AeroCut X / XPro SERVICE MANUAL

2

Contents

1Installation....................................................................................................4

1.1 Installing options(AeroCut X)............................................................. 4

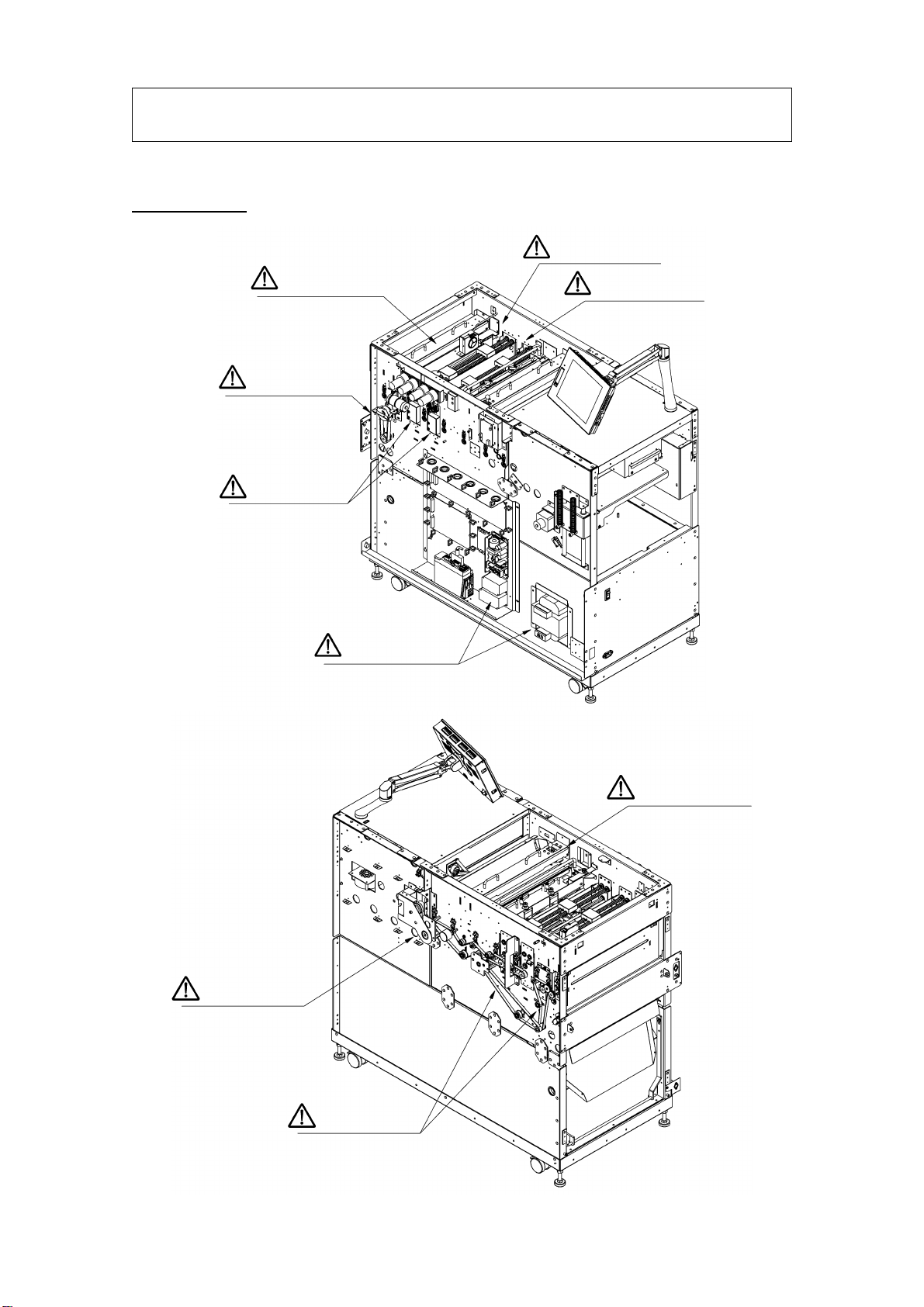

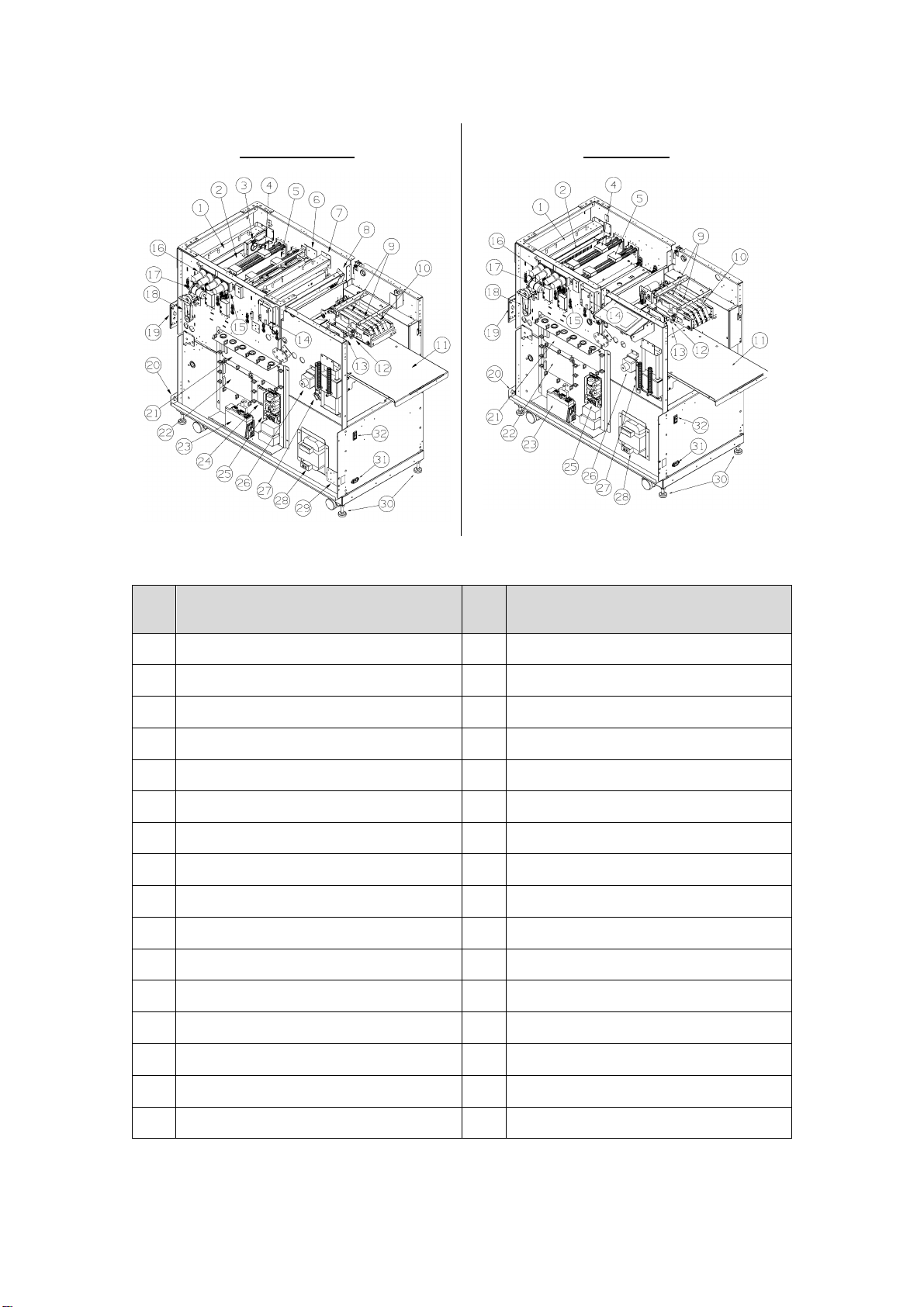

2General instruction .......................................................................................6

3Touch screen operation..............................................................................12

