TTI QPX600D User manual

QPX600D & QPX600DP

PowerFlex+ Dual DC Power Supplies

INSTRUCTIONMANUAL

1

Table of Contents

Specification 2

EMC 6

Safety 7

Installation 8

Connections 9

Initial Operation 11

Manual Operation – Independent Mode 13

Manual Operation – Link Modes 21

Maintenance 22

Remote Operation 23

Remote Commands (QPX600DP only) 32

Note: The latest revisions of this manual, device drivers and software tools can be

downloaded from: http://www.tti-test.com/go/qsx

This manual is 48511-1460 Issue 7

2

Specification

General specifications apply for the temperature range 5°C to 40°C. Accuracy specifications

apply for the temperature range 18°C to 28°C after 1 hour warm-up with no load and calibration at

23°C. Typical specifications are determined by design and are not guaranteed.

OUTPUT SPECIFICATIONS (Each Output)

Voltage Range: Two ranges: 0V to 60V or 0V to 80V

Current Range: 0.01A to 50A

Power Range: Up to 600W

Voltage Setting: Resolution: 1mV (60V Range),

2mV (80V Range)

Accuracy: 0.1% of setting ± 2mV,

(± 4mV on 80V range)

Current Setting: Resolution 10mA

Accuracy: 0.3% of setting ± 20mA

Operating Mode: Constant voltage or constant current

with automatic cross-over provided

that the power demanded stays within

the power envelope, see graph.

Outside of this envelope the output

becomes unregulated. CV, CI or

UNREG mode indication in display.

Output Switch: Independent electronic switching, with ON indication. In addition, BOTH ON

and BOTH OFF keys permit both outputs to be switched on/off

synchronously (±10µs). Preset voltage and current displayed when off.

Output Terminals: Rear panel safety terminals accepting 6mm wire diameter, 6mm plugs or

8mm spades at 50 Amps max, or 4mm plugs at 30 Amps max.

Sensing: Switchable between local and remote. Screwless remote sense terminals on

rear panel. Sense miswiring trip and indication.

Ripple & Noise

(20MHz bandwidth):

Typically <3mVrms, <20mV pk-pk at maximum load, CV mode

Load Regulation: Change in output for any load change within PowerFlex envelope, using

remote sense:

Constant voltage: <0.01% ± 5mV

Line Regulation: Change in output for a 10% line change:

Constant voltage: <0.01% ± 5mV

Transient Response: <2ms to within 100mV of set level for a 5% to 95% load change.

Output Protection: Output will withstand an applied forward voltage of up to 90V.

Reverse protection by diode clamp for reverse currents up to 3A.

Over-voltage Protection

(OVP): Range 2V to 90V. Resolution 0.1V; accuracy: 0.2% ± 0.2V.

Response time typically 100µs.

Over-current Protection

(OCP): Range 2A to 55A. Resolution 0.1A; accuracy: 0.5% ± 0.2A.

Response time typically 100ms.

Over-temperature

Protection: The output will be tripped off if a fault causes the internal temperature to rise

excessively.

Temperature Coefficient: Typically <100ppm/°C

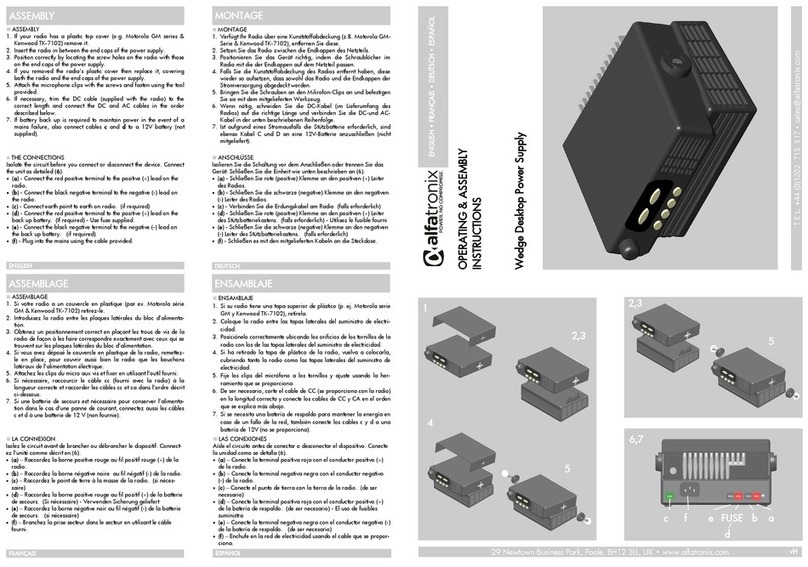

QPX600D & DP

Power Envelope

(per channel)

3

METER SPECIFICATIONS (Each Output)

Display Type: 5-digit (Volts), 4-digit (Amps), black-on-white backlit LCD.

Voltage

(CI Mode and Unreg): Resolution 1mV

Accuracy: 0.1% of reading ± 2 digits

Current

(CV Mode and Unreg): Resolution 10mA

Accuracy: 0.3% of reading ± 2 digits

V x A: Resolution 0·1W

Accuracy: 0·5% ± 0·1W

V/A: Meter shows calculated nominal V/A value, together with uncertainty

range; 5 digit resolution.

LOGIC CONTROL INPUT and OUTPUT (Each Output)

LOGIC IN is a rear-panel opto-isolated input that is activated at an input current greater than

approximately 1mA. User can set LOGIC IN (via the keyboard) to enable the output, disable the

output, or be ignored when it is activated.

LOGIC OUT is an isolated rear-panel open-collector output that will sink up to 2mA when activated

(‘switch closure’); the maximum voltage that can be applied to LOGIC OUT is 30VDC. User can

set LOGIC OUT to be ‘closed’ or ‘open’ for output enabled or disabled, current limit

(CI mode), power limit (UNREG mode), or for any fault trip.

ANALOG REMOTE CONTROL and MONITORING (Each Output)

Quasi-analogue inputs and outputs to set voltage and current limit and to monitor actual output

voltage and current. The control inputs are read four times per second by the

A-D converter and the output is set according to the selected input scaling; similarly the monitor

outputs are updated four times per second with values representing the actual output voltage and

current. These signals each have a range of 0 to 10V or 0 to 5V with respect to the shared COM

return signal; the set range applies to all inputs and outputs.

