2

Dear customer. Thank you for purchasing equipment from KH Trading, s.r.o.

Our company is ready to offer you our services - before, during and after you buy our product.

If you have any question, comment or idea, please contact our business centre. We will do our best to address

your comment or question in timely matter.

Before first use, please read this manual carefully. It is your responsibility to study all instructions,

necessary for safe use and operation and to understand all risks that may be involved during the use

of power machines.

WARNING! Do not try to use this machine before reading this entire manual and before you know

how to handle it. Keep this manual for future reference.

Pay special attention to safety instructions. Not complying with safety rules may cause injury to the

operating person or to people standing by or it may cause damage to the machine or to the work

piece. Pay special attention to safety notes and safety labels on the machine.

Never remove or damage them.

Please, write information such as the invoice number

and the number of the sale receipt here in this box.

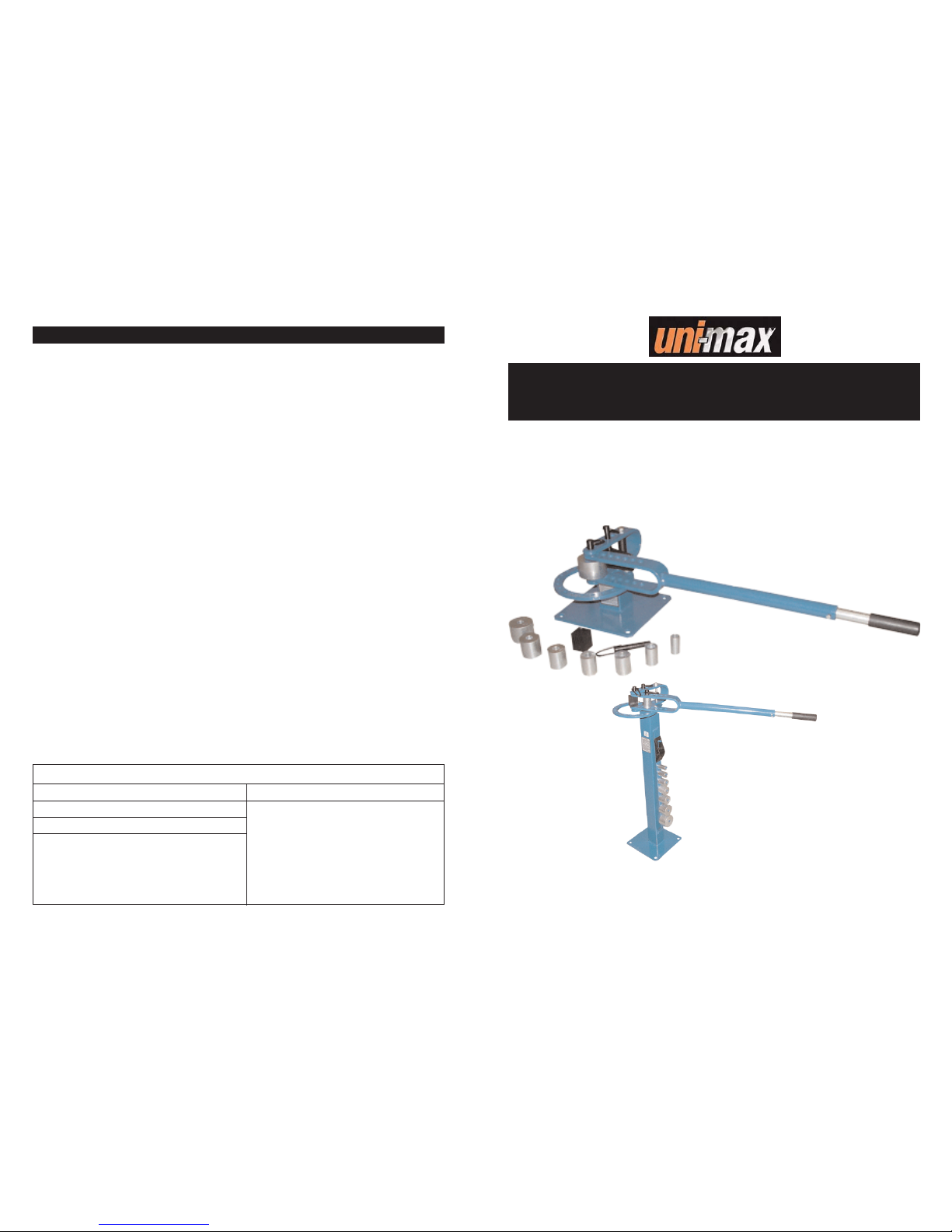

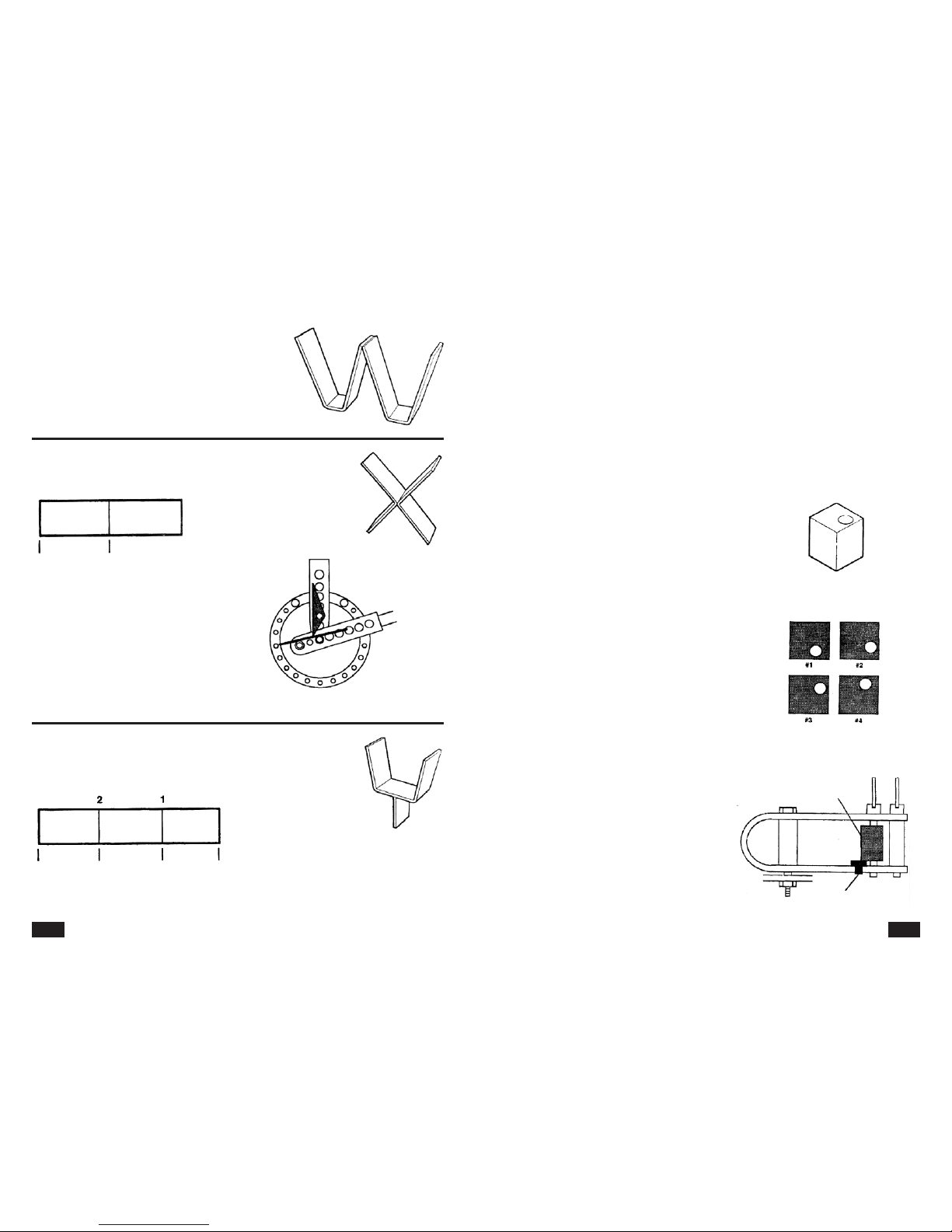

This universal bending machine with a massive steel stand that also serves as a storage place for bending

accessories, enables you to perform professional bending work of various type of metal struts and poles with

various cross cut sections (flat, square and circular). Equipped with a telescopic arm - length up to 90 cm

ensures enough power to perform your bending works. Machine is available in two options - a model with

a table mount and model with its own stand.

