0411 IH-2957PAGE 3 OF 17

SYSTEM SET-UP

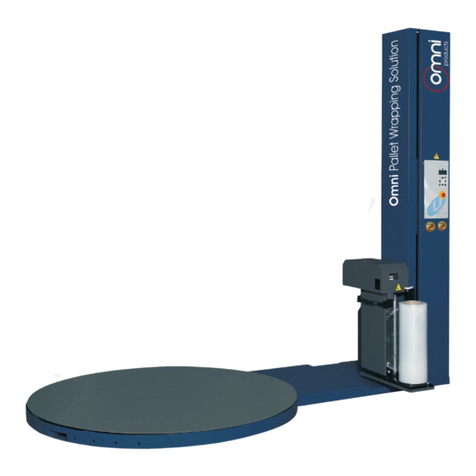

MACHINE PLACEMENT

Place the Automatic Stretch Wrap Machine close to

an area where you will be wrapping your pallet loads.

Make sure that there is sufficient room to load/unload

the machine and that you do not stretch the wiring

cable. Remember, you will need to provide electrical

service to a 120 VAC, 15-AMP outlet.

FLOOR WEIGHT BEARING TOLERANCE

The floor must be able to bear the weight of the

machine, the weight of the maximum load, plus a safety

factor. The floor must also be able to tolerate the stress

of the machine’s operation. If the fork trucks will operate

on the same weight bearing area, add the weight

of the trucks to the weight bearing stress tolerance

requirements.

WARNING! The Stretch Wrap Machine must be

anchored securely to the floor, using the type

of anchor recommended for your floor.

MACHINE SET-UP

1. Place skidded machine close to the designated

wrap area. Remove all shipping fasteners holding

the machine to the pallet. The machine may be

crated with the tower tilted down with the motor

cover front carriage roller removed for shipping

purpose.

2. Place forks of the forklift through the tubes provided

at the rear base of the module, remove the machine

from these skids, and place it at the designated

wrap area.

