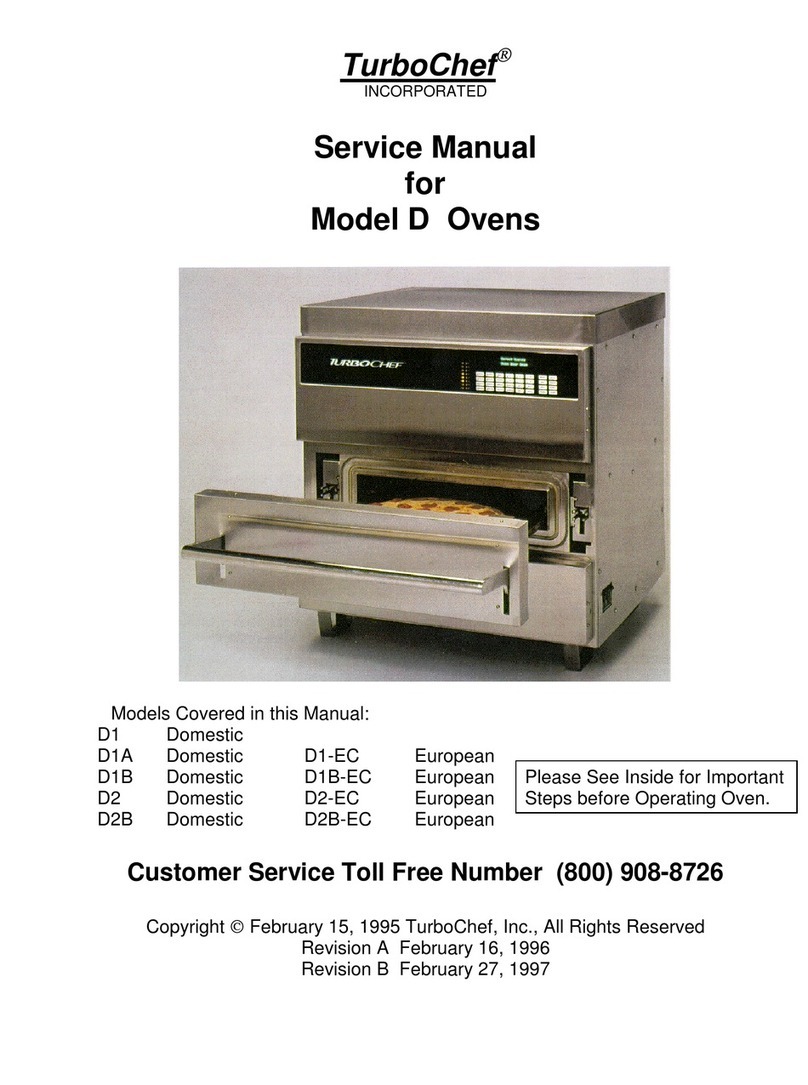

ExtErior ConstruCtion

nStainless steel front, top, back, and powder-coated sides

n4” (102 mm) matte black legs

nErgonomic, cool to touch powder-coated door handle

intErior ConstruCtion

n304 stainless steel interior

nWatertight construction

nInterchangeable jetplates for customized cooking results

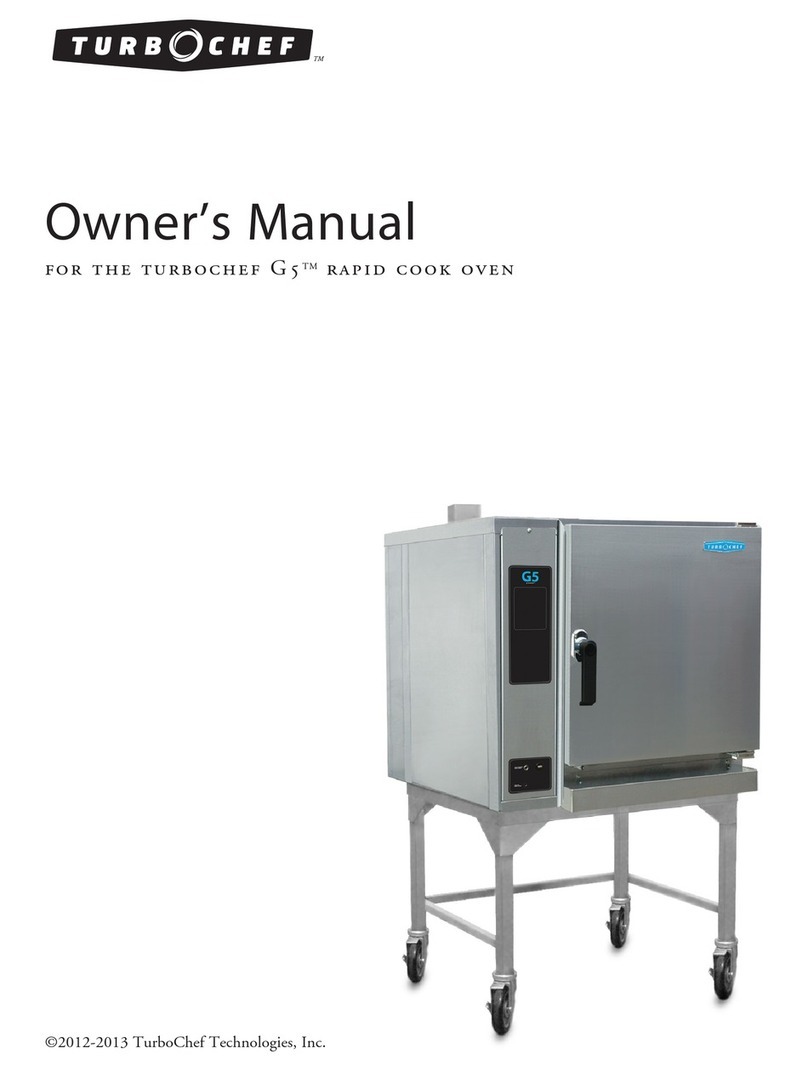

standard FEaturEs

nIntegral recirculating catalytic converter for UL®(KNLZ)

listed ventless operation

nVariable-speed High h recirculating air impingement system

nOscillating rack for high heat transfer without spotting

nHalf-sheet pan/16-inch pizza capacity

nSmart Voltage Sensor Technology* (N.A. only)

nStackable design (requires stacking kit)

nSmart menu system capable of storing up to 72 recipes

nBuilt-in self diagnostics for monitoring oven components

and performance

nIncludes plug and cord (6 ft. nominal)

nSmart card compatible

nWarranty − 1 year parts and labor

ComEs with standard aCCEssoriEs

n1 Aluminum Paddle (NGC-1478)

n1 Bottle Oven Cleaner (103180)

n1 Bottle Oven Guard (103181)

n2 Trigger Sprayers (103182)

n1 14x16 PTFE Screen (100018)

This product conforms to the ventilation recommendations set forth by NFPA96 using

EPA202 test method.

* Smart Voltage Sensor Technology does not compensate for lack of or over voltage situations. It is the

responsibilityoftheownertosupplyvoltagetotheunitaccordingtothespecicationsonthebackofthissheet.

†Ventlesscerticationisforallfooditemsexceptforfoodsclassiedas“fattyrawproteins.”Suchfoodsinclude

bone-in, skin-on chicken, raw hamburger meat, raw bacon, raw sausage, steaks, etc. If cooking these types of

foods, consult local HVAC codes and authorities to ensure compliance with ventilation requirements.

Ultimate ventless allowance is dependent upon AHJ approval, as some jurisdictions may not recognize UL

certification or application. If you have questions regarding ventless certifications or local codes please

TurboChefreservestherighttomakesubstitutionsofcomponentsorchangespecicationswithoutpriornotice.

Project _______________________________________________________

Item No. ______________________________________________________

Q u a n t i t y _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _______________________________________

