TTI EX752M User manual

EX752M

75V/150V

Multimode Power Supply

Service Manual

Manual Part Number 48511-0470 Issue 1

Table of Contents

Specification 1

Safety 3

General 4

Circuit Description 5

Calibration 9

Parts List 11

Component Layouts 19

Circuit Diagrams 21

Specification

OUTPUTS

Voltage Range: 0V to 75V minimum, Modes A and B.

0V to 150V minimum, Mode C.

Current Range: 0A to 2A minimum, Modes A and C.

0A to 4A minimum, Mode B.

Output Voltage Setting: By coarse and fine controls.

Output Current Setting: By single logarithmic control.

Operating Mode: Constant voltage or constant current with automatic cross-over.

Output Switch: Electronic. Preset voltage and current displayed when off.

Output Terminals: 4mm safety terminals on 19mm (0.75”) pitch.

Output Impedance: Typically <5mΩin constant voltage mode.

Typically >50kΩin constant current mode (voltage limit at max).

Output Protection: Output will withstand forward voltage of up to 85V (Modes A and B) or

170V (Mode C).

Reverse protection by diode clamp for reverse currents up to 3A.

Load & Line Regulation: <0.01% of maximum output for a 90% load change or 10% line change;

<0.1% load regulation for Mode C (150V/2A).

Ripple & Noise

(20MHz bandwidth):

Typically <2mVrms, <15mV pk-pk, constant voltage mode.

Transient Response: <200µs to within 50mV of set level for 90% load change.

Temperature Coefficient: Typically <100ppm/°C

Status Indication: Output on lamp. Constant current mode lamp.

1

OPERATING MODES

Mode Selection: By front panel rotary switch.

Mode A: Independent outputs each capable of 0-75V at 0-2A.

Mode B: Output 2 only active, 0-75V at 0-4A.

Output 1 disabled.

Mode C: Output 2 only active, 0-150V at 0-2A.

Output 1 disabled.

METER SPECIFICATIONS

Meter Types: Dual 3 digit meters with 14mm (0.56") LEDs. Reading rate 4 Hz.

Meter Resolutions: 100mV, 10mA

Meter Accuracies: Voltage 0.3% of reading ± 1 digit,

Current 0.6% of reading ± 1 digit

Operating Modes: Output 1 meters are blanked in Modes B and C.

GENERAL

AC Input: 110V-240V AC ±10%. Installation Category II.

Power Consumption: 500VA max.

Operating Range: +5ºC to +40ºC, 20% to 80% RH.

Storage Range: −40ºC to + 70ºC.

Environmental: Indoor use at altitudes up to 2000m, Pollution Degree 2.

Safety: Complies with EN61010-1.

EMC: Complies with EN61326.

Size: 260 x 160 x 320mm (WxHxD).

Weight: 4.3kg

2

Safety

This power supply is a Safety Class I instrument according to IEC classification and has been

designed to meet the requirements of EN61010-1 (Safety Requirements for Electrical Equipment

for Measurement, Control and Laboratory Use). It is an Installation Category II instrument

intended for operation from a normal single phase supply.

This instrument has been tested in accordance with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 2 environment in the

temperature range 5°C to 40°C, 20% - 80% RH (non-condensing). It may occasionally be

subjected to temperatures between +5°C and –10°C without degradation of its safety. Do not

operate while condensation is present.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to its supply, terminals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, maintenance or repair. Capacitors inside the power supply may still be

charged even if the power supply has been disconnected from all voltage sources but will be

safely discharged about 10 minutes after switching off power.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be avoided

as far as possible and, if inevitable, shall be carried out only by a skilled person who is aware of

the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protection may be impaired and the apparatus should be

withdrawn from use and returned for checking and repair.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is prohibited.

Do not wet the instrument when cleaning it.

The following symbols are used on the instrument and in this manual:-

Earth (ground) terminal.

mains supply OFF.

l mains supply ON.

alternating current (ac)

direct current (dc)

CAUTION – refer to accompanying documentation;

incorrect operation may damage the power supply.

3

General

Service Handling Precautions

Service work or calibration should only be carried out by skilled engineers using high quality test

equipment. If the user is in any doubt as to his competence to carry out the work, the instrument

should be returned to the manufacturer or their agent overseas for the work to be carried out.

The tracks on the printed circuit boards are very fine and may lift if subjected to excessive heat.

Use only a miniature temperature-controlled soldering iron and remove all solder with solder wick

or suction before attempting to remove a component.

Dismantling the instrument

WARNING!

Disconnect the power supply from all voltage sources before it is opened for adjustment or repair.

Capacitors inside the supply may still be charged even if the supply has been disconnected from

all voltage sources but will be safely discharged about 10 minutes after removing power.

If any adjustment or repair of the opened supply under voltage is inevitable it shall be carried out

only be a skilled person who is aware of the hazard involved. The incoming AC supply to the unit

under test should be isolated for safety by means of a 1:1 isolation transformer of at least 700VA.

High voltages (up to 400V) are always present in the primary-side circuitry which lies in a clearly

defined area at the rear of the main printed circuit boards.

1. Remove the 6 side screws and front handle screw to release the top cover.

2. Unplug the 3 connector assemblies linking the main pcb to the front panel control pcb,

noting their orientation (brown wire to pin 1 corner marker).

3. Unplug the mains connection at the rear of the pcb and remove the chassis safety earth

connection.

4. Undo the 10 screws which secure the main pcb support pillars to the chassis (i.e. the

screws accessible underneath the chassis) and lift out the pcb with its mounting pillars

attached.

