5

A. OPERATIONAL PRECAUTIONS

WARNING: to reduce the risk of fire, electric shock or injury to persons or property:

•If the supply cord is damaged, it must be replaced by the manufacturer, its service agent

or similarly qualified persons in order to avoid a hazard.

•The A-weighted sound pressure level is below 36 dBs.

•The appliance shall be disconnected from its power source during maintenance.

•Always operate the unit from a power source of equal voltage, frequency and rating as

indicated on the product identification plate.

•Alwaysusea power outlet thatisgrounded.

•Unplug the power cord when cleaning or when not in use.

•Do not operate with wet hands. Prevent water from spilling onto the unit.

•Do not immerse or expose the unit to rain, moisture or any other liquid.

•Do not leave the unit running unattended. Do not tilt or turn over the unit.

•Do not unplug while the unit is operating.

•Do not unplug by pulling on the power cord.

•Do not use an extension cord or an adapter plug.

•Do not put objects on the unit.

•Do not climb or sit on the unit.

•Do not insert fingers or other objects into the air outlet.

•Do not touch the air inlet or the aluminum fins of the unit.

•Do not operate the unit if it is dropped, damaged or showing signs of product

malfunction.

•Do not clean the appliance with any chemicals.

•Ensure the unit is far away from fire, inflammable, or explosive objects.

•The unit shall be installed in accordance with national wiring regulations.

•Do not use means to accelerate the defrosting process or to clean, other than those

recommended by the manufacture.

•The appliance shall be stored in a room without continuously operation sources (for

example: open flames, an operating gas appliance or an operating electric heater).

•The appliance shall be stored so as to prevent mechanical damage from occurring.

•Do not piece or burn, even after use.

•Be aware that refrigerants may not contain an odor.

•Pipe-work shall be protected from physical damage and shall not be installed in an

unventilated space, if that space is smaller than 4m².

•Compliance with national gas regulations shall be observed.

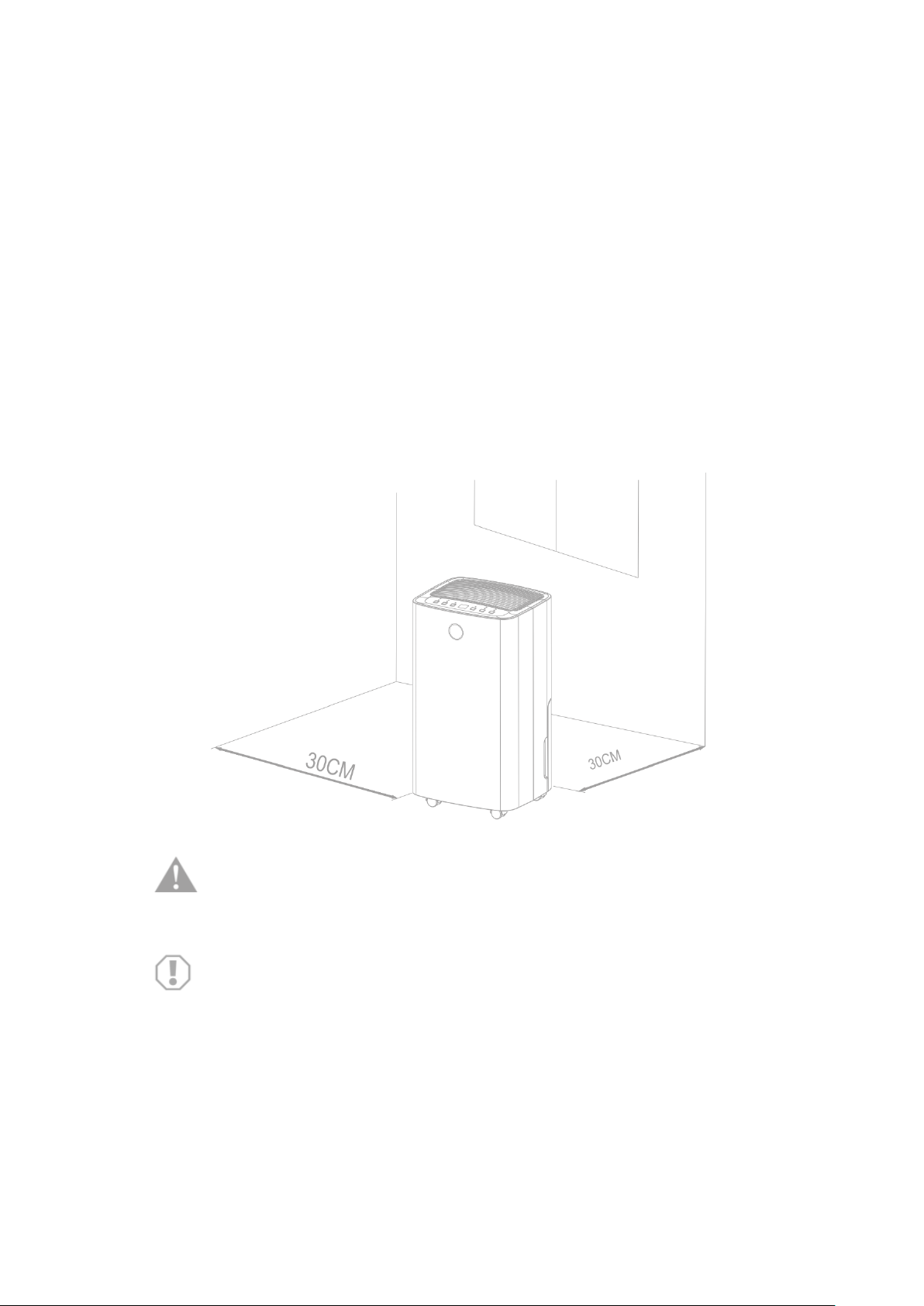

•Keep any required ventilation openings clear of obstruction.

•The appliance shall be stored in a well-ventilated area where the room size corresponds

to the room area as specified for operation.

Any person who is involved with working on or breaking into a refrigerant circuit

should hold a current valid certificate from an industry-accredited assessment