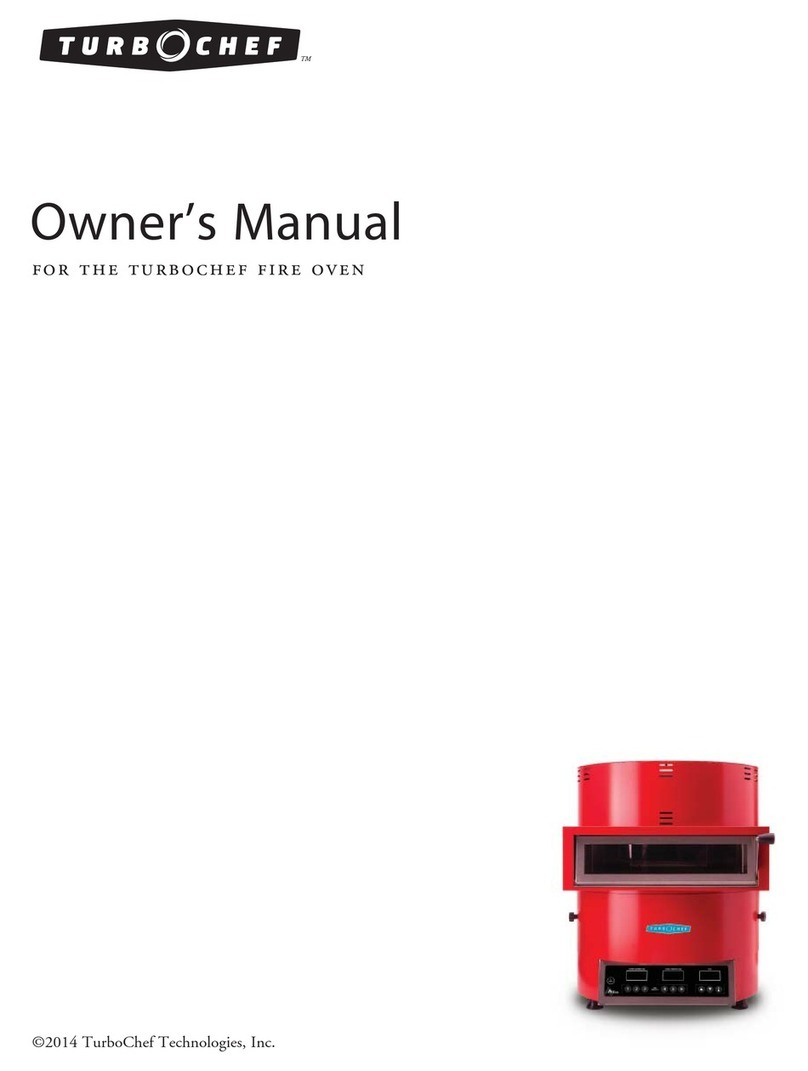

HIGH hBATCH 2TM

THE

HIGH hBATCH 2TM

PErFormanCE

nHeat transfer rates (h) are 3X-4X typical

convection oven

nHeat transfer rates (h) are 2X typical

conveyor oven

nThe High h Batch 2 oers high quality, full

baking capabilities up to 5X faster than

traditional cooking equipment, achieving

conveyor-type results in a compact size

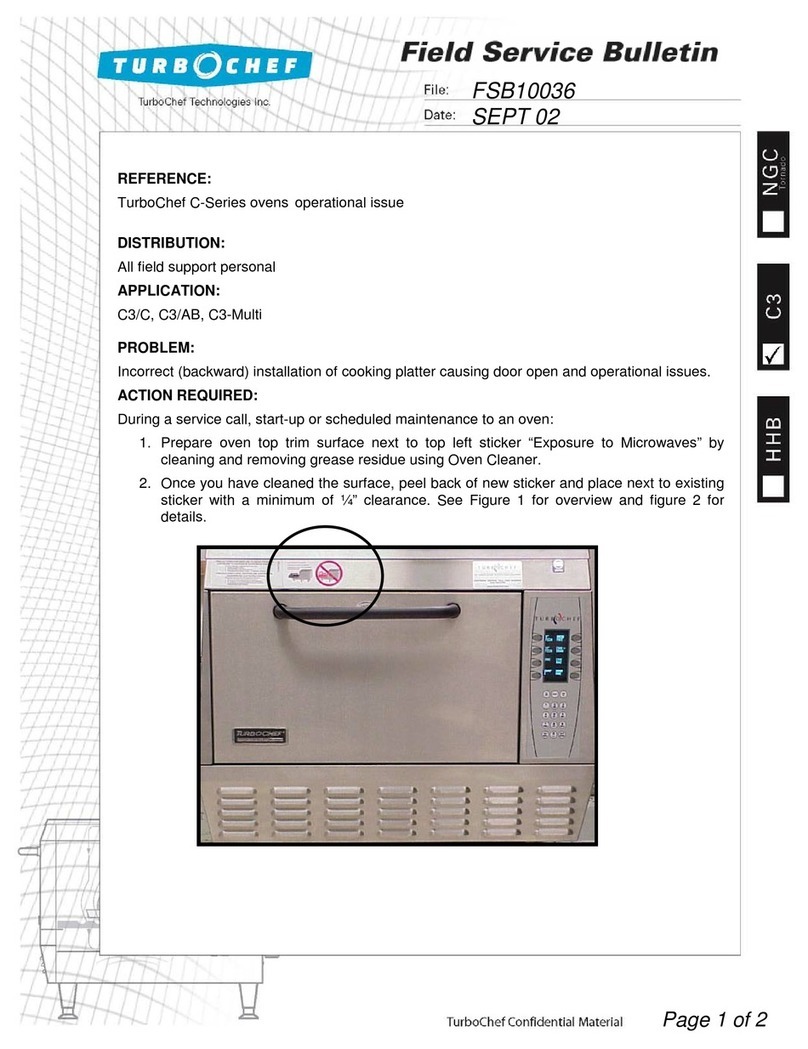

1. Blower Motor

2. Impinged Air

