3

???

Symbols used in this manual

Warning!

This symbol informs you about the risk of personal

injury or damage to the machine or materials.

Warning!

Danger of damage

General instructions

•Make sure you know your tool or machine and you are familiar with its operating procedure. Know the

hazards that may occur, if not used correctly.

•If other person is using this machine make sure that he knows how to safely operate this equipment and that

he is familiar with hazards and risk that may occur, if not used correctly.

•Pay special attention to safety notes and safety labels on the machine. Never remove or damage them.

If the warning label becomes unreadable, please contact your vendor.

•Keep your working place clean.

•Never work in tight spaces or in purely lit rooms. Make sure the floor is solid and stable and that you can

move around easily.

•Maintain your tools clean and in safe working conditions.

•Handles must be kept free of grease and dirt.

•Make sure no children, unauthorized persons or animals have access to your workshop.

•Never put your hands or legs inside the working area.

•Never leave your machine / equipment unattended during operation.

•Use only for purposes for which it has been designed.

•Use personal protective gear such as safety goggles, ear protection, respirator, safe working shoes etc.

•Do not overreach, use both hands.

•Never work under the influence of alcohol or other drugs.

•Do not use the machine if you feel dizzy or week.

•Any modifications or improvements to the machine are strictly prohibited. Do not use if you discover

damage, bent part, crack or other condition that may prevent the machine from working properly.

•Never perform any maintenance during operation.

•If you see any unusual sign or hear any strange sound, switch off machine immediately.

•Do not forget to remove all wrenches and screwdrivers from the machine after use.

•Before use, make sure all screws are tightened securely.

•Perform maintenance regularly. Before use make sure the machine is in good working conditions and

without any damage.

•Use only original spare parts during repairs.

•Using non-original spare parts or other parts not approved by the manufacturer may cause damage to the

machine or personal injury to the operating personnel.

•Use this machine only for work that could be handled by it. Do not overload tools, accessories or the

machine. For large work volume use more powerful machine.

•Do not overload. Measure the work load in such way, so it could be done with a comfortable speed.

•Do not expose to extremely high temperature or direct sunlight.

•This machine is not designed for use in humid environments or under water.

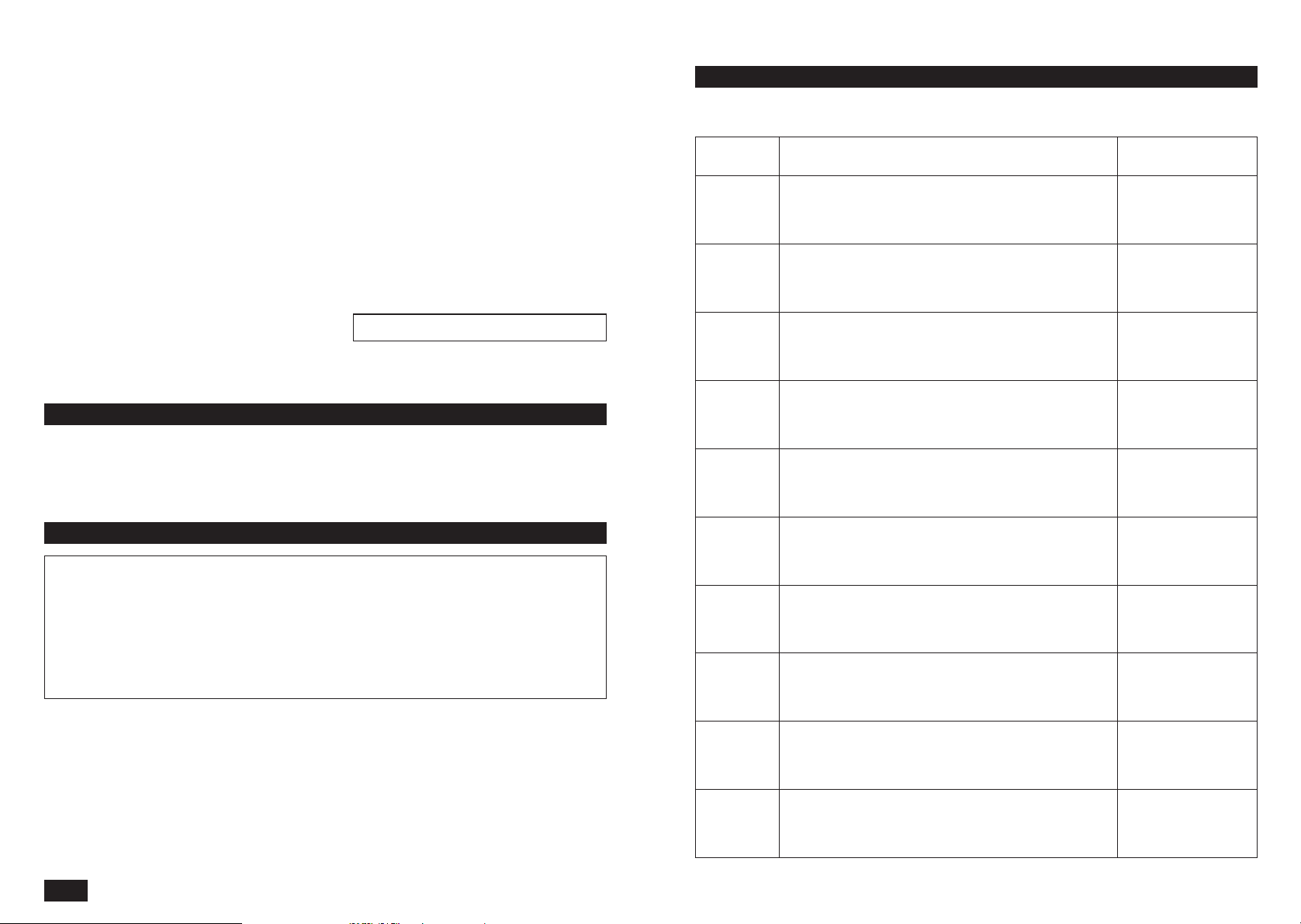

SAFETY PRECAUTIONS

Danger of bodily injuries

Read manual before use

Danger of having fingers cut

Use protective gloves