2

Information for the Installer

Technical data

1. Before installation make sure that there is available the right space for the correct

installation of the system. The system must always face the South for North

hemisphere or North for South hemisphere. The system must be connected with

tubes with nominal diameter from 18-22mm.

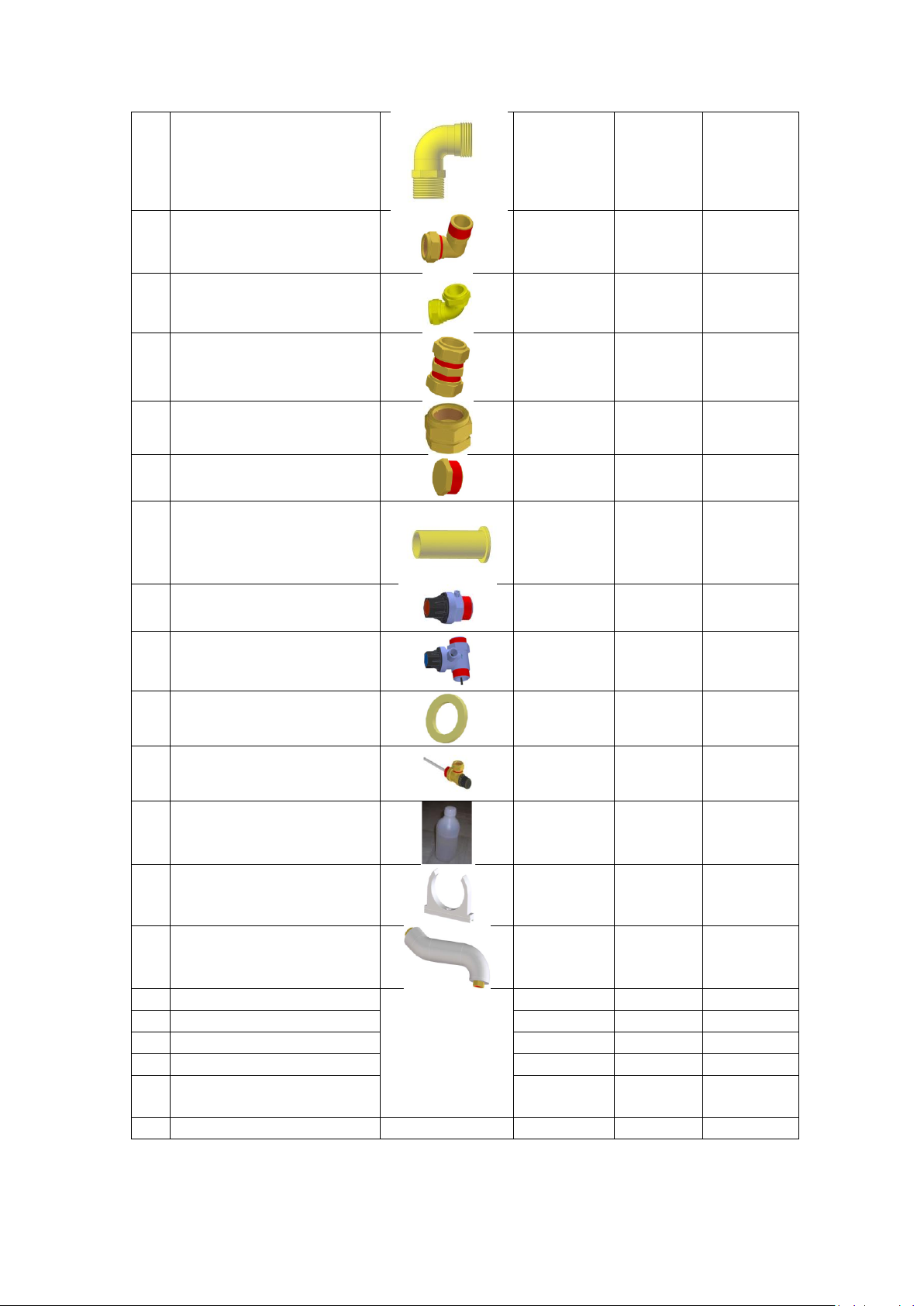

2. The system is containing the following components:

2.1 The solar tank

2.2 The solar collector (s)

2.3 The support base and the installation kit. Detailed information about them is

indicated above.

3. The maximum operation pressure is at 6 bars. In case of higher pressure in the main

it is suggested to use pressure reducer. The closed loop’s maximum operation

pressure is at 3 bars.

4. The maximum temperature of the system is 94C.

5. The system is protected against corrosion, by using 2 Mg anodes. The tank internally

is protected by enamel layer.

6. The used heat transfer fluid is Glycol.

Packaging and transportation

1. The system is packed in a way to ensure the safe transport of its components. For

the tank, there are indication arrows to show the up or down part of the tank in

order to avoid any possible damage. For the collector, there are indication arrows in

order to avoid the damage of the glass.

2. The products must be stored in a protected area against weather conditions. If

necessary to store them outdoors, the packaging of the product must be removed.

Installation guidelines

1. Before install the system make sure that the chosen installation surface can resist

the weight of the system. It must be given a written confirmation by the engineer of

the building that the installation area is proper for this use.

2. In order to make the maintenance of the system easier, the system must be installed

at least 1 m from the walls or the end of the roof.

3. In order to avoid humidity problems or water ingress on the roof, the pipes which

are entering the roof must be very well sealed. The building engineer should provide

you the precise guidelines, depending in the kind of roof construction.

4. All the connection pipes must be very well insulated to avoid freezing or destruction

of them due the UV radiation. Depending on the local weather conditions, it must be

chosen the correct insulation material. For more information contact to the local

dealer.