Page 3

Safety

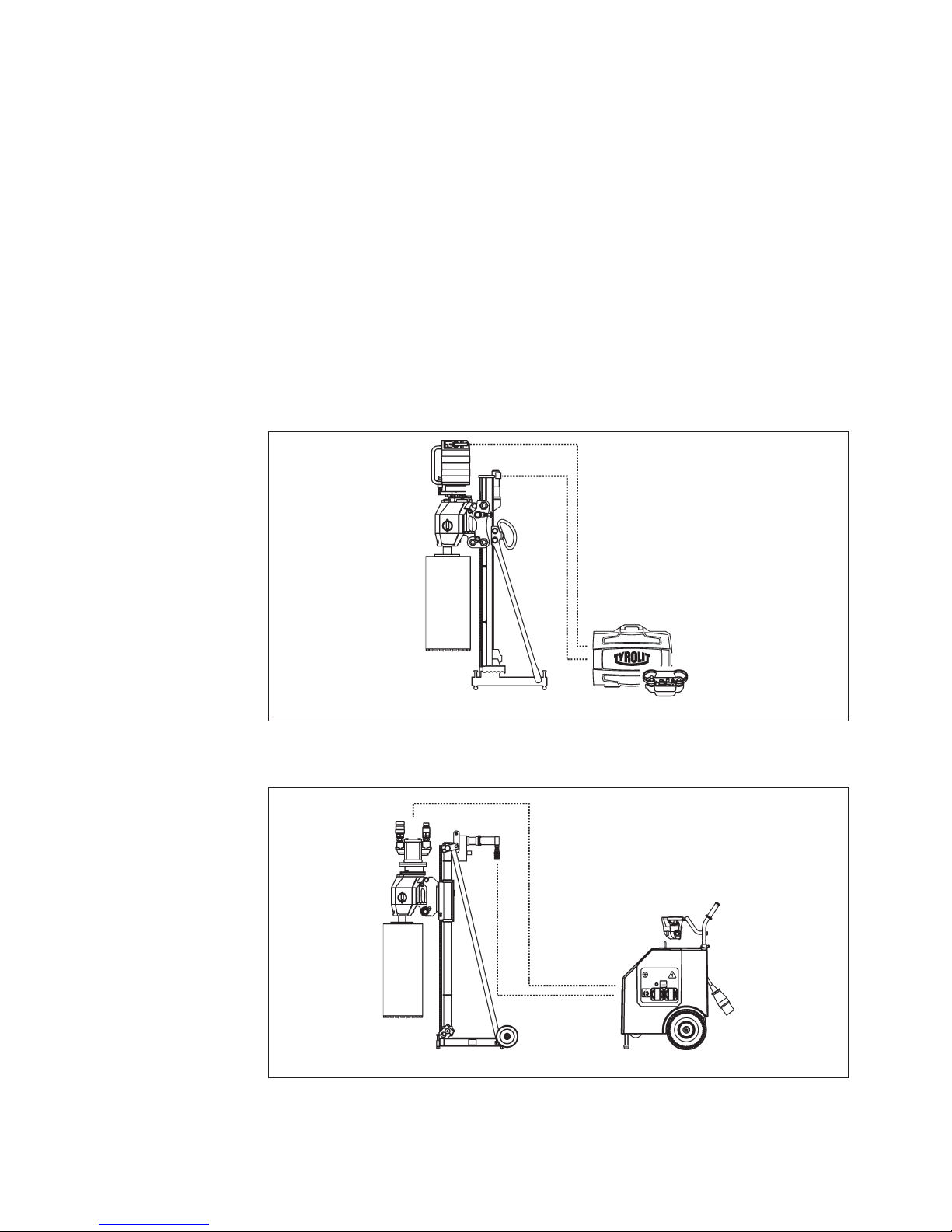

These instructions are just one part of the documentation which is supplied together with the

drilling gearbox. These instructions go together with the "Core Drill Safety Manual / System De-

scription" to form a complete set of documentation.

DANGER

Failure to comply with the safety instructions in the "Safety Manual / System Handbook" may

result in serious injury or even death.

XPlease ensure that the "Safety Manual / System Description for Core Drilling" has been read

and understood in full.

DANGER

Risk of cutting injuries from the drill bit!

