E| 3

twall®Compact32 mobile/stationary | User Manual Rev. 1.0

Table of contents:

1 Product description---------------------------------------------------------------------------------------- 4

1.1 Normal use --------------------------------------------------------------------------------------------------------4

2 Product Contents -------------------------------------------------------------------------------------- 5

2.1 Summary of the product contents for the twall®Compact32 mobile ----------------------------------5

2.1.1 Detailed list of the product contents for each assembly step --------------------------------------------5

2.2 Summary of the product contents for the twall®Compact32 stationary -----------------------------7

2.2.1 Detailed list of the product contents for each assembly step --------------------------------------------7

3 Assembly ------------------------------------------------------------------------------------------------------- 9

3.1 Assembling the twall®Compact32 mobile -------------------------------------------------------------------9

3.1.1 Requirements in terms of floor space ------------------------------------------------------------------------9

3.1.2 Assembly principles for the profile connectors -------------------------------------------------------------9

3.1.3 Assembly instructions -----------------------------------------------------------------------------------------10

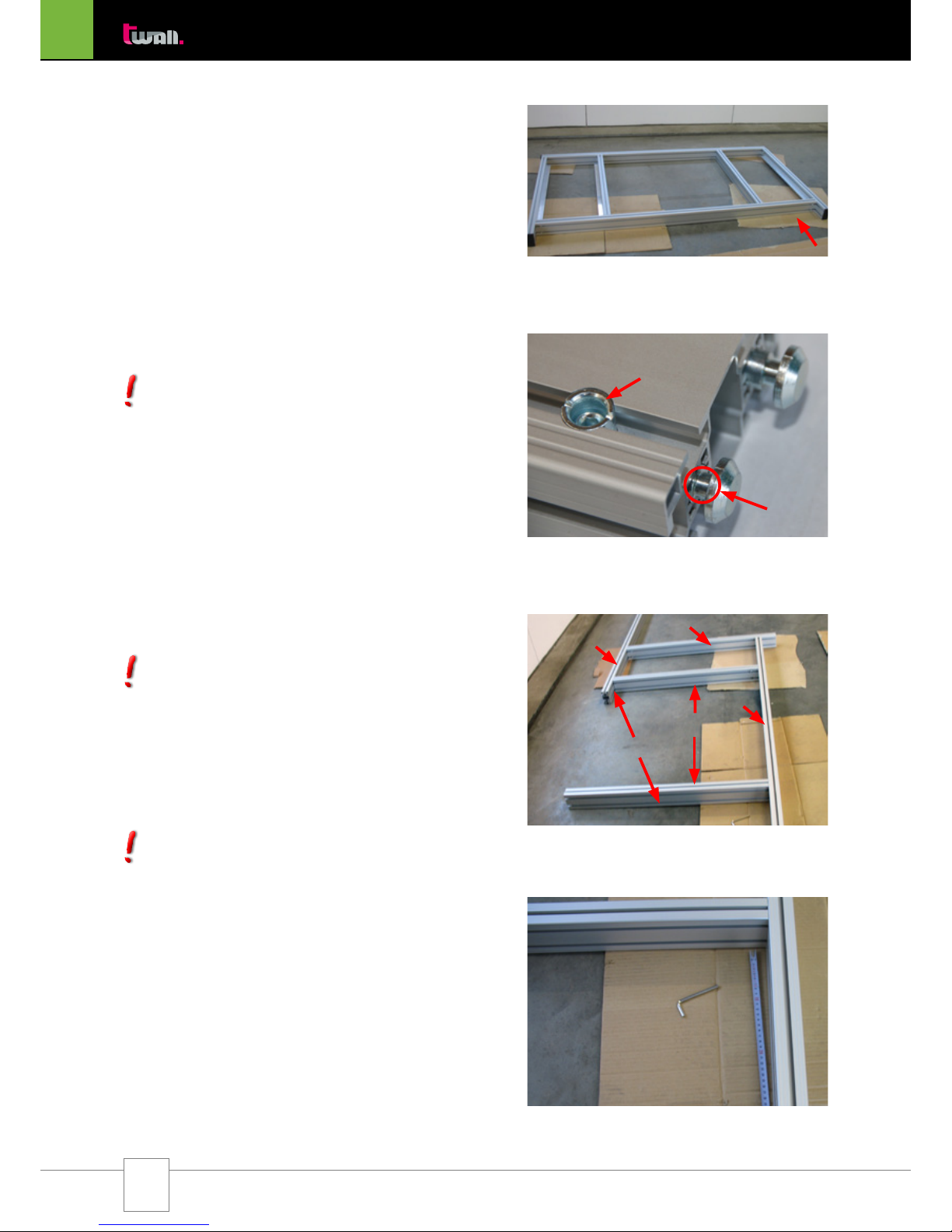

3.1.3.1 Assembling the frame base ---------------------------------------------------------------------------------- 10

3.1.3.2 Assembling the universal wall -------------------------------------------------------------------------------12

3.1.3.3 Assembling the pushbutton modules ---------------------------------------------------------------------- 15

3.2 Assembling the twall®Compact32 stationary -------------------------------------------------------------- 17

3.2.1 Requirements in terms of floor space --------------------------------------------------------------------- 17

3.2.2 Assembly instructions -----------------------------------------------------------------------------------------17

3.2.2.1 Assembling the universal wall ------------------------------------------------------------------------------ 17

3.2.2.2 Assembling the pushbutton modules ---------------------------------------------------------------------- 20

4 Maintenance -------------------------------------------------------------------------------------------------21

5 Troubleshooting -------------------------------------------------------------------------------------------21

6 Technical data -----------------------------------------------------------------------------------------------22

6.1 Datasheet for twall®Compact32 mobile and stationary ----------------------------------------------- 22

6.2 Datasheet for accessories -------------------------------------------------------------------------------------22

7 Operating the twall® without a computer -------------------------------------------------------23

7.1 Executing twall® programmes ------------------------------------------------------------------------------ 23

7.2 Viewing high scores -------------------------------------------------------------------------------------------24

7.3 Settings ---------------------------------------------------------------------------------------------------------- 24

8 Operating the twall® with a computer-------------------------------------------------------------25

8.1 Connecting to the computer ---------------------------------------------------------------------------------25

8.2 Driver installation ---------------------------------------------------------------------------------------------- 25

8.2.1 Driver installation under Microsoft Windows XP -------------------------------------------------------- 25

8.2.2 Driver installation under Microsoft Windows Vista® ----------------------------------------------------- 26

8.2.3 Driver installation under Windows 7® ---------------------------------------------------------------------- 27

8.3 Software installation ------------------------------------------------------------------------------------------ 28

8.4 Description of the software ----------------------------------------------------------------------------------29

8.4.1 The start page -------------------------------------------------------------------------------------------------- 29

8.4.2 Programme settings ------------------------------------------------------------------------------------------- 29

8.4.3 Executing twall® programmes ------------------------------------------------------------------------------- 29

8.4.3.1 Saving programmes on the twall® -------------------------------------------------------------------------- 30

8.4.3.2 High scores ------------------------------------------------------------------------------------------------------31

8.4.4 Simulating new twall® programmes ------------------------------------------------------------------------ 31

8.4.5 Creating new twall® programmes -------------------------------------------------------------------------- 32

8.4.6 Editing twall® programmes ---------------------------------------------------------------------------------- 34

8.4.7 Editing sound sets --------------------------------------------------------------------------------------------- 34

8.5. Firmwareupdate ------------------------------------------------------------------------------------------------35

9 Service ---------------------------------------------------------------------------------------------------------36

Annex: Exploded views

Software Documentation Hardware Documentation