Three-in-One Air Brad Nailer

E&OE ©2017Unimac 2

Preface

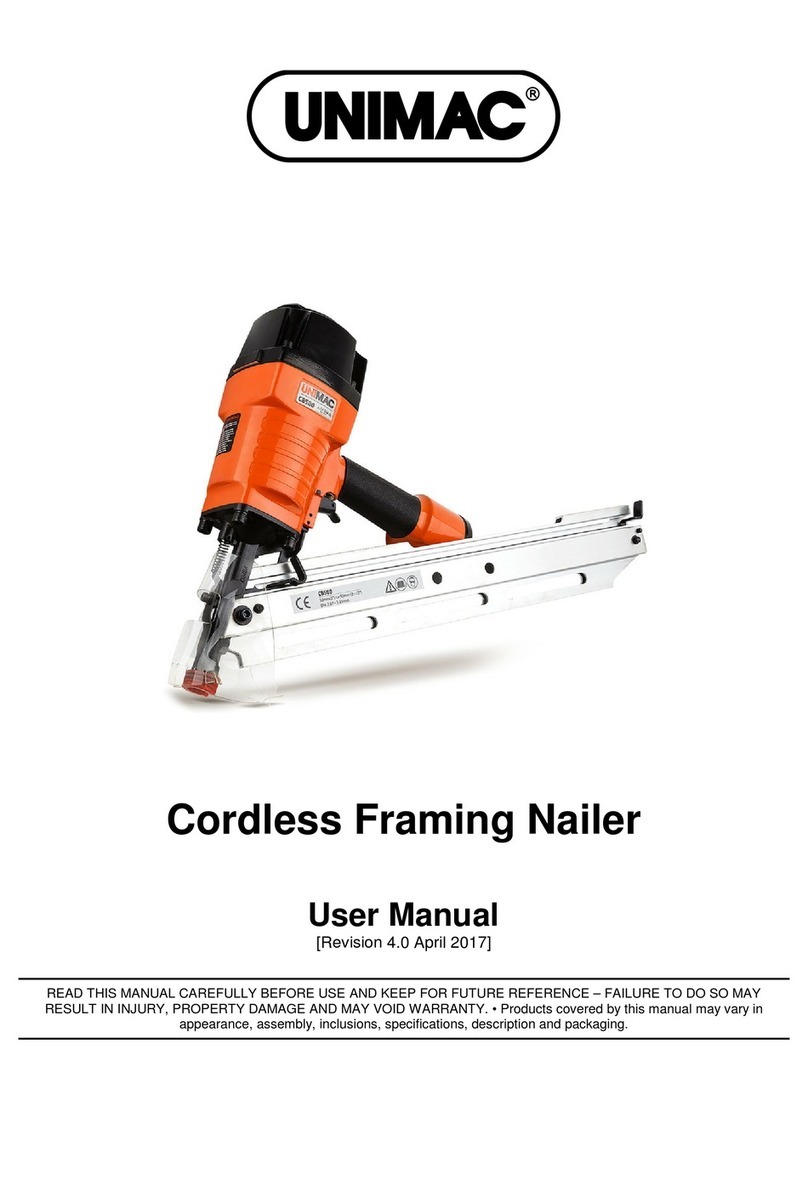

Thanks for buying the Nailer, another high-quality machine from our company.

To get the most out of your purchase, please read the manual before using the Nailer.

We ask you to please read this manual carefully beforehand to familiarise yourself with this product and after

reading, please store this instructional manual for future reference. Failure to follow the proper protocols listed in

the manual may cause personal injury to the operator or damage to equipment.

Safety Information

WARNING! ENSURE THAT NO PART OF ANY HUMAN, ANIMAL OR CLOTHING IS PLACED IN/NEAR THE

AREA WHERE NAILS ARE FIRED OUT OF THE GUN, REGARDLESS OF WHETHER YOU THINK THE GUN IS

EMPTY OR LOADED WITH NAILS.

•Keep your working area clean.

•Do not allow children to enter areas where the nailer is stored or in use, or handle the nailer even if the nailer

is unpowered.

•Do not operate the nailer under the influence of alcohol or drugs.

•Use safety glasses. Safety glasses should conform to ANSI Z87.1 specifications. Safety glasses should be

worn when loading, operating, unloading or servicing the nailer.

•Use ear protection. Exposure to high noise levels can lead to hearing damage.

•Never use oxygen combustible gases, bottled gases or high pressure compressed gas as a power source

for this tool as it may explode and cause serious injury.

