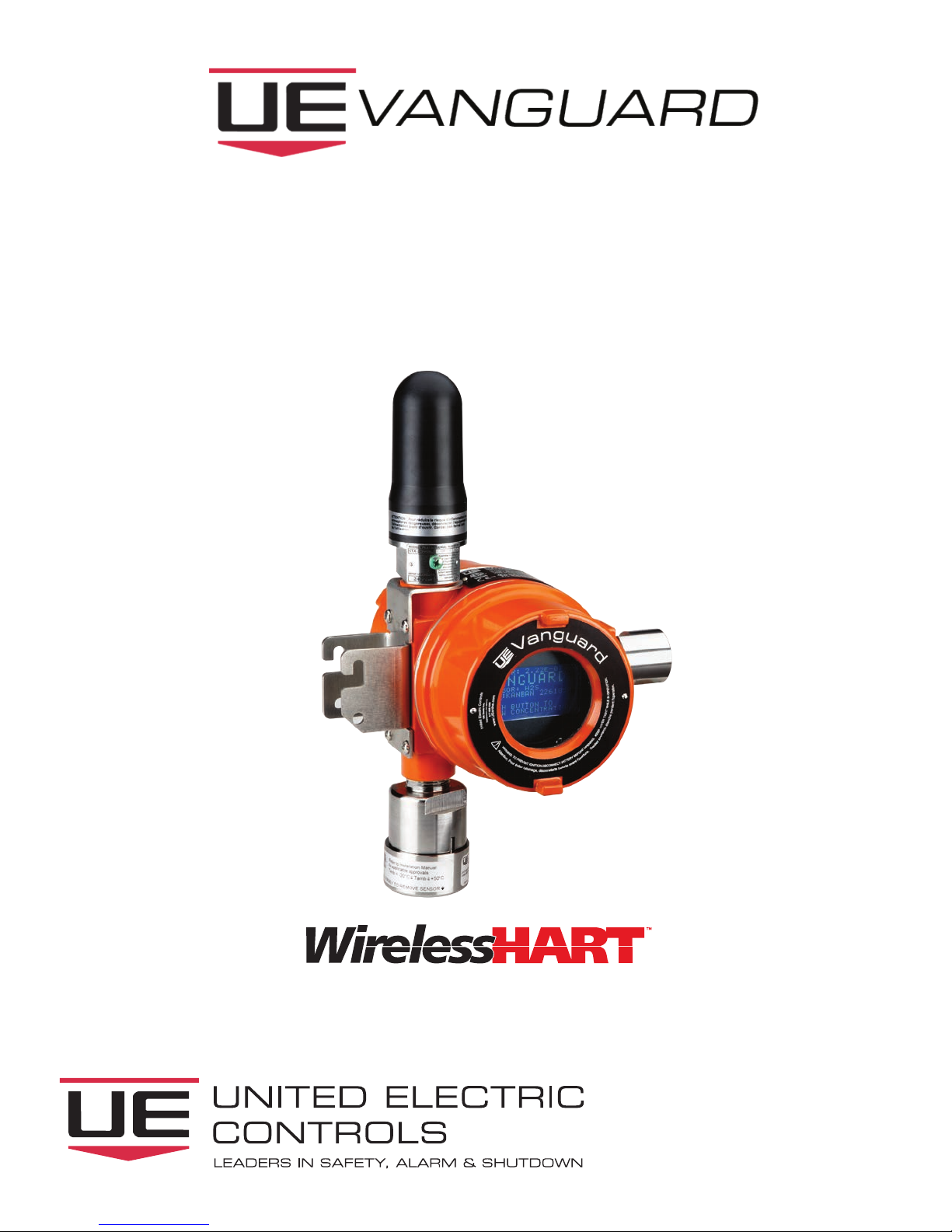

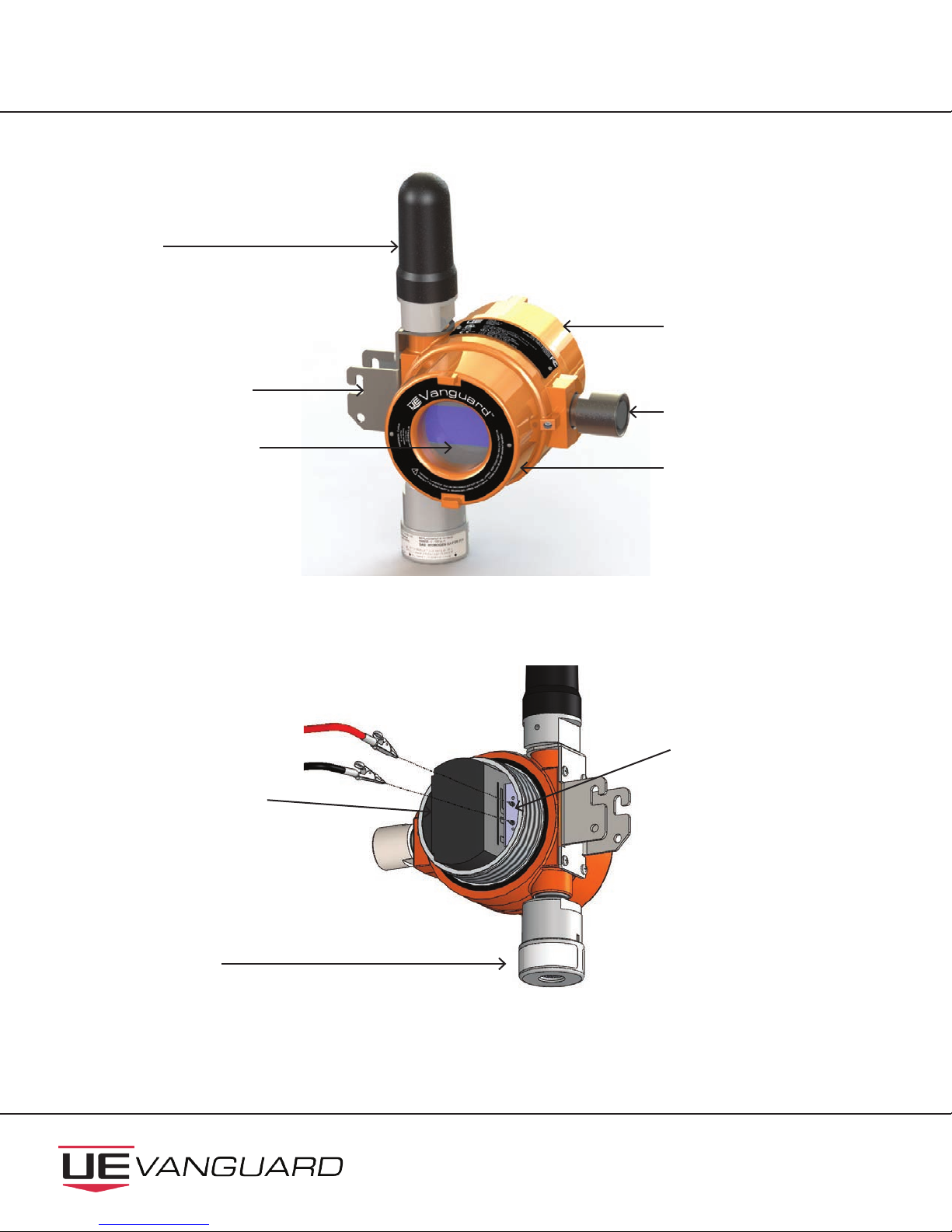

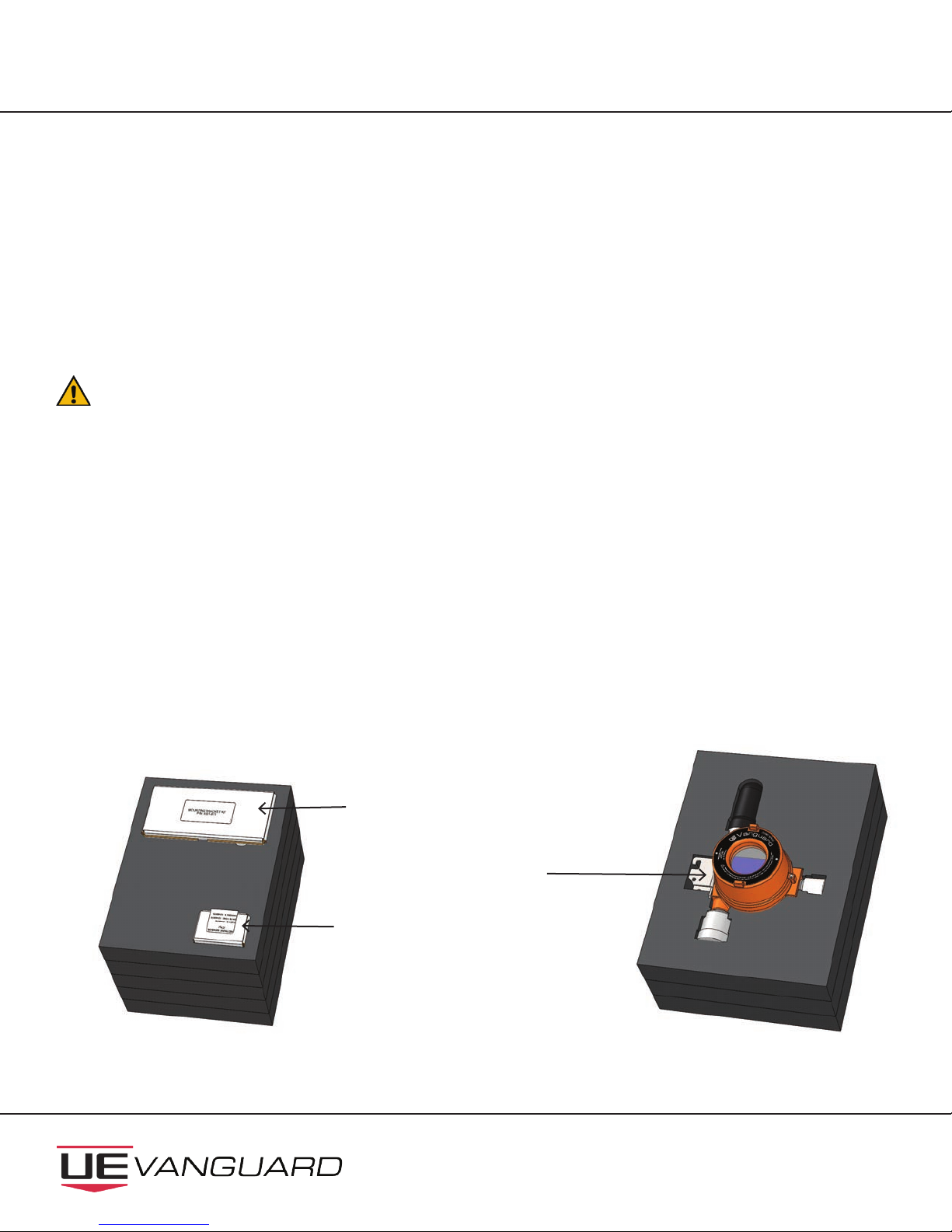

WirelessHART Toxic & Combustible Gas Detector

IM_TCD50-05

www.ueonline.com/vanguard

5

Standard Issue Date Title

Conform to IEC 60079-0:2011 2011/06/22 (6th Edition) Explosive Atmospheres - Part 0: Equipment

General Requirements

Conform to IEC 60079-1:2014 2014/06/27 (7th Edition) Explosive Atmospheres - Part 1: Equipment

Protection by Flameproof Enclosures “d”

Conform to IEC 60079-11:2011 2011/06/30 (6th Edition) Explosive Atmospheres - Part 11:

Equipment protection by intrinsic safety “i”

Conform to IEC 60086-4:2014 2014/09/03 (4th Edition) Primary batteries - Part 4: Safety of lithium

batteries

Conform to IEC 61010-1 2010 Electrical equipment for measurement,

control, and laboratory use; Part 1: General

requirements

Conform to EN 55011:2009+A1:2010 2010/01/31 Industrial, scientific and medical equipment.

