V

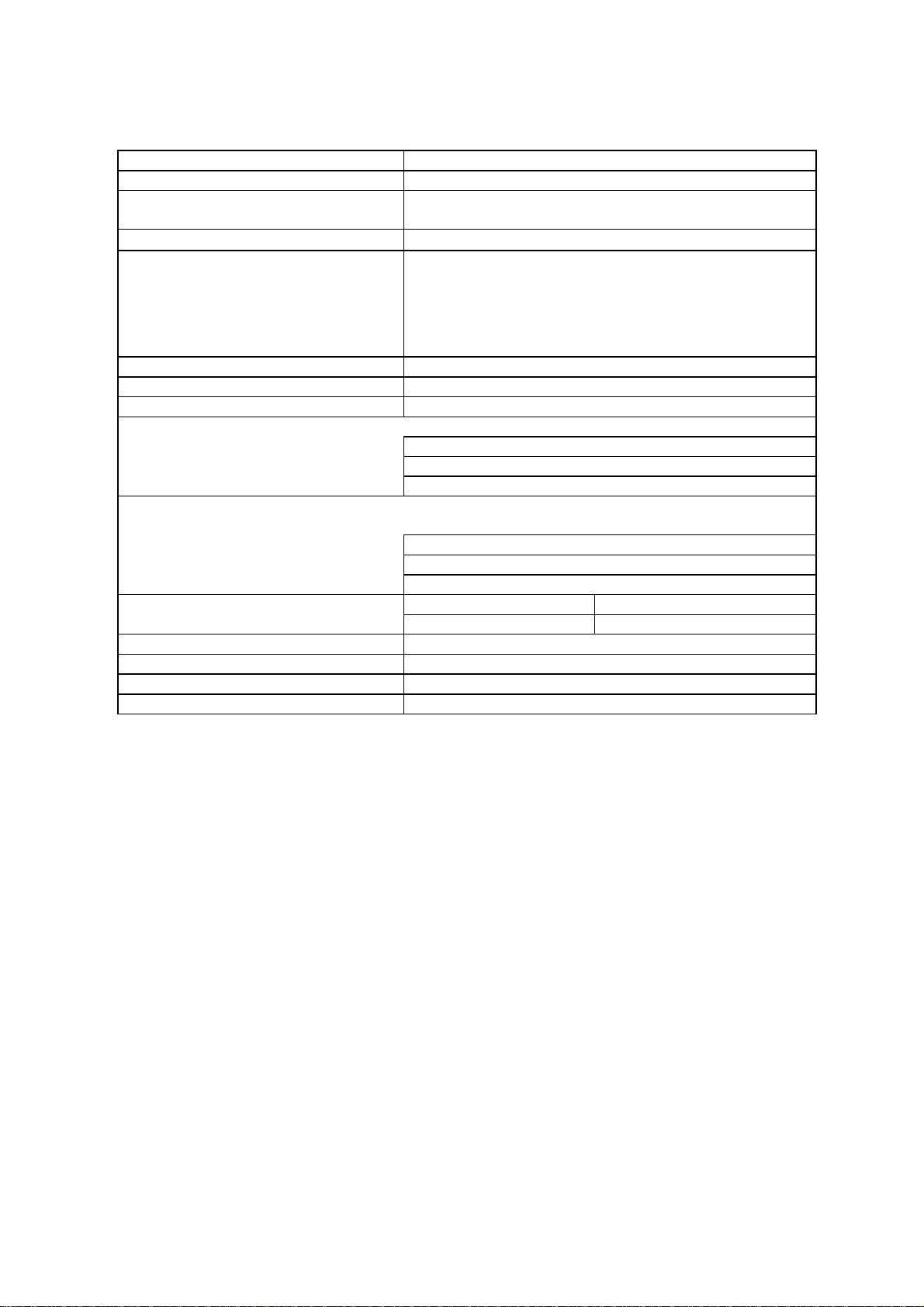

Contents

Page

Prior to Operation..................................................................................................................................I

Safety Denotations ................................................................................................................................I

Safety Cautions ....................................................................................................................................II

Revision History................................................................................................................................. IV

Contents................................................................................................................................................V

1. Explanation of Terms................................................................................................................... 1

