Turbidity Plus Sensor

998-2187 Rev. G Page 10

3. Calibration

Note: To make accurate and repeatable measurements it is important to

keep the sensor clean; see Section 5.1 for information on cleaning your

sensor.Refer to Appendix B - Recommended Measurement Practices.

3.1 Direct Concentration Calibration

Calibrating Turbidity Plus is a simple process that requires calibration standards

to create a correlation factor which is used to convert raw voltage data to NTU

concentrations.

Turner Designs recommends Amco Clear Turbidity Standards. They are non-

toxic safe solutions consisting mainly of deionized water that come prepared in a

broad range of concentrations and have a shelf life guaranteed for one year.

These standards are available from GFS Chemicals under part numbers 8506

(10 NTU), 8507 (100 NTU), 8620 (1000 NTU) and 8621 (3000 NTU). Follow

instructions below to establish a correlation between the standard’s

concentration and the sensor’s voltage response. Use the equation in step 6 to

calculate NTU concentrations.

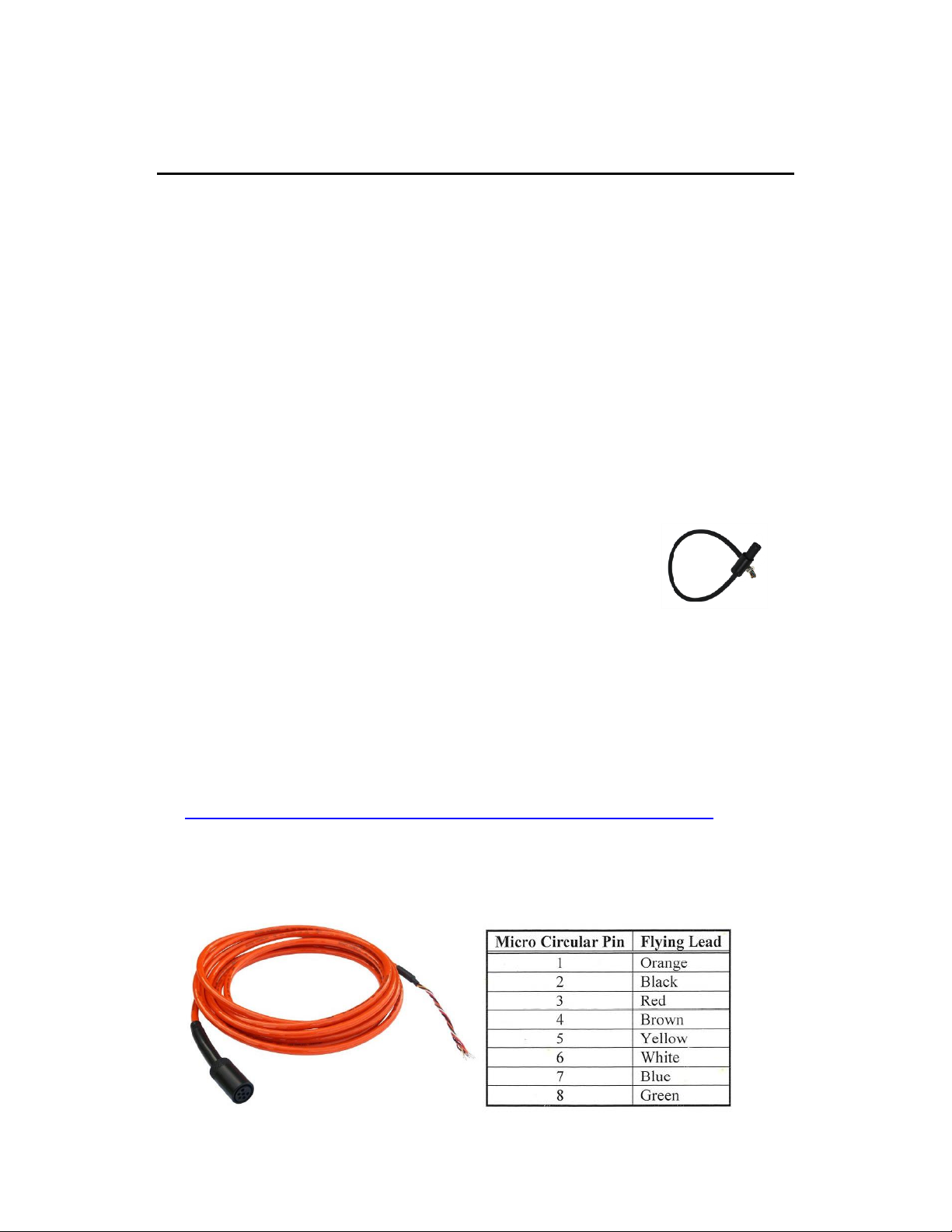

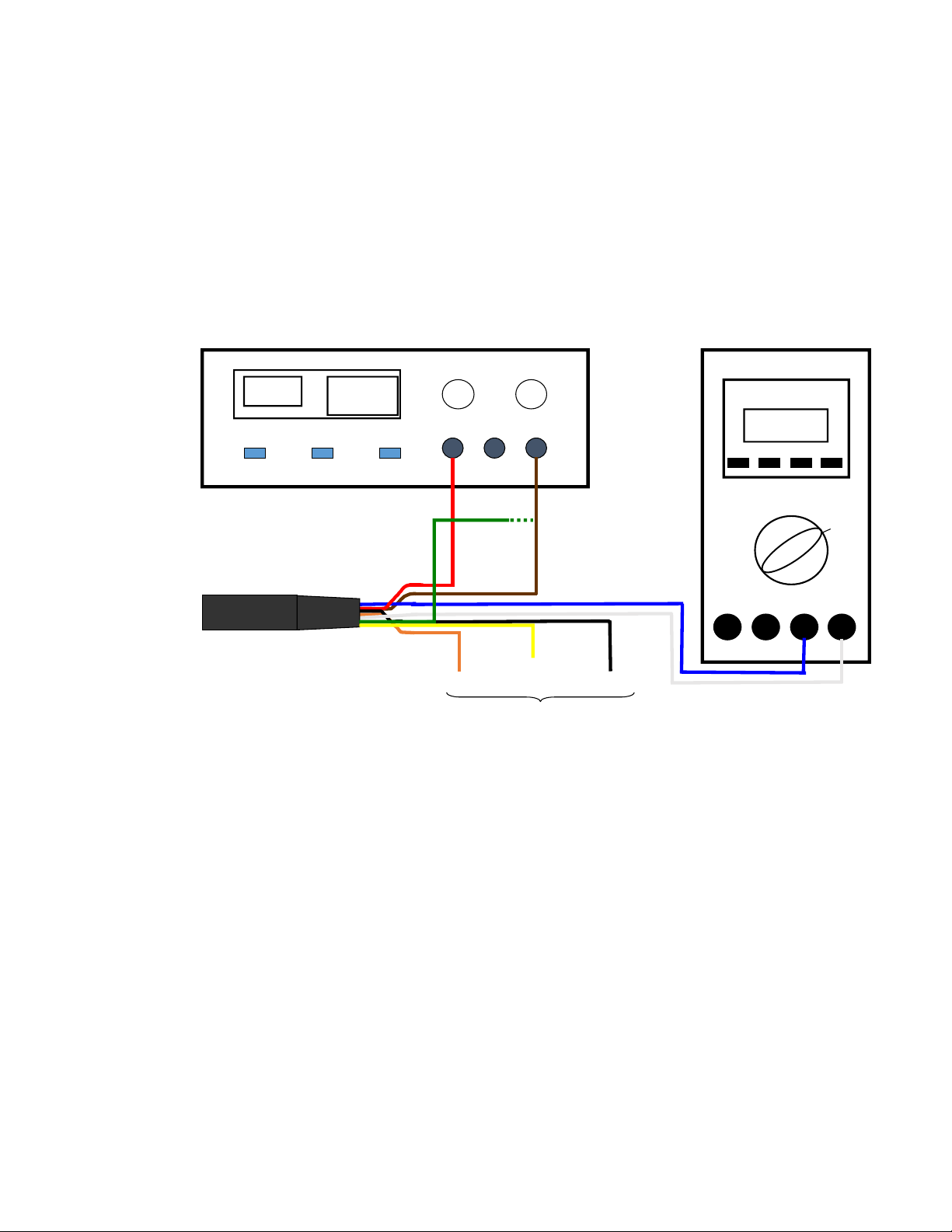

1) Connect Turbidity Plus to a power source and multimeter; see figure 1 for

details.

2) Fill a darkened beaker with blank sample and use Turbidity Plus to measure

the voltage of the blank.

Note: A good blank to use for this application is ultra-pure or

deionized water.

3) Remove Turbidity Plus from the blank, pour out the blank sample, and fill the

same darkened beaker with a standard solution of known concentration.

4) Measure the voltage response of the standard solution.

5) Use the following equation to create a correlation factor:

[(CStd)/(VoltsStd - VoltsBlank)] = Correlation Factor

CStd = Concentration value of standard used for calibration

VoltsStd = Voltage reading from standard concentration

VoltsBlank = Voltage reading from blank

6) Use the following equation to calculate concentration from measured voltage

response:

CSample = (Correlation Factor) * (VoltsSample –VoltsBlank)

Csample = Concentration of sample