5. To remove the control pcb on the front panel first remove the main pcb. Pull off the 6

control knobs and the mode knob, then undo the 5 screws which retain the pcb to the

moulding and the 4 nuts which connect the pcb to the output terminals. The control pcb

can then be lifted clear.

6. Reassemble in the reverse order taking great care to ensure that all connections are

exactly as before dismantling and that no insulation creepage and clearance distances

have been compromised. Ensure that only the correct fastenings have been used

otherwise earthing, and hence EMC and safety performance, may be impaired.

4

Circuit Description

Main Pcb

Mains Input, Filtering and Rectification

The AC input is via a pcb mounted IEC plug, PJ3.

X-capacitors C1, C9 and C47, together with the Y-capacitors C6, C7 and common mode

inductors L1 and L2 comprise an input filter which ensures that the supply meets both conducted

emission and conducted immunity EMC requirements.

VDR1 clips mains spikes for component protection, while R1 discharges the X-capacitors after

removal of the mains supply.

Pcb mounted fuse FS1 limits damage on boost-stage or forward converter failure. The front panel

mains switch is connected via PJ4.

The bridge rectifier BR1 has C11 and C12 connected across it to bypass noise signals and to

snub reverse recovery transients in the bridge rectifier.

C89 further decouples the input filter and rectifier from the boost converter, while R113

discharges C89 after removal of the mains supply.

RT1 is an NTC which limits the initial inrush current into the boost stage output capacitor C88.

Primary Control

The primary control is by means of IC8.

This contains all the processing circuitry to shape the current taken by the power supply from the

mains supply to be sinusoidal and in phase with the voltage.

Initial start-up is via R79 and R80 which charge C32. When the voltage on C32 exceeds the

under voltage lockout level of 16V, IC8 starts up and supplies drive pulses to the boost MOSFET

Q5 . The gate drive pulses to Q5 are given a slight negative offset by C94, D52, D53 and R112 to

give extra noise immunity.

C117 provides a degree of soft start.

Once the boost converter is running, the supply to IC8 is derived from an auxiliary winding on the

boost inductor L3, rectified and filtered by D7, C2 and C15 and also from a power back winding

on the main converter transformer, rectified and filtered by D6, C87 and C93.

R131, R132, R133, R71, C4, and C34 form a two stage RC filter to feed a voltage proportional to

the mains voltage to pin 7 which, after a 1/V2 transformation, is fed to the multiplier . For a

universal mains input, the voltage at this pin will vary between 1.5V and 5.5V.

R135 and R136 supply a current derived from the full wave rectified mains voltage to pin 4 to be

used by the internal multiplier.

Also fed to the multiplier is the output of the voltage error amplifier of pin 13. The input to the error

amplifier at pin 14 is from potential divider R74, R75 and R93. This potential divider monitors the

voltage on the boost stage output capacitor C88 and this is compared to an accurate internal

reference voltage. Thus a steady voltage of about 380V is maintained across C88.

Another potential divider R81, R82, R98 monitors the voltage across C88 and feeds into pin 3 of

IC8 which is the over voltage shutdown.

Pin 8 is the output of the multiplier and is the programming current for the internal current error

amplifier. This signal is taken to the mains supply side of the current sense resistor R83 via R8.

The other input of the current error amplifier is taken to the other side of R83 via R72. The current

error amplifier thus compares the signal across the current sense resistor R83 with the

programming current and adjusts the PWM drive to the boost MOSFET Q5 accordingly. R73 and

C86 with R72 form the compensation network around the current error amplifier.

When the mains supply falls below about 85Vrms, the circuit comprising of long tail pair Q6 and

Q10 and Q1 act on the soft start input of IC8 to curtail operation.

5

Boost Stage and Forward Converter

Q5 and boost inductor L3 raise the incoming, full wave rectified, sinusoidal mains voltage to a

value some 20V higher than the peak of the maximum rms input voltage. This is achieved by

storing energy in L3 when Q5 is conducting and transferring it to C88 via boost diode D54 when

Q5 is turned off.

When Q5 next turns on, D54 is still conducting current. To prevent large switch on losses in Q5, a

delay inductor L9 is placed in series with Q5. This ensures that the current in the boost diode D54

is reduced at a gradual rate and the reverse recovery time is minimised at the same time as Q5

drain voltage is allowed to fall rapidly.

The energy stored in L9 is stored in C119 via D67 and dissipated in R92 and R95.

A dual ended forward converter comprising of Q4, Q7 and TX2 converts the boost voltage across

C88 to provide two isolated low voltage secondaries and also the required secondary auxiliary

voltages.

TX2 leakage energy is returned to the high voltage supply rail via D2, D3 and D4, D5 . The turnoff

voltage rise is controlled by ‘loss less’ snubber network C27, C28, D61, D63, D69, L10. R20

damps any oscillation across L10 .

The gate drive to Q4 and Q7 is by means of a gate drive transformer TX1.

The drive signal is generated by an oscillator IC1A and IC1B. This is converted into two square

waveforms by D-types IC7A and IC7B.

The square waveform from IC7A is ‘duty cycle reduced’ by R9, D39, IC1D then buffered by IC1E

and IC1F and is used to drive Q2 and Q3.

The current in the forward converter is monitored by R16 and, if excessive, activates latch Q22,

Q23 to provide a pulse-by pulse current limit.

The square waveform from IC7B is processed by Q19 to provide a synchronisation pulse for IC8.

Main Outputs

The component references given refer to Channel A, the left-hand (slave) channel which is

marked Output 1 on the front panel. Channel B, the right-hand (master) Channel is identical

except for Q15 and L7 which are up-rated components because Channel B supplies 4 Amps in

the 75V/4A mode; refer to the circuit diagram and parts lists for details.

