GENERAL

Dear customer!

We are pleased that you decided to purchase our machine. Forestry winch is a forestry machine

of modern design, whose construction enables effective and safe work in the forest. Work in the

forest can only be safe if you follow the instructions for safe work and use. Upon following all

instructions, the machine will operate flawlessly, and you will avoid unnecessary costs. We

recommend reading the instructions carefully. If you are not sure about something, you can also

contact us. We wish you safe work.

Index

GENERAL .....................................................................................................................................................2

Index........................................................................................................................................................2

Intended purpose ..................................................................................................................................3

Technical data: ......................................................................................................................................3

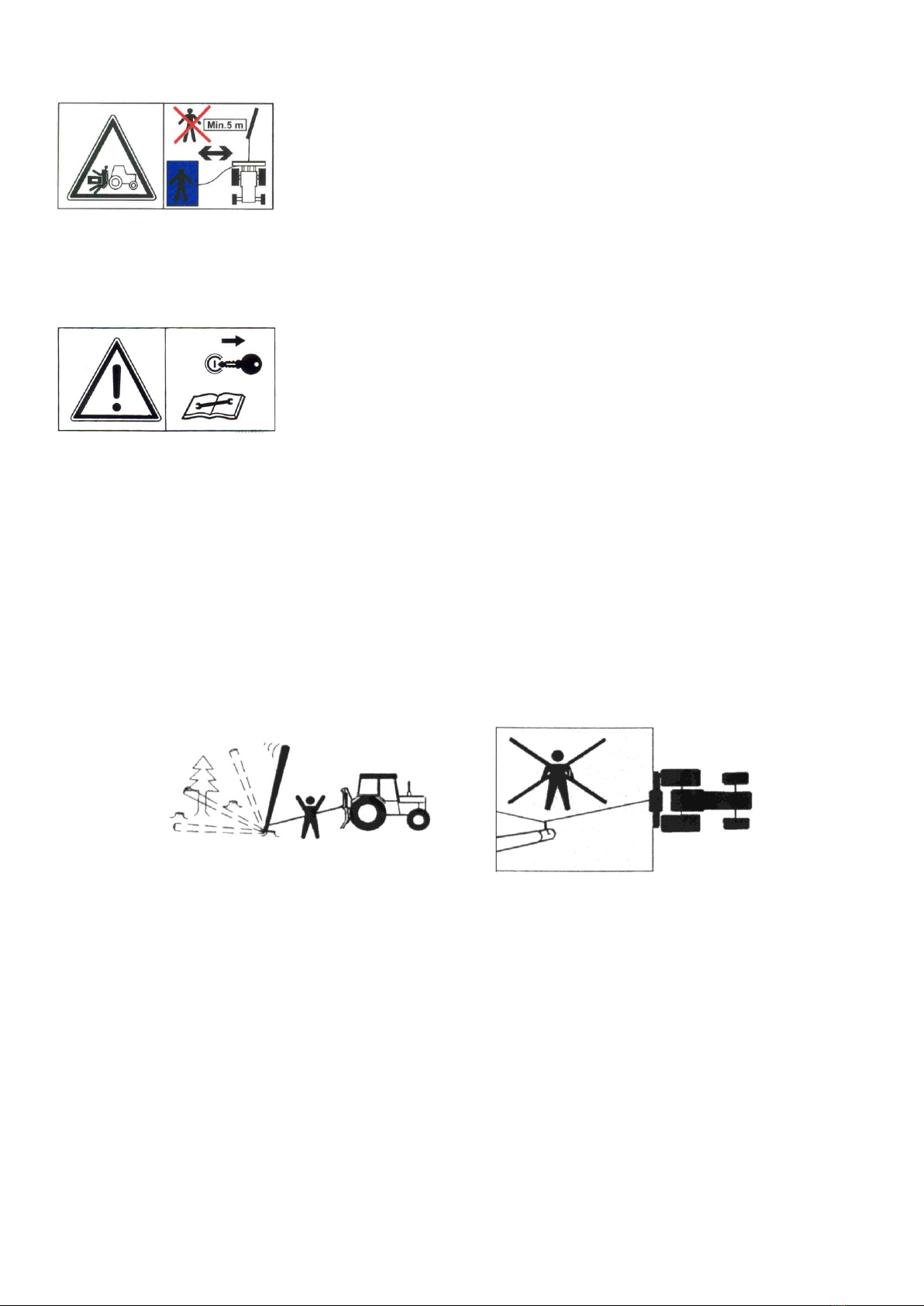

INSTRUCTIONS FOR SAFE WORK.................................................................................................................4

1. General: ...........................................................................................................................................4

PTO shaft .................................................................................................................................................7

INSTRUCTIONS FOR USE ..............................................................................................................................8

1. Description .......................................................................................................................................8

Required equipment of the tractor ......................................................................................................8

PTO shaft adjustment .............................................................................................................................8

Tractor mounting....................................................................................................................................9

Wire rope unwinding............................................................................................................................10

