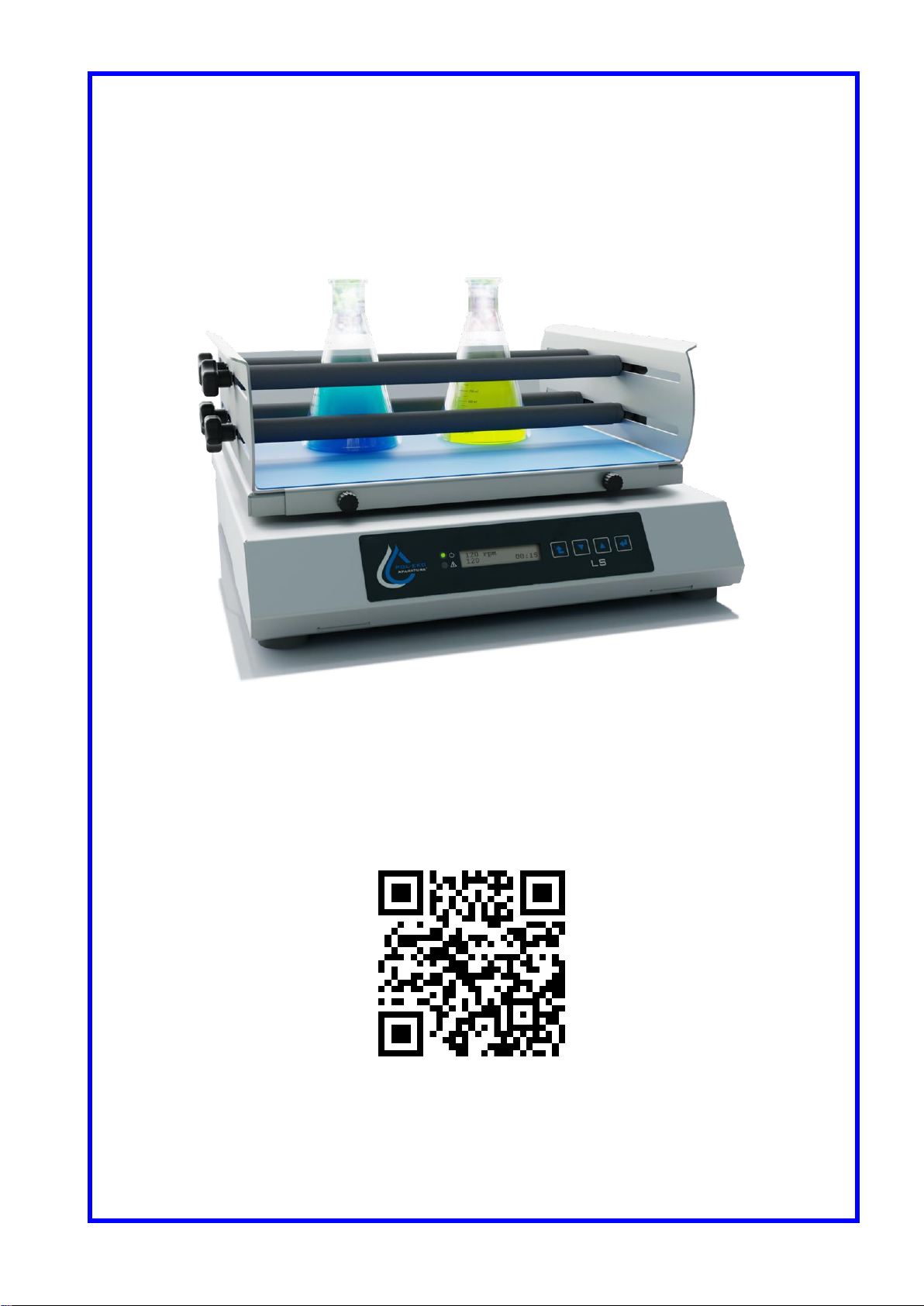

Instruction Manual LS 280 / 350 / 500 / 700

POL-EKO-APARATURA sp.j. • ul. Kokoszycka 172 C • 44-300 Wodzisław Śl. • tel./fax +48/ 32 453 91 70 • e-mail info@pol-eko.com.pl

10

7 CLEANING AND MAINTENANCE

Before cleaning the unit, it must be unplugged as it might cause an electric shock.

To preserve aesthetic exterior of the unit, it must be cleaned from time to time. Enamel elements and a panel

should be cleaned with a cloth damped in warm water. The user should secure the unit from getting the water to

the interior of the unit, power switch and socket in the unit. To remove stubborn dirt the user can use water with

detergent.

To assure failure-free and long-lasting work the user should maintain the unit periodically. The maintenance is

carried out by POL-EKO-APARATURA service. If you want the maintenance work to be performed, call +48 32

453 91 70, +48 32 453 91 96 or mail to us.

If the unit is not used for a long period of time

In the case of longer shut-down, the unit should be switched off by using power switch which is located at the

back part of the unit. The unit should also be unplugged.

