

8 TXD2 Secondary transmitted data

9 GND Signal ground

Pin 2, 3 and 5 may be used as a conventional RS232 interface with XON/XOFF handshaking.

Pins 7,8 and 9 are additionally used when the instrument is connected to the ARC interface.

Signal grounds are connected to safety ground.

To ensure compliance with EMC legislation use only screened cable assemblies with screened

connectors when connecting to other equipment.

GPIB (IEEE-488)

An IEEE-488 interface is available on the alternative mains-only version; IEEE-488 is not a

retrofittable option. The GPIB connector is located on the rear panel together with the switch

which selects between RS232 and GPIB.

12

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 13

The interface is fully isolated from the measurement system and the GPIB signal grounds are

connected to the safety ground. The pin connections are as specified in IEEE std. 488.1-1987.

The implemented subsets are:

SH1, AH1, T8, L4, SR0, RL2, PP0, DC1, DT0 C0, E2

The address is selectable from the front panel.

Switching On

Power Switch

The multimeter is switched on and off with alternate presses of the Operate key; this key only

switches the DC power to the measurement circuits. It does not switch the AC power, when this is

connected, which means that the isolated RS232 and GPIB circuitscontinue to be powered and

rechargeable cells (if fitted) continue to be charged. When the instrument is not in use, and if

battery recharging is not required, disconnect from the AC supply.

If the AC supply is removed whilst the meter is switched on one of two things will happen. If the

meter had been switched on (with the Operate key) after connection to AC power the meter will

automatically power off; if continued operation (from batteries) is required it will be necessary to

switch the instrument back on again. In this way the accidental exhaustion of batteries is avoided

when AC power is switched off, e.g. when a whole bench of equipment is switched off from a

master switch.

However,if the meter had been switched on and run from batteries before the AC power was

connected it will continue to run when the AC power is later removed. In this mode the batteries

provide back-up in the event of an AC power failure, useful if the meter is “baby-sitting” making,

for example, Min-Max measurements over a long time period.

When the instrument is switched on with the Operate key the display first shows all the display

segments whilst running an auto-zero routine before setting the operating conditions as described

below.

Power-up Settings

At power-up the default action is to restore power-down settings, including any modifiers selected

at the time that the meter was turned off.

To restore factory default settings (see Default Settings section), hold the Cancel key depressed

whilst the meter is turned on with the Operate key; the buzzer will sound to signify that the

defaultshave been restored.

To review the revision of the installed software hold the Shift key depressed whilst the meter is

turned on with the Operate key; the revision will be shown as r x.x until the Shift key is released.

To show all the display segments together (i.e. perform a display test) hold any other key

depressed whilst the meter is turned on with the Operate key; the display will continue to show all

segments until another key is pressed.

Buzzer

Ashort beep is sounded whenever a valid key is pressed. Longer beeps are reserved to indicate

illegal key presses, e.g. selecting Hz in the secondary display when the primary display has been

set to Vdc; such keystrokes are not accepted.