The voltage on the secondary winding is rectified and L-C filtered and fed to a linear regulator. To

minimise power dissipation in the linear regulating element, the voltage across it is maintained at

about 1V by means of a magamp.

The linear regulation is performed by MOSFET Q14 which receives gate drive from the front

panel pcb. The voltage across Q14 is monitored by Q11 which generates reset current to the

magamp whenever the voltage across Q14 forward biases the base-emitter junction of Q11.

D24 is the main rectifier and flywheel diode. The rectified pulse is filtered by L6 and C33.

Q8 minimises parasitic reset of the magamp by bypassing D24 reverse leakage currents during

the fly back period.

D44, D47, D48, R111 and C76 generate a negative rail to sink the base bias current of Q11 which

would otherwise cause the output to remain slightly positive when 0V was set on the front panel.

In the event of a fault where control of the magamp is lost and the voltage across the filter

capacitor C33 rises above 88V, the opto isolator IC13 is activated and causes primary side

thyristor SC1 to discharge the primary control power rail. This is followed by a normal restart. If

the fault persists, the PSU will continue to ‘hiccup’.

Secondary Auxiliary Power Supply

The power rails for the control electronics of the two main outputs are generated from auxiliary

windings on the main converter transformer.

6

Again referring to channel A, the +15V is peak rectified by D40 and zener regulated by D42.

The +5V rail is rectified by D18, D19 and filtered by L4 and C23. The inductor L4 is held in

continuous conduction and thus the voltage at the input to the three terminal regulator IC2 is

maintained at low value.

The –5V rail is peak rectified by D13 and zener regulated by D20.

Mode Switching

The opto-isolators IC14 – IC16 and associated components which provide control signal isolation

between the two channel are described in the Control Board section.

Control Board

Component references are given for Channel A, the left-hand (slave) channel viewed from the

front; components of Channel B, the right-hand (master) channel, are all numbered from 100

upwards,e.g.RP3, C9 and R24 on Channel A are RP103, C109 and R124 on Channel B.

The linear regulator is in series with the positive output but, because of the way in which the

control and metering works, it is convenient to consider the regulator output (OP) as 0V and to

regard the negative output as the controlled output voltage (-V).

Supply rail and signal names on the schematics are followed by /A or /B for Channels A and B

respectively, e.g. OP/A.

Voltage Control

IC7C buffers the voltage control potentiometers VR1 and VR2; VR5 sets the maximum output

voltage. D6 provides the reference (VREF) which is nominally 2.45V.

IC7A is a differential amplifier with a voltage gain of 14.7; for an output voltage of 75V the voltage

at IC7C pin 8 will be 5.1V. VR9 trims differential gain to ensure good voltage regulation, see

Calibration section.

The output of IC7C drives the input of IC7A when the ON-OFF switch, SW1B, is in the ON

position. When SW1B is in the OFF position the input of IC7A is grounded via R50, setting the

output volts to zero.

The output of IC7A provides the gate drive (GATE) to the regulating MOSFET Q14 (Q15) on the

main pcb via D3.

Current Control

IC7D is the error amplifier which compares the voltage on the wiper of VR3, the current limit

control with the voltage generated across the current sense resistor R21. When the output current

reaches the set limit IC7D takes control via D4, changing the supply from constant voltage to

constant current mode. At the same time Q1 is turned on by IC7D, making ILIMIT go high; this is

read by the microcontroller IC3 which turns on the constant current lamp, LED2.

VR4 sets the maximum output current; VR8 adjusts the output current to be the same as the

preset current at low levels, see Calibration section.

7

Measurement and Display

The measurement and display is controlled by a microcontroller, IC3. IC5, IC2 and associated

components, together with IC3, form a dual slope A-to-D converter. Multiplexer IC4, under the

control of IC3, selects the signals to be measured. The status line SW1 from the output ON/OFF

switch is read by IC3 to determine which signals are measured, as follows:

Status Voltage Measurement Current Measurement

Output Off Preset Volts (VPRT & ILO) Preset Current (IPHI & ILO)

Output On Output Volts (+SENSE & VOLO) Output Current (IOHI & ILO)

IC3 processes the measurement and drives the two multiplexed 3-digit, 7-segment, LED displays

via digit driver IC1 and segment latch IC6. Individual segment current limit is provided by RP1

and RP2. The constant current lamp, LED2, is part of this multiplexing scheme; the output on

lamp, LED1, is driven directly from the +5V auxiliary rail via R2 when the dc output switch SW1-A

is closed.

Mode Control

The three operating modes are selected by a 4-pole 3-way break before make switch, SW2.

Opto-isolators IC14, 15 and 16 on the Main pcb provide isolation of the control signals between

the 2 channels.

Isolated: The two channels operate independently and are isolated.

Parallel: The slave side is turned off and the control of the master is changed such that it can

supply up to 4 Amps. SW2-C disconnects the voltage setting controls from the

voltage error amplifier IC7-A of the slave, forcing the slave output to 0V. Signal X is

high on IC8-A turning off the slave display. Signal P is low on IC108-B doubling the

master current limit. Whenever the parallel mode is exited the PAR signal goes high

pulsing the MUTE signal low via IC6 on the Main board, turning off both outputs

momentarily. At power-on C52 and Q25 on the Main board also mute the outputs

momentarily.

