3

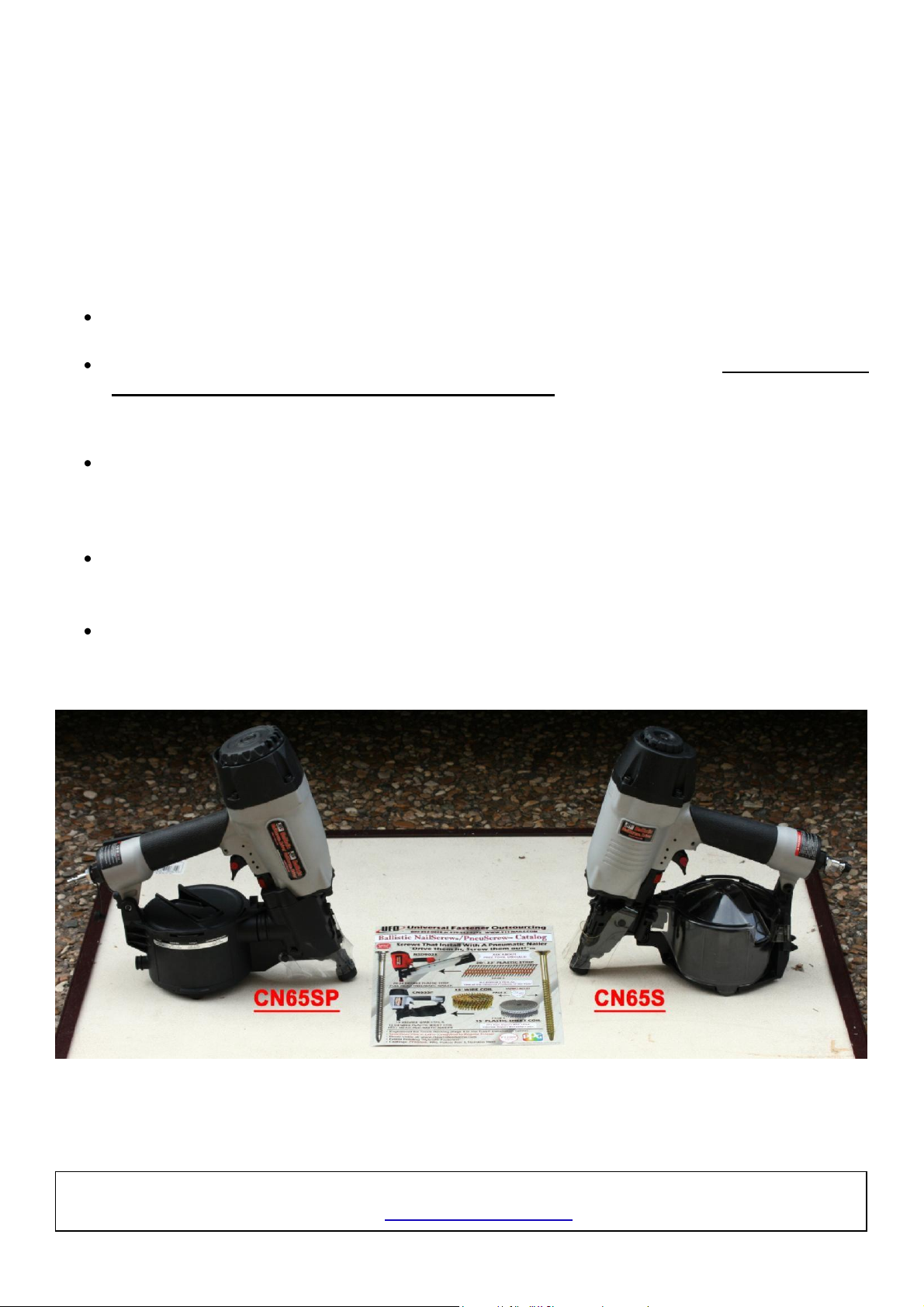

IMPORTANT! Upon receipt of your NailScrew® Driver, Read and

follow all safety rules and operating instructions.

