TTI QPX1200 User manual

QPX1200

DC Power Supply

Service Manual

Manual Part Number 48511-1130 Issue 1

Table of Contents

Specification 2

EMC 5

Safety 6

General 7

Circuit Descriptions 9

Calibration Procedure 17

Parts List 19

Component Layouts 35

Circuit Diagrams 37

1

Specification

General specifications apply for the temperature range 5°C to 40°C. Accuracy specifications apply

for the temperature range 18°C to 28°C after 1 hour warm-up with no load and calibration at 23°C.

Typical specifications are determined by design and are not guaranteed.

OUTPUT SPECIFICATIONS

Voltage Range: 0V to 60V

Current Range: 0.01A to 50A

Power Range: Up to 1200W

Voltage Setting: Resolution 1mV

Accuracy: 0.1% of setting ± 2mV

Current Setting: Resolution 10mA

Accuracy: 0.3% of setting ± 20mA

Operating Mode: Constant voltage or constant current with automatic cross-over

provided that the power demanded stays within the power

envelope, see graph. Outside of this envelope the output becomes

unregulated. CV, CI or UNREG mode indication in display.

QPX 1200

POWER ENVELOPE

Output Switch: Electronic, with ON indication.

Preset voltage and current displayed when off.

Output Terminals: Front panel safety terminals accepting 6mm wire diameter, 6mm

plugs or 8mm spades at 50 Amps max, or 4mm plugs at 30 Amps

max. Duplicate rear panel terminals.

Sensing: Switchable between local and remote. Screwless remote sense

terminals on both front and rear panels. Sense miswiring trip and

indication.

Ripple & Noise

(20MHz bandwidth):

Typically <3mVrms, <20mV pk-pk at maximum load, CV mode

Load Regulation: Change in output for any load change within PowerFlex envelope,

using remote sense:

Constant voltage: <0.01% ± 5mV

Line Regulation: Change in output for a 10% line change:

Constant voltage: <0.01% ± 5mV

Transient Response: <250us to within 100mV of set level for a 5% to 95% load change.

Output Protection: Output will withstand an applied forward voltage of up to 70V.

Reverse protection by diode clamp for reverse currents up to 3A.

2

Over-voltage Protection

(OVP):

Range 2V to 65V. Resolution 0.1V; accuracy: 0.2% ± 0.2V.

Response time typically 100µs.

Over-current Protection

(OCP):

Range 2A to 55A. Resolution 0.1A; accuracy: 0.5% ± 0.2A.

Response time typically 100ms.

Over-temperature Protection: The output will be tripped off if a fault causes the internal

temperature to rise excessively.

Temperature Coefficient: Typically <100ppm/°C

METER SPECIFICATIONS

Display Type: 5-digit (Volts), 4-digit (Amps), black-on-white backlit LCD.

Voltage (CI Mode and Unreg): Resolution 1mV

Accuracy: 0.1% of reading ± 2 digits

Current (CV Mode & Unreg): Resolution 10mA

Accuracy: 0.3% of reading ± 2 digits

V x A: Resolution 0·1W

Accuracy: 0·5% ± 0·1W

LOGIC CONTROL INPUT and OUTPUT

LOGIC IN is a rear-panel opto-isolated input that is activated at an input current greater than

approximately 1mA. User can set LOGIC IN (via the keyboard) to enable the output, disable the

output, or be ignored when it is activated.

LOGIC OUT is an isolated rear-panel open-collector output that will sink up to 2mA when activated

(‘switch closure’); the maximum voltage that can be applied to LOGIC OUT is 30VDC. User can set

LOGIC OUT to be ‘closed’ or ‘open’ for output enabled or disabled, current limit (CI mode), power

limit (UNREG mode), or for any fault trip.

ANALOG REMOTE CONTROL and MONITORING

Non-isolated inputs and outputs to set voltage and current limit and to monitor actual output voltage

and current. These signals are referenced to the positive output and have a range of 0 to 10V or 0

to 5V (selectable via the keyboard).

Analogue Control Accuracy: Voltage: 0.3% ± 4mV; Current: 0.5% ± 40mA

Analogue Monitor Accuracy: Voltage: 0.3% ± 4mV; Current: 0.5% ± 40mA

KEYBOARD & ROTARY CONTROL

All functions, including the selection and set-up of the remote control interfaces, can be set from the

keyboard. The rotary Jog control can be used to adjust output voltage and current settings in a

quasi-analogue mode.

DISPLAY FEATURES

The display is a 240 x 64 pixel transflective LCD, backlit by white LEDs; contrast is software-

controlled and can be adjusted from the keyboard.

The default status display shows the VOLTS (5 digits) and AMPS (4 digits) in 10mm high characters,

plus the present output mode. At other times, for example during store or recall of instrument set-

ups, the display shows up to 6 lines of information, instructions, or prompts.

3

INTERFACES

Full digital remote control facilities are available through the RS232 and USB interfaces. Setting and

readback resolutions are the same as the Output and Meter specifications respectively.

RS232: Variable Baud rate, 19200 Baud maximum. 9-pin D-connector.

Single instrument or Addressable RS232 operation.

USB: Standard USB 2.0 hardware connection.

Remote Command

Processing Time:

Typically <100ms between receiving the command terminator for a

step voltage change at the instrument and the output voltage

beginning to change.

GENERAL

AC Input: 110V – 240V AC ± 10%, 50/60Hz.

Installation Category II.

Power Consumption: 1600VA max.

Operating Range: +5ºC to +40ºC, 20% to 80% RH.

Storage Range: −40ºC to + 70ºC.