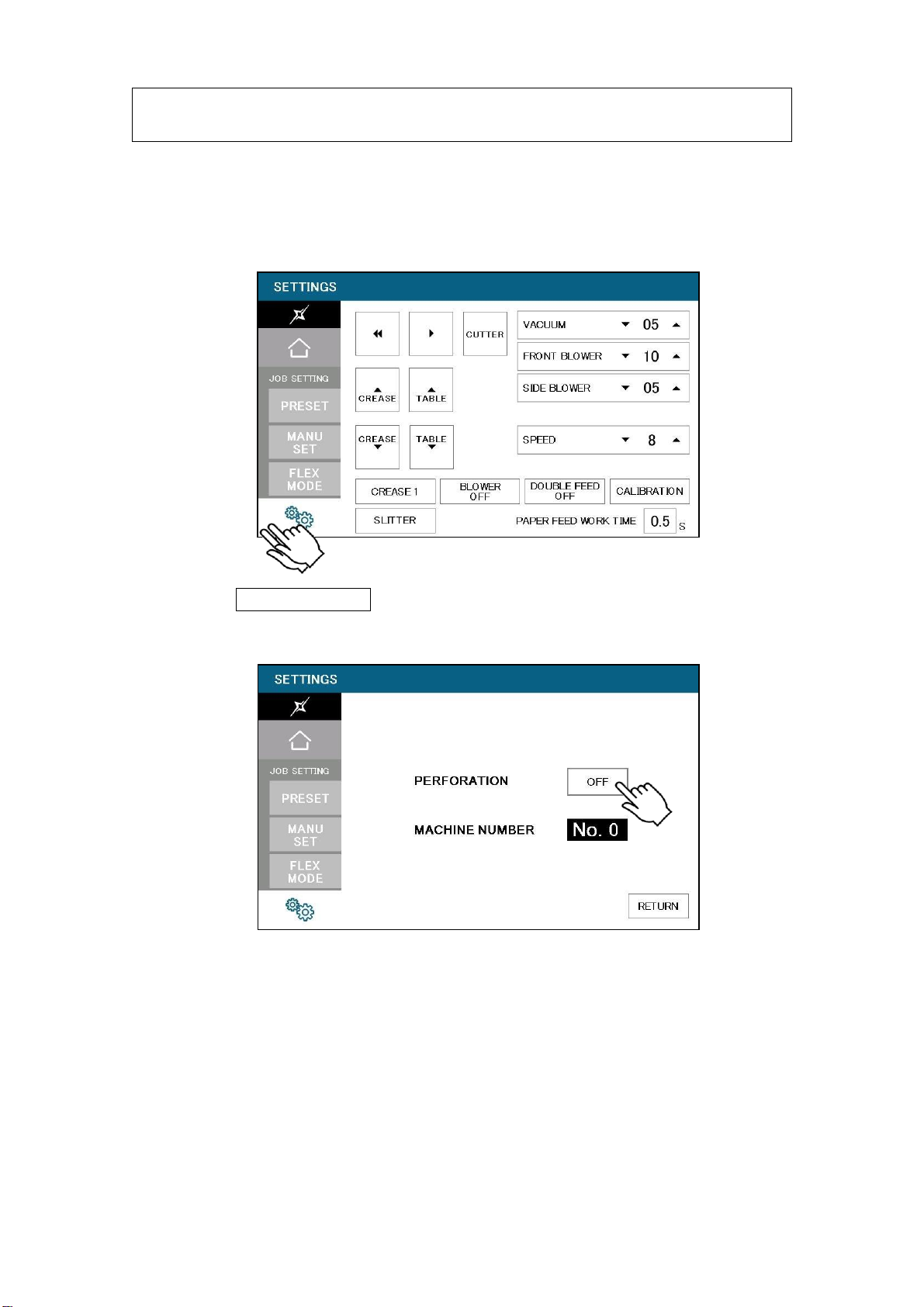

3.1 SERVICE MENU.................................................................................. 12

3.2 MANUAL OPERATION Screen ............................................................14

3.3 SPEED Screen ....................................................................................18

3.4 SLITTER Operation Screen .................................................................18

3.5 INPUT DATA CHECK Screen...............................................................19

3.6 LANGUAGE Screen.............................................................................26

3.7 MAINTENANCE Screen ......................................................................27

4Paper jam...................................................................................................29

5Replacement of parts ................................................................................. 31