Important Safety Rules

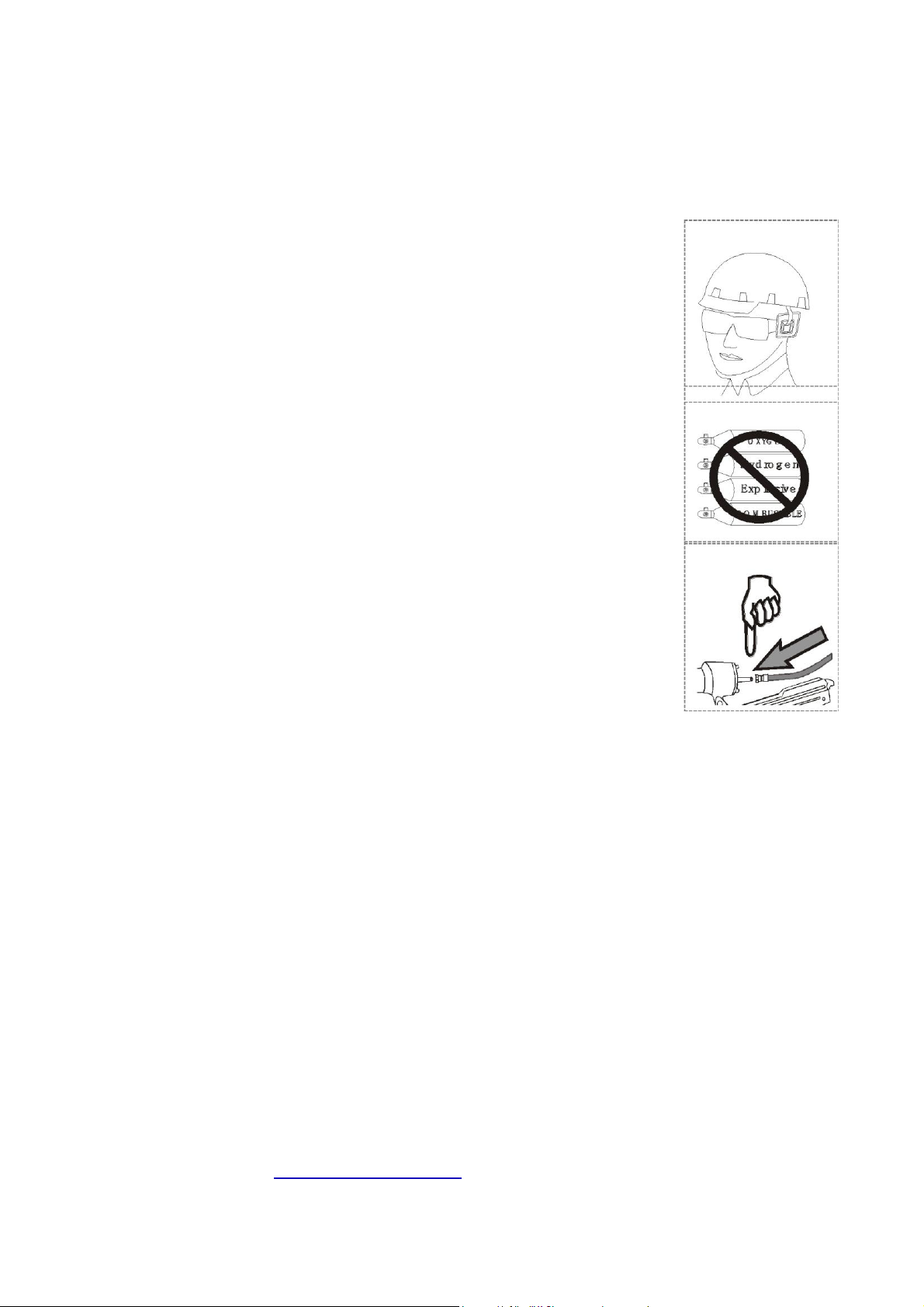

1. KEEP CHILDREN AWAY. All children should be kept away from the work area.

Do not allow them to handle the tool. Fig 1.

2. USE SAFETY GLASSES AND EAR PROTECTION. Air tool operators and

others in the work area should always wear safety glasses to prevent injury from

fasteners and flying debris during use and when loading and unloading this tool.

Wear ear protection to safeguard against hearing loss. (See fig 1.)

3. NEVER USE OXYGEN, COMBUSTIBLE FUELS OR ANY OTHER BOTTLED

GAS as a power source as it will cause explosion and serious personal injury.

4. DO NOT CONNECT TOOL TO COMPRESSED AIR WITH

PRESSURE EXCEEDING 120PSI.

5. DO NOT USE AN EXCESSIVELY LONG AIR HOSE in the working area as it

will create an operator tripping hazard. Secure all connections tightly.

CARRY TOOL ONLY BY THE HANDLE

and keep finger off the trigger pull.

will allow the safety yoke mechanism to prevent the unintentional firing of

7. KEEP THE TOOL POINTED AWAY FROM YOURSELF AND OTHERS at all

times. Keep hands and all body parts away from the nose area and rear area of

the tool to guard against possible injury.

8. DISCONNECT TOOL FROM AIR SUPPLY BEFORE LOADING FASTENERS to prevent accidental

fastener firing. (See fig3.)

9. DO NOT DEPRESS TRIGGER OR SAFETY YOKE MECHANISM DURING FASTENER LOADING

to prevent the unintentional firing of a fastener that can cause personal injury.

10. DISCONNECT TOOL FROM AIR SUPPLY HOSE and disconnect from air compressor before

performing maintenance, altering accessories, or while not in operation.

11. DO NOT OPERATE ON SCAFFOLDINGS OR LADDERS, and do not work in airtight containers or vehicles.

12. DO NOT DRIVE FASTENERS CLOSE TO THE EDGE OF THE WORK PIECE. The work piece could split,

causing the fastener to fly free or ricochet, causing personal injury.

13. DO NOT DRIVE FASTENERS ON TOP OF OTHER FASTENERS or the fasteners can ricochet

causing personal injury.

14. NEVER USE A TOOL THAT IS LEAKING AIR, HAS MISSING OR DAMAGED PARTS, OR IS IN NEED

OF REPAIR. Make sure that all screws are securely tightened.

15. INSPECT DAILY FOR FREE MOVEMENT of trigger, safety mechanism and spring to insure safe and

proper operation of the tool.

16. ONLY USE PARTS AND ACCESSORIES RECOMMENDED BY THE MANUFACTURER.

Parts & Service Contact: http://elder-hayesinc.com or call 1-800-769-0775