Environmental: Indoor use at altitudes up to 2000m, Pollution Degree 2.

Store/Recall: Up to 10 set-ups can be saved and recalled via the keyboard or

remote interfaces.

Safety: Complies with EN61010-1.

EMC: Complies with EN61326.

Size: 130mm H (3U) x 356mm W x 413mm D

Weight: 9.2kg

Options: 19-inch rack kit.

4

EMC

This instrument has been designed to meet the requirements of the EMC Directive 89/336/EEC.

Compliance was demonstrated by meeting the test limits of the following standards:

Emissions

EN61326 (1998) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use. Test limits used were:

a) Radiated: Class A

b) Conducted: Class A

c) Harmonics: EN61000-3-2 (2000) Class A; the instrument is Class A by product category.

Immunity

EN61326 (1998) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use.

Test methods, limits and performance achieved were:

a) EN61000-4-2 (1995) Electrostatic Discharge : 4kV air, 4kV contact, Performance A.

b) EN61000-4-3 (1997) Electromagnetic Field, 3V/m, 80% AM at 1kHz, Performance B.

c) EN61000-4-11 (1994) Voltage Interrupt, 1 cycle, 100%, Performance B.

d) EN61000-4-4 (1995) Fast Transient, 1kV peak (AC line), 0·5kV peak (DC Outputs),

Performance B.

e) EN61000-4-5 (1995) Surge, 0·5kV (line to line), 1kV (line to ground), Performance B.

f) EN61000-4-6 (1996) Conducted RF, 3V, 80% AM at 1kHz (AC line only; DC Output

connections <3m not tested), Performance B.

According to EN61326 the definitions of performance criteria are:

Performance criterion A: ‘During test normal performance within the specification limits.’

Performance criterion B: ‘During test, temporary degradation, or loss of function or performance

which is self-recovering’.

Performance criterion C: ‘During test, temporary degradation, or loss of function or performance

which requires operator intervention or system reset occurs.’

Where Performance B is stated it is because DC Output regulation may deviate beyond

Specification limits under the test conditions. However, the possible deviations are still small and

unlikely to be a problem in practice.

Note that if operation in a high RF field is unavoidable it is good practice to connect the PSU to the

target system using screened leads which have been passed (together) through an absorbing ferrite

sleeve fitted close to the PSU terminals.

Cautions

To ensure continued compliance with the EMC directive observe the following precautions:

a) after opening the case for any reason ensure that all signal and ground connections are remade

correctly and that case screws are correctly refitted and tightened.

b) In the event of part replacement becoming necessary, only use components of an identical type,

see the Service Manual.

5

Safety

This power supply is a Safety Class I instrument according to IEC classification and has been

designed to meet the requirements of EN61010-1 (Safety Requirements for Electrical Equipment for

Measurement, Control and Laboratory Use). It is an Installation Category II instrument intended for

operation from a normal single phase supply.

This instrument has been tested in accordance with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 2 environment in the

temperature range 5°C to 40°C, 20% - 80% RH (non-condensing). It may occasionally be subjected

to temperatures between +5°C and –10°C without degradation of its safety. Do not operate while

condensation is present.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to its supply, terminals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live parts.

The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, maintenance or repair.

Capacitors inside the power supply may still be charged even if the power supply has been

disconnected from all voltage sources but will be safely discharged about 10 minutes after switching

off power.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be avoided

as far as possible and, if inevitable, shall be carried out only by a skilled person who is aware of the

hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protection may be impaired and the apparatus should be withdrawn

from use and returned for checking and repair.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is prohibited.

Do not wet the instrument when cleaning it.

The following symbols are used on the instrument and in this manual:-

Earth (ground) terminal.

mains supply OFF.

l mains supply ON.

alternating current (ac)

direct current (dc)

6

General

Service Handling Precautions

Service work or calibration should only be carried out by skilled engineers using high quality test

equipment. If the user is in any doubt as to his competence to carry out the work, the instrument

should be returned to the manufacturer or their agent overseas for the work to be carried out.

The tracks on the printed circuit boards are very fine and may lift if subjected to excessive heat. Use

only a miniature temperature-controlled soldering iron and remove all solder with solder wick or

suction before attempting to remove a component.

Dismantling the instrument

WARNING!

Disconnect the power supply from all voltage sources before it is opened for adjustment or repair.

Capacitors inside the supply may still be charged even if the supply has been disconnected from all

voltage sources but will be safely discharged about 10 minutes after removing power.

If any adjustment or repair of the opened supply under voltage is inevitable it shall be carried out

only be a skilled person who is aware of the hazard involved. The incoming AC supply to the unit

under test should be isolated for safety by means of a 1:1 isolation transformer of at least 1500VA.

High voltages (up to 400V) are always present in the primary-side circuits on both the PFC board

and Power board; on the Power board the primary side occupies a clearly defined area at the rear

of the board.

1. Remove the 4 side screws to release the top cover.

2. To gain access to the Control PCB and Keyboard, release the front panel assembly from the

chassis by removing the 2 M3 side nuts, the countersunk M3 screw securing the top bracket,

and the 4 M3 screws (with integral shakeproof washers) along the bottom edge.

3. Keyboard: Remove the 5V supply from PJ4, the 4 connections to the mains switch, and the

3-way connections to the Control (PJ10) & Interface (PJ9) boards. The Keyboard is released

from the front panel by removing the 7 screws which secure it.