3. Oscillating Rack

4. Catalytic Converter

5. Impingement Heater DOC-1199/Revision J/

May 2013

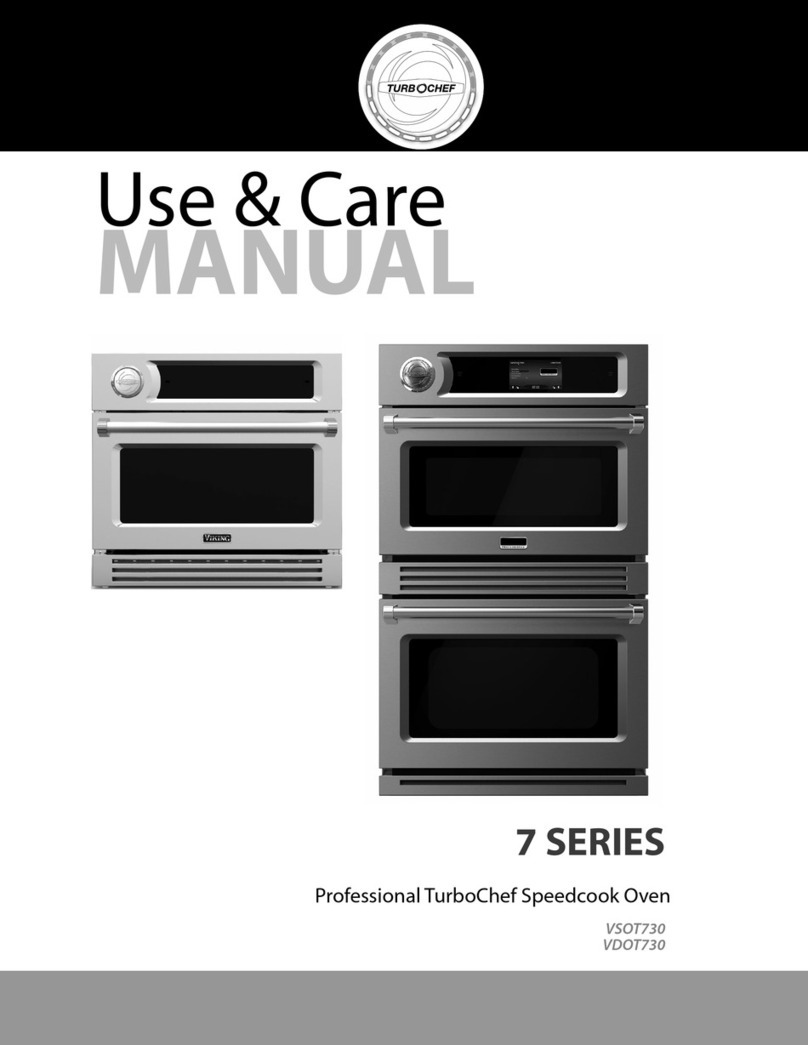

VEntiLation

nUL (KNLZ) listed for ventless operation.†

nEPA 202 test (8 hr):

- Product / Results

- Fries, Chicken Breasts, Chicken Wings,

and Ground Beef Patties / 0.10 mg/m3

- Pepperoni Pizzas / 0.40 mg/m3

- Ventless Requirement: <5.00 mg/m3

nInternal catalytic ltration to limit smoke,

grease, and odor emissions.