Analogue Control Voltage Range: Keyboard selectable to be 0 to 10Vdc or 0 to 5Vdc for

range maximum output. Absolute maximum input 20Vdc.

Analogue Control Accuracy: Voltage: 0.3% ± 4mV; Current: 0.5% ± 40mA.

Analogue Control Common Mode Range: ± 2.5Vdc max to negative output.

Analogue Control Input Impedance: Nominally 40kΩ.

Analogue Monitor Voltage Range: Same as set for Analogue Control Voltage Range.

Analogue Monitor Accuracy: Voltage: 0.3% ± 4mV; Current: 0.5% ± 40mA.

Analogue Monitor Output: Connect to isolated measuring system with >10kΩinput

impedance. Will withstand a short-circuit.

LINK MODES

In addition to independent output operation, the instrument is capable of operating in a number of

different voltage tracking modes which can be activated from the LINK MENU. These modes

include Output 2 voltage (V2) tracking Output 1 voltage (V1) by any ratio in the range 5% to

2000%, V2 and I2 set to track V1 and I1 (1:1) with total V1 + V2 displayed (useful when Output 1

and Output 2 are series connected), V2 and I2 set to track V1 and I1 (1:1) with total I1 + I2

displayed (useful when Output 1 and Output 2 are parallel connected).

KEYBOARD & ROTARY CONTROL

All functions, including the selection and set-up of the remote control interfaces, can be set from

the keyboard. The rotary Jog control can be used to adjust output voltage and current settings in a

quasi-analogue mode. The output to be controlled is first selected with the appropriate Control key.

4

DISPLAY FEATURES

The displays (one for each output) are graphic LCDs, backlit by white LEDs; contrast is software-

controlled and can be adjusted from the keyboard.

The default status displays show the VOLTS (5 digits) and AMPS (4 digits) in 12mm high

characters, plus output range and status. At other times, for example during store or recall of

instrument set-ups, the displays show up to 7 lines of information, instructions, or prompts.

INTERFACES (QPX600DP only)

Full digital remote control facilities are available through the RS232, LAN, USB and GPIB

interfaces. Setting and readback resolutions are the same as for the Output and Meter

specifications respectively.

RS232: Standard 9-pin D-connector. Baud rate 9600.

USB: Standard USB 2.0 hardware connection.

LAN: Auto speed detect(10/100MHz), Auto MDIX.

LXI V1.2, Class C compliant.

GPIB: Conforms with IEEE488.1 and IEEE488.2.

Remote Command

Processing Time: Typically <100ms between receiving the command terminator for a

step voltage change at the instrument and the output voltage

beginning to change.

GENERAL

AC Input: 115V – 240V AC ± 10%, 50/60Hz.

Installation Category II.

Power Consumption: 1600VA max.

Operating Range: +5ºC to +40ºC, 20% to 80% RH.

Storage Range: −40ºC to + 70ºC.

Environmental: Indoor use at altitudes up to 2000m, Pollution Degree 2.

Store/Recall: Up to 10 set-ups can be saved and recalled via the keyboard or

remote interfaces.

Safety: Complies with EN61010-1.

EMC: Complies with EN61326.

Size: 130mm H (3U) x 356mm W x 413mm D

Weight: 9.2kg

Options: 19-inch rack kit.

5

EC Declaration of Conformity

We Thurlby Thandar Instruments Ltd

Glebe Road

Huntingdon

Cambridgeshire PE29 7DR

England

declare that the

QPX600DP & QPX600D Power Supplies

meet the intent of the EMC Directive 2004/108/EC and the Low Voltage Directive 2006/95/EC.

Compliance was demonstrated by conformance to the following specifications which have been

listed in the Official Journal of the European Communities.

EMC

Emissions: a) EN61326-1 (2006) Radiated, Class A

b) EN61326-1 (2006) Conducted, Class A

c) EN61326-1 (2006) Harmonics, referring to EN61000-3-2 (2006)

Immunity: EN61326-1 (2006) Immunity Table 1, referring to:

a) EN61000-4-2 (2009) Electrostatic Discharge

b) EN61000-4-3 (2006) Electromagnetic Field

c) EN61000-4-11 (2004) Voltage Interrupt

d) EN61000-4-4 (2004) Fast Transient

e) EN61000-4-5 (2006) Surge

f) EN61000-4-6 (2009) Conducted RF

Performance levels achieved are detailed in the user manual.

Safety

EN61010-1 Installation Category II, Pollution Degree 2.

CHRIS WILDING

TECHNICAL DIRECTOR

2 January 2013

6

EMC

This instrument has been designed to meet the requirements of the EMC Directive 2004/108/EC.

Compliance was demonstrated by meeting the test limits of the following standards:

Emissions

EN61326-1 (2006) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use. Test limits used were:

a) Radiated: Class A

b) Conducted: Class A

c) Harmonics: EN61000-3-2 (2006) Class A; the instrument is Class A by product category.

Immunity

EN61326-1 (2006) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use.

Test methods, limits and performance achieved are shown below (requirement shown in brackets):

a) EN61000-4-2 (2009) Electrostatic Discharge: 4kV air, 4kV contact, Performance A (B).

b) EN61000-4-3 (2006) Electromagnetic Field:

3V/m, 80% AM at 1kHz, 80MHz – 1GHz: Performance B*(A) and

1.4GHz to 2GHz: Performance A (A); 1V/m, 2.0GHz to 2.7GHz: Performance A (A).

c) EN61000-4-11 (2004) Voltage Interrupt: ½ cycle and 1 cycle, 0%: Performance A (B);

25 cycles, 70%: Performance A (C); 250 cycles, 0%: Performance B (C), if Function 11 is

set (Output status at power-up same as at last power-down), otherwise Performance C.

d) EN61000-4-4 (2004) Fast Transient, 1kV peak (AC line only; DC Output connections <3m,

therefore not tested†), Performance B (B).

e) EN61000-4-5 (2006) Surge, 0·5kV (line to line), 1kV (line to ground), Performance B (B).

f) EN61000-4-6 (2009) Conducted RF, 3V, 80% AM at 1kHz (AC line only; DC Output

connections <3m, therefore not tested†), Performance A (A).

†signal lines were not tested on the basis that typical use will be with connections <3m, for which

there is no test requirement. Immunity performance with connections >3m is not guaranteed.