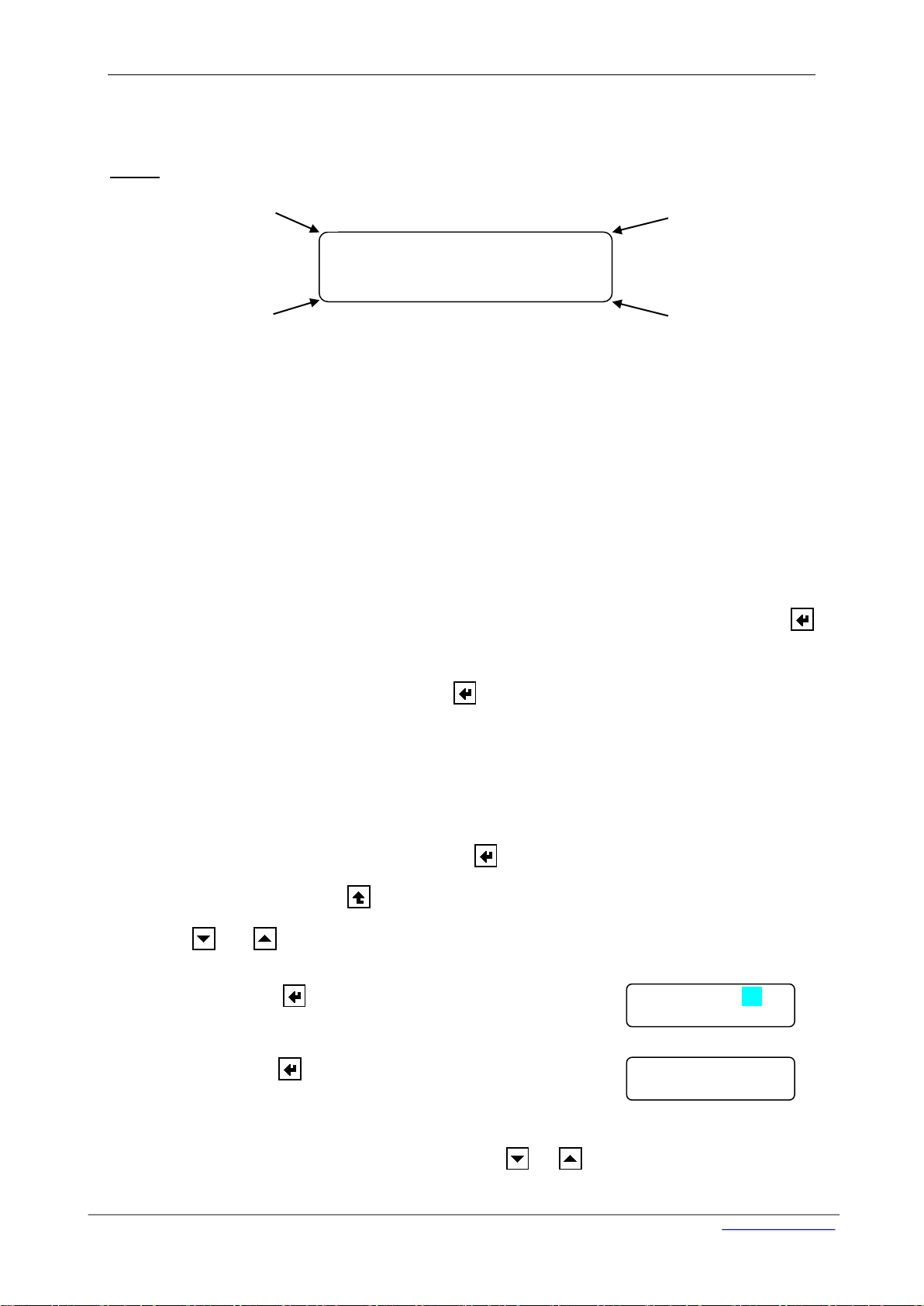

8 DIFFICULTIES WITH THE UNIT

The list of faults and description of the activities before calling the service is given below.

The unit does not turn

on

Mains cable is bent or damaged

The unit is not connected to any power supply

Plug the unit into wall socket ( 230V)

The button switch at the back of the unit is not

activated

Activate the button switch to the “I” posi-

tion.

Active program (blue

LED is blinking), unit is

not working

Switch off and on the unit . If the

plate/table does not work, call the service.

Set the continuous program so that the unit

works continuously

unit has stopped, red

LED is blinking

Remove the excess overload from the

plate/table

The plate/ table cannot rotate easily

Remove objects that are around the unit

and can disturb the work of the plate/table.

The plate/table is not overloaded

Switch off and on the unit . If the unit does

not work, call the service.

„Power failure…” mes-

sage, red LED on

Power failure encountered

Press down . The shaker Works cor-

rectly.

If the unit does not work properly, contact us +48 32 453 91 70, +48 32 453 91 96, or mail to us serwis@pol-

eko.com.pl. An application form should contain information about the unit (model, type, purchase date, installa-

tion place) and possibly the most precise description of the defect. This information enables to solve the problem

quickly and efficiently.