vi

Contents

Page

Prior to Operation.............................................................................................................................................i

Safety Notations...............................................................................................................................................i

Safety Precautions...........................................................................................................................................ii

Revision History.............................................................................................................................................. v

Contents ........................................................................................................................................................vi

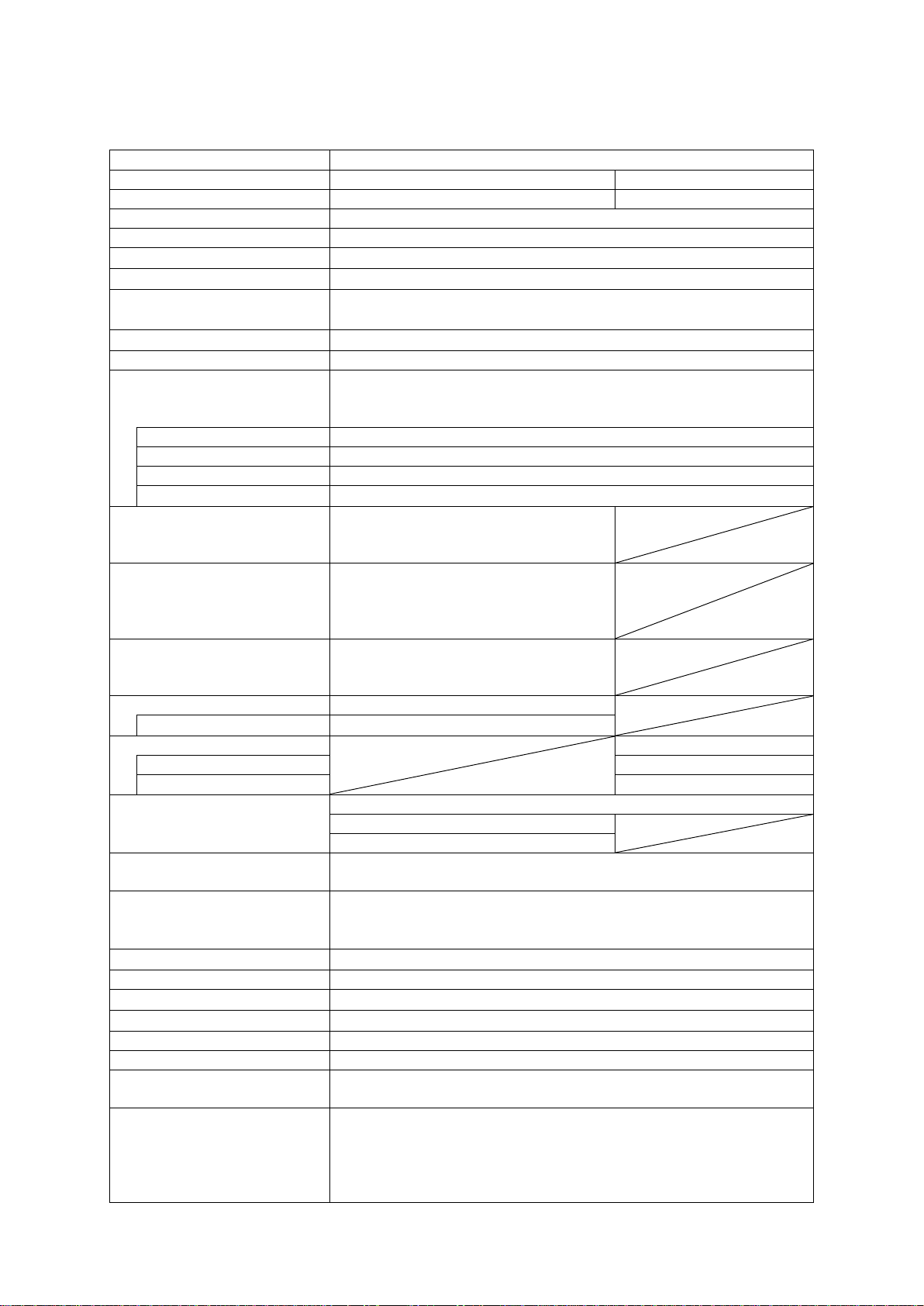

1. Specifications ..................................................................................................................................1

1.1. Standard Specifications...................................................................................................................1

1.2. Unpacking and quantity check ........................................................................................................2

1.3. Option..............................................................................................................................................2

1.4. Dimensional Drawings....................................................................................................................3

1.4.1. SW1-1/SW1-2 Dimensional Drawings.................................................................................3

1.4.2. SWP-16 Dimensional Drawings...........................................................................................4

1.5. Unpacking and Quantity Check ......................................................................................................4

2. Cautions in Operation......................................................................................................................5

2.1. Checks immediately after operation................................................................................................5

2.2. Cautions on Operating Environment...............................................................................................5

2.3. Cautions in Operation......................................................................................................................6

2.4. Installing the Instrument..................................................................................................................6

2.4.1. Sensor installing environment ..............................................................................................6

2.4.2. Installing the sensor head......................................................................................................7

3. Names of Components and Description of Functions..................................................................... 8

3.1. Controller Unit ................................................................................................................................8

3.2. Front Panel Standard Type SW1-1............................................................................................9

3.3. Front Panel Serial Communication type SW1-2...........................................................................10

3.4. Input / Output Connector Standard type SW1-1 ........................................................................11

3.5. Input/Output Connector Serial Communication type SW1-2.....................................................12

4. Circuit in the power supply........................................................................................................... 13

5. Signals...........................................................................................................................................14

5.1. Pressure Signal Output (SW1-1 and SW1-2)................................................................................14

5.1.1. Pressure converting equation..............................................................................................14

5.1.2. Output of measurement value in each state ........................................................................14

5.2. I/O Signal Output (Standard Type SW1-1 only)...........................................................................15

5.2.1. Sensor error signal (Standard Type SW1-1 only)...............................................................15

5.2.2. Setpoint actuating signal (Standard Type SW1-1 only)......................................................15

5.3. I/O Input Signal (Standard Type SW1-1 only)..............................................................................16

6. Setting the Setpoint (Standard Type SW1-1 only)........................................................................17

6.1. Set point ON/OFF pressure...........................................................................................................17

6.2. Wiring in setting Setpoint..............................................................................................................17

6.3. Setting of Setpoint.........................................................................................................................18

7. How to use Serial Communication (Serial communication type SW1-2 only).............................19

7.1. Communication Specifications......................................................................................................19

7.2. Various Settings ............................................................................................................................19

7.2.1. Connection diagram............................................................................................................19

7.2.2. Baud rate setting.................................................................................................................20

7.2.3. Address setting....................................................................................................................20

7.3. Standard Data Format....................................................................................................................21

7.3.1. List of commands ...............................................................................................................21