According to EN61326-1 the definitions of performance criteria are:

Performance criterion A: ‘During test normal performance within the specification limits.’

Performance criterion B: ‘During test, temporary degradation, or loss of function or performance

which is self-recovering’.

Performance criterion C: ‘During test, temporary degradation, or loss of function or performance

which requires operator intervention or system reset occurs.’

*Performance B is stated because DC Output regulation, or V & I measurement accuracy, may

deviate beyond Specification limits under the test conditions. However, the possible deviations are

still small and unlikely to be a problem in practice. Minor deviations are possible at 300-350MHz,

670-740MHz and 810-820MHz at 3V/m.

Note that if operation in a high RF field is unavoidable it is good practice to connect the PSU to the

target system using screened leads which have been passed (together) through an absorbing

ferrite sleeve fitted close to the PSU terminals.

Cautions

To ensure continued compliance with the EMC directive observe the following precautions:

a) after opening the case for any reason ensure that all signal and ground connections are remade

correctly and that case screws are correctly refitted and tightened.

b) In the event of part replacement becoming necessary, only use components of an identical type,

see the Service Manual.

7

Safety

This power supply is a Safety Class I instrument according to IEC classification and has been

designed to meet the requirements of EN61010-1 (Safety Requirements for Electrical Equipment

for Measurement, Control and Laboratory Use). It is an Installation Category II instrument intended

for operation from a normal single phase supply.

This instrument has been tested in accordance with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 2 environment in the

temperature range 5°C to 40°C, 20% - 80% RH (non-condensing). It may occasionally be

subjected to temperatures between +5°C and –10°C without degradation of its safety. Do not

operate while condensation is present.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to its supply, terminals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, maintenance or repair.

Capacitors inside the power supply may still be charged even if the power supply has been

disconnected from all voltage sources but will be safely discharged about 10 minutes after

switching off power.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be avoided

as far as possible and, if inevitable, shall be carried out only by a skilled person who is aware of

the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protection may be impaired and the apparatus should be

withdrawn from use and returned for checking and repair.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is prohibited.

Do not wet the instrument when cleaning it.

The following symbols are used on the instrument and in this manual:-

Earth (ground) terminal.

mains supply OFF.

l

mains supply ON.

alternating current (ac)

direct current (dc)

Caution – risk of danger. Refer to the documentation (this manual) to find

out the nature of the potential hazard and any actions which have to be taken.

8

Installation

Mains Operating Voltage

This instrument has a universal input range and will operate from a nominal 115V or 230V mains

supply without adjustment. Check that the local supply meets the AC Input requirement given in

the Specification.

Mains Lead

Connect the instrument to the AC supply using the mains lead provided. Should a mains plug be

required for a different mains outlet socket, a suitably rated and approved mains lead set should

be used which is fitted with the required wall plug and an IEC60320 C13 connector for the

instrument end. To determine the minimum current rating of the lead-set for the intended AC

supply, refer to the power rating information on the equipment or in the Specification.

WARNING! THIS INSTRUMENT MUST BE EARTHED.

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited.

Mounting

This instrument is suitable both for bench use and rack mounting. It is delivered with feet for bench

mounting. The front feet include a tilt mechanism for optimal panel angle.

A rack kit for mounting in a 19” rack is available from the Manufacturers or their overseas agents.

Ventilation

The power supply is cooled by intelligent multi-speed fans which vent at the rear. Take care not to

restrict the air inlets at the front (top, bottom & side panels) or the exit at the rear. In rack-mounted

situations allow adequate space around the instrument and/or use a fan tray for forced cooling.

9

Connections

Rear Panel Connections

Output Terminals (each output)

The load should be connected to the positive (red) and negative (black) terminals marked

OUTPUT. The terminals accept 4mm plugs into the end (but note that 4mm plugs will only support

30 Amps), 6mm diameter wire or plugs into the cross-hole or 8mm spade connections (with a

maximum blade width of 16mm). The wiring and connectors must be capable of supporting the

current required; for 50 Amps, 6mm2cable is needed.

Remote sense connections to the load, if required, are made from the positive (+) and

negative (−) REMOTE SENSE terminals. Remote sense operation is selected from the keyboard

or via a remote control interface; R/SNS (Remote Sense) shows in the display beside the output

status ( OFF, CV, CI or UNREG ) when remote sense is selected and goes off when remote

sense is deselected.

The M4 threaded opening marked

provides a connection point to safety earth ground.

Warning! Voltages above 70Vdc are hazardous live according to EN 61010-1 and great care must

be taken when using the power supply at voltages above this level.

Always ensure that connections to the terminals are only made in a manner that does not

compromise the protection provided by the terminals themselves.

Ensure that the contact parts of all connecting wires are fully inserted and inaccessible to the touch.

Always make connections to the instrument with the OUTPUT off.

Logic Input (each output)

LOGIC IN is connected directly to the input of an isolating opto-coupler; there is no series resistor.

The input is activated when a current greater than approximately 1mA is forced between LOGIC IN

and LOGIC COMMON. The function of LOGIC IN is set from the keyboard.

Do not force a current exceeding 25mA between the terminals. Do not apply a voltage to LOGIC

IN / LOGIC COMMON exceeding 50V with respect to .

Logic Output (each output)

LOGIC OUT is the open-collector output of an opto-isolated NPN transistor that will sink up to 2mA

when active (‘switch closure’). The function of LOGIC OUT is set from the keyboard.

The maximum voltage that can be applied between LOGIC OUT and LOGIC COMmon is 30VDC.

Do not apply external voltages between the terminals exceeding 30VDC.

Analogue Control (each output)

V CONTROL and I CONTROL inputs provide quasi-analogue control of the Output Voltage and

Current Limit respectively. The inputs are read 4 times per second by the A-to-D converter and the

output is set according to the selected input scaling. The input scaling for both can be set as 0 to

10 Volts or 0 to 5 Volts for range maximum output. The Analogue Control functions and scaling are

both selected from the keyboard.

The V CONTROL and I CONTROL inputs are differential, with a limited common mode range of

± 2.5Vdc with respect to the negative output. They should be driven from a ‘floating’ source such

as another power supply.

Do not apply external voltages between the terminals exceeding 20Vdc.