5.1 Slitter Unit ............................................................................................ 31

5.2 Slitter head...........................................................................................33

5.3 Guillotine Unit.......................................................................................36

5.4 X-perforator blade ................................................................................37

5.5 Y-perforator blade ................................................................................ 39

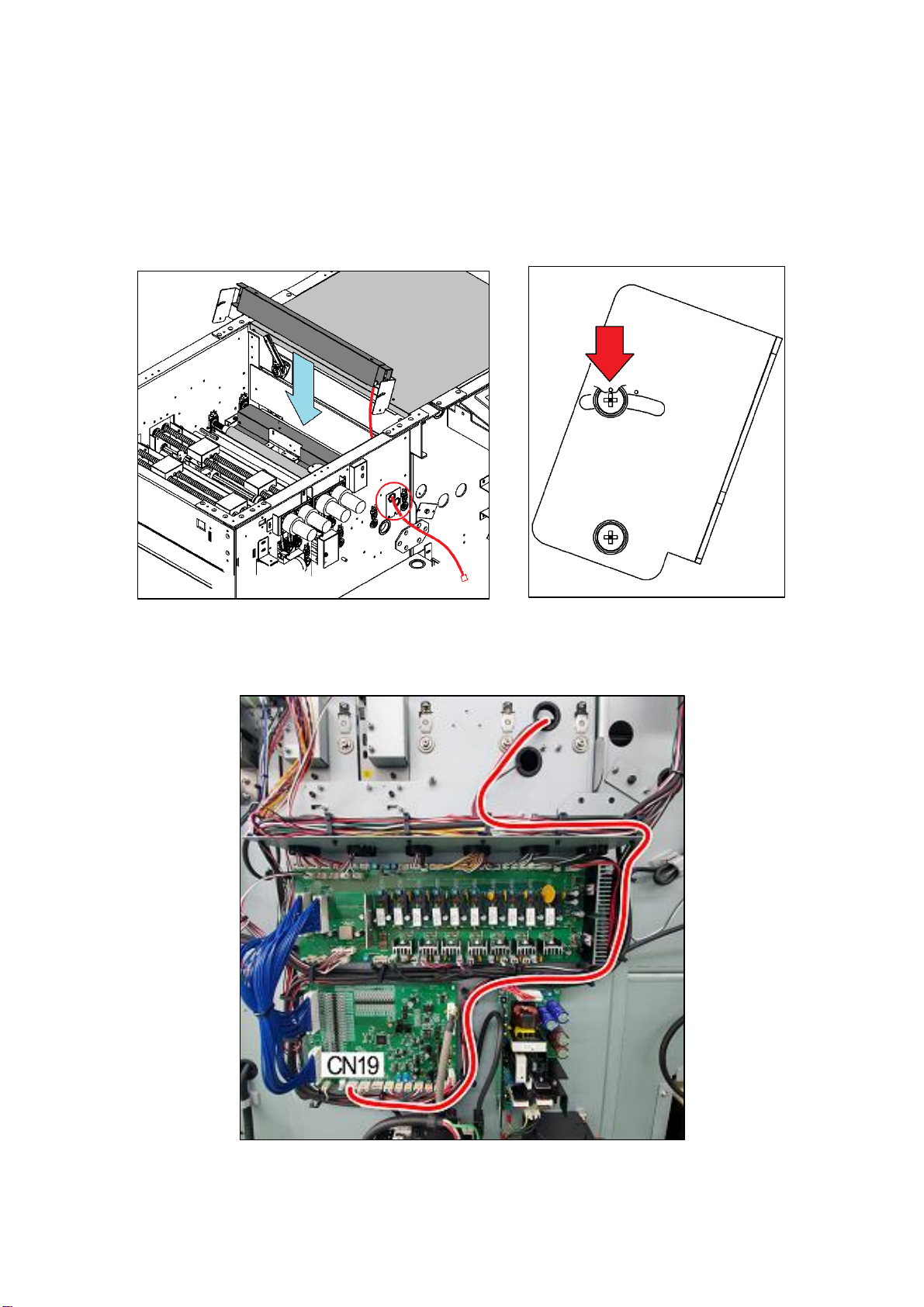

5.6 Feed belt Unit.......................................................................................40

6Adjustment .................................................................................................42

6.1 Settings................................................................................................ 42

6.1.1 Feed settings.................................................................................42

6.1.2 Accuracy adjustment .....................................................................43

6.2 Feed unit adjustment ........................................................................... 44

6.3 Electrical equipment.............................................................................51

6.3.1 CPU board.....................................................................................51

6.3.2 I/O board........................................................................................52

6.3.3 Sensor PCB...................................................................................53

6.3.4 Cut mark sensor ............................................................................54

6.3.5 Ultra-sonic PCB .............................................................................55