Series: The two channels are connected in series and to the master terminals. SW2-B

disconnects the master negative terminal from its own supply and connects it to the

slave negative terminal. SW2-A disconnects the slave positive output from its

terminal and connects it to what was the master negative terminal supply thus

putting the supplies in series. Relay RL1 switches the sense connections. SW2-C

switches the input to the slave error amplifier to the master positive terminal forcing

the slave to track the master. Signal X is high on IC8-C forcing the slave current

limit to a little over 2 Amps so that the master current limit is always in control.

Signal Y is low on IC108-A doubling the preset voltage measurement. Signal X is

high on IC8-A turning off the slave display.

8

Calibration

Refer to the General section for dismantling instructions and safety precautions. Component

adjustment references are given as Channel A/ Channel B, e.g. VR5/VR105; Channel A is the

left-hand output. All adjustments are on the front panel control board unless otherwise stated.

Allow 5 minute warm-up before commencing calibration.

Control pcb calibration points (viewed from rear)

Equipment Required

A 5½ digit multimeter with better than 0.05% accuracy on dc volts and better than 0.1% accuracy

on dc current (to 4A); alternatively use a precision shunt for current measurement.

Rheostat or other high power load arrangement to provide up to 4A load at 75V.

Mode A (75V/2A x 2)

Adjust Channel A and Channel B independently as follows.

Voltage Calibration

Connect the DMM (set to Volts) across the output. Set voltage and current controls to minimum.

Switch output ON (Check LED is on) and check for a reading of 00.0V ± 0.1V on the Volts display

and DMM; check the Amps display reads 0.00 ± 0.01A.

Set voltage and current controls to maximum. Adjust VR5/VR105 (maximum output volts) for a

reading of 75.35V to 75.45V on the DMM. Adjust VR6/VR106 (measured output volts) until the

Volts display matches the reading on the external DMM.

Switch output OFF. Adjust VR10/110 (preset volts) until the Volts display shows 75.4.

Current Calibration

Switch output OFF. Set output voltage to nominally 2V. Set current control to minimum. Connect

the DMM (set to Amps) and load in series across the output. Switch output ON.

Adjust VR8/108 (offset compensation of current control error amp) for a reading of 0.003A

± .001A on the DMM. Check that the CC LED is ON.

Increase voltage controls and current control to maximum. Adjust load until the DMM reads 2.00A

± 0.02A. Adjust VR7/107 (measured output current) until the Amps display matches the DMM

reading.

Reduce load until the CC LED is ON. Adjust VR4/104 (maximum output current) until the Amps

display shows 2.05.

9

Voltage Regulation

Connect the DMM (set to Volts) across the output, no load, output ON.

Adjust voltage controls for a reading of 18.xxxx on the DMM; note exact reading.

Connect load and adjust it to give an output current of 2.00A on the Amps display. Adjust VR9/109

(differential voltage gain) until the external DMM matches the previous reading.

Mode B (75V/4A)

With both outputs OFF select Mode B (75V/4A). Set the voltage and current controls to maximum

and check that the current display (preset maximum current) reads ≥4.05 Amps. Connect the

rheostat, switch the output ON and adjust the load until the CC LED is just ON; check that the

current display (measured output current) matches the preset current ± 0.05 Amps.

Mode C (150V/2A)

With no loads connected and both outputs OFF select Mode C (150V/2A). Switch the output ON

and check that the reading on the Volts display (measured output volts) is ≥150.1V. Switch the

output OFF and adjust VR111 to give the same reading on the Volts display (preset output volts).

Noise Measurements

Differential and common-mode noise checks can be made using the arrangement below. Keep all

unscreened connections as short as possible.

Make measurements with the output fully loaded. Measure differential and common-mode noise

one at a time on a 20MHz TRMS voltmeter or use a 20MHz bandwidth-limited scope for peak-to-

peak measurements.

10

Parts List

PCB ASSY – MAIN (44115-0960)

