INSTALLATION

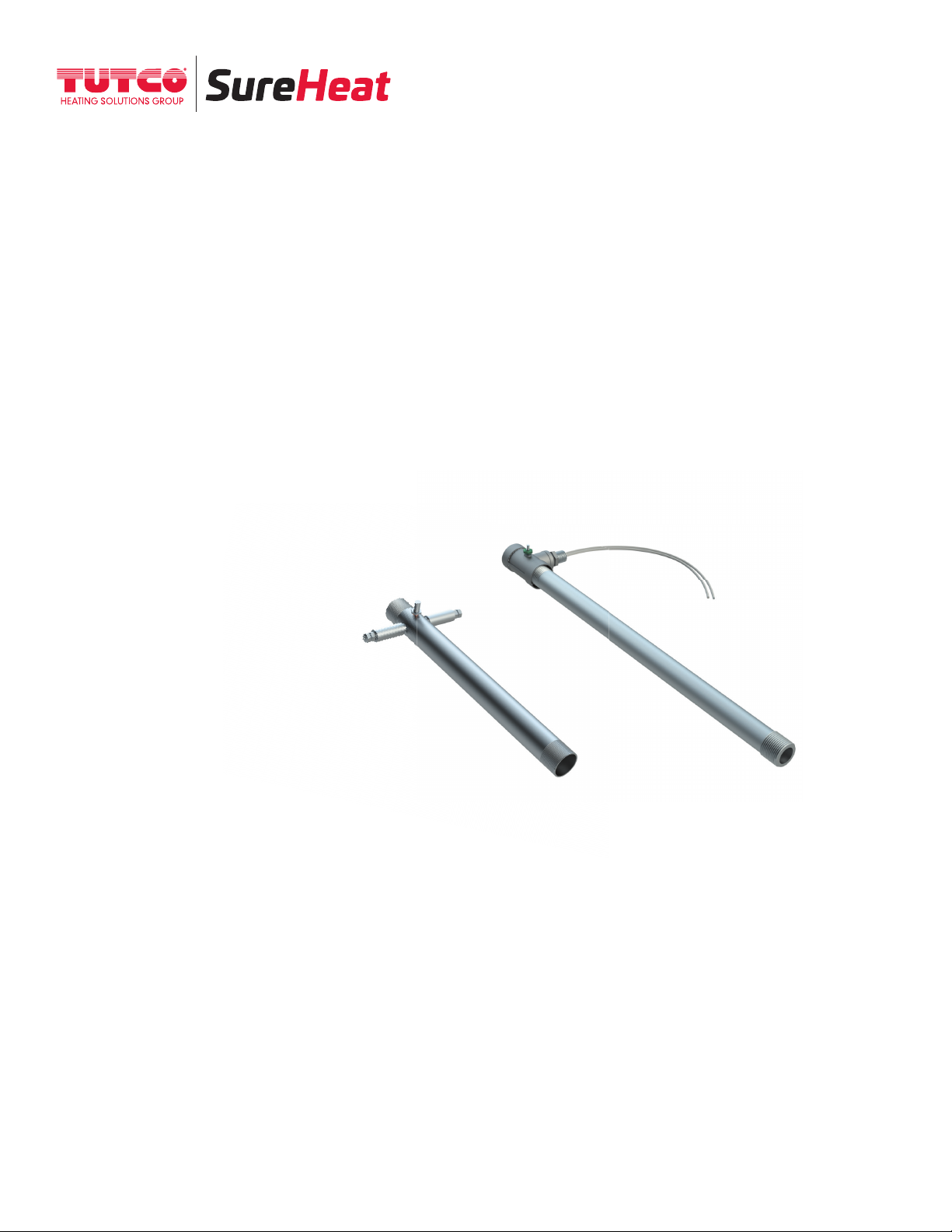

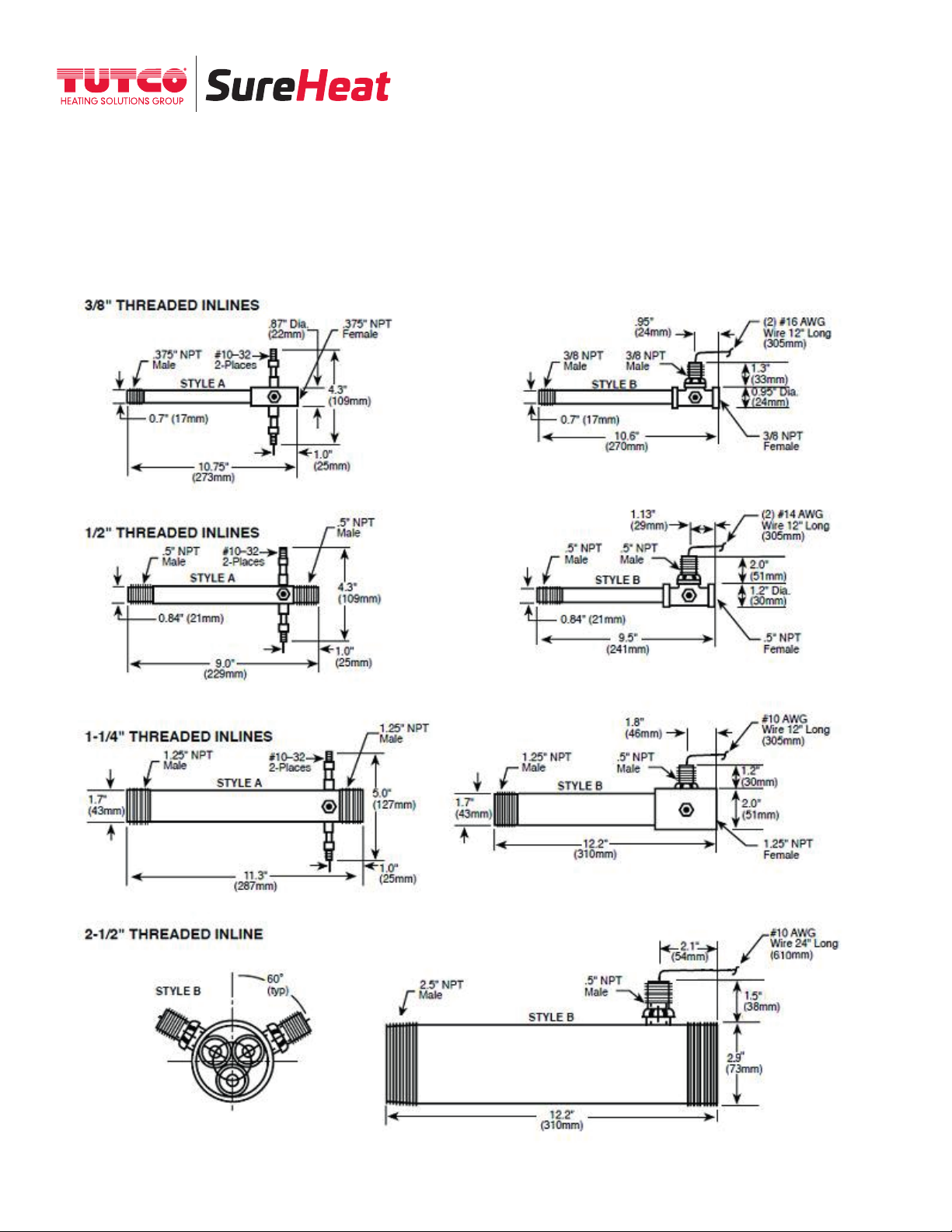

For 3/8”, 1/2”, & 1-1/4” HEATER ONLY (#F038821, F038822, F038823, F038824, F038825 & F038826):

1. There are two (2) feed-thrus on the heater. Connect one power lead to one heater electrical feed-thru

(ƒ one lead wire) and connect the other power lead to the other electrical feed-thru (or the other lead wire).

2. Connect the ground wire to the green grounding nut on the heater body.

3. Connect the air source to the heater.

4. If a thermocouple is used, ensure that it is located within one inch from the heater exit.

For 2-1/2” HEATER ONLY (#F063007): 18 kW - 240 Volt - 1Ø Operation:

Note: Running this heater at 240 Volts 1Ø will draw up to 75 Amps

1. The heater has two (2) set of power feed-thrus with three (3) wires (marked 1, 2, or 3) coming out of it.

2. Connect one side from the power to all three (3) leads that exit one (1) feed-thru (1, 2, and 3 together).

3. Connect the other side of the power to all three (3) leads that exit the second feed-thru (1, 2, and 3 together).

4. Make sure the heater is properly grounded.

5. Connect the filtered air source to the heater.

6. If a thermocouple is used, ensure that it is located within one inch from the heater exit.

FOR 2½” HEATER ONLY (#F063007 & F074439): 18 & 24 kW - 240 Volt – 3Ø Operation:

1. The heater has two (2) set of power feed-thrus with three (3) wires (marked 1, 2, or 3) coming out of it.

2. Connect the elements in a standard delta configuration. (Connect one (1) power lead to each of the

following pairs: 1-2, 2-3, 3-1).

3. Check resistance leg to leg. They should be approximately within 0.1 ohms of each other if wired properly.

4. Make sure the heater is properly grounded.

5. Connect the filtered air source to the heater.

6. If a thermocouple is used, ensure that it is located within one inch from the heater exit.

FOR 2½” HEATER ONLY (#F076418): 18 kW - 480 Volt – 3Ø Operation:

1. The heater has one (1) set of three (3) wire leads (marked 1, 2, or 3) coming out of it.

2. Connect the leads directly to the output of the power controller for standard 480V 3Ø operation.

3. Check resistance leg to leg. They should be approximately within 0.1 ohms of each other if wired properly.

4. Make sure the heater is properly grounded.

5. Connect the filtered air source to the heater.

6. If a thermocouple is used, ensure that it is located within one inch from the heater exit.

9