•Dress safely. Protective gloves and non-skid footwear or safety shoes are recommended when working with

and operating the nailer. Do not wear loose clothing or jewellery as they can get caught in moving parts.

Also, wear a protective hair covering to prevent your hair from getting caught in the nailer.

•When operating the tool, keep proper footing and balance to avoid damage resulting from losing balance.

•Before using the tool, carefully check if there are damaged parts.

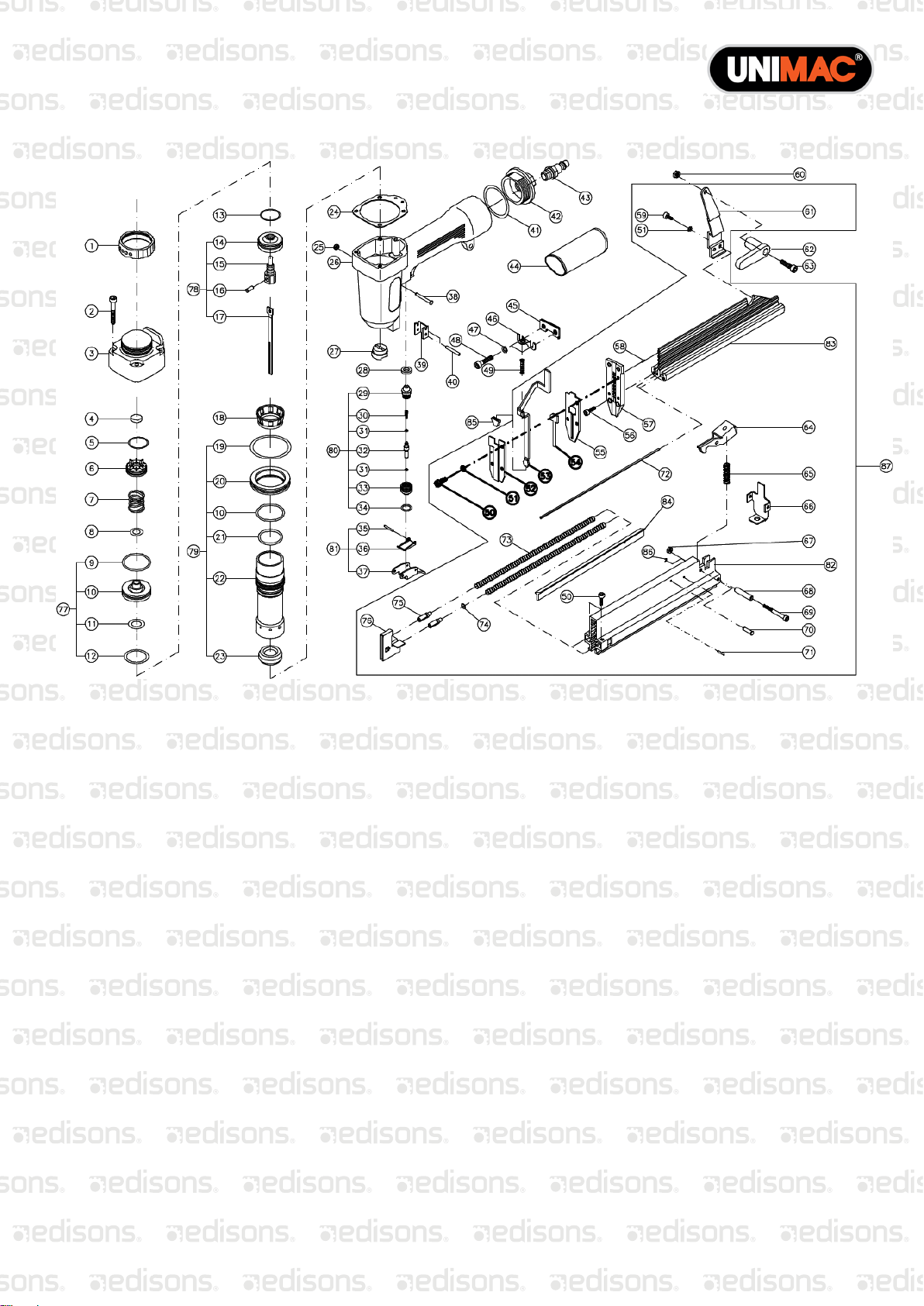

•Replace parts and accessories. Only allow the use of the same replacement parts while servicing. Approved

accessories and replacement parts are available.