Radio-frequency disturbance characteristics.

Limits and methods of measurement

Conform to EN 60079-0 2011/06/22 (6th Edition) Explosive Atmospheres - Part 0: Equipment

General Requirements

Conform to EN 60079-1:2014 2014/06/27 (7th Edition) Explosive Atmospheres - Part 1: Equipment

Protection by Flameproof Enclosures “d”

Conform to EN 60079-11:2012 2012/01/31 (6th Edition) Explosive Atmospheres - Part 11:

Equipment Protection by intrinsic safety “i”

Conform to EN 61326-1:2013 2013/02/28 Electrical equipment for measurement,

control and laboratory use. EMC

requirements. General requirements

Certified to CSA C22. 2 60079-0 2011/12/01 Explosive Atmospheres Part 0: Equipment

General requirements

Certified to CSA C22.2 60079-1 2011/12/01 Explosive Atmospheres Part 11: Equipment

protection by intrinsic safety “d”

Certified to CSA C22.2 60079-11 2011/12/01 Explosive Atmospheres Part 11: Equipment

protection by intrinsic safety “i”

Certified to CSA C22.2 61010-1-12 2012/5/11 Electrical equipment for measurement,

control, and laboratory use; Part 1: General

requirements

Conform to UL 60079-1 2009/04/10 (Edition 6) UL standard for safety electrical apparatus

for explosive gas atmospheres Part 1:

Flameproof Enclosures “d”

Conform to UL 913 2013/12/06 (Edition 8) Intrinsically safe apparatus and associated

apparatus for use in Class I, II and III,

Division I Hazardous (Classified) Locations

Conform to UL 1203 2013/11/22 (Edition 5) Explosion Proof and Dust Ignition proof

electrical equipment for use in hazardous

(Classified) Locations.

Conform to UL 61010-1 2012/5/11 (Edition 3) Electrical equipment for measurement,

control, and laboratory use; Part 1: General

requirements

FCC Rule Part 15b Declaration of Conformity (DoC) &

Verification

The device has been certified in accordance with the applicable requirements of the following standards:

Table 1