3

Revised 05/12

SDC

Shaker Dust Collector

3. INSTALLATION

The SDC dust collection system ships standard in

two individual assemblies: the filter module and

hopper assembly. Additional accessories or options

(silencers, storage drums, afterfilter assemblies,

control panel assemblies, etc.) may be

packaged separately.

TIP OVER HAZARD

Lift the dust collector components by the packing

skids or the lifting locations provided on the filter

module. Do not lift the filter module of the dust

collector by placing lift truck forks through the filter

access door(s). This is unsafe and could result in

significant damage to the dust collector.

Upon receipt of your unit, check for any shipping

damage. A damaged carton indicates that the

equipment may have received rough handling during

shipping that could have caused internal damage to the

dust collector. Notify your delivery carrier and enter a

claim if any damage is found.

3.1 INSTALLATION PLANNING

The proper location of your dust collection equipment is

very important. Refer to Figure 2 for typical installation

details.

Certain items should be considered when locating the

unit, such as emptying of the dust storage drum(s), filter

removal requirements, access to the clean air plenum,

the shaker mechanism, electrical connections, and air

inlet and discharge location. The shortest duct length

with a minimum number of elbows and losses will

maximize the performance of the unit. Ease of

maintenance should also be considered when selecting

the location and orientation of the system.

In the case of spark-producing processes, system

design should incorporate measures to prevent live

sparks from entering the dust collector. Consult local

authorities for the location of the unit and any

additional precautions to consider when collecting

combustible, explosive or hazardous dusts. General

warning and cautions are provided on page ii and in

Section 1.

TIP OVER HAZARD

The SDC dust collector should be mounted on a solid,

level, reinforced concrete foundation. Other mounting

options are also possible. Each standard SDC unit

has been designed to meet Seismic Zone 4 and 100

MPH wind loading conditions. Structural calculations

for the foundation or other mounting arrangements

must include the weight of the collected material and

the weight of all auxiliary equipment installed with the

dust collector (ducting, silencers, afterfilter

assemblies, etc.). Consult a professional engineer

when designing the foundation for the unit.

Interconnecting ducting should be properly sized to

meet the recommended air velocities for the material

being collected. Follow ducting design methods as

listed in the

Industrial Ventilation Manual

, as

recommended by the American Conference of

Governmental Industrial Hygienists.

3.2 STANDARD EQUIPMENT ASSEMBLY

CRUSH AND ELECTROCUTION HAZARD

Use adequate safety measures when lifting and

assembling any heavy components. Consult your local

plant safety personnel for recommendations.

In preparing to attach the filter module to the hopper,

connect lifting slings and spreader bars to all filter

module lifting points with clevis pins. Use spreader

bars to distribute the load evenly. Location must be

clear of all obstructions, such as utility lines or roof

overhangs.

Remove all crating, strapping and hold-down bolts.

Locate all hardware bags, sealant and other assembly

materials provided with your unit.

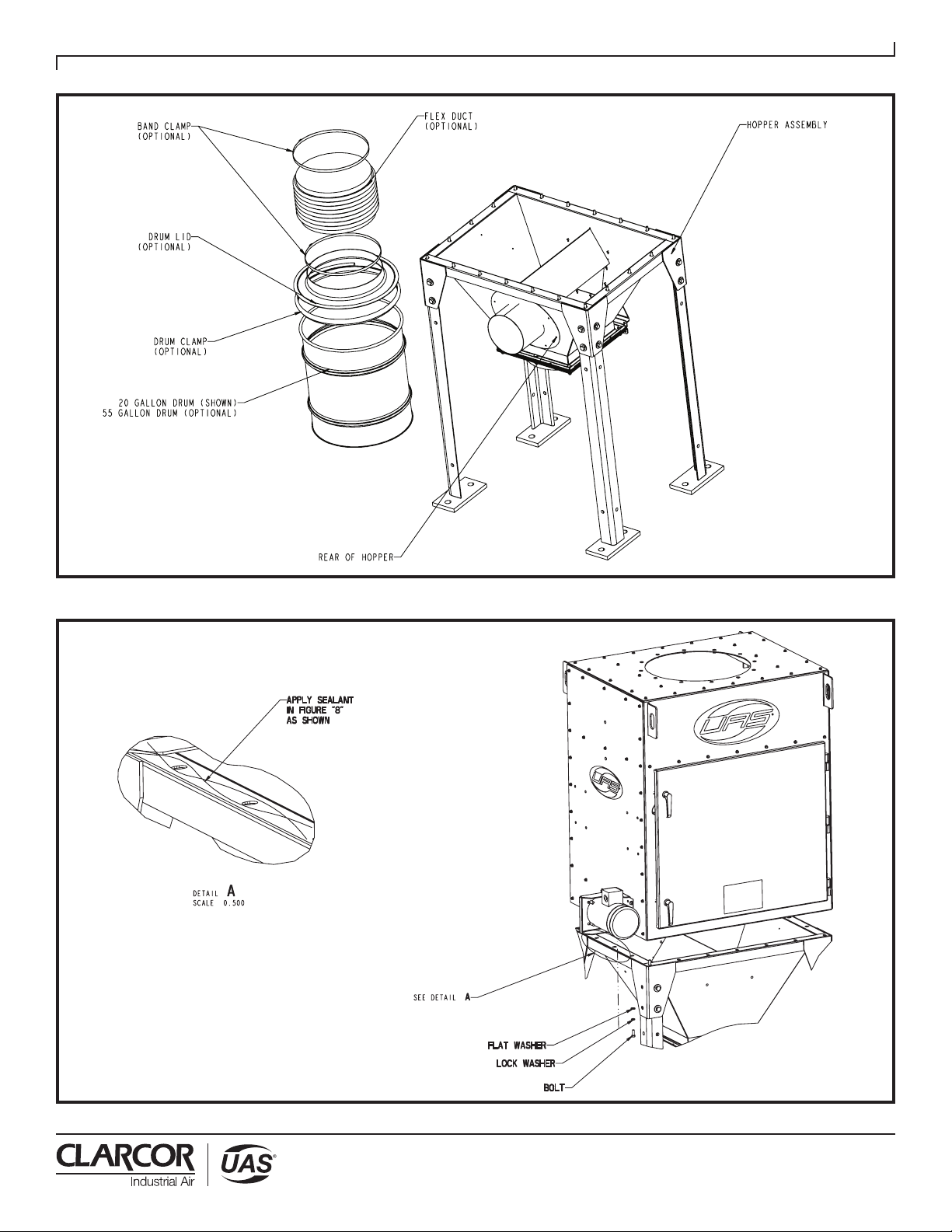

3.2.1 HOPPER ASSEMBLY

The SDC unit is designed to mount directly on top of the

hopper assembly. The hopper assembly consists of a

hopper bin, legs, sway-bracing (on larger models), optional

flex duct, hose clamps, 20 or 55-gallon drum, drum lid and

drum clamp. A hardware kit is also included to bolt the

filter module to the hopper.