Part Number Description Position

20030-0263 WASHER M3 ZPST SPACERS, BR1

20037-0301 WASHER M3 SHK/PROOF I/T ZPST SPACERS TO UNDERSIDE OF PCB

20038-9501 WASHER M3 Spring SPACERS, BR1

20210-0101 NUT M3 ZPST BR1

20234-0011 SCREW M3 X 10 PNHDPZ ZPST

20234-0027 SCREW M3 X 6 PNHDPZ ZPST SPACERS

20613-0007 WASHER (SIL-PAD) TO220 PLAIN SKD24,SKD26,SKD54,SKQ4,SKQ7, SKQ14

20613-0018 WASHER SIL-PAD TO-3P/247 PLAIN SKQ5,SKQ15

20661-0225 SPACER Hex M3 x 12 NPBR PCB

20670-0135 CLIP GP02 FOR PCB MTG H/SINKS SKD24,SKD26,SKD54,SKQ4,SKQ7,

SKQ14,SKQ15

20670-0300 HEATSINK PCB MTG 63MM PLAIN SKD24,SKD26,SKD54,SKQ4,SKQ7,

SKQ14,SKQ15

20670-0340 HEATSINK TO220 CLIP-ON 29DEG/W SKIC2, 3

20670-0400 HEATSINK PCB MTG 3.7DEG C/W SKQ5

20670-0401 CLIP FOR 20670-0400 SKQ5

20670-0410 HEATSINK – BOLT ON – 7DEG C/W HSBR1

22040-0940 BEAD (DOUBLE) – FERRITE FB1-5, 8

22109-0130 TRANSFORMER GATE DRIVE TX1

22109-0180 TRANSFORMER HF POWER TX2

22154-0160 CHOKE 1mH AXIAL 1.3 OHMS L4, 5

22154-0180 CHOKE 350uH/4A L6

22154-0181 CHOKE 350uH/4A LOW LOSS L7

22154-0230 CHOKE 1.8mH/6A COMMON MODE L1, 2

22154-0240 BOOST INDUCTOR L3

22154-0390 CHOKE 4uH L9

22154-0400 CHOKE 1mH L10

22154-0520 MAGAMP 75V/4A MA1, 2

22312-0242 FUSE CLIPS PCB MTG FS1

22315-0248 FUSE 10A ANTISURGE (T) HBC CER

22455-0040 TAB 4.8MAX 0.8MM STR PCB MTG PJ4

22520-0190 AC RECEP 10AMP R/A SOLDER MTG PJ3

22573-0041 HEADER 2WAY STR SIL STD/GOLD TP1, 2

22573-0208 HEADER 8 WAY STRAIGHT .156P PJ5

23185-0000 RES ZERO OHM LK1-26,28,32,35

23202-0100 RES 10R0F W25 MF 50PPM R61

11

PCB ASSY – MAIN (44115-0960) continued/...

Part Number Description Position

23202-0220 RES 22R0F W25 MF 50PPM R13,67,68,69,70,105,120,121

23202-0330 RES 33R0F W25 MF 50PPM R127

23202-0470 RES 47R0F W25 MF 50PPM R11,15,122

23202-1100 RES 100RF W25 MF 50PPM R44,106

23202-1220 RES 220RF W25 MF 50PPM R84

23202-1330 RES 330RF W25 MF 50PPM R89

23202-1470 RES 470RF W25 MF 50PPM R2,10,85,123

23202-2100 RES 1K00F W25 MF 50PPM R77,112,118

23202-2220 RES 2K20F W25 MF 50PPM R14,40,41,47

23202-2270 RES 2K70F W25 MF 50PPM R9

23202-2330 RES 3K30F W25 MF 50PPM R8,72

23202-2390 RES 3K90F W25 MF 50PPM R5

23202-2470 RES 4K7OF W25 MF 50PPM R33,34,55

23202-3100 RES 10K0F W25 MF 50PPM R43,45,144,146

23202-3110 RES 11K0F W25 MF 50PPM R93

23202-3220 RES 22K0F W25 MF 50PPM R35,65,66,73,98

23202-3270 RES 27K0F W25 MF 50PPM R12

23202-3330 RES 33K0F W25 MF 50PPM R71,147-150

23202-3470 RES 47K0F W25 MF 50PPM R6

23202-4100 RES 100KF W25 MF 50PPM R18,19,36,48-52,57,78,140,141,143, 145

23202-4360 RES 360KF W25 MF 50PPM R133

23202-4390 RES 390KF W25 MF 50PPM R74,75

23202-4470 RES 470KF W25 MF 50PPM R53

23202-4620 RES 620KF W25 MF 50PPM R131,132,135,136

23202-4820 RES 820KF W25 MF 50PPM R81

23202-4910 RES 910KF W25 MF 50PPM R82

23206-2100 RES 1K00F W60 MF 50PPM R25,26

23206-5680 RES 6M80F W60 MF 50PPM R96,97

23206-5680 RES 6M80F W60 MF 50PPM R91,101

23209-4220 RES 220KF W75 MF 100PPM R1,113

23210-1100 RES 100RJ 2W MF 250PPM R90,129

23210-1220 RES 220RJ 2W MF 250PPM R27,30

23210-1470 RES 470RJ 2W MF 250PPM R92,95

23210-2470 RES 4K70J 2W MF 250PPM R42,46,86,87

23210-3220 RES 22K0J 2W MF 250PPM R3,4

23210-3330 RES 33K0J 2W MF 250PPM R79,80

23210-3390 RES 39K0J 2W MF 250PPM R39,63,64,94

12

PCB ASSY – MAIN (44115-0960) continued/...