10

Analogue Monitor (each output)

The output terminal voltage and output current may be monitored on V MONITOR and I MONITOR

respectively. The output scaling for both is the same as that set for V CONTROL and I CONTROL,

see previous section.

The Analogue Monitor outputs should be connected to a measuring system with ‘floating’ inputs

such as a DMM.

Do not apply external voltages to these terminals.

RS232 (QPX600DP only)

9−pin female D−connector with pin connections as shown below. Can be connected to a standard

PC port using a fully wired 1:1 male-female cable without any cross-over connections.

Pin

Name

Description

1 RI Passively asserted (+V through 10kΩ)

2 TXD Transmitted data from instrument

3

RXD

Received data to instrument

4 CTS

5 GND Signal ground

6 RTS Passively asserted (+V through 10kΩ)

7

DSR

No internal connection

8 DTR

9 CD No internal connection

Signal ground is connected to instrument ground.

USB (QPX600DP only)

The USB port is connected to instrument ground. It conforms with USB 2.0 (Full Speed) and

accepts a standard USB cable. The Windows plug-and-play functions should automatically

recognise that the instrument has been connected. If the correct driver is not found, follow the

Windows on-screen prompts and install the required files from the CD supplied.

LAN (QPX600DP only)

The LAN interface is designed to meet LXI ( Lan eXtensions for Instrumentation) version 1.2;

the instrument is Class C compliant. Remote control using the LAN interface is possible using a

TCP/IP Socket protocol. The instrument also contains a basic Web server which provides

information on the unit and allows it to be configured. Since it is possible to misconfigure the LAN

interface, making it impossible to communicate with the instrument over LAN, a LAN Configuration

Initialise (LCI) mechanism is provided via a recessed switch on the rear panel (marked LAN

RESET) to reset the unit to the factory default.

Further details are given in the Remote Operation chapter. For more information on LXI standards

refer to www.lxistandard.org/home

GPIB (QPX600DP only)

The GPIB signal grounds are connected to the instrument ground. The implemented subsets are:

SH1 AH1 T6 L4 LEO SR1 RL2 PP1 DC1 DT0 C0 E2

The GPIB address is set from the front panel.

11

Initial Operation

This section of the manual is a general introduction to the controls and operation of the instrument

and is intended to be read before using the power supply for the first time. In this manual front

panel keys, connections and indicators are shown in capitals, e.g. ESCAPE, JOG SET, OUTPUT,

ON. Messages shown on the display are printed in a different type-font, e.g. Enter V,

Limits,CV,Store.

Switching On, Output On/Off

The power switch is located at the bottom left of the front panel.

At power-up the default behaviour is for the instrument's settings to be restored to those

automatically saved when it was switched off, but with the outputs in independent mode and

always off ( OFF is shown at the top right-hand side of each output’s display). However, the user

can change this default setting such that the power-down status of the individual outputs and of the

tracking mode are restored at power-up, see the Extra Functions section.

Each DC Output is switched on and off electronically with alternate presses of its key; the ON

lamp illuminates when the Output is on. At the same time the message above the VOLTS and

AMPS display changes from OFF to CV (constant voltage) or CI (constant current) to indicate

the present operating mode; should the load cause the instrument to operate outside its

guaranteed power range the display will instead show UNREG (unregulated). Alternatively, the

BOTH ON or BOTH OFF keys can be used to switch both outputs on or off together; the outputs

switch synchronously within <10µs of each other. Note that, if one output is already on and the

other off, BOTH ON will turn the off output on and BOTH OFF will turn the on output off.

Select Output

The output to be adjusted is selected by pressing CONTROL 1 or CONTROL 2; the corresponding

LED lamp will light to show which output is currently under the control of the numeric keypad or

rotary control. Note that the individual ON keys, as well as the BOTH ON and BOTH

OFF keys, will always operate regardless of which output is currently selected by the CONTROL

keys. Control of Output 1 is the default setting at power-up.

Keypad

Only the principles of operation are outlined here; the setting of individual parameters is given in

detail in later sections. The paramount consideration in designing the user interface has been to

make changing settings as 'safe' as possible (i.e. with minimal risk of accidentally applying

excessive voltages to a load) whilst achieving ease of use. This has been achieved by requiring

the user to confirm (OK) new numeric settings, with the option to ESCAPE at any point or even to

simply pause until the operation times-out and the instrument returns to its original settings. In

addition, display messages and LED indicators prompt, guide or warn the user such that entry or

control errors are minimised. Where some of these features (e.g. beeps) are considered

unnecessary by regular users, the option exists to disable them, see the Extra Functions section.

Press CONTROL 1 or 2 to select the output to be adjusted. Under normal conditions the numeric

keypad is disabled; any numeric key presses will simply be ignored. To set a voltage with the

keypad first press the V NUMERIC SET key; the VOLTS display changes to show the present set

value in a smaller font, with the message Enter V or ESC below it, and the OK lamp starts

flashing. The new value is then entered from the keyboard; as it is entered it is displayed directly

below the present setting, replacing the prompt message. At any time during entry the new setting

can be confirmed with the OK key, e.g. it is sufficient to key in 1, OK to change the setting to

1Volt. When OK is pressed the display reverts to show just the new setting in the full-size font and

the OK lamp stops flashing; if OK is not pressed within 10s of the last numeric key the entry is

cancelled and the display returns to its original setting. If ESCAPE is pressed anytime in the entry

procedure, entry is cancelled and the display returns to its original setting. The current limit is set in

exactly the same way after first pressing I NUMERIC SET.

The OK key is used to confirm most keypad entries. At all other times it becomes the VIEW V/I

LIMITS key and pressing it will cause the display to show preset output voltage and current limit for

3 seconds; during this period the Limits message shows in the display.

12

Pressing SHIFT illuminates the ▲lamp and gives the numeric keys the functions marked above

them, e.g. STR (Store), RCL (Recall), etc. When a shift function is selected SHIFT is cancelled

(the ▲lamp is no longer lit). The further key presses required to complete the selected function

are described in detail in the sections that follow; if no key is pressed within 10 seconds to

complete the function, the function will terminate as if ESCAPE has been pressed. SHIFT is a

toggle key; pressing SHIFT again when it has been selected will cancel SHIFT. SHIFT is also

cancelled by ESCAPE, or by pressing SET V or SET I.