4. Control: Remove the 10-way connector (PJ100) to the Power board, noting polarity (corner

marker to pin1); remove the flat cable connection to PJ101 and the 3-way connection to the

Keyboard (PJ105). Remove the nuts which secure the front and rear output connecting

cables from the terminals on the front panel/Control board after noting their positions. To

release the Control board remove the 3 M3 screws to the front panel plus the 3 nuts which

secure it directly to the +, −, & earth terminals. When re-assembling do not forget the brass

bus-bar between the Red output terminal and the current measurement shunt connection.

5. PFC: Remove the 5V supply to the Keyboard (at PJ2) and the mains connections at W1,

W2, W3 &W4; when reassembling note that W1 & W4 (to the front panel switch) share a

ferrite sleeve and W2 & W3 (return from the switch) share a ferrite sleeve. Remove the 4-

way primary AUX connection at PJ1 ( note the position of ferrite sleeve at the Power board

end of the connection) and the HT connection at FAS5, FAS6 & W5. To release the PFC

board from the chassis remove the 9 M3 screws (with integral shakeproof washer) from the

underside of the chassis, leaving the support pillars attached to the board assembly. Ease

the board forward a little in the chassis, so that the safety earth connection to the rear panel

can be undone, and lift the board free.

7

6. Power: Remove the 10-way connector (PJ5) to the Control board, noting polarity (corner

marker to pin1); remove the flat cable connection to PJ4 at the rear of the board; remove the

HT connection from the PFC board at FAS1 & FAS2; remove the 4-way primary AUX

connection from the PFC board at PJ1; remove the 3 2-way fan power connections

(PJ6,PJ7, PJ8); remove the 2 M6 barb nuts which secure the output cables to the front

panel. To release the Power board from the chassis it is first necessary to remove the 3rd,

internal, fan; push out the centres of the 2 plastic push-rivets which secure the top of the fan

to the bracket and lift out the fan with its lower bracket still attached. When re-assembling

note that the fan label faces the transformer (airflow towards the transformer). Remove the

10 M3 screws (with integral shakeproof washer) from the underside of the chassis, leaving

the support pillars attached to the board assembly, and lift the assembly forward and up.

7. Interface: Remove the 3-way connection to the Keyboard at PJ3. The Interface board is

secured only by the RS232 screwjacks; undo these to release the board.

8. When reassembling, take great care to ensure that all connections are exactly as before

dismantling and that no insulation creepage and clearance distances have been

compromised. Ensure that only the correct fasteners have been used otherwise earthing,

and hence EMC and safety performance, may be impaired.

8

Circuit Descriptions

PFC Board

Mains Input, Filtering and Rectification

The AC input is via PJ3, a pcb mounted IEC plug, and fuse FS1.

X-capacitors C1, C4, C7, C10 & C68, together with the Y-capacitors C5, C6, C11 & C12, common

mode inductors L1, L2 & L3 and differential inductors L4 & L8 comprise an input filter which ensures

that the supply meets both conducted emission and conducted immunity EMC requirements.

VD1 clips mains spikes for component protection, while R1 discharges the X-capacitors after

removal of the mains supply.

Pcb mounted fuse FS1 limits damage on boost-stage or forward converter failure. The front panel

mains switch is connected via connectors W1, W2, W3 and W4.

The bridge rectifier comprised of D1, D2, D3 and D4 has C13 and C14 connected across it to

bypass noise signals and to snub reverse recovery transients in the bridge rectifier.

C15, C16 further decouple the input filter and rectifier from the boost converter.

R2 limits the initial inrush current into the boost stage output capacitors C19 and C20 and is by-

passed by relay PL1 once the boost converter starts.

Auxiliary Supplies

Primary Side

The primary auxiliary supplies are generated by IC5. This is a 7 pin TO220 style device which

incorporates the control circuitry and power switch to implement an off line flyback power supply.

It derives its power from the boosted HT rail.

R93 sets the power switch peak current to 0.4A. D20, R55 and C47 clamp the drain voltage of the

power switch at a safe level. The low voltage output of transformer T9 is peak rectified by D21 and

C49 . The output voltage is regulated to 24V by zener diode D22 and feedback to the control pin is

via opto coupler IC15. The 24V rail powers the fans.

IC6 generates an 18V rail for the PFC control IC4.

IC7 generates a 15V rail for the power pcb primary control circuit.

Secondary Side

A 5V supply for the front panel keyboard is generated by IC9. This is an 8 pin SMD style device

which incorporates the control circuitry and power switch to implement an off line flyback power

supply.

It derives its power from the AUX_HT line, which is generated by D36, D37 and C81, C37. This rail

is decoupled from the HT boost rail. When the mains supply is switched off, this AUX_HT rail falls

quickly and the front panel display vanishes very rapidly.

Start-up Control Circuit

D23 and R58 provide a 5.1V reference voltage to the negative inputs of all 4 op-amps of IC8.

When the mains is switched on, potential divider R59, R59B, R60, R60B and R61 feeds the

attenuated full wave rectified mains voltage to the positive input of IC8-A.

The bulk storage capacitors C19, C20 are being charged via inrush current limiting resistor R2.

When the mains voltage exceeds approximately 80Vrms, the output of IC8A begins to produce

pulses, which charge C21 via D24. When the mains voltage reaches approximately 87Vrms, the

voltage on C21 exceeds the reference voltage on IC8-B negative input and the output of IC8-B goes

high, charging C55,C56 via R67.

9

After a delay of about 0.4s, the voltage on C55, C56 exceeds the reference voltage on IC8-C

negative input and the output of IC8-C goes high, turning on Q8 via D29 and R74 thus energising

RL1 which bypasses the current inrush resistor R2.