Part Number Description Position

23222-0047 RES 4R70J W33 MF FUSIBLE NFR25 R7,21,22,23,24,54

23222-0220 RES 22R0J W33 MF FUSIBLE NRF25 R17,110,111

23222-1100 RES 100RJ W33 MF FUSIBLE NRF25 R37,38

23222-1220 RES 220RJ W33 MF FUSIBLE NFR25 R99,100,102,103

23222-1470 RES 470RJ W33 MF FUSIBLE NFR25 R29,32

23222-2100 RES 1K00J W33 MF FUSIBLE NFR25 R56,62

23271-0020 RES 0R047J 2W MR R83

23274-0005 RES 0R22K 2W5 WW R16

23274-0136 RES 100RJ 4W WW R28,31

23274-0310 RES 10K0J 4W WW R20

23386-0010 VARISTOR V275LA20A VDR1

23386-0060 THERMISTOR INRUSH LIMIT 6A 10R RT1

23424-0443 CAP 10NZ 1KV CER D10 P5 C5

23424-0459 CAP 4N7 250V AC CER STR/LNG Y C6,7,11,12

23424-0466 CAP 1N0K 1KV CER P5 C82-85

23424-0468 CAP 470PK 1KV CER P5 C20,21,58,59

23424-0469 CAP 220PK 1KV CER P5 C22,29,118,121

23424-0472 CAP 2N2K 1KV CER P5/P7.5 C27,28

23427-0388 CAP 220PK 100V CER P2.5 C68

23427-0389 CAP 2N2K 100V CER MED K P2.5 C17

23427-9211 CAP 470PK 100V CER MED K P2.5 C8,10,49

23557-0610 CAP 100U 50V ELEC RE2 P3.5 C32

23557-0612 CAP 1U0 100V/50V ELEC RE2 P2 C50,52

23557-0661 CAP 470U 25V ELEC RE2 P5 C23,25

23557-0673 CAP 22U 35V ELEC RE2 P2 C18,19

23557-0681 CAP 220U 100V ELEC P5/P7.5 C70,71

23557-0693 CAP 2U2 160V ELEC P2.5 C30

23557-0820 CAP 10U 50V ELEC LOW ESR P2 C15,72,73,93

23557-0827 CAP 470U 100V LOW ESR P7.5 C33,37

23557-0950 CAP 470U 400V ELEC S/I P10 C88

23620-0236 CAP 1N0K 100V P/E P5 C3,86

23620-0246 CAP 100NK 63V P/E P5 C2,13,24,26,41,42,44,45,69,74,75,80,81,87,

92,102,107-110,111,115,117,120

23620-0247 CAP 220NK 63V P/E P5 C4,34

23620-0252 CAP 2N2K 63V P/E P5 C48

23620-0264 CAP 100NK 400V P/E 368 SER P15 C51,54,76,77

23620-0267 CAP 100NK 100V P/E P5 C31,35,61,62

13

PCB ASSY – MAIN (44115-0960) continued/...

Part Number Description Position

23620-9007 CAP 10NK 100V P/E P5 C90,91,101

23621-0314 CAP 1UOK 400V P/E P27.5 C14

23684-0016 CAP 220NM 250VAC MIN X2 P22.5 C89

23684-0020 CAP 1UM 250VAC X2 P/P P27.5 C1,9,47

23685-0013 CAP 330NK 160V P/P P15 C16,94,119

25021-0901 DIO 1N4148 B/R D8,11,13,14,25,27

25021-0910 DIO BAV21 D39,40,41,53,56,57,68,77

25031-0060 DIO BYV27 D6,7,18,19,21,22

25031-0100 DIO BAX12A D1

25031-0110 DIO BYV26C D44,45,50,61,63,69

25031-0120 DIO BYM26C D2,3,4,5

25031-0140 DIO DUAL MURH860CT D24,26,54,67

25031-0150 DIO UF4006 D9,10,15,16,30,31

25115-0910 DIO 1N4007 B/R D78

25130-0207 DIO ZEN 15V W4 D42,43

25130-0246 DIO ZEN 22V W4 D66

25130-0903 DIO ZEN 5V1 W4 D20,23

25130-0915 DIO ZEN 75V W4 D58,60

25130-0916 DIO ZEN 3V3 W4 D52

25130-9209 DIO ZEN 12V W4 D62,64

25130-9210 DIO ZEN 18V W4 D33,34,59

25131-0230 DIO ZEN 75V 1W3 D47,48,49,51

25210-0050 THYRISTOR 2N5064 SC1

25211-0301 RECTIFIER BRIDGE D20XB60 BR1

25349-3500 TRAN PNP MJE350 Q11,12

25349-4210 RAN PNP BF421 Q8,9

25349-5560 TRAN PNP BC556 Q23

25349-7510 TRAN PNP ZTX751 Q3

25349-7580 TRAN PNP ZTX758 Q6,10

25381-0404 TRAN NPN 2N3904 Q19

25383-0506 TRAN NPN BC337 Q22

25383-0507 TRAN NPN BC546 Q1,25

25388-0211 TRAN NPN ZTX651 Q2

25601-0510 TRAN MOSFET N-CHAN 500V 20A Q5

25601-0570 TRAN MOSFET N CHAN IRF540 Q14

25601-0600 TRAN MOSFET N CHAN IRFP250 Q15

25601-0610 TRAN MOSFET N CHAN IRFB11N50A Q4,7

14

PCB ASSY – MAIN (44115-0960) continued/...

Part Number Description Position

27001-0060 OPTO-COUPLER SFH615A-3 IC12-16

27160-0009 IC V/REG 7805 IC2,3

27160-0013 IC V/REG 7815 IC4

27168-0040 IC L4981A IC8

27226-0130 IC 4013B IC7

27226-0690 IC 4069UB IC1

27226-0930 IC 4093B IC6

35515-1620 PCB - MAIN

PCB ASSY - CONTROL (44115-0970)

Part Number Description Position

20661-0851 SPACER .56 INCH 7-SEG LED DIS1,2,101,102

22220-0011 SWITCH ROTARY 4P3W SPLINE SHAFT SW2

22225-0220 SWITCH PUSH/PUSH SPPH11470B SW1,101

22240-0070 RELAY TYPE 47 (12VDC) RL1

22573-0209 HEADER 9 WAY STRAIGHT .156P PJ1,101 (SOLDER SIDE)

22575-0208 SKT 8W .156 20AWG (YELLOW)IDT CONTROL TO MAIN PJ5

23202-0100 RES 10R0F W25 MF 50PPM R50,150

23202-0220 RES 22R0F W25 MF 50PPM R25,125

23202-1100 RES 100RF W25 MF 50PPM R40,55,140

23202-1330 RES 330RF W25 MF 50PPM R22,122

23202-1470 RES 470RF W25 MF 50PPM R45,145

23202-1680 RES 680RF W25 MF 50PPM R2,102

23202-2100 RES 1K00F W25 MF 50PPM R10,11,12,23,48,110,111,112,123,148

23202-2360 RES 3K60F W25 MF 50PPM R147

23202-2390 RES 3K90F W25 MF 50PPM R46,146

23202-2470 RES 4K7OF W25 MF 50PPM R38,39,138,139,157

23202-2499 RES 4K99F W25 MF 50PPM R34,134

23202-2820 RES 8K20F W25 MF 50PPM R18,118

23202-3100 RES 10K0F W25 MF 50PPM R5,14,15,17,24,28,30,32,41,43,44,47, 51,58,

105,114,115,117,124,128,130, 132,141,143,

144,151,158

23202-3127 RES 12K7F W25 MF 50PPM R103

23202-3143 RES 14K3F W25 MF 50PPM R4,35,135

23202-3150 RES 15K0F W25 MF 50PPM R33,104,133

23202-3240 RES 24K0F W25 MF 50PPM R27,127,152,153

23202-3330 RES 33K0F W25 MF 50PPM R6,7,8,106,107,108

23202-3560 RES 56K0F W25 MF 50PPM R31,131

15

PCB ASSY - CONTROL (44115-0970) continued/...