Jog Control

The rotary 'jog' control permits the output voltage or current limit to be incremented or

decremented in steps with a resolution set by the JOG SET keys; the output immediately follows

the setting, i.e. no OK is required.

Press CONTROL 1 or 2 to select the output to be adjusted. At power-up jog is always off. To jog

the voltage or current setting press the V or I JOG SET key; the associated lamp will illuminate and

the appropriate parameter display now changes to two lines. With the output ON the top line

continues to show the actual output, but the additional lower display now shows the present

Limits value; in the lower display, the JOG indicator ( ) is positioned under the digit that was last

jogged. Whilst the V or I JOG SET indicator is lit, each further press of the V or I key moves the

JOG indicator one digit to the left; the selection 'wraps-round' such that when the largest value of

jog increment has been reached the next press returns it to the lowest. The default position at

power-up is under the LSD, i.e. the lowest jog increment is selected.

Turning the rotary jog control clockwise/anti-clockwise increments/decrements the selected digit;

digits to the left of the one being jogged are automatically incremented/decremented when the

decade overflow/underflow point is reached. Digits to the right of the one being jogged remain

unchanged unless the jog step overflows/underflows the maximum/minimum settings in which

case they are set to zero. For example, 59·861V goes to 59·961V goes to 60·000V for a 0.1V jog

increment; 1.60A goes to 0·60A goes to 0·01A for a 1A jog decrement.

The jog steps that can be selected are 1mV, 10mV, 100mV and 10mA, 100mA, 1A.

To disable the jog rotary control press the JOG SET OFF key; reselecting JOG SET V or I will

enable jog on the last used digit position. Jog is not cancelled by using numeric entry or any of the

SHIFT functions but it is disabled whilst that function is enabled. Jog is disabled when control is

switched to the other output using the CONTROL 1 or 2 keys but is automatically enabled again

when control is switched back.

Note that the dual display of the parameter being jogged is primarily of use if the output is ON; with

the output off both lines of the display show the Limits value and change simultaneously as the

parameter is jogged.

Display

At power-up the display briefly shows the instrument model number and installed firmware revision

in the left-hand display before both displays revert to the standard status display.

The standard status display shows the voltage range and output voltage on the left (above the

front panel VOLTS marking) and the current on the right (above the front panel AMPS marking)

together with the present output status, i.e. OFF, CV, CI, or UNREG; if the output is off then

Limits is also shown in the display above the V and I values. The status of the LAN connection

is also shown in the top left corner of the display, as required for LXI compliance. Refer to the

'LAN Status Indication' paragraph in the LAN Interface section for details. During other operations,

however, the display capabilities are used more extensively to show, for example, prompts during

function settings, e.g. memory store and recall operations or the extra functions accessed via the #

shift function; details are given in the relevant sections of this manual.

The display contrast is set at the factory but can be adjusted from the keyboard to optimise it for

particular ambient operating conditions. Press SHIFT, # , select Extra Function 90, and follow the

on-screen prompts. Contrast can be adjusted independently for the two displays.

13

Manual Operation – Independent Mode

New users should first read the Initial Operation chapter which describes the operating principles

of the keypad and rotary jog control.

The default mode at power-up is ‘Tracking Off’, i.e. the two outputs are fully independent. The

following sections describe operation of either output in this mode. See the later ‘Manual

Operation – Link Menu’ chapter for details of the various tracking modes that can be set.

Set Voltage Range

There are two voltage ranges for each output – a low range (0 to 60V) and a high range (0 to 80V).

To select the range press SHIFT followed by RANGE. Changing to the higher range is always

possible and the display will show Select 0 to 80V range: 2mV resolution. OK to

confirm, ESC to cancel; pressing OK accepts the change. Because the resolution of the

80V range is 2mV the set-point will rounded down, if necessary, to the nearest 2mV figure (e.g. if

output is set to 59.997 it will be changed to 59.996).

When changing to the low range the display will show Select 0 to 60V range: 1mV

resolution. OK to confirm, ESC to cancel unless the output is set above 60V in which

case the display will show Can’t select 0 to 60V range. Set point too high. Esc

to cancel. The output must first be set to <60V before the low range can be selected.

Set Voltage

With the output off, the standard status display shows the set voltage; Limits shows as a

reminder beside OFF in the top line of the display. With the output ON the mode changes to CV

(constant voltage) or CI (constant current), depending on the set current limit and load conditions,

and the display shows the actual output voltage (measured at the sense point); note that in CI

mode the actual output voltage will be less than the set voltage. Both the set and actual voltage

are shown to a resolution of 1mV (0-60V range) or 2mV (0-80V range). If the set voltage and load

conditions cause the instrument to operate outside its guaranteed power range the display will

show UNREG (unregulated) and the actual output voltage will again be less than the set voltage.

The voltage can be set directly from the numeric keypad: press the NUMERIC SET V key, enter

the new value using the numeric keys and confirm by pressing OK. The broad principles of

keypad entry are explained in the Initial Operation chapter, which should be read by new users.

When SET V is pressed the VOLTS display changes to show the present set value in a smaller

font, with the message Enter V or ESC below it, and the OK lamp starts flashing. The new

voltage is then entered from the keyboard, e.g. 12·345V is entered as 1, 2, ·, 3, 4, 5. As it is

entered it is displayed directly below the present setting, replacing the prompt message.

The minimum voltage setting is 0·000V; the maximum setting is 60·000V (0-60V range) or 80.000V

(0-80V range).

Pressing OK at any point will set the voltage entered with any remaining digits set to zero,

e.g. 1, 2, ·, 3, OK will set 12·300V; 1, OK will set 1·000V. When OK is pressed the set voltage is

changed and the display reverts to the standard status mode.

Pressing ESCAPE at any time during the sequence, or making no further key press within

10 seconds of the previous one will cause the display to return to its original reading before

SET V was pressed.

Entering a voltage outside the range maximum (including trying to enter 3 digits before the decimal

point) or trying to enter more than 5 digits will cause the buzzer to beep; the last key entry will be

ignored.

The voltage can also be set using the Jog control. Pressing JOG SET V will illuminate the V JOG

SET lamp and the VOLTS display will again change to two lines. With the output ON the top line

continues to show the actual output, but the additional lower display now shows the present

Limits value; in the lower display, the JOG indicator ( ) is positioned under the digit that was last

jogged. Whilst the V SET lamp is lit, each further press will move the JOG indicator one digit to

the left; the selection 'wraps round' such that when the largest value of jog increment has been

reached the next press returns it to the lowest.