The output of IC8-C also charges C58 via R70 thus producing a short delay before the output of

IC8-D goes high and turns on Q9 which in turn switches Q10 and Q11 off. When Q11 goes off, the

SS signal is no longer clamped to 0V and allows the PFC control IC4 to start up.

When the mains voltage is switched off, C21 is no longer supplied with top-up pulses and is

discharged by R64. IC 8-B output goes low and quickly discharges C55, C56 via D25. IC8-C output

then goes low and immediately turns off Q9 via D28. This causes Q11 to come on, clamping the SS

signal to 0V and stopping the PFC control IC4.

IC8-B output going low, discharges C58 via R71 and D26, thus providing a short delay before IC8-D

output goes low and switches off the bypass relay driver Q8.

The above timing sequences ensure that the inrush relay RL1 contacts only switch under zero load

conditions.

Primary Boost stage Control circuit

The primary boost stage control is by means of IC4.

This contains all the processing circuitry to shape the current taken by the power supply from the

mains supply to be sinusoidal and in phase with the voltage.

For a detailed description refer to the ST ‘Power Factor Corrector Applications Manual‘.

When the mains is switched on, the +18V supply to IC4/pin19 is established and IC4 becomes

active after a short delay when the SS signal is released by the start-up control circuit. During this

short delay the bulk storage capacitors C19, C20 are charged via the inrush-limiting resistor R2.

IC4 starts up and supplies drive pulses to the gate ICs IC1, IC2, IC3, which drive the gates of the

boost MOSFETs Q1, Q2, Q3, Q4, Q5, Q6.

C44 is connected to the soft start pin of IC4 and provides a soft start.

R34, R34b, R35, R35b, R37, C35, C35b, C36, C36b form a two stage RC filter to feed a voltage

proportional to the mains voltage to IC4/pin 7 which, after an internal 1/V2 transformation, is fed to

the internal multiplier. For a universal mains input, the voltage at this pin will vary between 1.5V and

5.5V.

R38+R38a and R39+R39a supply a current derived from the full wave rectified mains voltage to

IC4/pin 4 to be used by the internal multiplier.

Also fed to the internal multiplier is the output of the voltage error amplifier of IC4/pin 13. The input

to the error amplifier at pin 14 is from potential divider R41, R41b, R42, R42b, R62, R63 and VR1.

This potential divider monitors the voltage on the boost stage output capacitors C19, C20 and this is

compared to an accurate internal reference voltage. Thus a steady voltage of about 395V, as set by

VR1, is maintained across C19, C20.

Another potential divider R44, R44b, R45, R45b, R46 monitors the voltage across C19, C20 and

feeds into pin 3 of IC4 which is the over-voltage shutdown. C80 slows the signal going into the

over-voltage pin to prevent the over-voltage circuit from activating during transient load changes.

Pin 8 is the output of the multiplier and is the programming current for the internal current error

amplifier. This signal is taken to the mains supply side of the current sense resistor R52 via R48.

The other input of the current error amplifier is taken to the other side of R52 via R50. The current

error amplifier thus compares the signal across the current sense resistor R52 with the

programming current and adjusts the PWM drive to the boost MOSFETs accordingly.

R49 and C42 with R50 form the compensation network around the current error amplifier.

10

Boost Stage

Three boost inductors L5, L6, L7 are each driven by a pair of MOSFETs Q3+Q6, Q2+Q5, Q1+Q4

respectively to raise the incoming, full wave rectified, sinusoidal mains voltage to a value some 30V

higher than the peak of the maximum rms input voltage. This is achieved by storing energy in the

boost inductors when the MOSFETs are conducting and transferring it to C19, C20 via boost diodes

D5, D6, D33 when the MOSFETs are turned off.

When the MOSFETs turn on, the boost diodes D5, D6, D33 are still conducting current. To prevent

large switch on losses, delay inductors L9, L10, L11 are placed in series with the MOSFETs. This

ensures that the current in the boost diodes is reduced at a gradual rate and the reverse recovery

time is minimised at the same time as the drain voltage of the MOSFETs is allowed to fall rapidly.

The energy stored in L9, L10, L11 is transferred to C18, C61, C62 via D19, D7, D8 and dissipated in

R23, R6, R9.

Snubber networks C22, R15, R19, C23, R16, R21, C24, R18, R22 reduce switch-off losses in the

MOSFETs.

The main boost heatsink is protected against excessive temperature by PTC2, IC12 and associated

components; once triggered it is necessary to turn the mains power off and on again to restart.

Power Board

Forward Converter

The 400V HT supply from the PFC board is connected to the Power board via FAS1 and FAS2 and

decoupled by C2.

C1 and C3 with their respective bleed resistors R149 and R150 form the voltage divider to feed the

converter transformer T1 of the half bridge forward converter.

The half bridge configured power MOSFETs Q28 and Q29 are connected to the converter

transformer T1 via the current transformer CT1 and ZVS inductor L2 and operate at a fixed duty

