2

Description

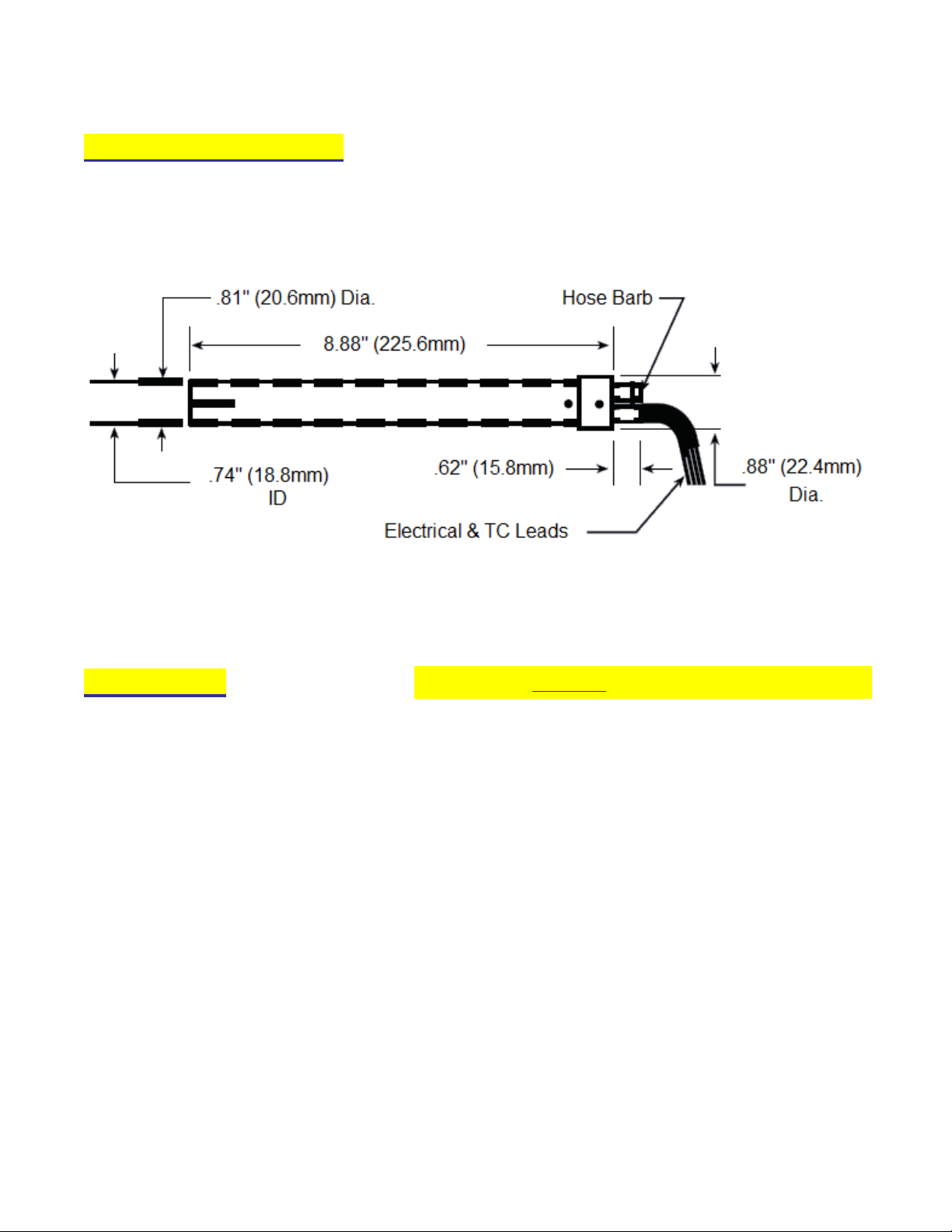

Compact, efficient heater with stainless steel housing and positive hose-barb air connection for heating air or inert

gases to 1400°F (760°C). Built in “K” Thermocouple allows for closed-loop control of temperature to ±1°F of set

point. If operated correctly, the heater will operate continuously for 5000 hours or longer.

Limited Warranty

Tutco SureHeat warrants that all products to be delivered hereunder will be free from defects in material and

workmanship at the time of delivery. Tutco SureHeat’s obligation under this warranty shall be limited to (at its

option) repairing, replacing, or granting a credit at the prices invoiced at the time of shipment for any of said

products. This warranty shall not apply to any such products which shall have been repaired or altered, except

by Tutco SureHeat, or which shall have been subjected. Tutco SureHeat shall be liable under this warranty

only if (A) Tutco SureHeat receives notice of the alleged defect within sixty (60) days after the date of

shipment; (B) the adjustment procedure hereinafter provided is followed, and (C) such products are, to Tutco

SureHeat’s satisfaction, determined to be defective.

THE WARRANTY SET FORTH IN THE PRECEDING PARAGRAPH IS EXCLUSIVE AND IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION, ANY IMPLIED

WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR OF MERCHANTABILITY.

The information contained in this manual is based on data considered to be true and accurate.

Reasonable precautions for accuracy has been taken in the preparation of this manual, however Tutco

SureHeat assumes no responsibility for any omissions or errors, nor assumes any liability for damages that

may result from the use of the product in accordance with the information contained in this manual.

Please direct all warranty/repair requests or inquiries to the place of purchase, and provide the following

information, in writing:

(A) Order number under which products were shipped

(B) Model/Serial Number of product

(C) Reason for rejection

PRODUCTS CAN NOT BE RETURNED TO TUTCO SUREHEAT WITHOUT AUTHORIZATION.

Replacement, repair, or credit for products found to be defective will be made by the place of purchase. All

products found to be not defective will be returned to the Buyer; transportation charges collect or stored at Buyer’s

expense.