13

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 14

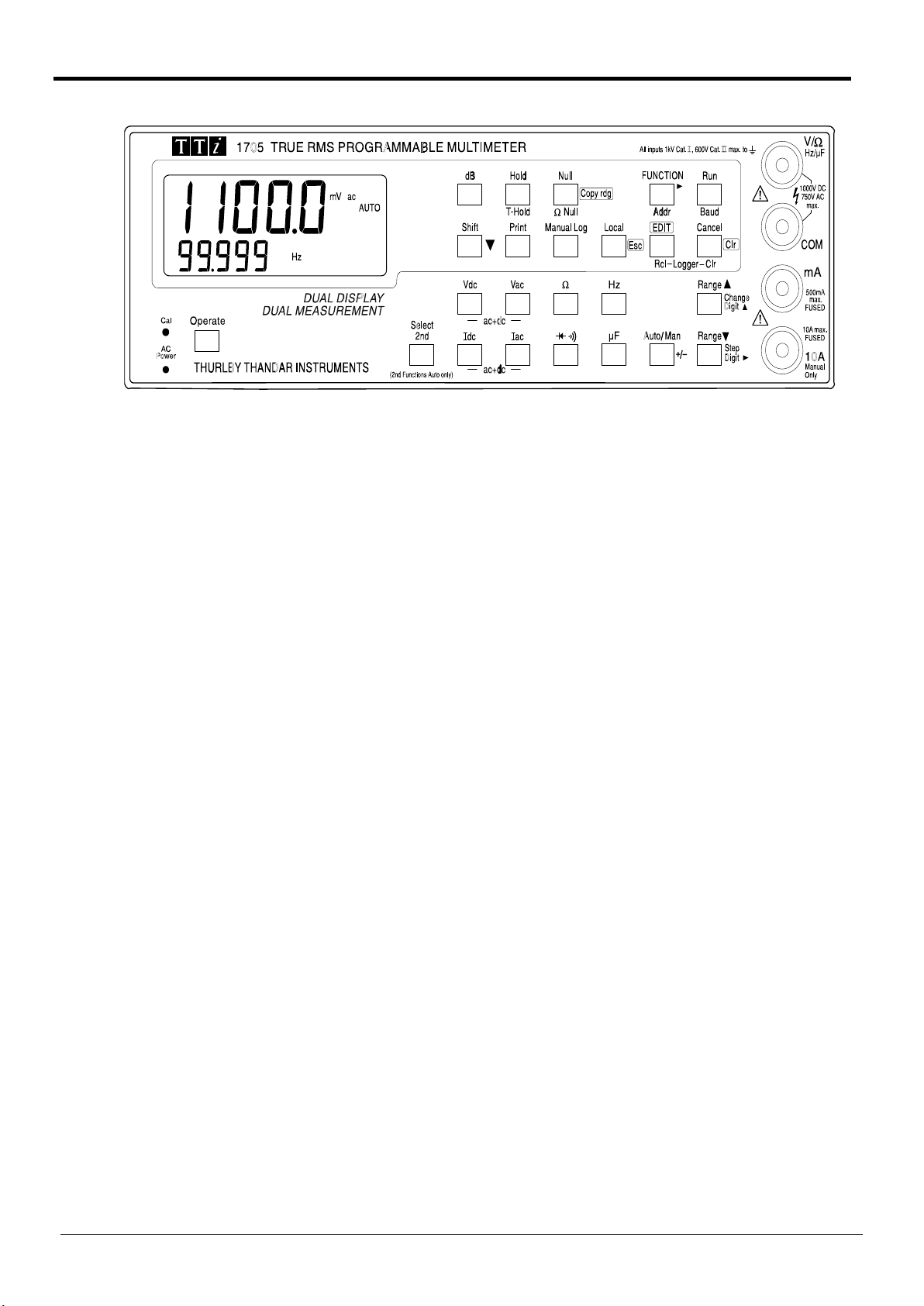

Keyboard

Keyboard Organisation

The keys can be considered in two groups:

The two rows of keys in the lower half of the keyboard directly select the functions and ranges of

both the primary and secondary displays. When pressed alone the function keys select the

function of the primary display,cancel any secondary function, and set autorange; the operating

range is shown in the secondary display.Pressing Select 2nd followed by a function key selects

the function of the secondary display; this is explained fully in the Dual Measurement Mode

section, which also details which combinations of functions can be used.

Auto/Man and Range Up/Range Down keys are additionally used when editing numbers for some

of the modifier functions, see the Number Editing section.

The two rows of keys in the upper part of the keyboard give access to all the modifiers, i.e.

mathematical functions which act upon the primary measurement function. At the simplest level

these are, for example, the display of ac voltages in dBs; more complex functions include Ax + b

scaling, delta% and data logging. The access to and operation of all modifiers is fully explained

in the Advanced Features section later in this manual. It is sufficient to note here that some keys

have different functions during modifier editing, indicated by the blue legend beside the keys, and

some keys have shifted functions (following the pressing of the Shift key), marked beneath the

keys in yellow.

Number Editing

Delta %, Limitsand Ax + b modifiers operate with numbers which are set by entering edit mode

after the modifier has been selected. Number editing operates in the same way for all these

modifiers and is described here to avoid repetition in each of the modifier sections.

