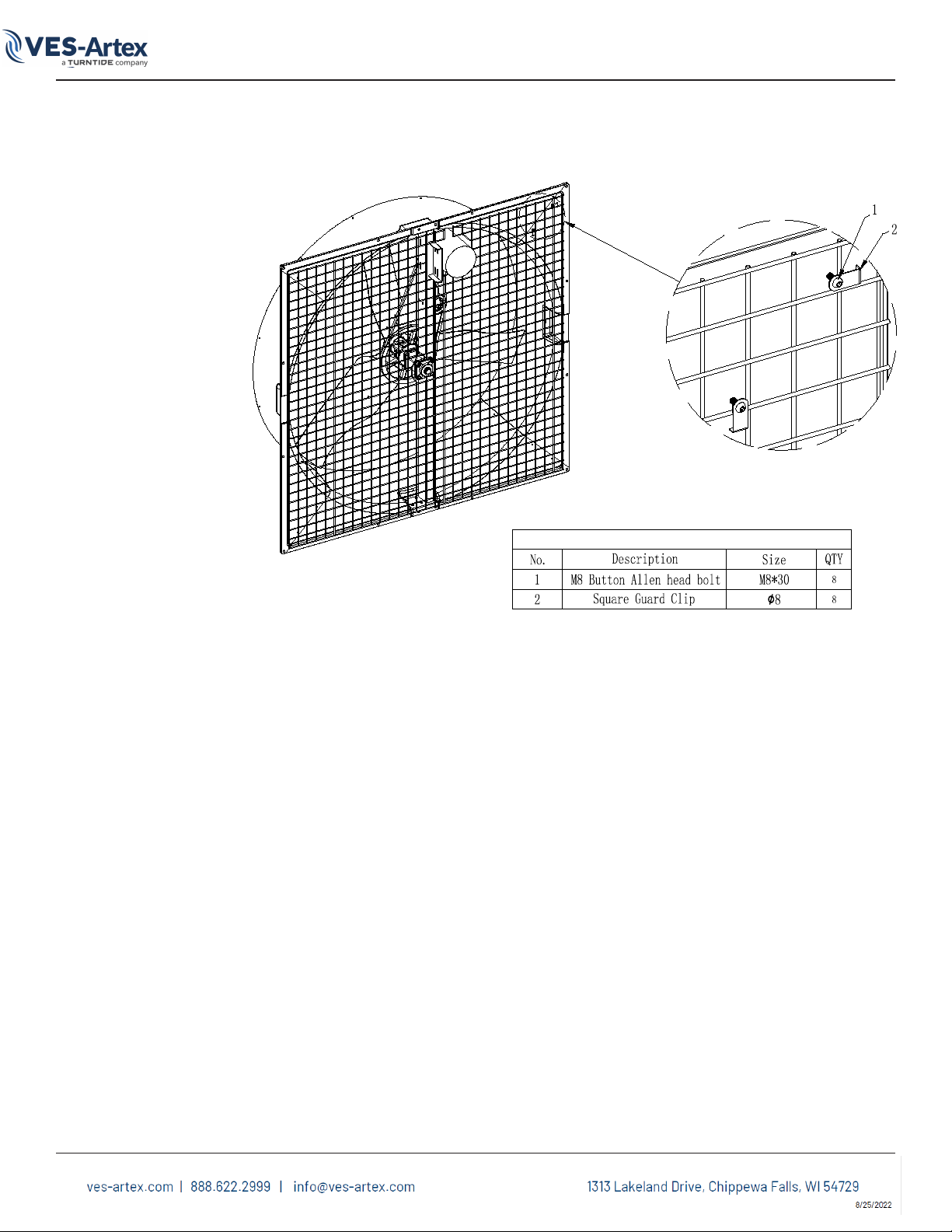

Installation Steps | PPFS 55 Instruction Manual |

TOOLS NEEDED

13mm Socket

Phillips-head screwdriver

Flat-head screw driver

4-3in wood screws (optional)

1-48in 2x4 lumber (optional)

Cordless drill

Drill-bit Set

Metric hex-key set

Drill socket adapter

Ratchet

14mm Socket

* For installation in metal

buildings, please contact

VES.

Always disconnect the power supply

before servicing or working with the

unit for any reason.

Parts replacement and

troubleshooting to be performed

only by qualied personnel.

Do not place ngers or objects in

the fan while motor is connected to

the power source.

Do not attach foreign objects to

the blades of the fan.

Do not use gasoline benzene,

thinner, harsh cleaners, etc., which

are dangerous and will damage fan.

Please follow all warning guidelines, failure to do so

could result in serious injury or death.

Assembly/Installation of the fan should be carried

out by qualied professionals.

During transportation, parts on the fan may become

loose and need to be checked during and after

installation.

• Ensure all hardware is tight and secure

• Ensure alignment of pulleys is correct

• Ensure proper belt tension is maintained

Disconnect electrical power before installing,

inspecting or servicing equipment. All electrical

wiring must be done by a qualied electrician in

accordance with all Local and National electrical and

safety codes, as well as the National Fire Protection

Agency (NFPA) where applicable.

Fans should be hung no lower than

7’ at the lowest point from the

ground/oor.

Always have the necessary number

of people before starting.

Always have the necessary number

of people available to properly

handle large fans.

SAFETY

Installation Safety

Prior to any installation product should be inspected

for any damage caused during shipping. Any damage

found should be documented and communicated to

liable parties.

Operation Safety

When fan is in operation no attempt should be made

to service or interact with parts from the fan. Any

attempt to interact with fan parts while the fan is

operating could result in injury. Inlet and exit guards

and or shutters are in place to help prevent foreign

objects from entering inside the outer perimeter of

the housing. If maintenance to the fan is required,

interrupt the source of power to the motor and allow

propeller to come to a complete stop before moving

forward with any efforts to service.

Maintenance Safety

Some safeguards must be

disassembled or removed for the

parts to be serviced or replaced. As

this fan does have moving parts and

is supplied with electrical power,

steps must be taken to ensure

safety around these presented

hazards.

Safety & Warnings

Read and save these instructions. Revised 9/1/18VESENVIRO.COM | 1.888.622.2999 3