4

•Do not use the machine/tool if you feel dizzy or week.

•Any modifications or improvements to the machine are strictly prohibited. DO NOT USE if you discover

bent part, crack or other damage.

•Never perform any maintenance during operation.

•If you see any unusual sign or hear any strange sound, switch off the machine immediately.

•Do not forget to remove all wrenches and screwdrivers after use.

•Before use, make sure all screws are tightened securely.

•Perform maintenance regularly. Before use make sure the machine is in good working conditions and

without any damage.

•Use only original spare parts during repairs.

•Using extension pieces or accessories not approved by the manufacturer may cause injuries to the

operating personnel.

•Use suitable tool for particular type of work. Do not overload tools, accessories or the machine. For large

work volume use more powerful machine.

•Do not overload your device. Measure the work load in such way, so it could be done with comfortable

speed. Damages due to machine overload are not covered by the warranty policy.

•Do not expose to extremely high temperature or direct sunlight.

•This machine is not designed for use in humid environments or under water.

•If you are not using your machine, store it in a dry and safe place, out of reach of children.

•Before use make sure that all safety elements work correctly and efficiently. Make sure all moving parts

are in good working conditions.

•Before use make sure that no part is cracked or stuck, Make sure all parts are attached and assembled

as designed. Beware of all other conditions that may have a negative effect on the proper functioning of

your machine.

•If not stated otherwise in this manual, all damaged parts and safety elements must be repaired or changed.

Fine mechanics

•Never use a vise to hold you device.

•Protect your machine from fall and impact. When you finish your work store your equipment back inside

the briefcase.

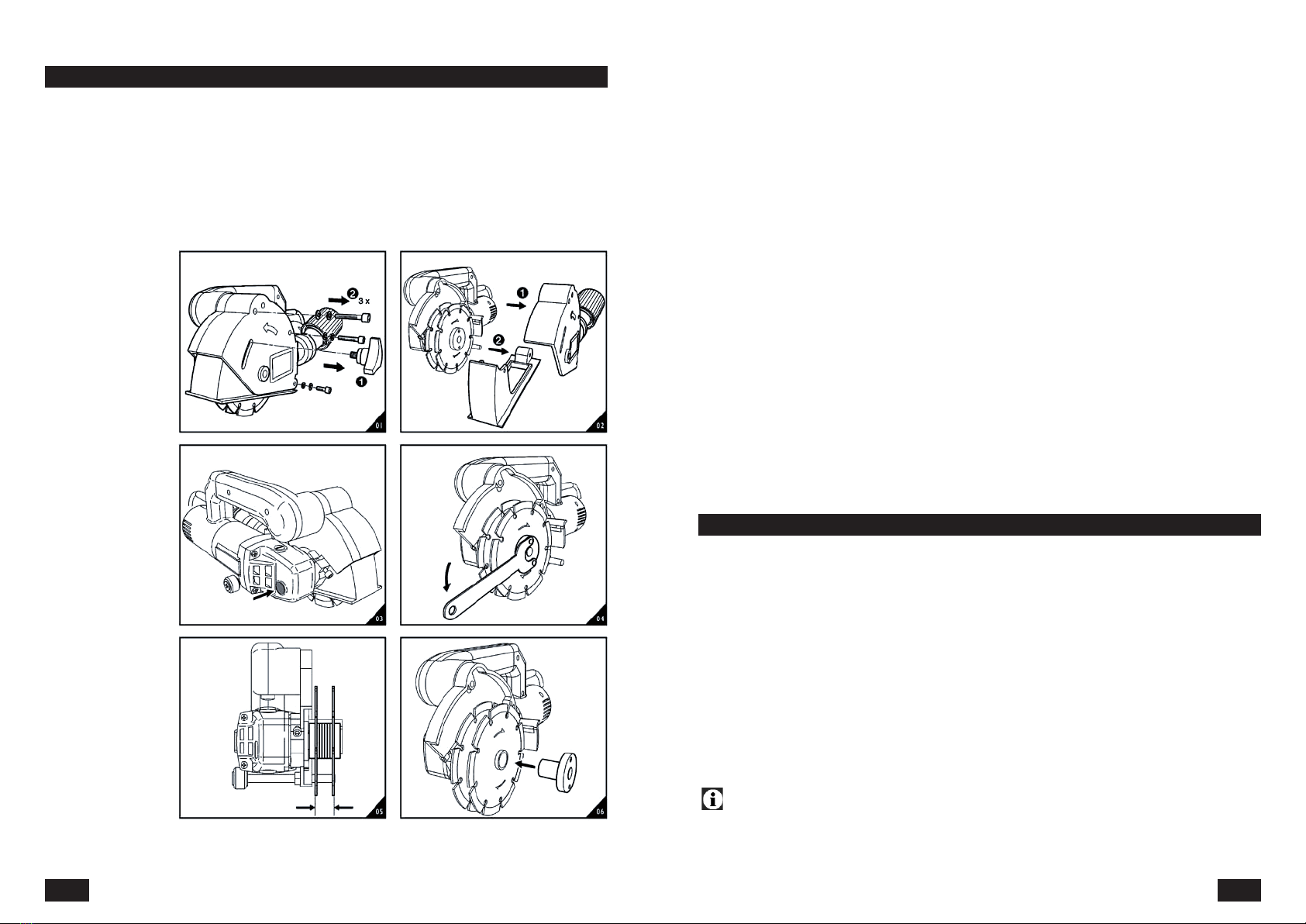

Assembly

•Do not use the machine unless completely assembled.

Electrical equipment

•Observe all basic safety rules when using electrical equipment to prevent risk of fire, injuries by electrical

shock and other hazards. Before using this device, read this manual entirely and follow all safety

instructions. Before using this device, read this manual entirely and follow all safety instructions.

•Make sure the power cable plug is plugged into the correct wall outlet. The voltage in the wall outlet must

be the same as shown on the specification label to prevent damage to the electric motor. Too low voltage

will not provide your machine with enough power.

•Before connecting the machine to the wall outlet make sure that the main switch is in the "OFF" position.

When you finished your work, disconnect the power plug from the wall outlet and switch off the main switch.

•Never carry electrical tools and appliances by their power cord. When disconnecting the plug from the

wall outlet, never pull the cable by its cord.

•Protect the power cable from high temperatures, oils, paint thinners and make sure that the cable is not

hanging over sharp edges.