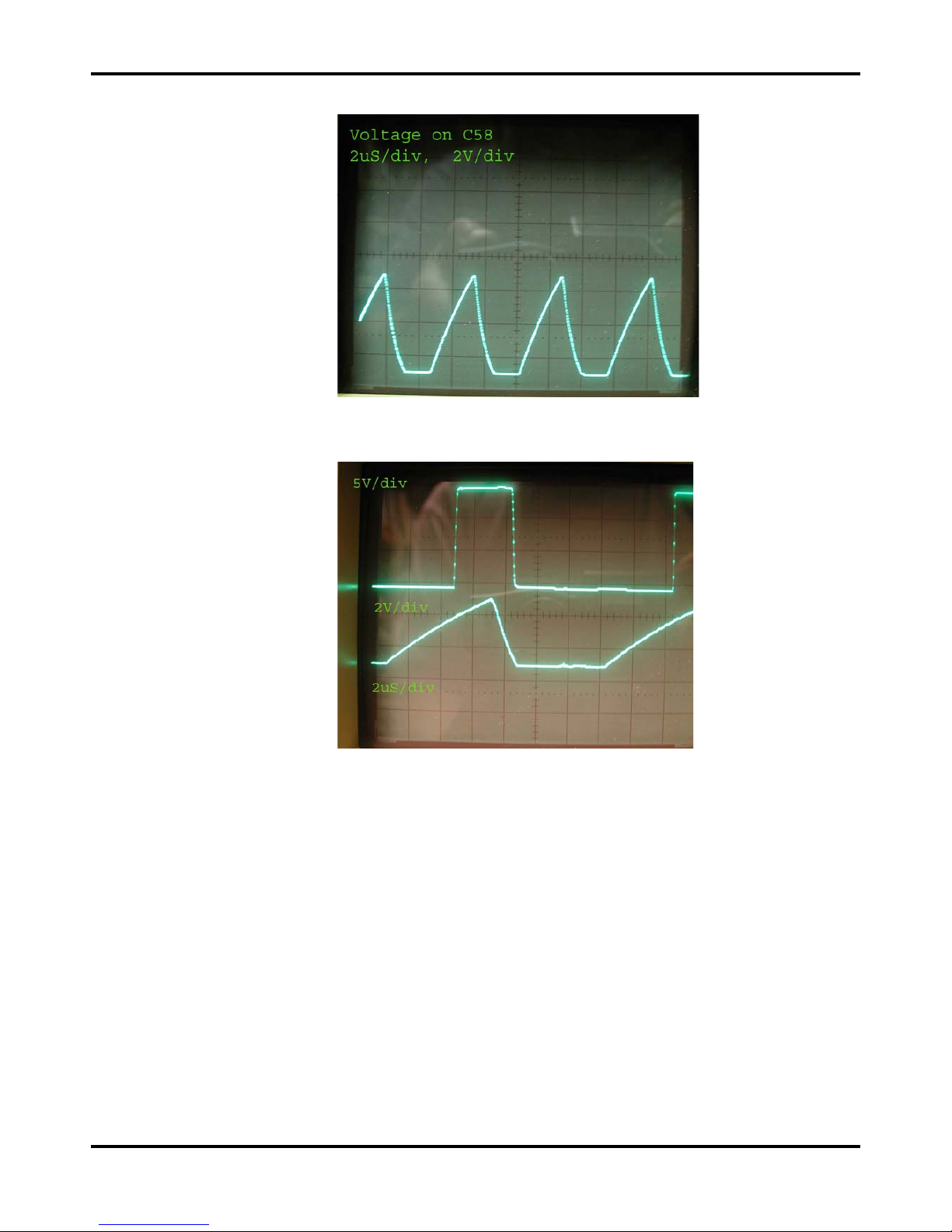

cycle of about 42% at a switching frequency of 73kHz. See the gate drive waveform in

Photograph1.

C4 and C12 work with L2 to facilitate zero voltage switching for Q28 and Q29.

R11, C16 and FB3 damp high frequency ringing across T1 primary. See photograph 02.

The gate drive pulses for Q28 and Q29 are generated by oscillator IC2-B/IC2-C feeding into IC3-A

to produce complimentary square waves at IC3-A pins 1 and 2.

The leading edges of these anti-phase square waves are slowed by R39/C37 and R42/C38 and

buffered by IC2-A,E,D,F to produce anti-phase pulse trains of the correct duty cycle to drive the gate

drive transformer T3 via Q13, Q15, Q17, Q18 and C35. The supply to the gate transformer drivers is

decoupled by C17, C28, C29, C30. The gates of Q28 and Q29 receive their anti-phase drive from

the secondaries of T3 via R52 and R73 and respective anti parallel diodes D1 and D2.

The output of the current transformer CT1 is full wave rectified by D16, D17, D22, D23 and loaded

with burden resistor R26. The voltage developed across R26 is utilised by two different circuits.

The first is to turn on Q11 via zener diode D27 when the current in the primary power switches

exceeds a certain value determined by R157 and R158. Q11 collector charges C26 negatively via

R21. When the voltage across C26 exceeds a threshold set by zener diode D10, latch Q9, Q14

turns on and pulls signal SDWN down to the P0V rail via D20. This in turn causes the power factor

correction circuit to shut down – requiring the removal of the mains supply in order to restart. This

would only happen under repeated short-circuiting of the output. Q9, Q14 latch can also be

activated by the signal OPTO1 via R102 – as would be the case when the voltage on the secondary

exceeds a value set by zener diode D5. The primary heatsink is protected against excessive

temperature by PTC TH3 which turns on Q16 and this in turn activates latch Q9, Q14.

The voltage developed across R26 is also utilised to regulate the fan speed. As the secondary

loading increases, the voltage across R26 is peak detected by D50 and C31 and sets a demand

11

voltage level at the positive input of op-amp IC14-A, the output of which turns on fan drive transistor

Q38. The fan current is monitored by R120, R121 and amplified by IC14-B to provide negative

feedback to the negative input of IC14-A.

Secondary Side

The main secondary winding is centre tapped and terminates on pins 19/20, 15/16 with the centre

tap on 17/18.

Snubber networks R7, C13 and C14, R18 across each half reduce high frequency ringing.

