5

USER MANUAL

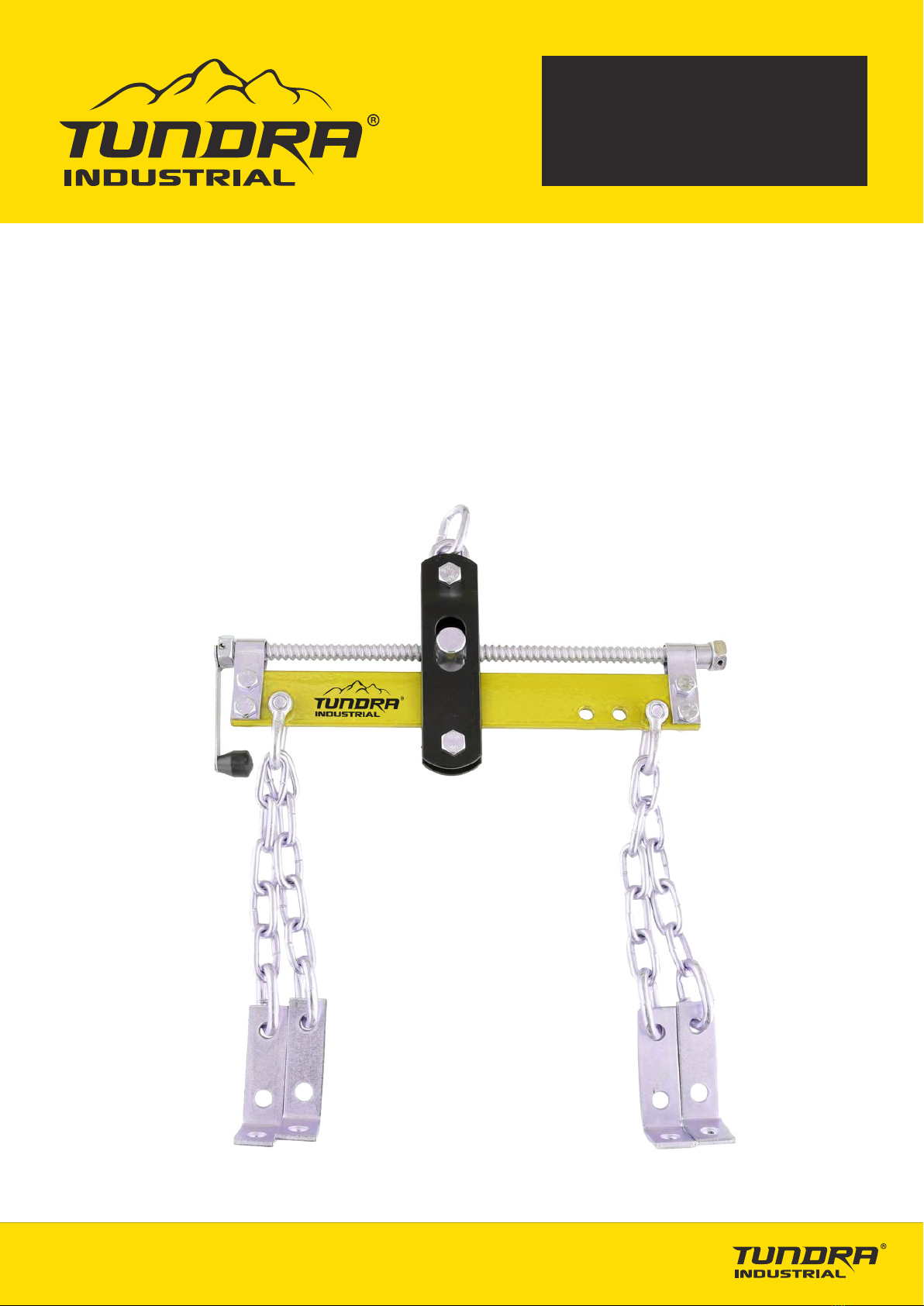

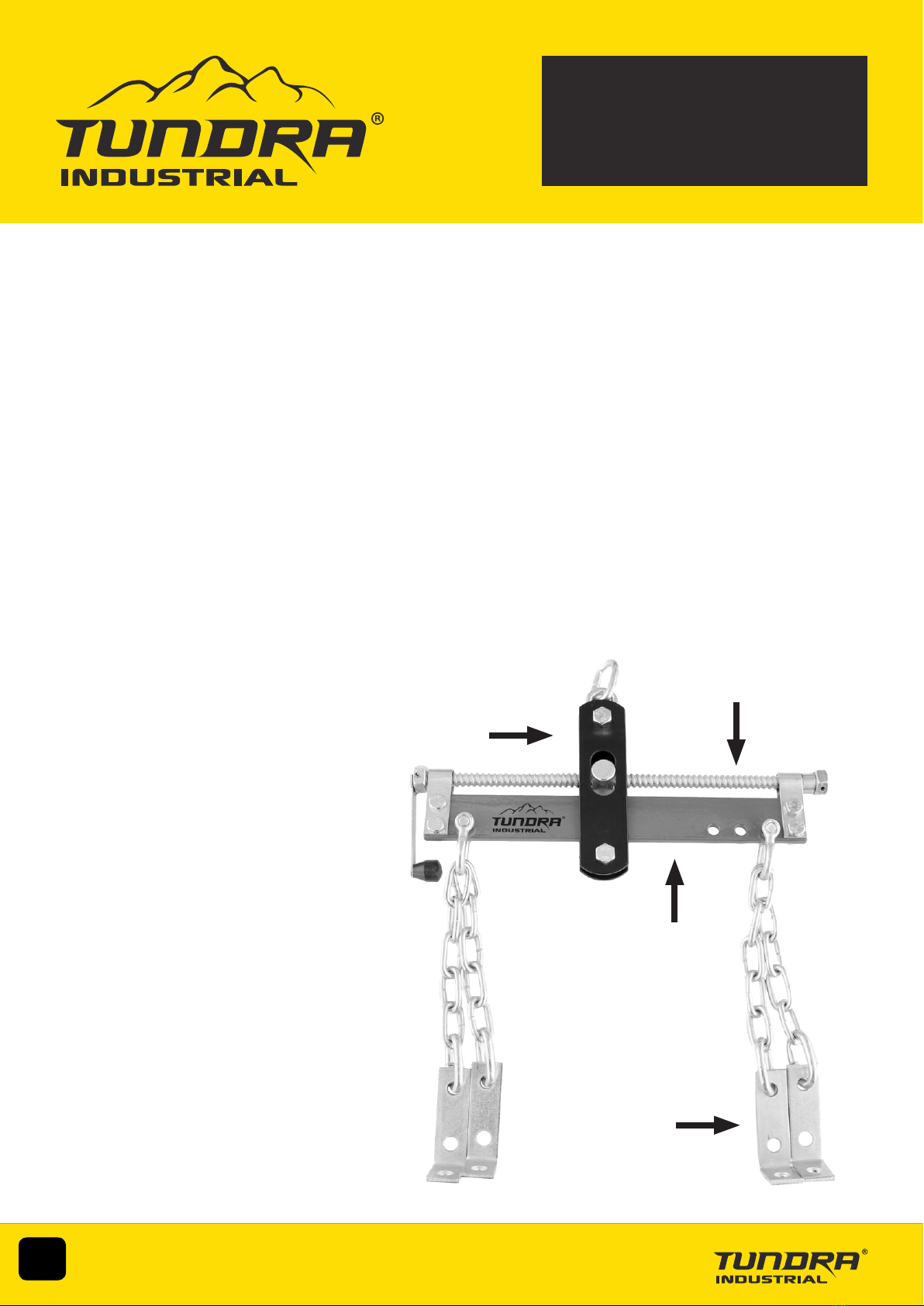

TUNENGCRALEV

LIMITED WARRANTY STATEMENT

Tundra Industrial warrants its customers that its products will be free of defects in workmanship or material.

Tundra Industrial shall, upon suitable notification, correct any defects, by repair or replacement, of any parts or components of

this product that are determined by Tundra Industrial to be faulty or defective.

This warranty is void if the equipment has been subjected to improper installation, storage, alteration, abnormal operations,

improper care, unauthorised service or repair.

Warranty Period

Tundra Industrial will assume both the parts and labour expense of correcting defects during the stated warranty periods below.

All warranty periods start from the date of purchase from an authorised Tundra Industrial dealer. If proof of purchase is not

available from the end user, then the date of purchase will be deemed to be 3 months after the initial sale to the distributor.

1 Year

• Tundra Industrial 680KG ENGINE LOAD LEVELLER [TUNENGCRALEV]

90 Days

• All replacement parts purchased outside of the warranty period

Important: All parts used in the repair or replacement of warranty covered equipment will be subject to a minimum of 90 days

cover or the remaining duration of the warranty period from the original date of purchase.

Warranty Registration / Activation

You can register and activate your warranty by visiting the Jefferson Tools website using the following address:

www.jeffersontools.com/warranty and completing the online form. Online warranty registration is recommended as it eliminates

the need to provide proof of purchase should a warranty claim be necessary.