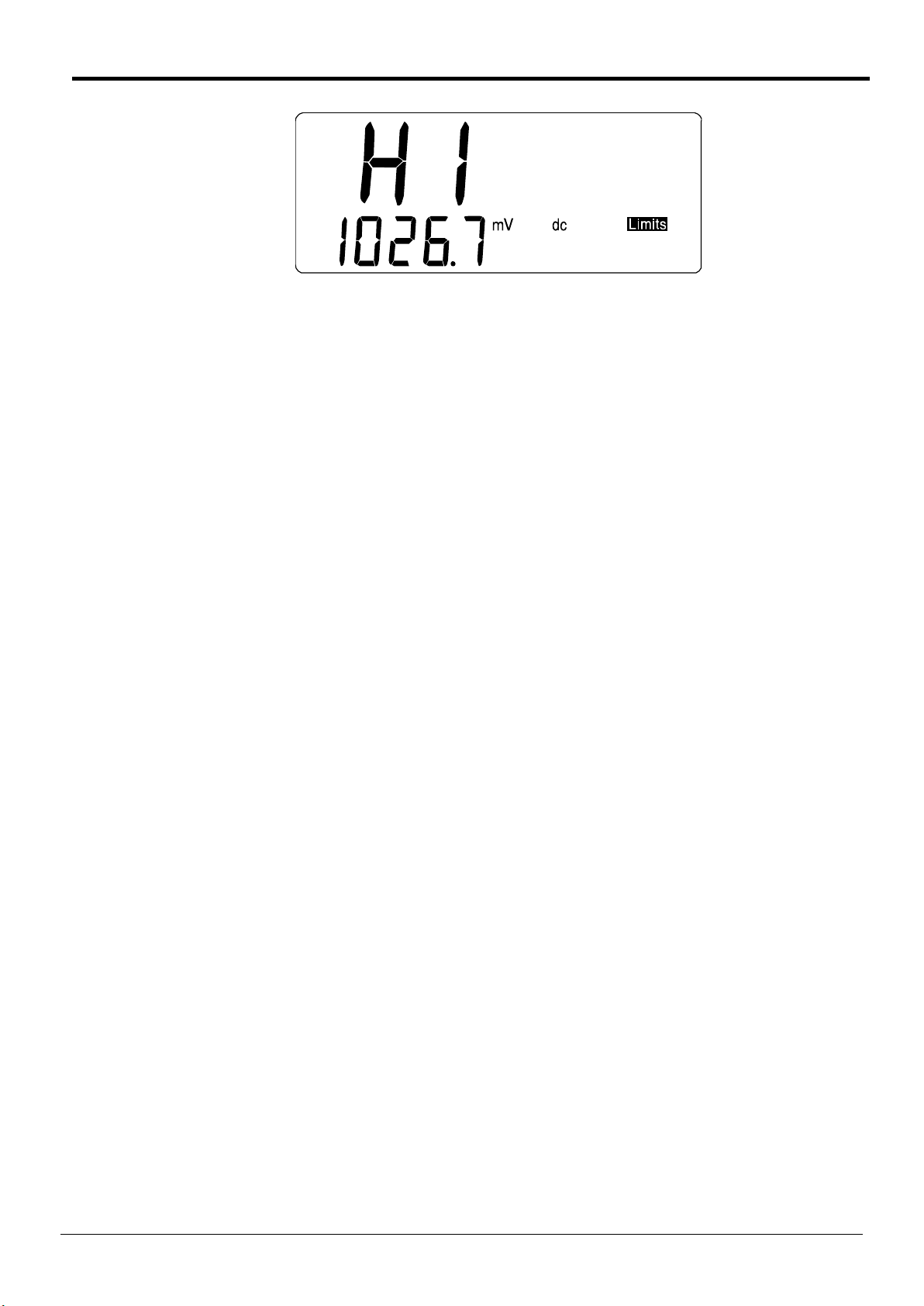

The appropriate modifier is first selected by successive presses of the FUNCTION key as

described fully in the Second Level Modifiers section. Edit mode is entered by pressing the EDIT

key whilst the selected modifier is flashing in the modifier menu. The primary display changes to

show the parameter being edited and the number itself, together with the appropriate units, is

shown in the secondary display; the selected modifier symbol continues to flash with all the other

annunciators off. For example, selecting Edit mode for the Limitsmodifier will show:

14

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 15

The position of the decimal point and the unitsof the parameter being edited are determined by

the range in use at the time the modifier is selected. The exception is Aof Ax+b which has its

decimal point position fixed after the first digit, i.e. the range for Ais ±0.0001 to ±9.9999. If the

meter is in autorange mode and the range in use is inappropriate (e.g. Ohms function is selected

with no input present, causing it to autorange to 20MΩ) first select the required range with the

Range Up/Range Down keys.

