TFP260

Page 4 of 4

NATIONAL FIRE PROTECTION ASSOCIATION and NFPA are registered trademarks of National Fire Protection Association;

TEFLON is a registered trademark of DuPont

1400 Pennbrook Parkway, Lansdale, PA 19446 | Telephone +1-215-362-0700

© 2018 Johnson Controls. All rights reserved. All specifications and other information shown were current as of document revision date and are subject to change without notice.

Care and

Maintenance

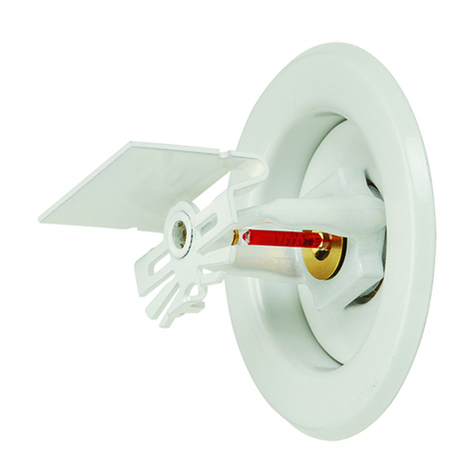

The TYCO Series RFII, 5.6 K-factor,

Royal Flush Concealed Pendent Sprin-

klers, (TY3532) must be maintained

and serviced in accordance with this

section.

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system

that it controls, obtain permission to

shut down the affected fire protec-

tion system from the proper authorities

and notify all personnel who may be

affected by this action.

Absence of the Cover Plate/Retainer

Assembly can delay sprinkler opera-

tion in a fire situation.

When properly installed, there is a

nominal 3/32 in. (2,4 mm) air gap

between the lip of the Cover Plate and

the ceiling, as shown in Figure 2. This

air gap is necessary for proper oper-

ation of the sprinkler. If the ceiling

requires repainting after sprinkler instal-

lation, ensure that the new paint does

not seal off any of the air gap.

Do not pull the Cover Plate relative to

the Enclosure. Separation may result.

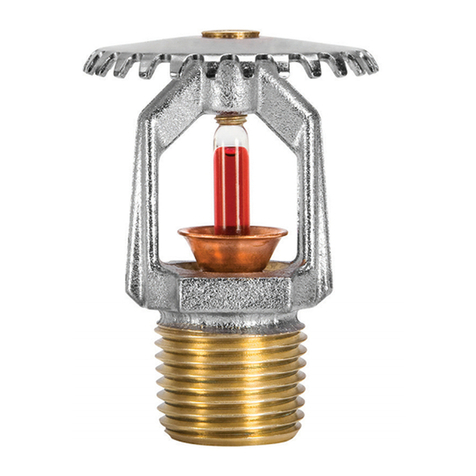

Replace sprinklers that are leaking or

exhibiting visible signs of corrosion.

Never repaint, plate, coat, or otherwise

alter automatic sprinklers after they

leave the factory. Never repaint fac-

tory-painted Cover Plates. If neces-

sary, replace them with factory-painted

units. Non-factory applied paint can

adversely delay or prevent sprinkler

operation in the event of a fire.

Replace modified or over-heated

sprinklers.

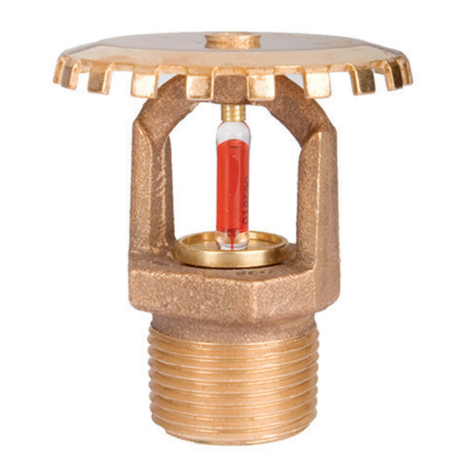

Exercise care to avoid damage to

the sprinklers before, during, and

after installation. Replace sprinklers

damaged by dropping, striking, wrench

twisting, wrench slipping, or the like.

Also, replace any sprinkler that has

a cracked bulb or that has lost liquid

from its bulb. Refer to the Installation

Section.

If you must remove a sprinkler, do not

reinstall it or a replacement without

reinstalling the Cover Plate/Retainer

Assembly. If a Cover Plate/Retainer

Assembly becomes dislodged during

service, replace it immediately.

The owner is responsible for the

inspection, testing, and maintenance of

their fire protection system and devices

in compliance with this document, as

well as with the applicable standards

of the NATIONAL FIRE PROTECTION

ASSOCIATION - for example, NFPA 25 -

in addition to the standards of any other

authorities having jurisdiction. Contact

the installing contractor or product

manufacturer with any questions.

Automatic sprinkler systems should

be inspected, tested, and maintained

by a qualified Inspection Service in

accordance with local requirements

and/or national code.

Limited

Warranty

For warranty terms and conditions, visit

www.tyco-fire.com.

Ordering

Procedure

Contact your local distributor for

availability. When placing an order,

indicate the full product name and Part

Number (P/N).

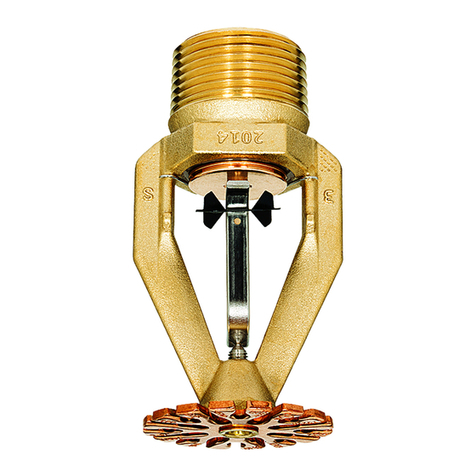

Sprinkler/Support Cup Assembly

Specify: Series RFII Royal Flush Con-

cealed Pendent Sprinkler, TY3532,

(specify) temperature rating, P/N

(specify):

155°F (68°C)

TY3532...................... 51-794-1-155

200°F (93°C)

TY3532......................51-794-1-200

Separately Ordered Cover Plate/

Retainer Assembly

Specify: (temperature rating, listed

below) Series RFII Concealed Cover

Plate with (finish), P/N (specify):

139°F (59°C)(a)

Grey White (RAL9002) . . . . . . . . . . 56-792-0-135

Brass .......................56-792

-

1-135

Pure White(c) (RAL9010). . . . . . . . . 56-792-3-135

Signal White (RAL9003)

. . . . .

56-792-4-135

Jet Black (RAL9005) . . . . . . . . . . . 56-792-6-135

Chrome......................56-792-9-135

Custom......................56-792-X-135

165°F ( 74°C) (b)

Grey White (RAL9002) . . . . . . . . . . 56-792-0-165

Brass .......................56-792-1-165

Pure White(c) (RAL9010 ). . . . . . . . . 56 -792-3-165

Signal White (RAL9003). . . . . . . . . 56 -792- 4-165

Jet Black (RAL9005) . . . . . . . . . . . 56-792-6-165

Chrome......................56-792-9-165

Custom......................58-792-X-165

a. For use with 155°F (68°C) sprinklers

b. For use with 200°F (93°C) sprinklers

c. Eastern Hemisphere sales only

Sprinkler Wrench

Specify: RFII Sprinkler Wrench,

P/N 56-000-1-075