10 SSK 4 | Version 1.08

Care, maintenance and overhaul

In order to meet the most varied requirements, various settings

must be made before the operation for the trouble-free operation

of the sand blasting cabin..

Proper functioning depends on various factors. On the

one hand, a clean and dry blasting medium and free li-

nes are an important prerequisite (operating pressure as

in the technical data). On the other hand, it depends on

which workpieces are to be processed with which abra-

sive, because each workpiece and abrasive has other

properties (hardness, grain size, weight, aggressive-

ness). The blasting media (e.g., normal, mixed, noble

corundum, crushed slag, glass beads, blasting balls,

etc.) are offered in various grain sizes.

Due to these different parameters, different settings must be

made to ensure proper functioning of the sand blasting cabin.

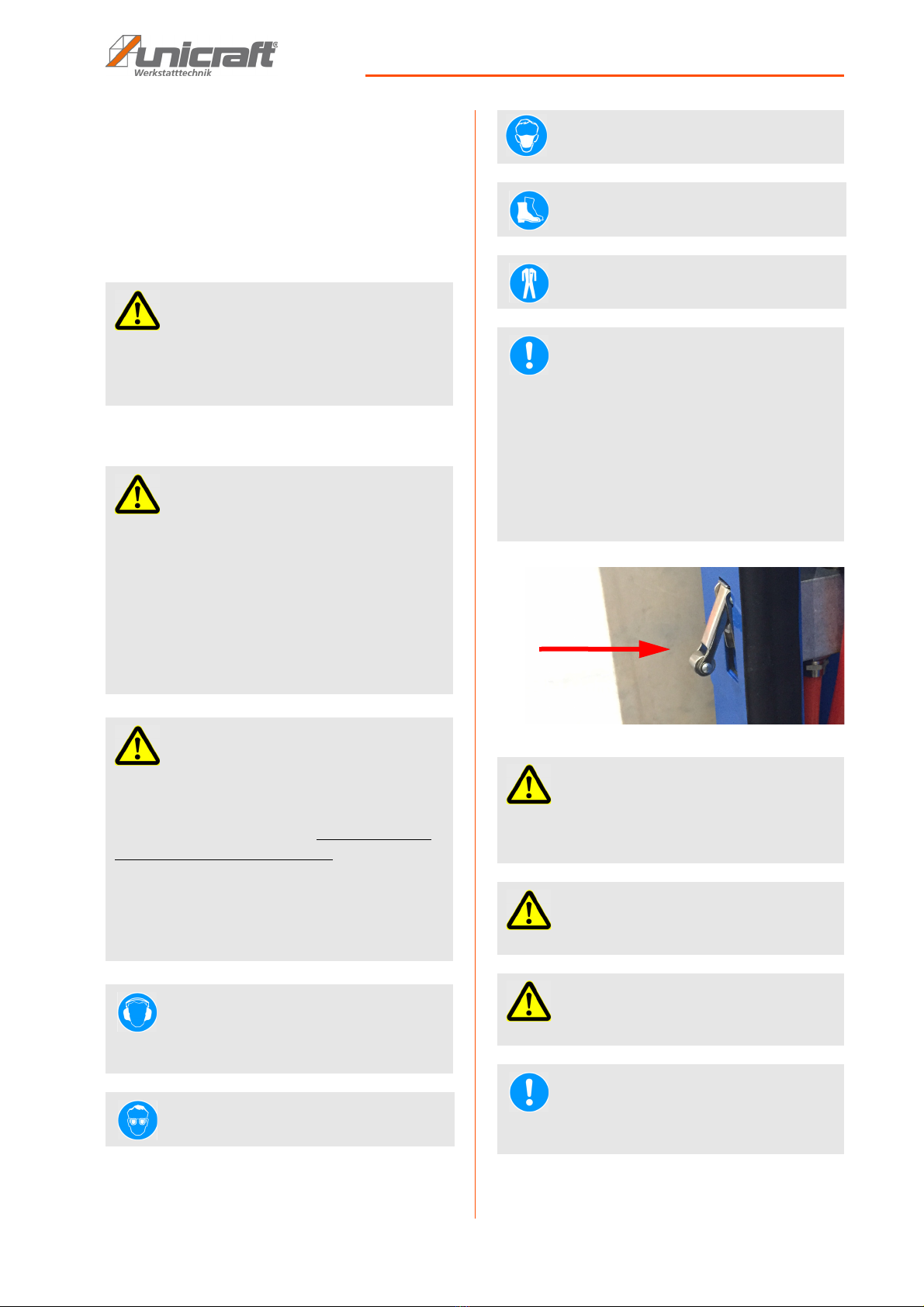

Adjustment of the blowgun

The generated negative pressure in the blow gun can be

determined by the depth of engagement of the compo-

nent [Pos. 7], if the lock nut [Pos. 5] and release the air

pressure connection [Pos. 8].

Fig. 6: Blow

Both settings are interdependent! It should always be tried seve-

ral settings to achieve an optimal result..

Here are two examples and their effects:

- too deeply screwed in component [pos. 7] (small di-

stance inside to the nozzle): too little negative

pressure and thus also little abrasive

- too far back turned component [pos. 7] (large di-

stance inside to the nozzle): no negative pressure

is generated, but blown into the blasting medium

line -> pressure build-up

Step1: Select a suitable blasting medium and fill in the

sandblasting booth.

Step 2: The workpiece must be free of oil, grease and

moisture. If necessary, clean the workpiece be-

fore placing it in the blast cabinet.

Step3: Set the desired working pressure at the com-

pressed air supply (compressor). Make sure

that the maximum pressure is not exceeded!

Adjust according to the sensitivity of the mate-

rial according to lower working pressure.

Step 4: Connect the sandblast booth to the compres-

sed air source.

Step 5: Place the workpiece to be machined in the blast

cabinet, close the door and turn on the blast

cabinet lighting.

Step 6: Use the integrated protective gloves to hold the

sand blasting gun and the workpiece and start

sandblasting. Hold the sand blasting gun at an

angle of 45 ° to 60 ° to the workpiece, the abra-

sive should be blown from the workpiece against

the back wall of the sandblast cabine.Use the

pedal to dose the blasting agent addition.

Attention:

When opening the cabin doors during

operation, the sandblasting booth switches off au-

tomatically.

Step 7: After finishing work, disconnect the tool from

the compressed air source and remove the

workpiece.Pflege, Wartung und Instandset-

zung

9 Care, maintenance and overhaul

9.1 Care by cleaning

The sandblasting booth should always be kept in a clean

condition.

NOTE!

There are no general guidelines for this setting. It

must be learned by testing, depending on the blasting

medium and requirement.

ATTENTION

Disconnect the tool from the compressed air supply

and the sandblasting booth from the mains before

carrying out any maintenance, servicing or cleaning

work. Maintenance and repair work may only be car-

ried out by qualified personnel.

Use protective gloves!

NOTE!

Never use harsh detergents for cleaning. This can

lead to damage or destruction of the device.