Part Number Description Position

23202-3866 RES 86K6F W25 MF 50PPM R156

23202-4100 RES 100KF W25 MF 50PPM R3,59,61,159

23202-4180 RES 180KF W25 MF 50PPM R1

23202-4210 RES 210KF W25 MF 50PPM R54

23202-4220 RES 220KF W25 MF 50PPM R36,37,42,136,137,142

23202-4270 RES 270KF W25 MF 50PPM R101

23202-4470 RES 470KF W25 MF 50PPM R29,129

23202-5100 RES 1M00F W25 MF 50PPM R19,60,119,160

23202-6100 RES 10M0F W25 MF 50PPM R13,26,113,126

23301-0415 RES NETWK SIL 1K0 X 4S RP3,103

23301-0464 RES NETWK SIL 56R X 4S RP1,2,101,102

23320-0003 RES R10 - FERRYALLOY R21,121

23347-0330 POT 10K LIN SPLINE SHAFT 25MM VR1,2,101,102

23347-0340 POT 10K LOG SPLINE SHAFT 25MM VR3,103

23385-1100 RES PS/H 100R CF 6MM VR7,107

23385-2220 RES PS/H 2K2 CF 6MM VR4-6,9,10,104-106,109,110

23385-2470 RES PS/H 4K7 CF 6MM VR111

23385-4100 RES PS/H 100K CF 6MM VR8,108

23388-0030 THERMISTOR PTC 100 OHM 265V PTC1,2

23424-0443 CAP 10NZ 1KV CER D10 P5 C30,130

23427-0323 CAP 22PJ 100V CER NPO P5 C4,5,38,104,105

23427-0329 CAP 47PG 63V CER N150 P5 C15,17,29,42,115,117,129,142

23427-0353 CAP 220PG 100V CER N750 P5T C19,119,41,141

23427-9205 CAP 47PJ 100V CER NPO P2.5 C39,139

23557-0612 CAP 1U0 100V/50V ELEC RE2 P2 C18,23,37,118,123,137

23557-0647 CAP 10U 35V ELEC RE2 P2 C25,26,125,126

23557-0665 CAP 2U2 50V ELEC RE2 P2 C16,116

23557-0668 CAP 220U 10V ELEC RE2 P2.5 C21,121

23557-0826 CAP 22U 100V LOW ESR P3.5 C20,22,120,122

23620-0246 CAP 100NK 63V P/E P5 C3,6,8,9,12,27,28,32,33,35,103,106,108,

109,112,124,127,128,134,135

23620-0247 CAP 220NK 63V P/E P5 C1,101

23620-0249 CAP 330NK 63V P/E P5 C10,11,110,111

23620-0252 CAP 2N2K 63V P/E P5 C40,140

23620-0264 CAP 100NK 400V P/E 368 SER P15 C36,136

23620-0267 CAP 100NK 100V P/E P5 C31,131

23620-9007 CAP 10NK 100V P/E P5 C13,14,113,114

16

PCB ASSY - CONTROL (44115-0970) continued/...