14

The default position at power-up is under the LSD, i.e. the lowest jog increment is selected. The

jog steps that can be selected are 1mV (2mV for the 0-80V range), 10mV and 100mV.

With jog enabled the output voltage can be incremented or decremented with the rotary jog control

with a step resolution indicated by the position of the JOG indicator. The output immediately

follows the setting, i.e. no OK is required. In CV (constant voltage) mode the actual output voltage

shown in the upper display line will follow the set voltage being ‘Jogged’ in the lower display;

however, if the output goes into constant current mode (indicated by the CV status message being

replaced by CI) the upper display, showing actual voltage, will show a value which is less than the

set voltage.

Note that the dual display during JOG SET V is primarily of use if the output is ON; with the output

off both lines of the display show the Limits value and change simultaneously as the voltage is

jogged.

Set Current Limit

With the output off, the standard status display shows the set current limit; with the output on it

shows the actual output current in all modes (CV, CI or UNREG). Both the actual current and the

current limit are shown to a resolution of 10mA.

The current limit can be set directly from the numeric keypad: press the NUMERIC SET I key,

enter the new value using the numeric keys and confirm by pressing OK. The broad principles of

keypad entry are explained in the Initial Operation chapter, which should be read by new users.

When SET I is pressed the AMPS display changes to show the present current limit value in a

smaller font, with the message Enter I or ESC below it, and the OK lamp starts flashing.

The new current limit is then entered from the keyboard, e.g. 12·34A is entered as 1, 2, ·, 3, 4. As

it is entered it is displayed directly below the present setting, replacing the prompt message.

The minimum current setting is 0·01A; the maximum setting is 50.00A, i.e. there is no over-range

capability.

Pressing OK at any point will set the current entered with any remaining digits set to zero,

e.g. 1, 2 ·, 3, OK will set 12·30A; 1, OK will set 1·00A. When OK is pressed the current limit is

changed and the display reverts to the standard status mode.

Pressing ESCAPE at any time during the sequence, or making no key press within 10 seconds of

the previous one will cause the display to return to its original reading before SET I was pressed.

Entering a value outside the range maximum (including trying to enter 3 digits before the decimal

point) or trying to enter more than 4 digits will cause the buzzer to beep; the last key entry will be

ignored.

The current limit can also be set using the rotary jog control. Pressing JOG SET I will illuminate

the I JOG SET lamp and the AMPS display will again change to two lines. With the output ON the

top line continues to show the actual output, but the additional lower display now shows the

present current limit; in the lower display, the JOG indicator ( ) is positioned under the digit that

was last jogged. Whilst the I SET lamp is lit, each further press will move the JOG indicator one

digit to the left; the selection 'wraps round' such that when the largest value of jog increment has

been reached the next press returns it to the lowest. The default position at power-up is under the

LSD, i.e. the lowest jog increment is selected. The jog steps that can be selected are 10mA ,

100mA and 1A.

With jog enabled the current limit can be incremented or decremented with the rotary jog control

with a step resolution indicated by the position of the JOG indicator. The output immediately

follows the setting, i.e. no OK is required. With the output ON and in CV mode the upper line of

the display showing actual current will be a lower value than the current limit being ‘Jogged’ in the

lower display; however, if the output goes into constant current mode (indicated by the CV status

message being replaced by CI) the upper display, showing actual current, will follow the current

limit value being ‘Jogged’ in the lower display.

Note that the dual display during JOG SET I is primarily of use if the output is ON; with the output

off both lines of the display show the Limits value and change simultaneously as the current

limit is jogged.

15

Instantaneous Current Output

The current limit control can be set to limit the continuous output current to levels down to 10mA.

However, in common with all precision bench power supplies, a capacitor is connected across the

output to maintain stability and good transient response. This capacitor charges to the output

voltage and short-circuiting of the output will produce a current pulse as the capacitor discharges

which is independent of the current limit setting.

Power Limit

The maximum current at different voltage settings is limited by the power envelope illustrated

below:

The power envelope is set to give 80V/7.5A and 10V/50A under all supply conditions (both outputs

loaded); at lower output voltages the output power is restricted by the 50A current maximum.

When the power limit is exceeded, the status indication will change from CV or CC to UNREG. For

example, if the supply is set to 20V, with the current limit at maximum, and is connected to a 1Ω

load, 20 Amps will flow and the supply will be in CV mode. As the voltage across the load is

increased, the power into the load increases until, at about 24V, the power limit is exceeded and

the supply changes from CV to UNREG.

Output Power (V x A)

If SHIFT, V x A is pressed the display shows the product of measured output voltage x measured

current in the form nn.n VA. . The V x A value is updated at the same measurement rate as for

V and I. Pressing ESCAPE cancels V x A mode.

Calculated Load Impedance (V/A)

If SHIFT, V/A is pressed the display shows the calculated result of measured output voltage ÷

measured current; this is a sampled result which can be updated by further presses of the OK key.

Pressing ESCAPE cancels V/A mode.

The display shows the calculated nominal V/A value with a resolution of 5 significant digits (10µΩ

resolution for V/A <1Ω). The accuracy is calculated from the uncertainty of the individual voltage

and current measurements and is indicated by showing the minimum and maximum possible

values (in brackets) beside the nominal. The uncertainty is worst when either (or both) V and I are

small.

This function is extremely useful for measuring low impedances at high currents, e.g. RDS(on) of

power MOSFETs. Always use the Remote Sensing function to eliminate the effects of connecting

lead and contact resistance when making low value V/A measurements.

Current Measurement Averaging

Press SHIFT, IAVG to select current averaging; IAVG shows in the top line of the display beside the

mode status. The AMPS reading is still updated at the same rate (4 times per second) but the

value displayed is the rolling average of the last 4 current measurements made.

QPX600D & DP

Power Envelope

16

Connection to the Load

The load should be connected to the positive (red) and negative (black) OUTPUT terminals. Both

are fully floating and either can be connected to ground.

Warning! Voltages above 70Vdc are hazardous live according to EN 61010-1 and great care must

be taken when using the power supply at voltages above this level.

