2

1. General Information

1.1) Models

Note: International font can be combined with others languages, for example

PRP-076C-BI-M-S, with cutter, Big5+International, beige, serial interface.

1.2) Features

Main Features:

-3.5 characters line/sec / 4.5 characters line/sec (32 bit ARM CPU)

-76 mm ± 5 mm Max. label width

-Low-noise dot matrix printing

-High reliability due to a stable mechanism

-Command protocol is based on the ESC/POS standard

-Support black mark anchor testing print

-Various Layouts are possible by using page mode

-Repeated operation and copy printing are possible

-Easy paper-roll installation

-Easy paper jam clearance

-Easy maintenance for tasks such as head cleaning

-Built-in interface provides control capability for cash drawer

Available fields:

-Print POS system receipts

-Print EFT POS system receipts

-Print gym, post, hospital, civil aviation system receipts

-Print inquiry, service system receipts

-Print instrument test receipts

-Print tax, tab receipts

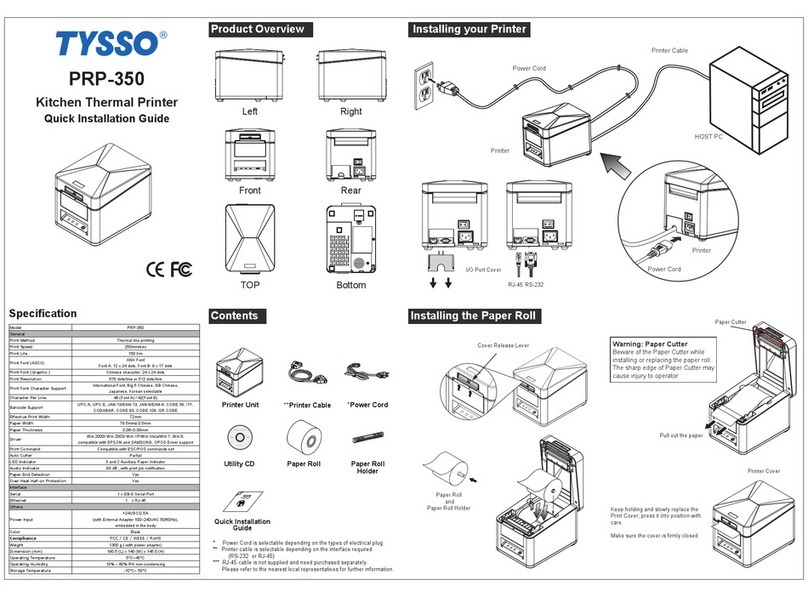

2. Quick Start