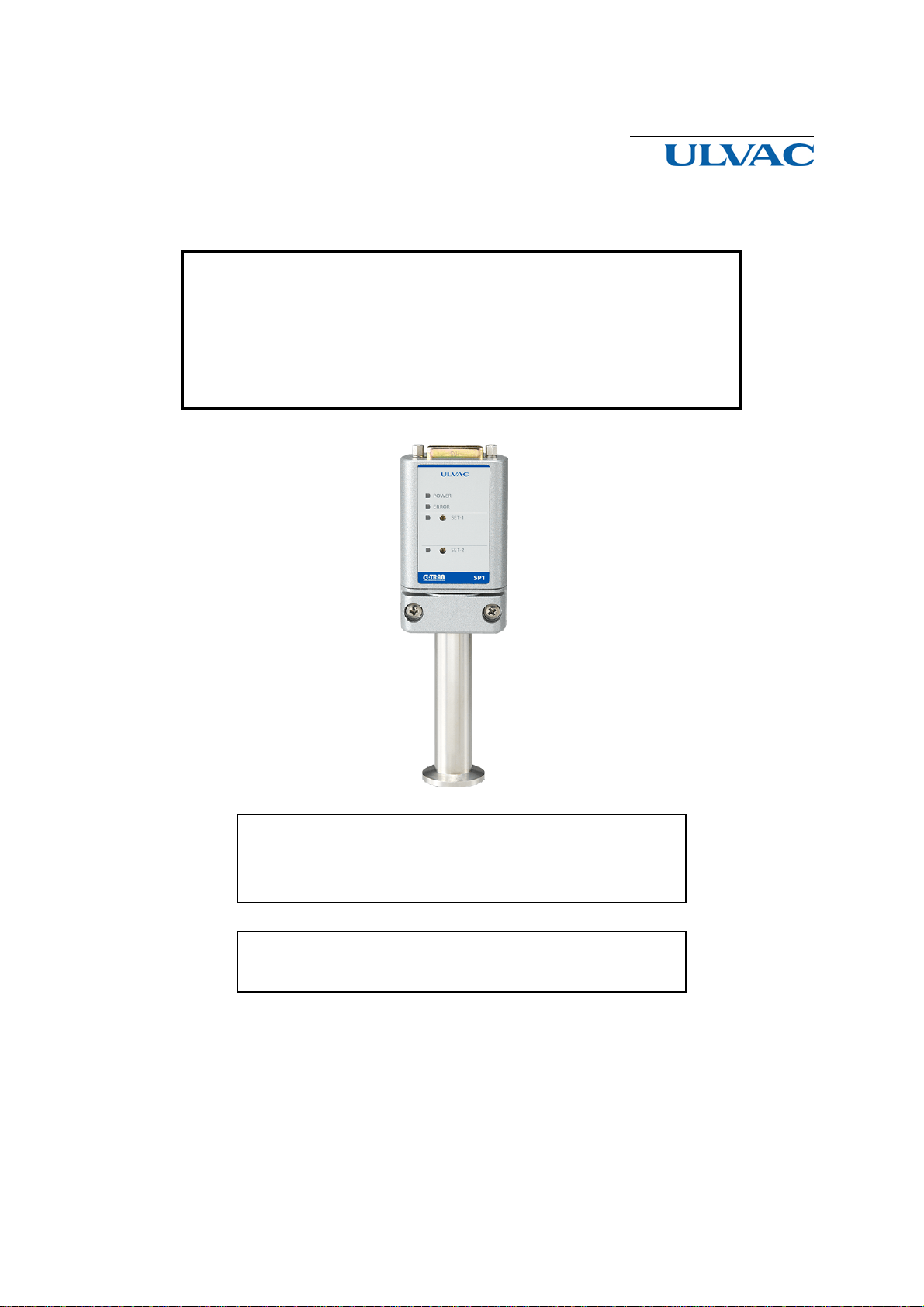

2. FEATURES OF SP1.................................................................................................................... 1

3. SPECIFICATIONS AND COMPONENTS ................................................................................ 2

3.1. Key Specifications ....................................................................................................... 2

3.2. Standard Accessories ................................................................................................... 3

3.3. Options......................................................................................................................... 3

4. NOMENCLATURE AND FUNCTIONS.................................................................................... 4

4.1. Assembly...................................................................................................................... 4

4.2. Front Panel ................................................................................................................... 5

4.3. Input/Output Connector ............................................................................................... 6

5. INSTALLATION......................................................................................................................... 7

5.1. Preparations.................................................................................................................. 7

5.2. Installation.................................................................................................................... 7

5.2.1. Installing the sensor head to the sensor unit......................................................... 7

5.2.2. Installing the sensor unit ...................................................................................... 8

5.2.3. Electrical connection.......................................................................................... 10

6. CAUTIONS IN HANDLING .................................................................................................... 11

7. OUTPUT SIGNALS.................................................................................................................. 12

7.1. Setpoint actuating signal [SET-1 ON/OFF][SET-2 ON/OFF]................................... 12

7.2. Filament open signal [ERR ON/OFF]........................................................................ 12

8. SETTING OF SETPOINT ......................................................................................................... 13

9. FUNCTIONS ............................................................................................................................. 15

9.1. Setpoint [SET-1 ON/OFF] [SET-2 ON/OFF]............................................................ 15

9.1.1. Setpoint .............................................................................................................. 15

9.1.2. Setting of setpoint .............................................................................................. 15

9.1.3. Setpoints of measuring unit and display unit ..................................................... 15

9.2. Open Detection [ERR ON/OFF]................................................................................ 15

9.2.1. What is open detection? ..................................................................................... 15

9.2.2. Confirmation of open filament........................................................................... 15