•Be alert. Watch what you are doing. Use common sense. Do not operate any tools while you are tired.

•Store the nailer when not in use. The nailer should be cleaned, fully assembled and then stored in a dry

location to reduce rust. For safety, keep out of reach of children.

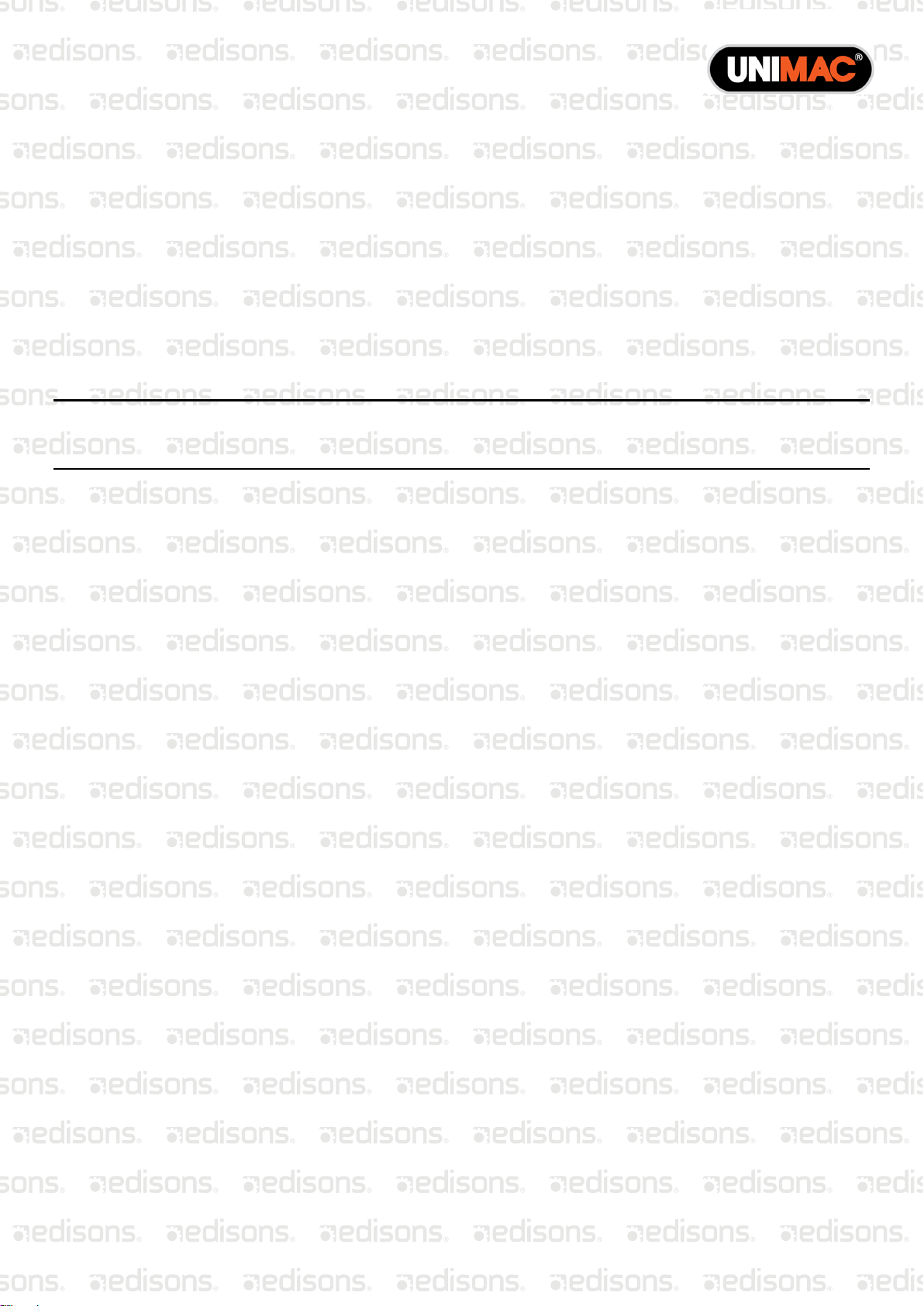

•Pay attention to the air hose and their connections. Don’t trip over hoses. Make sure that all connections are

tight.

•After loading the fasteners, never point the nail gun at yourself or others.

•Use the correct air connector. The connector on the nail gun must not hold pressure when the air supply is

disconnected. If the wrong fitting is used, the nail gun can be charged with air after being disconnected and

still be able to drive a fastener.