XSafety gloves must be worn when working on core drilling equipment, particularly the drill

bit.

DANGER

Risk of serious injuries from using excessive speed!

XPlease ensure that the correct speed has been selected using gear 1 or 2 before starting.

For speed table see pages 12 and 13.

DANGER

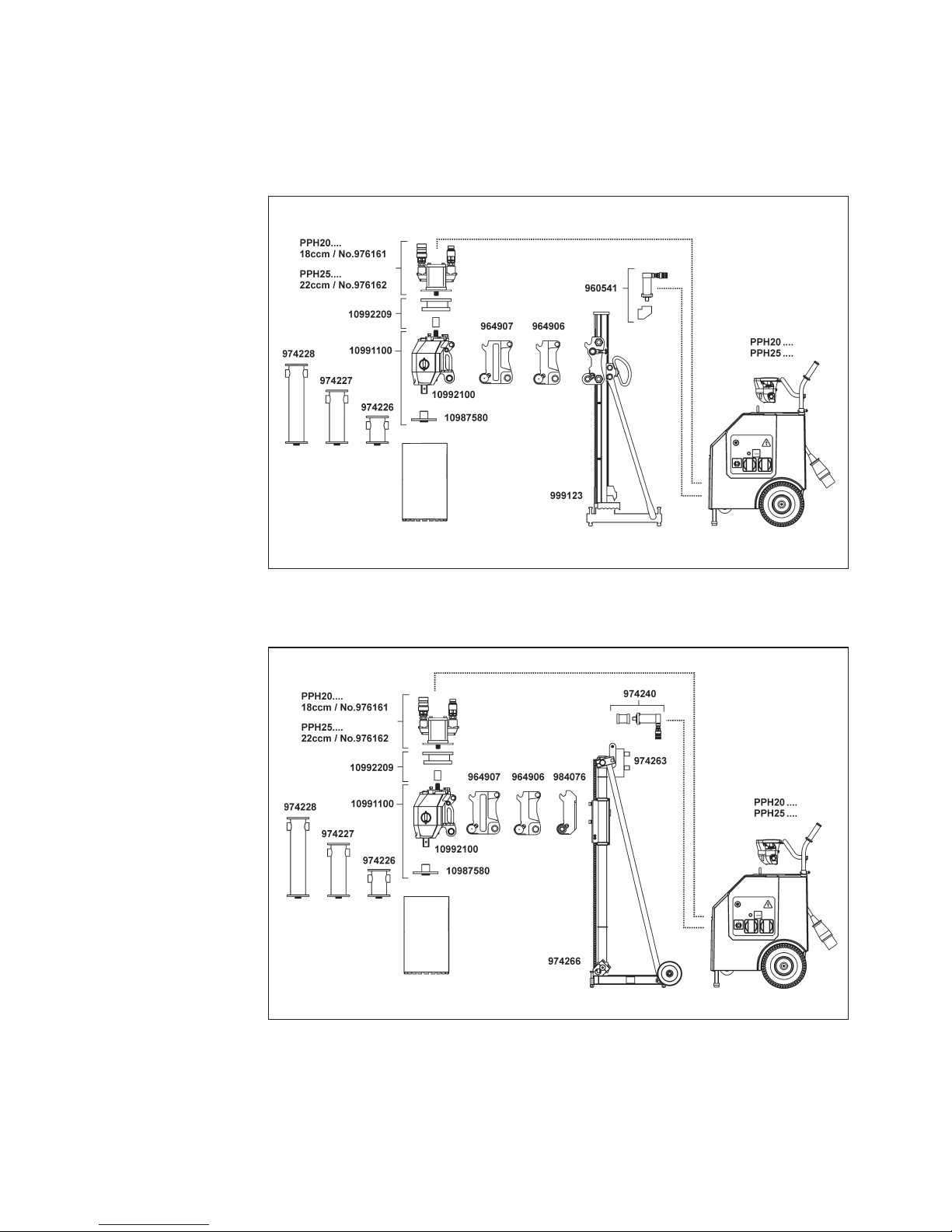

Risk of serious injuries from using system components that are too weak!

XOnly use approved TYROLIT Hydrostress system components

For approved system components see pages 6 and 7.

1