Always make connections to the instrument with the OUTPUT off.

Remote Sensing

The instrument has a very low output impedance, but this is inevitably increased by the resistance

of the connecting leads and the contact resistance between terminals and leads. At high currents

this can result in significant differences between the indicated source voltage and the actual load

voltage (even two 2mΩconnecting leads will drop 0·2V at 50 Amps, for instance). This problem

can be minimised by using short, thick, connecting leads, but where necessary it can be

completely overcome by using the remote sense capability.

This requires the sense terminals to be connected to the output at the load instead of at the

source; insert wires into the REMOTE SENSE terminals and connect directly to the load.

Warning! Voltages above 70Vdc are hazardous live according to EN 61010-1 and great care must

be taken when using the power supply at voltages above this level.

Ensure that the exposed end of the wire is fully inserted and inaccessible to the touch.

Always make connections to the instrument with the OUTPUT off.

Select remote sense by pressing SHIFT, SENSE; the message Turn On Remote sense?

OK to confirm, ESCAPE to cancel is shown in the display and the OK lamp flashes.

Press OK to confirm or press ESCAPE to exit without changing state. R/SNS (Remote Sense)

shows in the display beside the output status ( OFF, CV, CI or UNREG ) when remote sense is

selected. Remote sense is turned off by pressing SHIFT, SENSE again; the message Turn Off

Remote Sense? OK to confirm, ESCAPE to cancel is shown in the display and

the OK lamp flashes. Press OK to confirm or press ESCAPE to exit without changing state; the

R/SNS indication in the display goes off when remote sense is deselected.

To avoid instability and transient response problems, care must be taken to ensure good coupling

between each output and sense lead; this can best be done by twisting the leads together. An

electrolytic capacitor directly across the load connection point may also be beneficial.

The voltage drop in each output lead must not exceed 1 Volt.

Sense Miswiring Trip

The output will be tripped off if the voltage between an output terminal and its corresponding sense

terminal exceeds approximately 2V; this will happen if the sense wires are wired at the load to the

wrong output or if an attempt is made to draw power from the sense wires.

If the sense terminals are miswired in this way the output is turned off and the message Sense

Error – Check Connections is displayed. Pressing ESCAPE at this point removes the

message and the display now shows the preset voltage and current limit. When the cause of the

trip has been corrected the output can be turned on again.

Series or Parallel Connection with Other Outputs

The outputs of the power supply are fully floating and may be used in series with other power

supply units to generate high DC voltages up to 300VDC.

The maximum permissible voltage between any terminal and earth ground ( ) is 300VDC

Warning! Voltages above 70Vdc are hazardous live according to EN 61010-1 and great care must

be taken when using the power supply at voltages above this level.

Always make connections to the instrument with the OUTPUT off.

17

It should be noted that the unit can only source current and cannot sink it, thus units cannot be

series connected in anti-phase.

The unit can be connected in parallel with others to produce higher currents. Where several units

are connected in parallel, the output voltage will be equal to that of the unit with the highest output

voltage setting until the current drawn exceeds its current limit setting, upon which the output will

fall to that of the next highest setting, and so on. In constant current mode, units can be connected

in parallel to provide a current equal to the sum of the current limit settings.

Note that the output terminals are rated at 60A maximum; if several outputs are operated in

parallel to source higher currents than this the junction should be made at a separate point, not

one of the terminals.

Over-Voltage Protection

Over-Voltage Protection (OVP) can be set from 2.0V to 90.0V. If the output voltage exceeds the

set OVP the output is immediately turned off (typically within 100µs), thus avoiding damage to the

circuit under test. The OVP circuit will trip if an excessive voltage is accidentally set from the front

panel or via a remote control interface, or is the result of a failure in the control circuitry of the

instrument itself. OVP will also trip if an excessive voltage is impressed across the terminals from

an external source; however, when the output is tripped off, the external voltage will still be present

and it is up to the user to remove the source to avoid possible damage.

To set OVP press SHIFT, OVP. The display changes to show only the present OVP setting together

with the prompt Numeric Entry: Range 2-90 ; the OK lamp flashes. Enter the new OVP

value using the numeric keypad, exactly as described for setting output voltage, and press OK to

confirm the new setting; to exit without entering a new value press ESCAPE. The factory default

setting is 90·0V.

If the OVP is tripped the display shows the message OVP - Press ESC to Reset and

the output is turned off. Pressing ESCAPE at this point removes the message and the display now

shows the preset voltage and current limit. When the cause of the OVP has been removed (or the

OVP limit changed) the output can be turned on again.

Note also that it is possible and valid to set OVP below the set voltage. If the supply is in constant

current mode the output voltage will be below the set voltage; OVP could be set such that is was

above the actual output voltage but below the set voltage. This could be used to trip the output

under a fault condition which caused the load impedance to increase and the actual output voltage

to therefore rise above the OVP point.

Over-Current Protection

Over-Current Protection (OCP) can be set from 2.0A to 55.0A. If the output current exceeds the

set OCP the output is shut down (typically within 100ms).

To set OCP press SHIFT, OCP. The display changes to show only the present OCP setting

together with the prompt Numeric Entry: Range 2-55 ; the OK lamp flashes. Enter the

new OCP value using the numeric keypad, exactly as described for setting the current limit, and

press OK to confirm the new setting; to exit without entering a new value press ESCAPE. The

factory default setting is 55·0A.

If the OCP is tripped the display shows the message OCP - Press ESC to Reset and the

output is turned off. Pressing ESCAPE at this point removes the message and the display now

shows the preset voltage and current limit. When the cause of the OCP has been removed (or the

OCP limit changed) the output can be turned on again.

Note also that it is possible and valid to set OCP below the set current limit. For example, the

power supply may be used to repetitively test a unit under test (UUT) which normally takes a peak

current of, say, 10 Amps. However, a faulty UUT would take a current of more than 10 Amps and

would be damaged by being left in a 10 Amp current-limited state. In this case the current limit

could be set to 11A, say, and the OCP set to 10A to ensure that a faulty UUT will trip the supply off.