Part Number Description Position

23685-0007 CAP 100NK 160V P/P MKP4 P10 C2,102

25021-0901 DIO 1N4148 B/R D1,2,3,4,5,7,8,9,11,12,13,101,102,103,104,

105,107,108,109,113

25061-0200 LED - T1 ROUND (3mm) - RED LED1,2,101,102

25061-0519 DISPLAY 3 DIG .56 LED 9MM LEG DIS1,2,102

25061-0520 DISPLAY 4 DIG .56 LED 9MM LEG DIS101

25115-0907 DIO 1N4002 B/R D114,115

25117-0020 DIO 1N5401 D10,110

25336-5590 TRAN PNP BC559C Q1,101

25377-5490 TRAN NPN BC549C Q2,102

27106-0506 IC LM324N 14 PIN IC7,107

27106-0646 IC LF347 BI-FET OP AMP IC5,105

27161-0120 IC V/REF ZRA245(ZR404) 2.45V D6,106

27164-0507 IC ULN-2003A IC1,101

27226-0520 IC 4052B IC4,104

27226-0530 IC 4053B IC2,8,102,108

27231-5740 IC 74HC574 IC6,106

27250-2001 IC MCU8 PIC16C55A-04/P ROM IC3,103

28502-0010 RESONATOR CER 4MHZ XTAL1,101

35555-2910 PCB - CONTROL

MECHANICAL ITEMS

Part Number Description Position

10232-0425 SLEEVING H/SHR 19MM BR RED FERRITE SLEEVES

20030-0263 WASHER M3 ZPST CONTROL PCB TO GROUND, STANDOFFS,

BRACKET TO MOULDING

20030-0264 WASHER M2.5 ZPST CONTROL PCB

20030-0266 WASHER M4 ZPST EARTH

20037-0247 WASHER 4BA SHK/PROOF I/T ZPST EARTH TERMINAL

20037-0301 WASHER M3 SHK/PROOF I/T ZPST CHASSIS TO MAIN PCB SPACERS, GROUND

STANDOFFS

20037-0305 WASHER 5/16in.SHK/PRF I/T ZPST GREY TERMINAL

20037-0401 SOLDER TAG SHAKEPROOF - 4BA EARTH

20038-9502 WASHER M4 SPRING EARTH

20062-9501 SCREW No.6x3/4in RAISED CKHDPZ HANDLE TO COVER ,

HANDLE TO L BRACKET

20063-0010 SCREW NO6 X 3/8 NIB HDPZ ST/AB COVER TO CHASSIS,

FRONT PANEL TO CHASSIS

20065-0020 SCREW 2-28 X 5/16PLAS PNHDPZ CONTROL PCB & L BRACKET TO MOULDING

17

MECHANICAL ITEMS continued/...

Part Number Description Position

20210-0102 NUT M4 ZPST EARTH

20213-0040 CAPTIVE NUT SPIRE NO.6 COVER TO CHASSIS,

HANDLE TO COVER,

HANDLE TO L BRACKET

20234-0024 SCREW M3 X 16 PNHDPZ ZPST

20234-0027 SCREW M3 X 6 PNHDPZ ZPST MAIN PCB SPACERS

20236-0010 SCREW M4 X 12 TAMPERPROOF EARTH

20612-0011 WASHER FIBRE M3 CONTROL PCB

20653-0204 CABLE TIE 100 X 2.5MM MAINS HARNESS TO CHASSIS

20662-9301 SELF-ADHESIVE FEET

22040-0030 FERRITE SLEEVE APPROX 8/16/14L OUTPUT A, OUTPUT B, OUTPUT C, MAINS

22219-0090 SWITCH ROCKER DPST GREY 12

22225-0222 PUSHBUTTON PB10/50/000 BLACK

22491-0120 MAINS LD 2M ST IEC/UK PLUG 5A 230V UK

22491-0270 MAINS LD 2M ST IEC/EURO PLUG 230V EURO

22491-0040 MAINS LD 2M ST IEC/USA PLUG 115V USA

22571-0691 WASHER ALUMINIUM FOR TP2E TERM GREY TERMINAL

22571-0696 TERMINAL TP/2 GREY/GREY 12

22571-0740 TERMINAL TP/44 GREY/RED

22571-0741 PIN ANTI-ROTATION (TP/44&244L)

22571-0750 TERMINAL TP/44 GREY/BLACK

22575-0209 SKT9W .156 20AWG (YELLOW) IDT

OUTPUT

29211-0110 HANDLE EC254-OZ 6in BLACK/NICK

31512-0710 BRACKET FRONT PANEL

33111-0220 BRACKET HANDLE SUPPORT

33147-0140 FRONT MOULDING

33331-5860 OVERLAY NAME AND LOGO

33331-5870 OVERLAY TERMINAL AREA

33533-0370 OVERLAY DISPLAY WINDOW

33533-0400 OVERLAY DISPL WINDOW

33536-4090 CHASSIS

33536-4220 COVER

37151-0470 KNOB 21MM SPLINE L/GREY F/R

37151-0331 KNOB - MACHINED - 21MM SPLINED

44115-0960 PCB ASSY - MAIN

44115-0970 PCB ASSY - CONTROL

48511-0350 INSTRUCTION BOOK - EX752M

18

Component Layouts

Main Board

19

Other manuals for EX752M

1

Other TTI Power Supply manuals

Popular Power Supply manuals by other brands

Intel

Intel Entry Redundant Power 2U ERP2U Design guide

ZALMAN

ZALMAN ZM850-GVM user manual

Matsusada Precision

Matsusada Precision CO Series instruction manual

Linergy

Linergy SPY CENTER BASIC SCB050 Series manual

Johansson

Johansson 9933 instruction manual

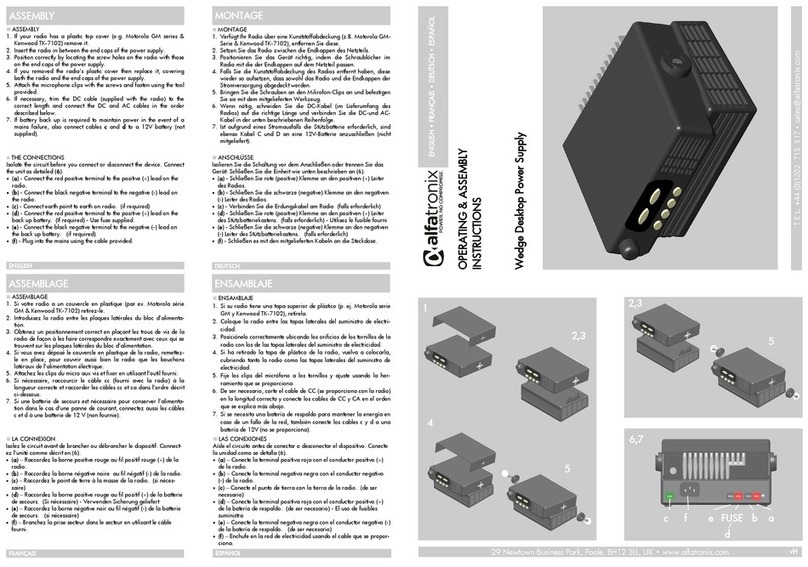

alfatronix

alfatronix AD Series Operating & assembly instructions