THANK YOU FOR CHOOSING A SERPENTINE HEATER

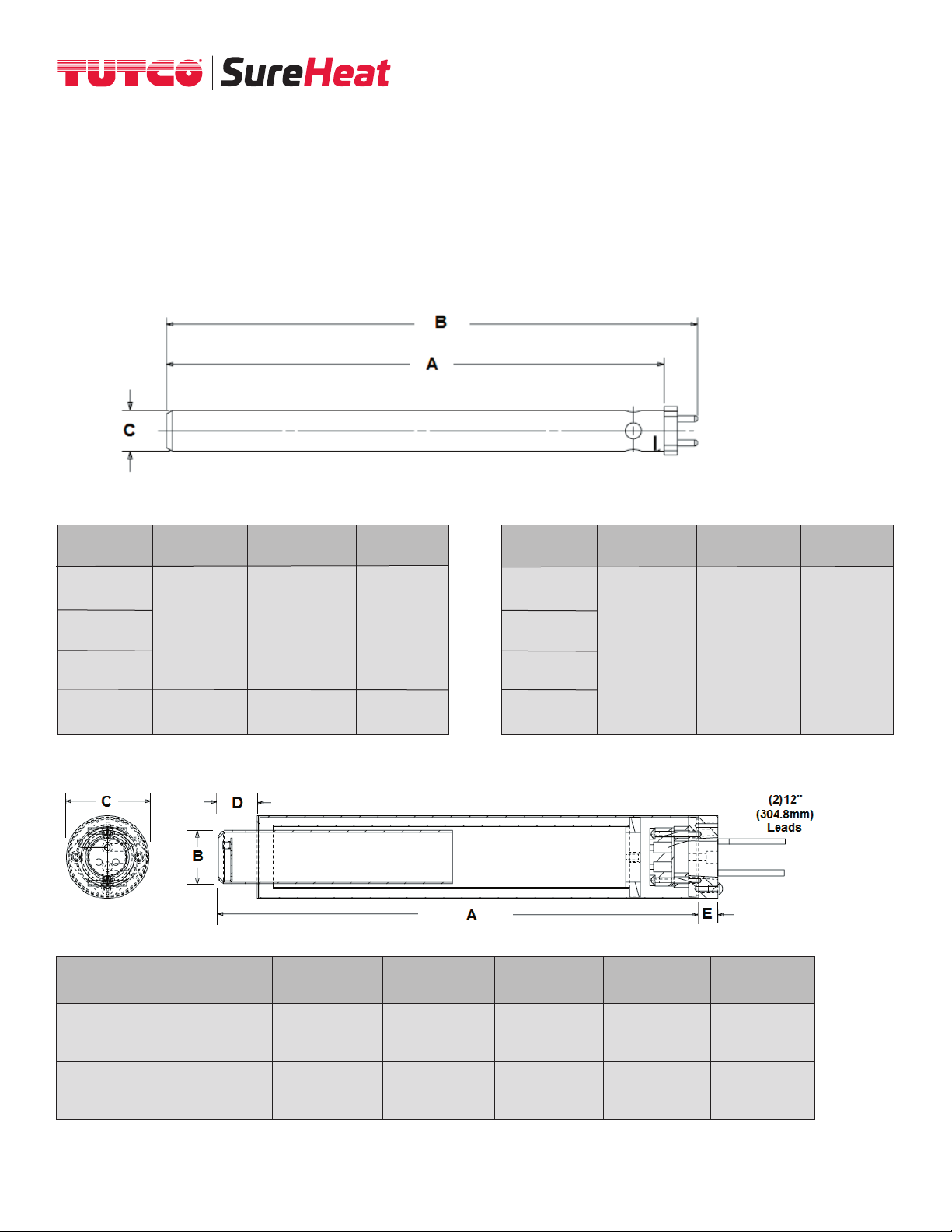

SERPENTINE II and VI

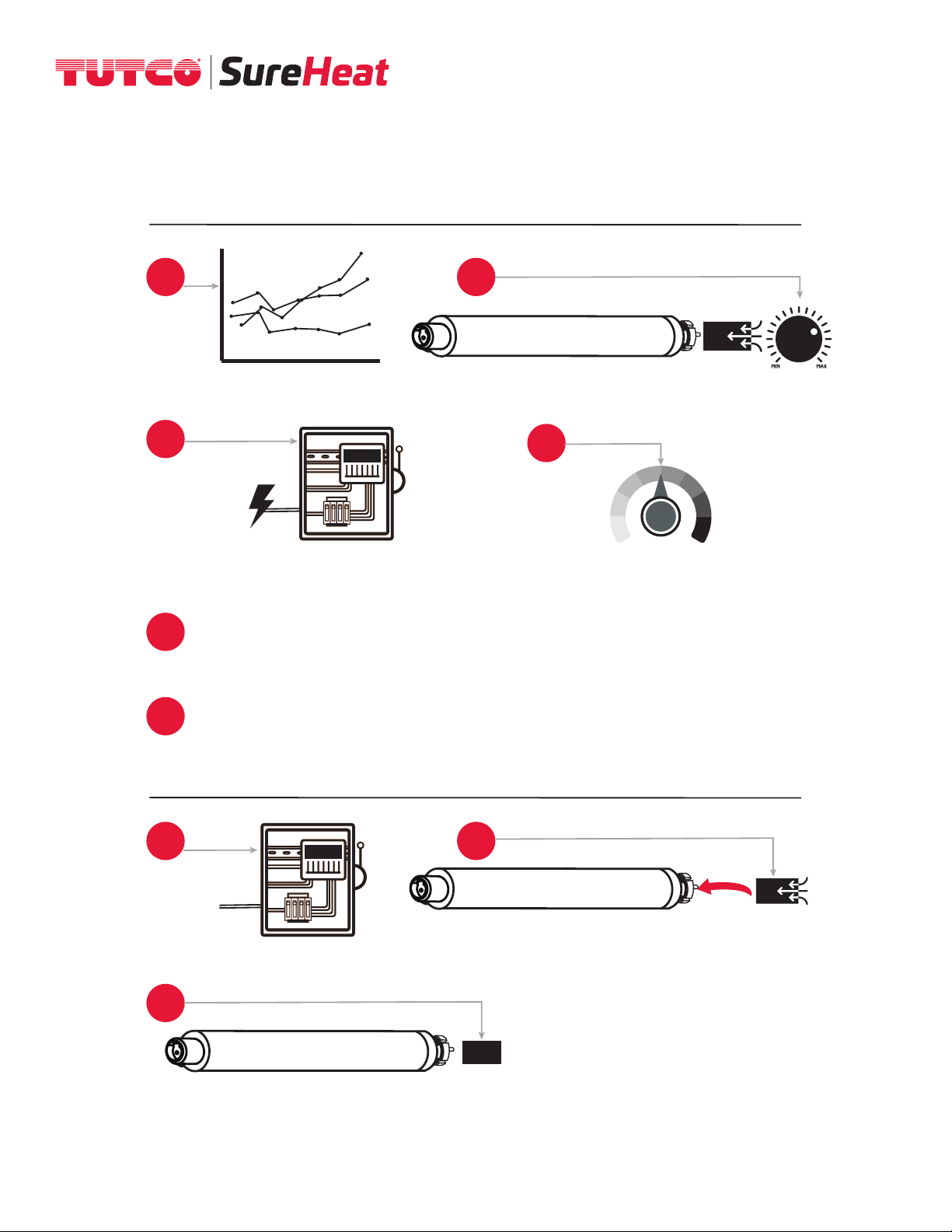

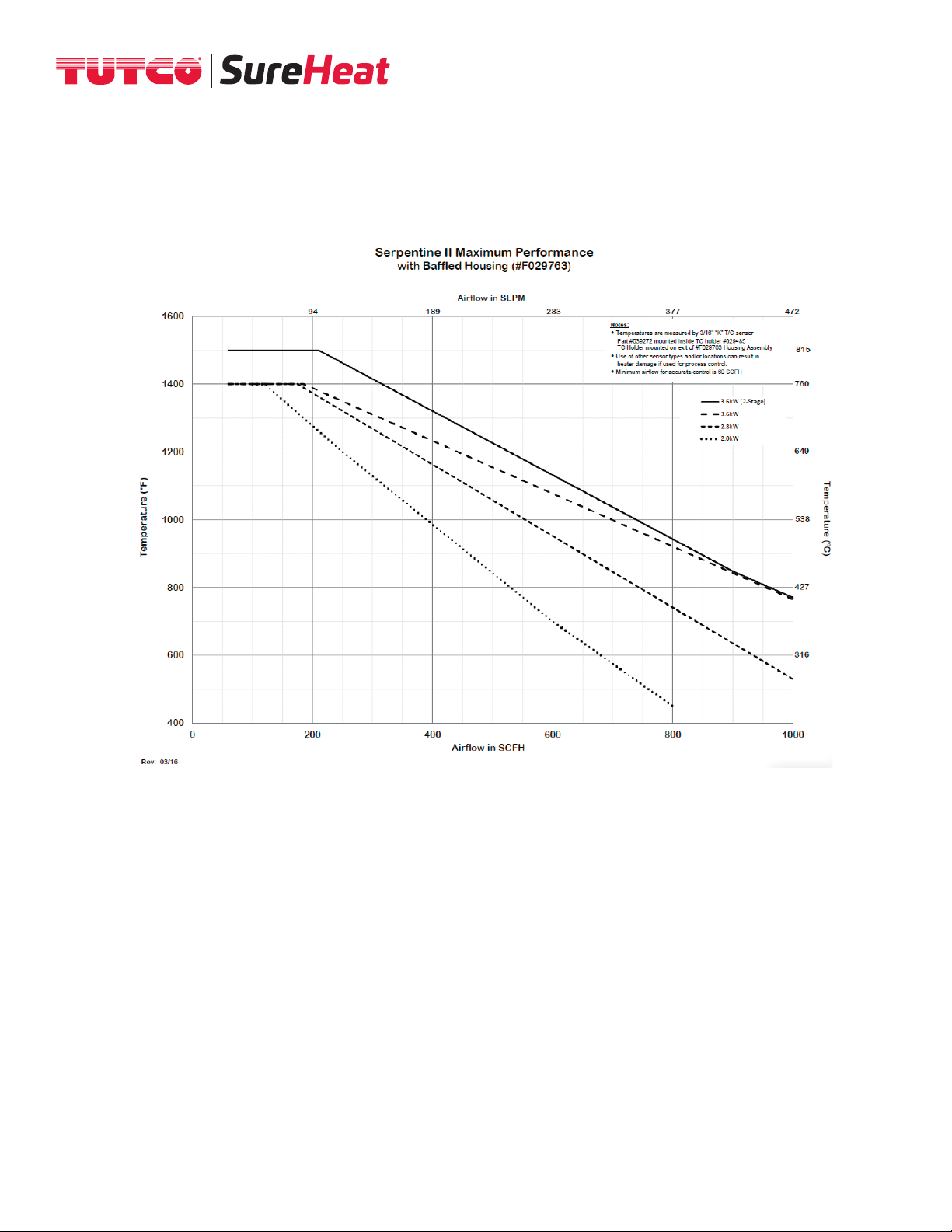

Compact and efficient process air/inert gas heater, capable of producing exit temperatures up to

1400°F (760°C) with standard elements, and up to 1500°F (815°C) with the “2-Stage” elements.

The heater unit consists of two parts - a replaceable serpentine-coil electric heater element,

which fits into a stainless steel “triple-pass” exchanger housing. This special housing uses the

incoming air to cool the outer shell prior to passing through the heater element. This not only

minimizes radiant heat losses but provides a cool outer shell, to minimize burn injury for

operators who accidentally contact the heater. Two heater sizes are available; the Serpentine II

(wattages from 2000 to 3600W) and the Serpentine VI (wattages from 5000 to 8000W). If

operated correctly, element life will be greater than 5000 hours.

SERPENTINE HEATER SPECIFICATIONS

Maximum Inlet Air Pressure 25 PSI (1.7 BAR)*

Maximum Inlet Air Temperature 200°F (93°C)

Maximum Exit Air Temperature 1400°F (760°C) Single Stage

1500°F (815°C) Two-Stage

(see page 10 for Performance Curves)

Minimum Airflow (Recommended) 60 SCFH (28 SLPM) for Serpentine II models

120 SCFH (57 SLPM) for Serpentine VI models

GENERAL INFORMATION

Environmental Conditions:

Ambient Temperature 32°F to 104°F (0°C to 40°C)

Humidity 0% to 95% R.H.