D47 and C80 generate a negative rail which bleeds a negative current from the output via resistors

R131 and R132.

The voltage on the secondary winding is rectified by D47 & D11, L-C filtered by L1, C5, C7, C8, C11

with flywheel diodes D6 & D7, and fed to a linear output stage comprised of MOSFETs Q3, Q4, Q5,

Q6. To minimise power dissipation in the linear output stage, the voltage across the MOSFETs is

monitored by error amplifier IC7-A (Sheet 2) which maintains the voltage across the linear output

MOSFETs to below 1V by adjusting the ‘Control’ signal to the synchronous post regulator MOSFETs

drive circuit (Sheet 3).

The synchronous post regulator MOSFETs Q2 and Q8 regulate the voltage across the linear output

MOSFETs by initially blocking the pulse from the secondary winding and only conducting after a

delay determined by the ‘Control’ signal.

Referring to Sheet 3, the drive to the post regulator MOSFETs is generated by two identical circuits

operating in anti-phase.

An auxiliary centre tapped winding on the converter transformer T1 terminated on pins 21, 22, 23,

and 24 generates the V+SEC and –8VSEC rails for the secondary control circuitry and also the

reference pulses AAA and BBB for the post regulator control circuit.

This description refers to the upper channel on sheet 3.

The reference pulse AAA is buffered and squared by AND gate IC10-B. The output of the AND gate

charges and discharges capacitor C58 via R66. The discharge time is shorter due to R69 and D41

conducting. The resultant triangular waveform is shown in photograph 03.

The long tail pair (LTP) comparator Q22 & Q23 switches when the triangle waveform at Q23 base

exceeds the reference voltage on Q22 base. The ‘Control’ voltage from IC7-A is fed to the base of

Q21 via R75 and VR3. The pulse width of the two sides is balanced by adjusting VR3.

Q21 emitter sets a pedestal level from which the charging of C58 begins.

The higher this pedestal level, the quicker C58 charges to the reference level on Q22 base and the

LTP comparator switches. This in turn switches Q20 which delivers a pulse to AND gate IC10-D

where it is gated with the AAA reference signal, the trailing edge of which has been slightly delayed

by R71 and C59.

The output of the AND gate IC10-D drives a MIC4428 driver IC, the antiphase outputs of which drive

the gate of the synchronous post regulator MOSFET Q2 via gate drive transformer T4.

Photograph 04 shows the triangular signal at the base of Q23 together with the pulse at IC10-D

pin 9. The reference voltage at the base of Q22 is coincident with the X-axis in the centre of the

oscilloscope screen.

To avoid uncontrolled post regulator conduction, Q32 and associated components ensure that the

‘Control’ signal is clamped to 0V during initial power-up.

The constant power limit is realised using analogue multiplier IC6.

The output voltage and output current are monitored by IC5-A and IC5-B respectively and the

resultant signals fed to the Y and X inputs of the analogue multiplier. The output of the multiplier is

of the form (X*Y)/10 +Z.

Z is a third input and is used to modify the power limit to give a lower power limit at high output

current. The correction signal is generated by IC15-B.

12

The signal across the current sense resistors R12, R13, R14 and R15 is fed into pin5 of IC15-B.

With the output current set to 20A, the signal at pin 5 is nulled by the current in R91/VR4 from the

negative voltage generated by zener D49. The null point setting is aided by comparator IC15-A

which drives two LEDs, the null being achieved when both LEDs are off .

Having nulled the voltage generated by the 20A output current in the current sense resistors, the

increasing current generates a voltage at the output of IC15B and this is fed to the Z input of the

analogue multiplier. The required level of correction is set by VR5.

The supply rails for the front panel control circuit are generated from an auxiliary winding on the

converter transformer T1 terminated on pins 13 and 14.

A V+ rail of approximately 10V is generated by D33, D34 and filter L4, C40.

A +15V rail is generated by D35, C43, R51 and D36.

A -8V rail Is generated by D38, C44, R55 and D37.

Photograph 1

Photograph 2

13

Photograph 3

Photograph 4

Control Board

The control board contains an ARM7 processor, IC111, programmed via JTAG header PJ103. The

three processors communicate via a shared bus but in this case it is isolated via opto-couplers

IC109 and IC110.

The board needs several power supplies and, with the exception on the ‘-8V’ and ‘+15V’ rails, these

are all derived from the ‘V+’ rail generated on the Power board and connected to the Control via

PJ100. IC117 generates a 5-volt rail, which is used to generate 3.3V via IC112, and finally IC113

generates a 1.95V supply for the processor core. In addition IC107d provides a power-fail signal

that ensures that data is saved at each power-off.

Regulation

The output current is sensed via shunt R143 and the signal amplified via IC116. This is fed into the

A/D converter IC102 and also into IC115c where it is compared against the demand to regulate the

current. Similarly IC115a and IC115d regulate the output voltage with the two loops having a diode

‘OR’ connection to give a clean crossover between constant voltage and constant power modes.

Unregulated mode is detected separately on the Power board. IC107a and IC107b provide signals

to the processor so that it knows what mode the power supply is in.