Once edit mode is selected, editing is controlled by the Range Up, Range Down and Auto/Man

keys which have the edit mode functions of Change Digit, Step Digit and +/- (change sign)

respectively, as indicated by the blue legend beside the keys.

The flashing digit is the one currently editable; its value can be incremented through the values 0

to 9 and back to 0 using the Change Digit key. The selection of the editable digit is made with the

Step Digit key which moves the flashing digit from leftto right, with wrap-around from the

rightmost digit to the leftmost. The sign of the number can be changed with the digit cursor in any

position by alternate presses of the +/- key.

During number editing the default value can always be entered by pressing Clr,the edit function

of Cancel. The current meter reading can be entered as the new number by pressing Copy Rdg,

the edit function of the Null key; this is not allowed for Aof Ax + b. If the modifier has more than

one parameter,pressing Edit will save the number just edited and display the new parameter.

Number editing can always be exited without changing the parameter being edited (i.e. the

previous value is restored) by pressing Esc, the edit function of Local.

To exit edit mode with the new number stored press Run to operate the modifier or Edit if there is

another parameter to be edited. To exit edit mode with the new number stored but the modifier

not running press FUNCTION to return to the modifier list and then Cancel.

If the range is subsequently changed the number is retained and will be correctly displayed if edit

mode is reselected in the new range. Note, however, that if a lower range is selected and the

number is too large to be shown on that range, the display will read 99999.

The Change Digit key is also used to increment through the available choices during the editing

of those parameters which have a limited selection of numbers; these include the reference

impedance for dB measurement, interface address and Baud rate.

The Range Up and Range Down keys autorepeat if held; autorepeat also operates when these

keys are used in edit mode.

15

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 16

Making Basic Measurements

This section describes how basic measurements are made, i.e. single measurement mode only

and no post-processing of the results.

Scale Length

The scale length is ±12000 for all measurements except capacitance (full scale 1200) and the

20MΩresistance range (full scale 2400).

Function Selection

All functions are directly selected by pressing the appropriate function key (Vdc, Ω, Hz, etc.).

Changing function always cancels any modifiers already running and setsautorange; providing

the appropriate function has been selected (e.g. Ωfor resistance measurement) and the

parameter to be measured is within the range of the meter,a valid reading should always be

shown. The exception is 10A current measurement which requires manual range selection, see

next section.

The unitsand function are shown in the display (e.g. mV dc) together with AUTOto indicate

autorange.

When a function is selected in this way the smaller secondary display will show the operating

range with units, except for capacitance. If this is not required the secondary display can be

turned off by pressing Select 2nd followed by Cancel; the range will be displayed again when the

function is next changed, or by pressing Select 2nd twice.

The Continuity/Diode check test key selects continuity test with the first press and then alternates

between the modes with further presses. The appropriate annunciator indicates the current

selection. Continuity setsthe meter to the 1000.0Ωrange and buzzes for values below

approximately 10Ω.

Vdc+Vac or Idc+Iac measurements are made by pressing both Voltage range or both current

range keys together. The reading displayed is the RMS sum √(dc2+ ac2) and ac+dc is shown

beside it. Both ac and dc measurements are made on the same range: the instrument will

autorange to a range which gives an in-range reading for both the ac and dc component of the

parameter. However,if the result exceeds the range maximum the meter will autorange up to

permit the result to be shown as an in-range reading.

Range Selection

Selecting a new function always setsautorange to ensure an in-range reading is made with

maximum resolution whenever possible; the meter ranges up at 12000 counts and ranges down

at 1000 counts.

There are, however, situations when it is desirable to lock the range; for example, to stop the

meter autoranging to the 20MΩrange and back between successive resistance measurements of

lower resistance values, or to set a lower resolution range when an unstable parameter is being

monitored. To lock the range, change from auto to manual ranging, see below.

Manual range changing is selected either by alternate presses of the Auto/Man key,which locks

the meter in its present range, or by using the Range Up/Range Down keys which both change

the range and lock the meter in that new range. The MAN annunciator is displayed to indicate

manual ranging. Overrange is indicated by flashing the display at 12000 counts. Autoranging can

be restored by pressing the Auto/Man key again.

As explained later in the appropriate sections, secondary functions in dual measurement mode

are autoranging only; the exception is 10A range selection which is manual only,for both main

and secondary displays, at all times.

16

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 17

Making Voltage Measurements

Voltage measurements are made using the red V/Ωsocket and the black COM socket having

selected the appropriate function and range as described above.

