2

NT UF 821 CO GB (a) / April 2014

TABLE OF CONTENTS

Note: A detailed table of contents is provided at the end of the manual.

Important: If you are unfamiliar with the transit time difference measuring technique, we recommend you start by

reading our training manual "Ultrasonic transit time flowmeter".

CHAPTER 1: OVERVIEW___________________________________________4

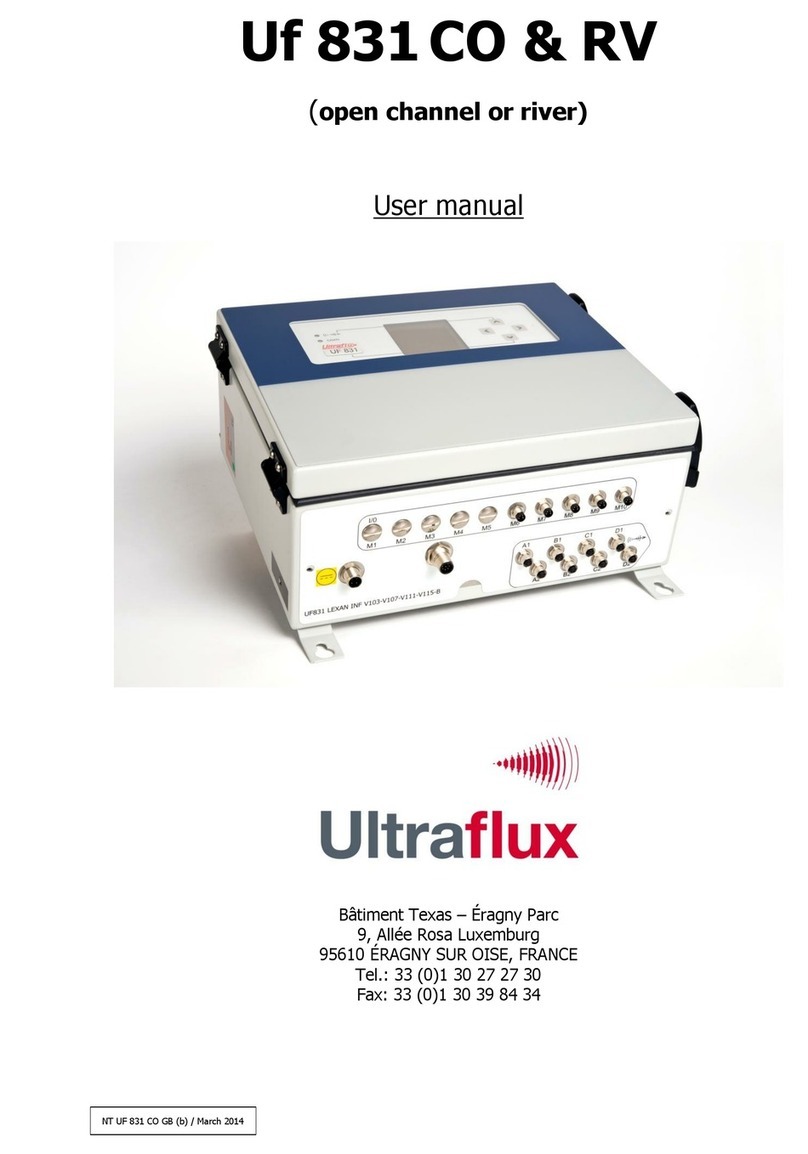

1.1 General view of the converter _____________________________________________________ 5

1.2 Nature of the equipment _________________________________________________________ 7

1.3 Dimensions and weight __________________________________________________________ 7

1.4 Operating environment __________________________________________________________ 7

1.5 Physical protection ______________________________________________________________ 7

1.6 Power supply __________________________________________________________________ 8

1.7 Communication ________________________________________________________________ 8

1.8 Inputs/Outputs_________________________________________________________________ 9

1.9 Ultrasound chords ______________________________________________________________ 9

1.10 Navigation keys _______________________________________________________________ 9

1.11 Operating lights ______________________________________________________________ 10

1.12 Screen _____________________________________________________________________ 10

1.13 Functions ___________________________________________________________________ 11

1.14 Performance of the flow meter __________________________________________________ 11

1.15 Cleaning the flow meter________________________________________________________ 11

1.16 Recycling the flow meter _______________________________________________________ 12

1.17 CE marking__________________________________________________________________ 12

CHAPTER 2: SAFETY INSTRUCTIONS________________________________13

2.1 Using the flow meter ___________________________________________________________ 14

2.2 Equipment connected to the flow meter ____________________________________________ 15

2.3 Symbols used on the flow meter __________________________________________________ 15

2.4 Maintenance work on the flow meter ______________________________________________ 16

2.5 Contact address _______________________________________________________________ 17

CHAPTER 3: INSTALLATION AND WIRING ___________________________18

3.1 General______________________________________________________________________ 19

3.2 Wall mounting and space requirement _____________________________________________ 19

3.3 Using the cabinet ______________________________________________________________ 20

3.4 Using the lid stay ______________________________________________________________ 21

3.5 Tool-free removal of the lid ______________________________________________________ 21

3.6 Wiring instructions _____________________________________________________________ 22

3.7 Connection to the protective ground (to be carried out first)____________________________ 22

3.8 Wiring the Terminals ___________________________________________________________ 22

3.9 USB Connection _______________________________________________________________ 27