14

Demand Setting

The voltage and current demands, together with OVP limit and the pseudo-analogue outputs are

generated by a digital to analogue converter IC105 together with analogue switch IC106 and a

series of sample and hold circuits. For each of the 5 channels the setting consists of a both a

setting of a DAC reference and a value setting. Consider the voltage demand as an example. First

the processor sets the analogue switch IC104a directly across IC103 and sets IC106 to connect to

IC108a. Writing a suitable value to the DAC sets the reference for the next conversion. The

processor now opens the switch to the input of IC108a so that the setting is held. Next, switch

IC104 is switched so that R119 and R120 in circuit. This gives the correct reference for the demand

to be set. Now the processor writes the correct demand to the DAC and once it has had time to

settle, the output is switched via IC106 through to IC108b where the demand is held on C113. This

whole process is repeated in a similar way for each of the 5 channels. Note that the voltage

demand channel ‘Volts Set’ and the current demand ‘Amps Set’ have additional filtering to prevent

large over/undershoots when the demand is changed.

Measurement

The system accurately measures the output voltage and current and also external demand signals

for pseudo-analogue control. This is achieved via IC402, an analogue to digital converter. IC101a

provides a clean, buffered reference. This chip communicates with the processor via an SPI bus.

OVP

IC107c provides over-voltage protection. It compares the OVP limit, set by IC108d, with the output

voltage. When the output voltage becomes excessive it latches, pulling the voltage demand to zero

via Q111 and Q112. The processor can reset the latch via Q113.

Remote Sense

RL100 selects between remote and local sensing controlled by the processor via Q109. Q106 and

Q107 sense excessive drop down the sense cables, indicating a sense fault to the processor via

Q105, if appropriate.

Logic in and Logic Out

The system has input and output logic signals which communicate with the processor via buffer

transistors Q100 and Q101.

Keyboard

The keyboard processor IC2 acts as the system master initiating all communications within the unit;

it is programmed in-circuit using the standard JTAG port accessed at PJ3. PJ9 and PJ10 provide

the connections to the other boards in the system; Q2 and IC5 enable the processor to pull down

the data line, allowing it to go high only if none of the processors in the system want to pull it low.

The firmware operates a master-slave system to ensure there are no data clashes.

The board is supplied with 5V from the PFC board via PJ4. This is used to generate a local 3.3V

supply (IC4) and 1.95V supply (IC3). IC7a, together with Q1 and associated components, provide a

current source for the display LED backlight. IC7b and associated components provides a crude

under-voltage detect to ensure the processor starts and shuts down cleanly. IC6 is a simple latch

for the LEDS and the keyboard is scanned directly by the processor: this is a quiet scan that only

scans when keys buttons are pressed or released not when the keys are left open or held down.

The diodes D1 to D4 allow the processor to use some pins for two purposes (key-scan and LED).

The display is a 240x64 pixel LCD mounted directly on the keyboard PCB and connected via PJ6.

The display contains its own voltage multiplier to generate the required bias levels; the switched

capacitors and decoupling are provided directly on the pins of the display connector.

15

Interface Board

The interface board allows the unit to communicate externally via USB or RS232. IC5 is an ARM7

processor which is programmed in-circuit using the standard JTAG port accessed at PJ5.

IC3 and IC6 generate the required supply rails. PJ3 provides an RS232 connection; IC1 and IC2

provide the necessary level shifting and inversion to convert the UART’s 5V ‘mark’ and 0V ‘space’ to

RS232’s –5V mark and +5V space. They also allow for data to pass through from one unit to

another for TTi’s Addressable RS232 Chain (ARC). USB is controlled directly by the processor; Q1

switches R22 to provide a soft connect/disconnect feature.

PJ3 provides a shared connection between the boards in the system; Q2 and IC4 allow the

processor to pull down the data line (pin) allowing it to go high only if none of the processors in the

system want to pull low. The firmware operates a master-slave system to ensure there are no data

clashes.

16

Calibration Procedure

The QPX1200 calibration menu can be found under extra functions “#99”. The output calibrations

are dependent on the measurement being in calibration so it is recommended that each of the

calibrations be done in the order they appear on the menu.

Equipment Required

Voltmeter capable of reading up to 65 Volts with 1mV accuracy and up to 15V with 100µV accuracy,

a Current measurement system capable of measuring 60 Amps with 10mA accuracy, and resistance

less than 100mΩ(e.g. a 4-terminal shunt).

Procedure

01: Vout measurement calibration

Ensure that there is no load connected to the unit and connect the voltmeter directly across the front

panel output terminals. Select option 1 from the Calibration menu (Vout measurement) and press

OK. The unit now gives an output of about 1 Volt; measure it, enter the actual voltage (to the

nearest mV) and press OK. After a few seconds the output changes to about 50 Volts; measure and

enter this to the nearest mV, press OK. After a few seconds the display changes to the Calibration

menu again; output voltage measurement is now calibrated.

02: Vout setting calibration

Ensure there is no load connected to the unit. Select option 2 from the Calibration menu (Vout

setting) and press OK. The unit self-calibrates; during this time the output voltage will be switching

between different levels. After a few seconds the display changes to the Calibration menu again;

output voltage setting is now calibrated.

03: Iout measurement calibration

Connect the current measurement system directly across the front panel terminals. Select option 3

from the Calibration menu (Iout measurement) and press OK. The unit now gives an output of

about 1 Amp; measure it accurately, enter the actual current to the nearest mA, and press OK. After

a few seconds the output changes to about 50 Amps; measure and enter this to the nearest mA and

press OK. After a few seconds the display changes to the Calibration menu; output current

measurement is now calibrated.

04: Iout setting calibration

Connect the current measurement system directly across the front panel terminals or alternatively

connect a direct short-circuit. Select option 4 from the Calibration menu (Iout setting). The unit self-

calibrates; during this time the output current will be switching between different levels. After a few

seconds the display changes to the Calibration menu; output current setting is now calibrated.

