3

USER MANUAL

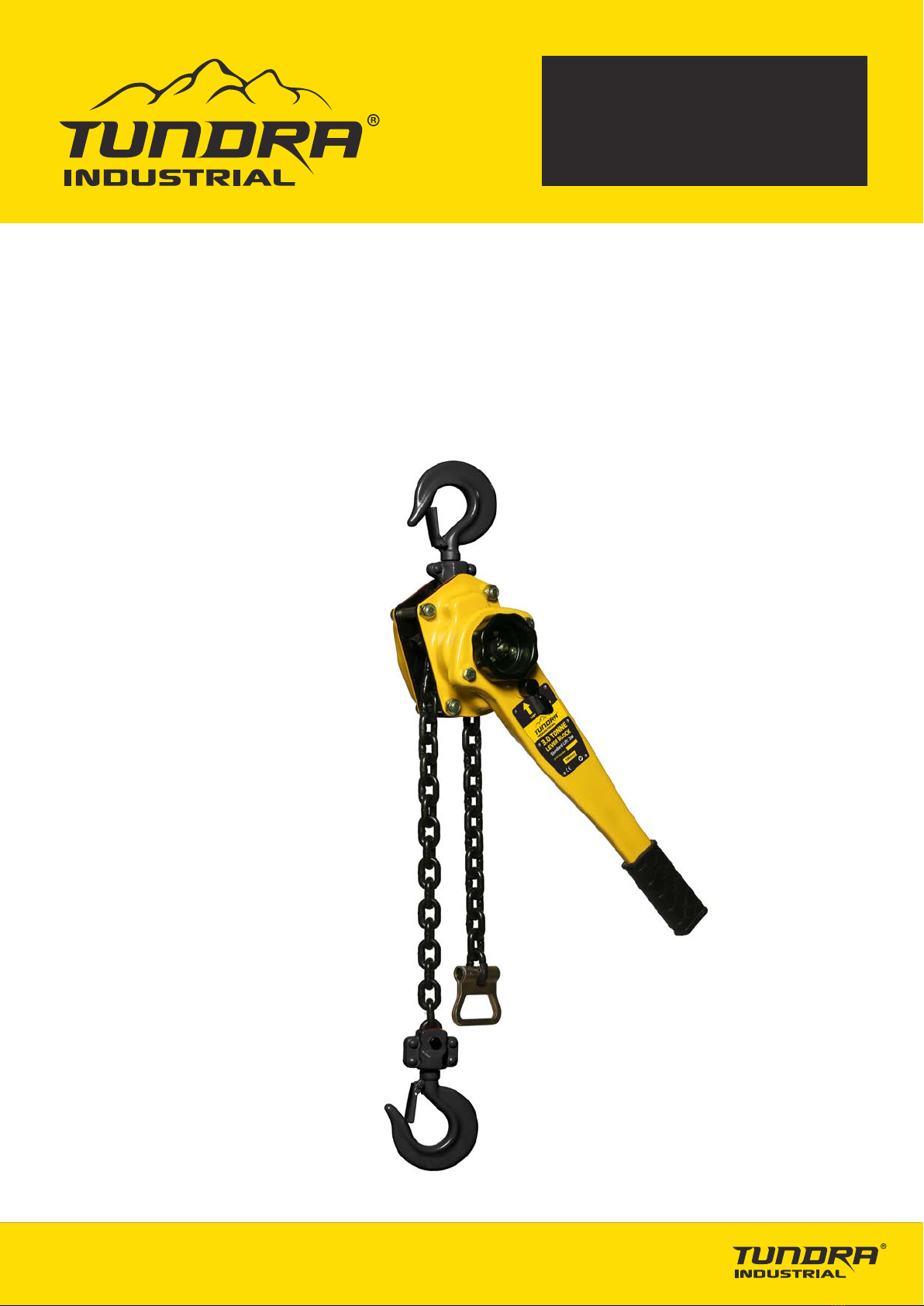

TUNLB0.75-3 • TUNLB1.50-3

TUNLB3.00-3 • TUNLB6.0

1. SAFETY GUIDELINES

Important: Read and understand all safety instructions before use. Keep instructions safe for future reference. Ensure that this

equipment is in sound, clean condition and good working order before use. The operator must have a clear and unobstructed view

of the entire travel area before operating the lever block - it is preferable to operate with one or more persons on hand.

General Safety:

• Always inspect equipment for damage before use

• Ensure any damaged parts are replaced before use - use only Tundra Industrial recommended parts - contact your dealer for

advice

• Do not use this equipment if damage or weakness is detected during inspection

• Do not modify this equipment for any use other than that which it has been designed and tested for

• Never exceed the rated capacity

• Keep the equipment clean and well maintained for optimal, safe performance

• Ensure that the working environment is well lit and kept clean and free from clutter, keep children and animals away

• Ensure that the floor is level and strong enough (preferably concrete) to take the weight of the lift and the bike

• This equipment should only be used by fully-trained and competent individuals (never under the influence of drugs or alcohol)

• Raise and lower the load in a smooth, controlled manner

• Use a qualified person to lubricate and maintain this equipment

• Unauthorised parts may be dangerous and will invalidate the warranty

Equipment Safety:

• Never use this equipment for lifting, supporting or transporting people or animals

• Never use your foot to apply pressure on the lever block

• Never use two or more lever blocks together to lift a load beyond the rated capacity

• Never lift up the load beyond the rated capacity

• Never lift or transport loads over or near people

• Keep children and animals out of the working environment during operation

• Ensure that the nameplate / specification plate is kept clean, clear and visible at all times

• Ensure hook is free from damage and rotates freely before use

• Check break system regularly

• Lubricate chain load regularly / as required

WARNING: Do not use this equipment if any damage or wear is detected - remove from service immediately and seek advice for

repair

• Never use a twisted, kinked, damaged or stretched load chain

• Never use this equipment as a sling

• Never use the chain as a support

• Never support a load on the tip of the hook

• Never run the load chain over a sharp edge

• Never weld or cut a load suspended by the lever block

• Never operate the equipment in such a way that the bottom hook touches the hoist body

• Never operate the lever block so far that the load chain pulls the anchorage

• Ensure that you always lower the load slowly and safely after lifting and never suspend a load for an extended period of time

WARNING:

No responsibility is accepted for incorrect use of this equipment. Incorrect use can result in damage to the equipment and

danger to the user. Warranty will be void in the event of incorrect use. The warnings, cautions and instructions discussed

in this instruction manual cannot cover all possible conditions and situations that may occur. It must be understood by the

operator that common sense and caution are factors which cannot be built into this product, but must be supplied by the

operator.