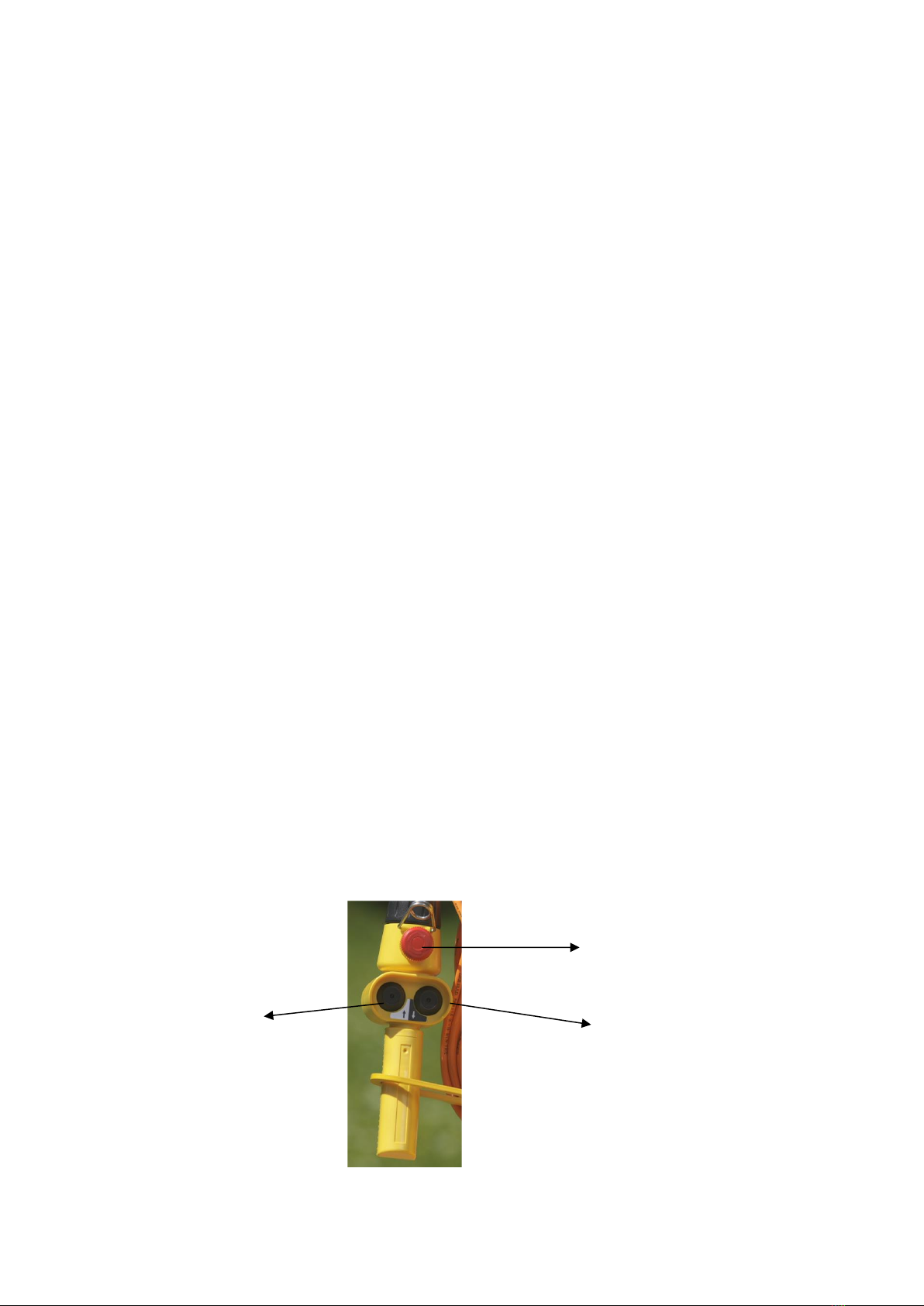

Winch controler ....................................................................................................................................11

The SMART 3in1 function ......................................................................................................................11

Limit switch............................................................................................................................................11

SETTINGS ....................................................................................................................................................14

1. Clutch .............................................................................................................................................14

Preliminary brake..................................................................................................................................14

Brake......................................................................................................................................................15

Drive chain tensioning .........................................................................................................................16

Wire rope assembly..............................................................................................................................16

Operation..............................................................................................................................................17

Adjusting the unwinding speed ..........................................................................................................19

Adjusting the limit switch......................................................................................................................19

Maintenance lubrication....................................................................................................................20

CONTROL OF HYDRAULIC OIL .................................................................................................................20

REMOVAL OF FAULTS................................................................................................................................22

Reeling machine ..................................................................................................................................24

ELECTRICAL EQUIPMENT...........................................................................................................................26

Version H+KS .........................................................................................................................................26

Version Hpro, Hpro+KS..........................................................................................................................27

EC DECLARATION OF CONFORMITY .......................................................................................................28

Spare parts list...........................................................................................................................................29