05: Vmon measurement calibration

On the rear panel terminals short ‘Vmonitor’ to ‘Vcontrol’. Ensure that there is no load connected to

the unit and connect the voltmeter from ‘Vmonitor’ to ‘Common’. Select option 5 from the

Calibration menu (Vmon measurement) and press OK. The unit now gives an output of about 1

Volt; measure the voltage at ‘Vmonitor’ and enter the output voltage this represents (e.g. 6 times the

voltage measured for the 0V to 10V range) to the nearest mV and press OK. After a few seconds

the output changes to about 50 Volts; measure and enter the voltage represented by the voltage at

‘Vmonitor’ to the nearest mV and press OK. After a few seconds the display changes to the

Calibration menu; output voltage control is now calibrated.

06: Vmon setting calibration

On the rear panel terminals short ‘Vmonitor’ to ‘Vcontrol’. Ensure there is no load connected.

Select option 6 from the calibration menu (Vmon setting) and press OK. The unit self-calibrates;

during this time the output voltage will be switching between different levels. After a few seconds

the display changes to the Calibration menu; output voltage monitor is now calibrated.

17

07: Imon measurement calibration

On the rear panel terminals short ‘Imonitor’ to ‘Icontrol’. Ensure that there is no load connected to

the unit and connect the voltmeter from ‘Imonitor’ to ‘Common’. Select option 7 from the Calibration

menu (Imon measurement) and press OK. The unit now gives an output of about 1 Amp; measure

the voltage at ‘Imonitor’ and enter the output current this represents (e.g. 5 times the current

measured for the 0V to 10V range) to the nearest mA and press OK. After a few seconds the output

changes to about 50 Amps; measure and enter the current represented by the voltage at ‘Imonitor’

to the nearest mA and press OK. After a few seconds the display changes to the calibration menu

output voltage control is now calibrated.

08: Imon setting calibration

On the rear panel terminals short ‘Imonitor’ to ‘Icontrol’. Connect the current measurement system

directly across the front panel terminals or alternatively connect a direct short-circuit. Select option

8 from the calibration menu (Imon setting) and press OK. The unit self calibrates; during this time

the output current will be switching between different levels. After a few seconds the display

changes to the Calibration menu; output current monitor is now calibrated.

18

Parts List

PCB ASSEMBLY - POWER - (44115-3060)

Part Number Description Position

20205-0800 STUD M6 x 20 HFHB M6-20-X OUTPUT CONNECTION

20234-0023 SCREW M4 x 8 PNHDPZ ZPST HEATSINKS

20234-0100 SCREW M3 x 6PNHDPZ C/W EXT SH/P PCB SUPPORT SPACERS

20613-0007 SIL-PAD TO220 PLAIN FOR TH1

20613-0026 SIL-PAD 900S 100MM X 25MM FOR HEATSINKS

20661-0225 SPACER Hex M3 x 12 NPBR PCB SUPPORT

20670-0135 CLIP GP02 FOR PCB MTG H/SINKS

20670-0310 HEATSINK PCB MTG 38MM PLAIN SK3

20670-0340 HEATSINK TO220 CLIPON 29DEG/W SK4

20670-0364 CLIP MAX01H FOR TO220+MAX H/S FOR TH1, TH3

20670-0365 CLIP MAX03H FOR TO247+MAX H/S FOR Q2-6, Q8, Q28, Q29, D3, D6-7, D11

20670-0550 HEATSINK MAX505 90MM PLAIN SK1

20670-0560 HEATSINK MAX505 210MM PLAIN SK2

22040-0940 BEAD (DOUBLE) - FERRITE FB1-7

22109-0130 TRANSFORMER GATE DRIVE T3

22109-0280 TRANSFORMR CURRENT SENSE CT1

22109-0370 TRANSFORMER HF POWER T1

22109-0400 TRANSF GATE DRIVE QPX POSTREG T4-5

22154-0160 CHOKE 1mH AXIAL 1.3 OHMS L3-4

22154-0770 CHOKE - OUTPUT -QPX L1

22154-0780 CHOKE - 3uH - ZVS L2

22455-0040 TAB 4.8MAX 0.8MM STR PCB MTG FAS1-2

22467-0130 TERMINAL BLOCK 2W R/A TB1-6

22482-0020 BEAD, CERAMIC 11-54-3557-0 FOR R12-15

22573-0086 HEADER 16W 2x8 LATCHING PJ4

22573-0210 HEADER 10 WAY STRAIGHT .156P PJ5

22573-0224 HEADER 4 WAY STR F/LOCK .156P PJ1 (FIT PIN 1 TO PIN 1)

22573-0247 HEADER 2 WAY STR .1P F/LOCK PJ6-8

22575-0038 HEADER 6 WAY STR SIL TP4, TP5

23185-0000 RES ZERO OHM R155, R156

23202-0100 RES 10R0F W60 MF 50PPM R37, R41, R52, R73

23202-0270 RES 27R0F W60 MF 50PPM R45

23202-1100 RES 100RF W60 MF 50PPM R2, R4-6, R49

23202-2330 RES 3K30F W60 MF 50PPM R33-34

23202-5680 RES 6M80F W60 MF 50PPM R27-28

19

Table of contents

Other TTI Power Supply manuals

Popular Power Supply manuals by other brands

Kramer

Kramer VA-100P user manual

SamplexPower

SamplexPower SEC-1212CE owner's manual

Stahl

Stahl 9160/19-11-10k operating instructions

EverFocus

EverFocus IP Sidekick-ESK1000 user manual

Eltek Valere

Eltek Valere Minipack Quick start guide and manual

Elenco Electronics

Elenco Electronics XP-660 instruction manual