Ventilation:

Use in a well-ventilated area away from excess dust, dirt, and moisture.

Cleaning:

With unit OFF and unplugged, exterior surfaces may be wiped clean using a dry, lint-free cloth.

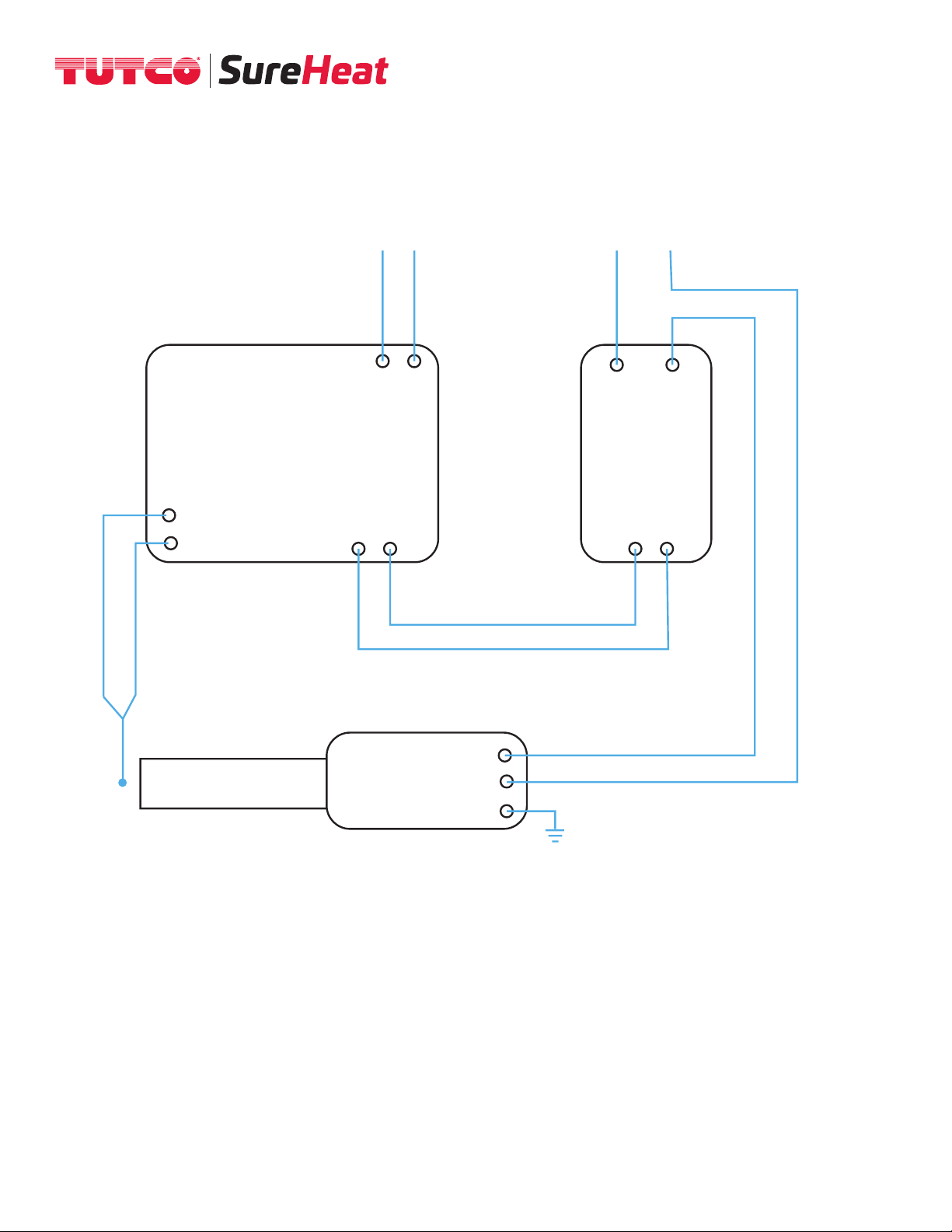

Protective Grounding:

Each heater comes with a convenient grounding stud and hardware located at the inlet of the

heater for earth ground.

2