18

Output Protection

In addition to OVP and OCP for forward over-voltage and over-current protection, the output is

protected from reverse voltages by a diode; the continuous reverse current must not exceed

3 Amps although transients can be much higher.

Temperature Trip and Other Faults

If the safe internal temperature limit is exceeded because, for example, the fan vents have been

blocked, the output is automatically tripped off. The display will show a message indicating that a

fault has occurred and that the AC supply must be turned off and on again to reset the unit. If

over-temperature is suspected, the cause of the fault should be rectified and the unit allowed to

cool before the AC supply is turned on again.

Note that an over-temperature trip shuts down the primary side of the instrument and it is that

condition that is detected and causes the fault message to be displayed. However, other faults

may occur which would also cause the primary side to shut down and these will not be

distinguishable from an over-temperature trip. If the unit does not restart after being allowed to cool

then another fault might be present and the unit should be returned for service.

Logic Control Input and Output

Digital signal connections LOGIC IN and LOGIC OUT are available on the rear panel; press the

orange actuators of the screwless terminals, insert the connecting wire and release the actuator to

secure the connection. LOGIC IN is connected directly to the input of an isolating opto-coupler;

there is no series resistor. The input is active when an input current greater than approximately

1mA is forced between LOGIC IN and LOGIC COMMON. LOGIC IN can be set to enable the

output, disable the output, or be ignored when it is activated, see the Extra Functions section. Note

that LOGIC IN can only be used to enable/disable the output if the output has already been turned

ON with the front panel key or by remote interface command; this permits the front panel

key to be used to turn the output off in an emergency, i.e. to override LOGIC IN. Note also that,

having turned the output ON with the key, the ON lamp remains lit even when the output is

disabled by the LOGIC IN signal.

LOGIC OUT is an isolated rear-panel open-collector output that will sink up to 2mA when active

(‘switch closure’); the maximum voltage that can be applied to LOGIC OUT is 30Vdc. LOGIC OUT

can be set to be ‘closed’ or ‘open’ for output enabled or disabled, current limit (CI mode), power

limit (UNREG mode), or for any fault trip. The default condition is for LOGIC OUT to be ‘closed’ for

the Output ON; loss of AC power, which would deactivate the opto, is also reliably detected with

this setting. See Extra Functions section for further details.

Analogue Control

Rear panel connections V CONTROL and I CONTROL provide quasi-analogue control of the

Output Voltage and Current Limit respectively. The inputs are read 4 times per second by the

A-to-D converter and the output is set according to the selected input scaling. The input scaling for

both can be set as 0 to 10 Volts or 0 to 5 Volts for range maximum output. The Analogue Control

functions and scaling are both selected from the keyboard, see Extra Functions section.

The V CONTROL and I CONTROL inputs are differential, with a limited common mode range of

± 2.5Vdc with respect to the negative output. They should be driven from a ‘floating’ source such

as another power supply.

Analogue Control is activated from the Bus menu, see Remote Operation section. When

activated, the top line of the display shows which functions (V and/or I) have been selected and the

corresponding functions on the front panel (NUMERIC SET / JOG SET for V and/or I ) are inhibited

to avoid contention between Analogue Control and front panel operation.

Analogue Monitor

The output terminal voltage and output current may be monitored on V MONITOR and I MONITOR

respectively. The output scaling for both will be the same as that set for V CONTROL and I

CONTROL, see above section. V MONITOR and I MONITOR are always available at the rear

panel terminals and should be connected to a measuring system with ‘floating’ inputs such as a

DMM.

19

Store Settings

The instrument can store 10 set-ups in non-volatile memory; the parameters stored are voltage,

current limit, OVP and OCP. The output state and remote sense setting are not stored.

To store a set-up press SHIFT, STORE to show the store locations and the currently saved set-ups

on the Store screen.

The store location to be used can be selected directly by pressing any key 0 – 9 or by scrolling to

the appropriate store number in the list using the JOG SET control; the selected store is indicated

by the square brackets [ ] at that location. Press OK to store the set-up at the selected

location; the screen returns to the standard status display. A full store can be overwritten with new

settings. At any time before the OK key is pressed the store function can be exited without saving

a set-up by pressing ESCAPE or by waiting for the operation to time out.

Deleting Stored Settings

Any store can be returned to 'empty' as follows: press SHIFT, STORE, and select the appropriate

store number as described in the Store Settings section above; at that point press ·followed by

OK to confirm the operation. At any time before the OK key is pressed the delete function can be

exited without erasing a set-up by pressing ESCAPE or by waiting for the operation to time out.

Recall Settings

To recall a set-up press SHIFT, RECALL to show the store locations and the currently saved set-

ups on the Recall screen. Each store location is displayed with its output voltage, current limit,

OVP and OCP settings; the output status (on/off) and sense settings (local/remote) are not stored.

Empty store locations are shown without data.

The store location containing the setting to be recalled can be selected directly by pressing any

key 0 – 9 or by scrolling to the appropriate store number in the list using the JOG SET control; the

selected store is indicated by the square brackets [ ] at that location. Press OK to recall the

set-up at the selected location; the screen returns to the standard status display. Settings may be

recalled with the output on or off.

Extra Functions

Options for extra functions such as LOGIC CONTROL and ANALOGUE CONTROL/MONITOR,

plus variations on some of the factory default functions, can be set by the user by using the # extra

functions facility. The complete list of functions is accessed by pressing SHIFT, # ; the required

function can be selected directly by entering nn from the keyboard, where nn is the 2-digit number

in the list below, or by scrolling to the appropriate function in the list using the JOG SET control;

the selected function is indicated by the square brackets [ ] at that position in the list. Press

OK to initiate the selected function, following the on-screen prompts where appropriate. At any

time before the OK key is pressed the extra function can be exited without implementation by

pressing ESCAPE or by waiting for the operation to time out.

Selected functions are indicated by a

beside the code in the on-screen list. Note that the

options within any decade group are mutually exclusive and selecting a function within any group

will automatically deselect any previously selected function in that group, including the factory

default option; for example, if #26 is selected, 20 -25 and 27 are all deselected.

With the exception of functions 30/31 and 70/71 all extra functions are specific to a particular

output and will only be changed for the output currently selected by the CONTROL keys; the extra

functions can therefore be set differently for each output. Functions 30/31 (buzzer) and 70/71

(Tracking) apply to the whole instrument therefore changing the selection for output 1 will

automatically change the selection on output 2.

This manual suits for next models

1

Table of contents

Other TTI Power Supply manuals