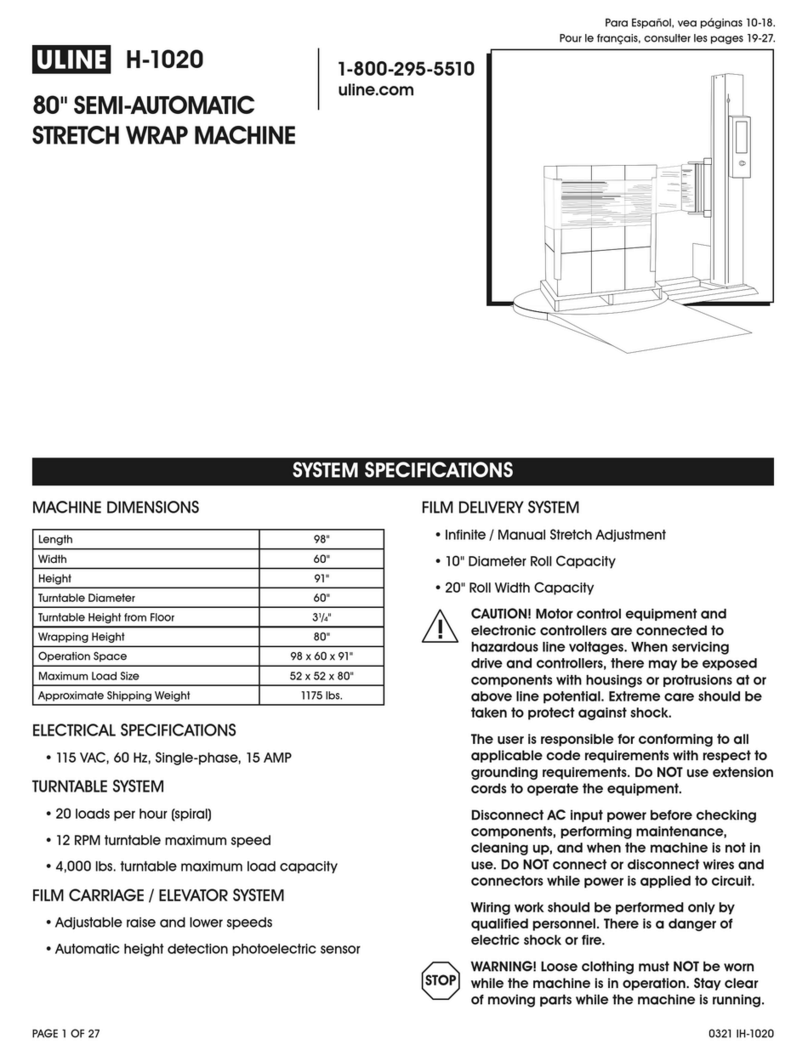

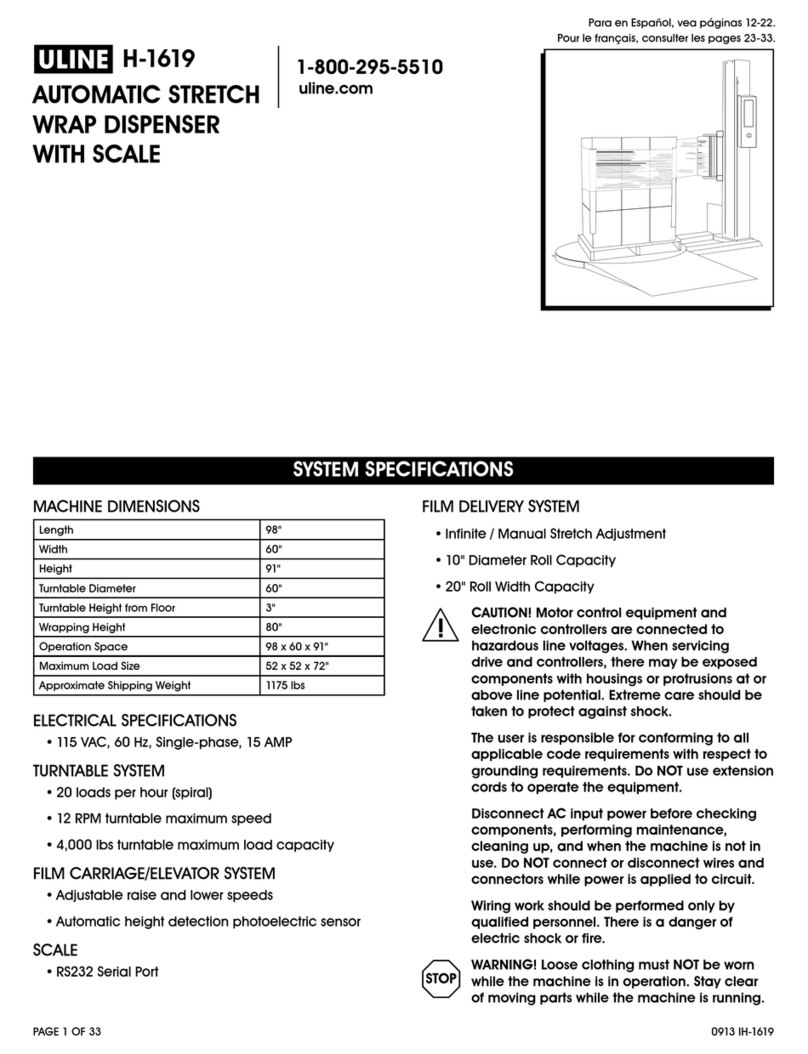

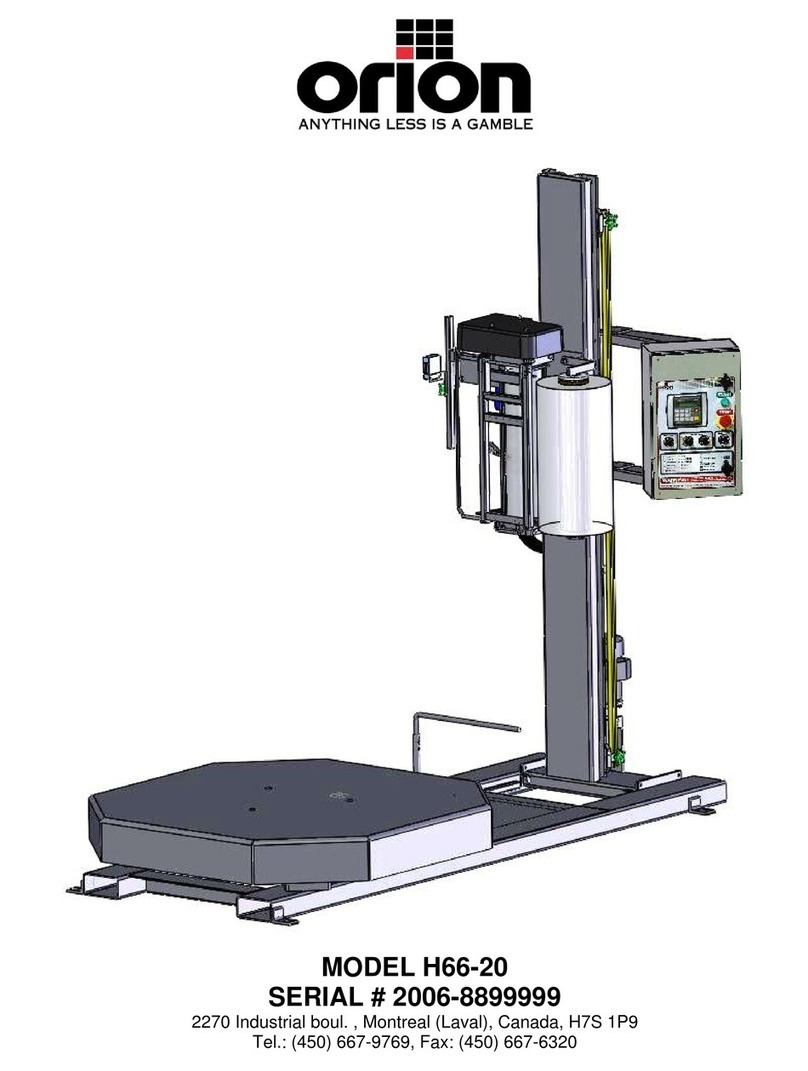

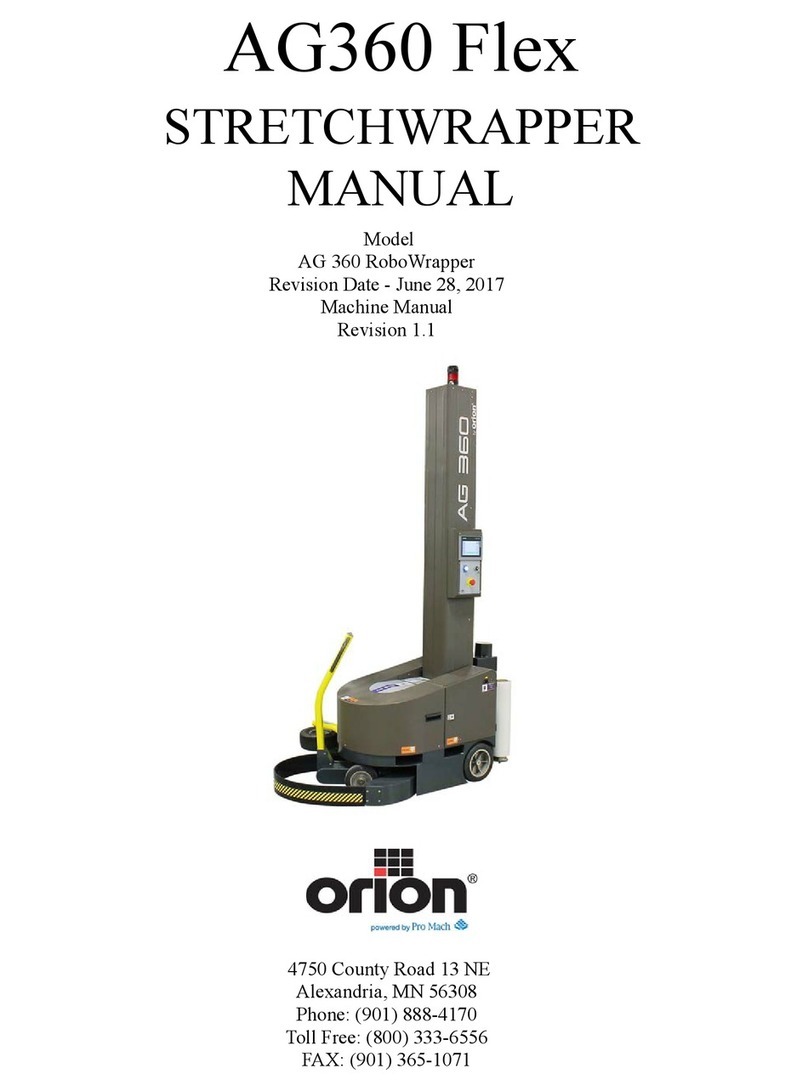

3. If the optional ramp (H-2958) is purchased:

Select a ramp position as illustrated below. The

ramp can be positioned anywhere in a 180° rotation

around the front of the turntable. There should be a

¼" gap between the turntable and the ramp. The

ramp should be fully supported by the floor. Both the

ramp and the machine should be lagged to the floor.

POWER AND SAFETY WIRING CHECKS

1. Using a voltage meter, check the AC voltage

coming to the system to insure proper voltage is

present.

2. Make sure the "E-STOP" button is pressed in. Turn the

disconnect switch to ON position.

3. Pull the "E-STOP" button on the operator panel out.

Power should be applied to the frequency drives,

operating touch-panel, photoelectric sensors,

switches, and LED’s.

4. Press the "E-STOP" button. Make sure all machine

power is completely removed when the "E-STOP" is

depressed. Pull the "E-STOP" button out to resume.

5. Open the film carriage door. Make sure all machine

power is completely removed when the carriage

door is open. Close the film carriage door to resume.

6. Open the electrical control box. Make sure all

machine power is completely removed when the

electrical control box is open. Close the electrical

control box to resume.

7. Trip the carriage foot security bar. Make sure all

machine power is completely removed when the

carriage foot security bar is tripped. Clear the bar to

resume.

PLC'S INPUT MODULE CHECKS

1. Open the electrical control box, and insert the key

latch onto the safety door switch.

2. Depress push buttons and activate selector

switches on the operator panel, check for each

corresponding input lights on the front face of PLC.

3. Block the "Product Height Detection" photoelectric

sensor (located on the film carriage), check for

corresponding input light on the front face of PLC.

4. Trigger magnetic proximity and limit switch sensors,

check each corresponding input lights on the front

face of the PLC.

WARNING! Do NOT remove or modify the fixed

upper and lower limit switch stops.

5. Remove the key latch, and close the electrical

control box to resume.

¼" Gap

180˚