Warranty Repair

Should Tundra Industrial confirm the existence of any defect covered by this warranty the defect will be corrected by repair or

replacement at an authorized Tundra Industrial dealer or repair centre.

Packaging & Freight Costs

The customer is responsible for the packaging of the equipment and making it ready for collection. Tundra Industrial will arrange

collection and transportation of any equipment returned under warranty. Upon inspection of the equipment, if no defect can be

found or the equipment is not covered under the terms of the Tundra Industrial warranty, the customer will be liable for any

labour and return transportation costs incurred. These costs will be agreed with the customer before the equipment is returned.

Warranty Limitations

Tundra Industrial will not accept responsibility or liability for repairs made by unauthorised technicians or engineers. Tundra

Industrial's liability under this warranty will not exceed the cost of correcting the defect of the Tundra Industrial products. Tundra

Industrial will not be liable for incidental or consequential damages (such as loss of business or hire of substitute equipment etc..)

caused by the defect or the time involved to correct the defect. This written warranty is the only express warranty provided by

Tundra Industrial with respect to its products.

Any warranties of merchantability are limited to the duration of this limited warranty for the equipment involved. Tundra Industrial

is not responsible for cable wear due to flexing and abrasion. The end user is responsible for routine inspection of cables for pos-

sible wear and to correct any issues prior to cable failure.