The meter will show a minus sign (on dc measurements) when the voltage applied to the red

socket is more negative than that applied to the black socket.

The maximum voltage that can be applied between V/Ωand COM is 1000V DC or 750V AC (Cat

I); damage to the instrument may result if this limit is exceeded.

WARNING! The maximum input voltage to ground must not exceed 1000V (Cat I) or 600V (Cat

II) dc or ac rms. Safety will be impaired if these ratings are exceeded, see Safety section at the

beginning of the manual.

Making Current Measurements

Having selected the appropriate current function, current measurements up to 120mA are made

using the white mA socket and the black COM socket; current measurements up to 10A are made

using the 10A and COM socket. The meter will show a minus sign (on dc measurements) when

the polarity of the current is out of the mA or 10A sockets.

Current measurements using the mA socket can be autoranged between 1.0000 mA and

100.00mA ranges; measurements up to 10A can be made using the 10A socket having manually

ranged to 10A with the Range Up key.

The 1mA and 100mA ranges, using the mA socket, are protected by a 500mA (F) HBC fuse and

the 10A range, using the 10A socket, is protected by a 10A (F) HBC fuse. Both fuses are fitted

inside the instrument and replacement is described in the Maintenance section later in the

manual.

Note: After measuring high current using the 10A input, thermal voltages are generated that may

create errors when making measurements on the most sensitive dc voltage, current or Ohms

ranges immediately afterwards. To ensure that the specified accuracy is maintained, allow 10

minutes for the thermal effects to fade before making sensitive measurements.

Making Resistance Measurements

Resistance measurements are made using the V/Ωand COM sockets. Residual test lead

resistance can be nulled out using the Ohms null facility as follows:

Connect the test leads together and press Shift, Null (ΩNull is the shifted function of Null). The

100Ωrange is set automatically and the NULL annunciator flashes; the meter stores the reading

that it detectsafter 5 seconds provided that it is less than 1.00Ω(100 counts). Abeep sounds

when the null is completed and the display should show zero Ohms and no NULL annunciator;

the meter returns to its previous range, or AUTOif autorange had been operational before Ohms

null was selected.

If the reading cannot be nulled, because the offset is too large, the reading will not change and

the buzzer will not sound.

The Ohms null is stored as a floating point value which is used on all ranges; it is not lost when

the function is changed or when the instrument is turned off. Ohms null can be cancelled by either

pressing the Ωand Cancel keys together, by selecting Ohms Null and not generating a sub 1.00Ω

reading within the next 5 seconds, or by holding the Cancel key down at power-up to restore the

system defaults.

Normal Null can be used together with Ohms Null.

17

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 18

Making Continuity and Diode Checks

Continuity and diode checks are made using the V/Ωand COM sockets.

Pressing the Continuity/Diode check key selects Continuity mode with the first press; the

continuity indicator is shown in the display. The 1000Ωrange is selected and readings below

approximately 10Ωsound the continuity buzzer.

Afurther press selects diode check; the diode annunciator is shown in the display. The 1000mV

range is selected and the approximate diode voltage at 0.5mA is shown (1.2V maximum).

Reverse diode connection will show overload.

Further presses of the key will alternate between Continuity and Diode check.

Making Capacitance Measurements

Capacitance measurements are made using the V/Ωand COM sockets. Capacitance

measurement is selected by pressing the µF key.Five ranges (10nF to 100µF) are available with

1200 count full scale giving resolutions of 10pF to 100nF respectively.

Zero calibration at the factory is carried out with no test leads connected; ideally, capacitors to be

measured should be connected directly to the sockets. Test leads, if used, should be kept as

short as possible to minimise stray capacitance but nevertheless a non-zero reading will generally

be present when the lowest ranges are selected. To eliminate this offset it is recommended that

the meter reading is nulled, once the require range has been selected, with the test leads in their

measurement positions but no capacitor connected. It is also recommended that battery

operation is used when making capacitance measurements, to minimise reading jitter.Note that

because the capacitor is discharged between each measurement, the reading rate on the 100µF

range is slower.

Making Frequency Measurements

Frequency measurements are made using the V/Ωand COM sockets.

Press the Hz key to select frequency mode. Four ranges (100Hz to 100kHz) are available giving

resolutions of 10mHz to 10Hz respectively over an operating frequency range of 10Hz to 120kHz.

Reciprocal counting techniques ensure fast reading updates (4 readings/second) even on the

lowest range.

Measurements are made using the ac Volts input circuitry which is autoranged to provide suitable

sensitivity. At low signal levels use a screened lead and an adaptor (BNC to 4mm plugs, 19mm

pitch) to preserve signal quality and avoid spurious readings from stray pick-up. The minimum

measurable signal is typically <30mV rms across the frequency range.

Frequency can also be measured in dual measurement mode, see next section. When measuring

the frequency of an ac current the minimum measurable signal is typically <10% of range

maximum, e.g. <0.1mA on the 1mA range.

Zero Calibration

An automatic zero calibration of the basic DC measurement circuitry is performed every time that

the instrument is switched on. However,if the meter has been stored at a temperature outside

the specified operating range, and is switched on before it has fully acclimatised to the working

environment, accuracy may be affected as the meter’s temperature changes. To ensure optimum

accuracy, particularly on the 100mV and mA current ranges, zero calibration can be repeated

when the meter has acclimatised by using the Null key as follows:

Press the Null key and continue to hold it down until nULL shows in the main display (about 3

seconds later). nULL continues to show whilst the auto-zero is being performed (typically 5

seconds); on completion the display returns to it previous mode.

Auto-zeroing in this way cancels Null if this was already selected; press Null again to re-select if

required.

18

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 19

Dual Measurement Mode

In Dual Measurement Mode a completely independent but complementary measurement can be

made and displayed on the secondary display. The two independent measurements are actually

made alternately,not simultaneously, and the display update rate for each measurement is

consequently reduced. Note that this is not the same as when, in dual display mode, both a

measurement and a modified version of that measurement are displayed, e.g. ac Volts and the

dB equivalent; in this case only a single measurement is being made and the measurement rate

is unchanged; further information is given later in this section.

Dual Measurement Combinations

All practical combinations of functions are allowed in Dual Measurement Mode; those of no

practical use (e.g. dc Volts and Frequency) are not selectable. The full list is as follows:

Main Display Secondary Display

Vdc Vac, Idc, Iac

Vac Vdc, Idc, Iac, Hz

Idc Vdc, Vac, Iac

Iac Vdc, Vac, Idc, Hz

Hz Vac, Iac

Capacitance, Ω, and Continuity/Diode check cannot meaningfully be combined with other

measurements and are therefore always excluded from the secondary display.Vac+Vdc and

Iac+Idc are also excluded because they already involve dual measurements; when they are being

used no secondary display can be set.

The same measurement can be displayed in both displays, if required, at the single measurement

update rate; in this mode the displays both use the range set for the main display.

The secondary display is selected by pressing Select 2nd followed by the function; pressing an

illegal function will cause a warning beep and the key entry will be ignored. Pressing Select 2nd

twice will return the meter to single measurement mode with the range shown in the secondary

display; pressing Select 2nd followed by Cancel turns the secondary display off. Selecting any

main display function will also return the meter to single measurement mode.

The secondary measurement, with the exception of the 10A current ranges, always autoranges.

The 10A current ranges are set by first selecting the function (Select 2nd followed by Iac or Idc)

then pressing Select 2nd followed by Range Up; return to the mA autoranges is by pressing

Select 2nd followed by Range Down. However,if both main and secondary displays are making

current measurements, the range of the secondary measurement is always that of the main

display.

If Vdc and Vac are the two measurement functions, autoranging of the secondary display is

restricted such that the dc measurement range is not lower than the ac range; this ensures that

the dc measurement is not affected by a high ac signal, see the table in the Specification (page

3). For example, if the main display is set to 10Vdc the secondary display can autorange between

the 100mV,1000mV and 10Vac ranges. In this example, low levels of ripple could be measured

(on the 100mV range) on a 10Vdc supply rail, but an ac input >12V will cause the secondary

display to flash 12000 (overload) warning the user to select a higher main display dc range such

that the secondary ac measurement is in range. Similarly,if the main display is set to 100Vac

then the secondary display will not autorange below 100Vdc, even for small dc inputs.

When frequency is selected for the secondary display the measurement is made using the ac

range set in the main display. This presents no problems if the main display is in autorange but if

a higher range has been set manually, such that the reading is less than 10% of the range

maximum, the signal level may not be adequate for frequency measurement.

19

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 20

Table of contents

Other TTI Multimeter manuals