Accessories:

Radius bending accessories: 1“, 1 1/4“, 1 1/2“, 1 3/4“, 2“, 2 1/2“, 3“.

The accuracy of instructions, graphs and information contained herein, depends on the printing date. Due to

continuous product improvement, the manufacturer reserves the right to change technical parameters of the

product, without prior customer notification.

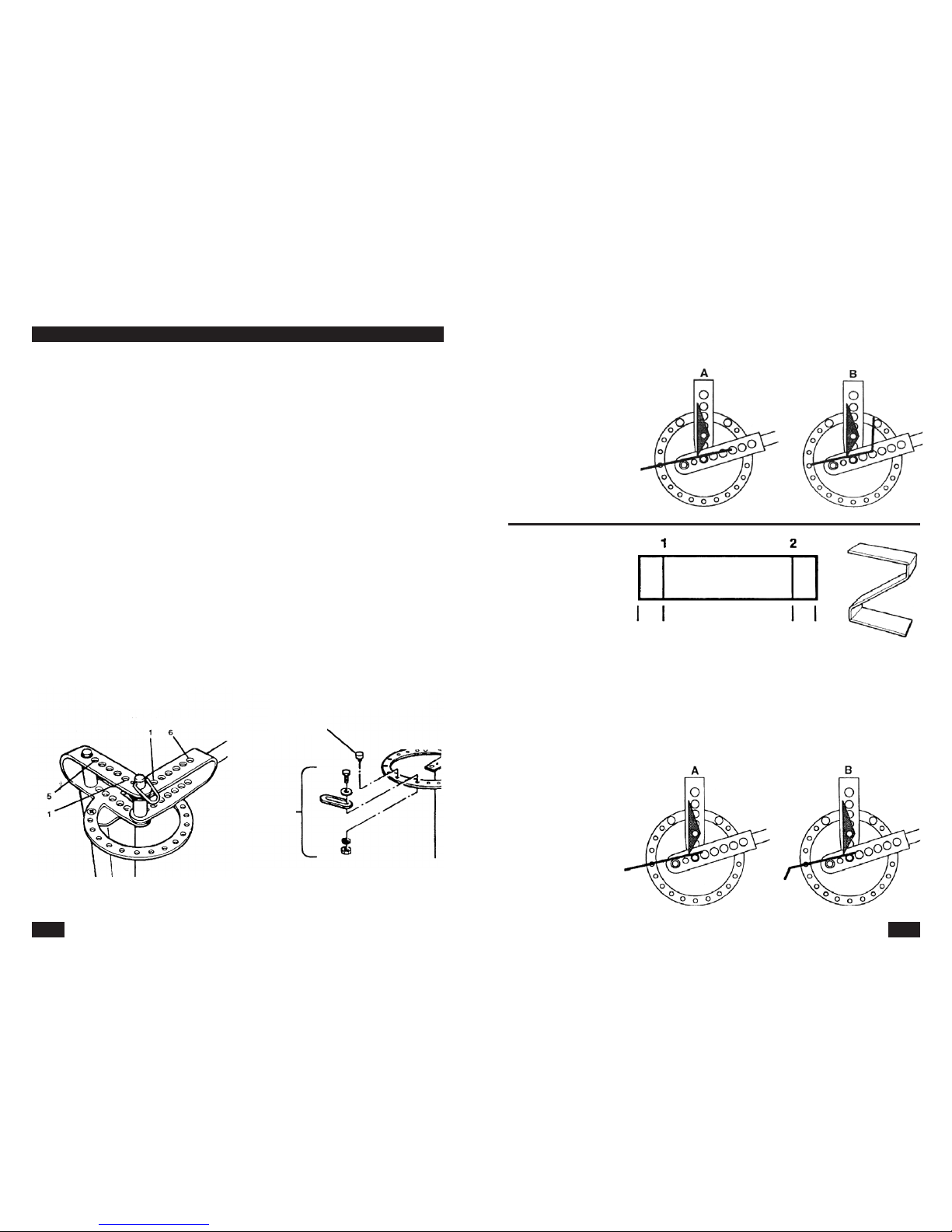

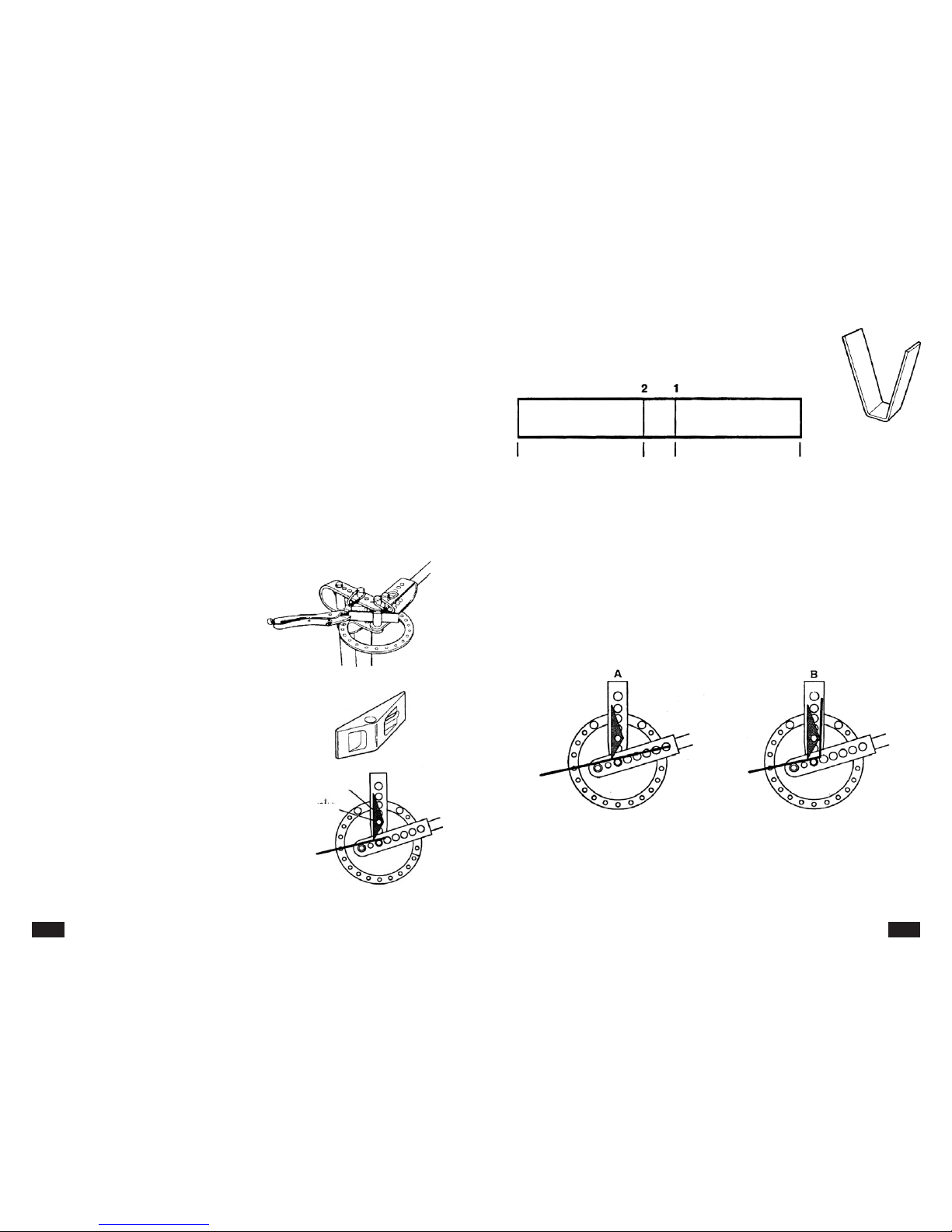

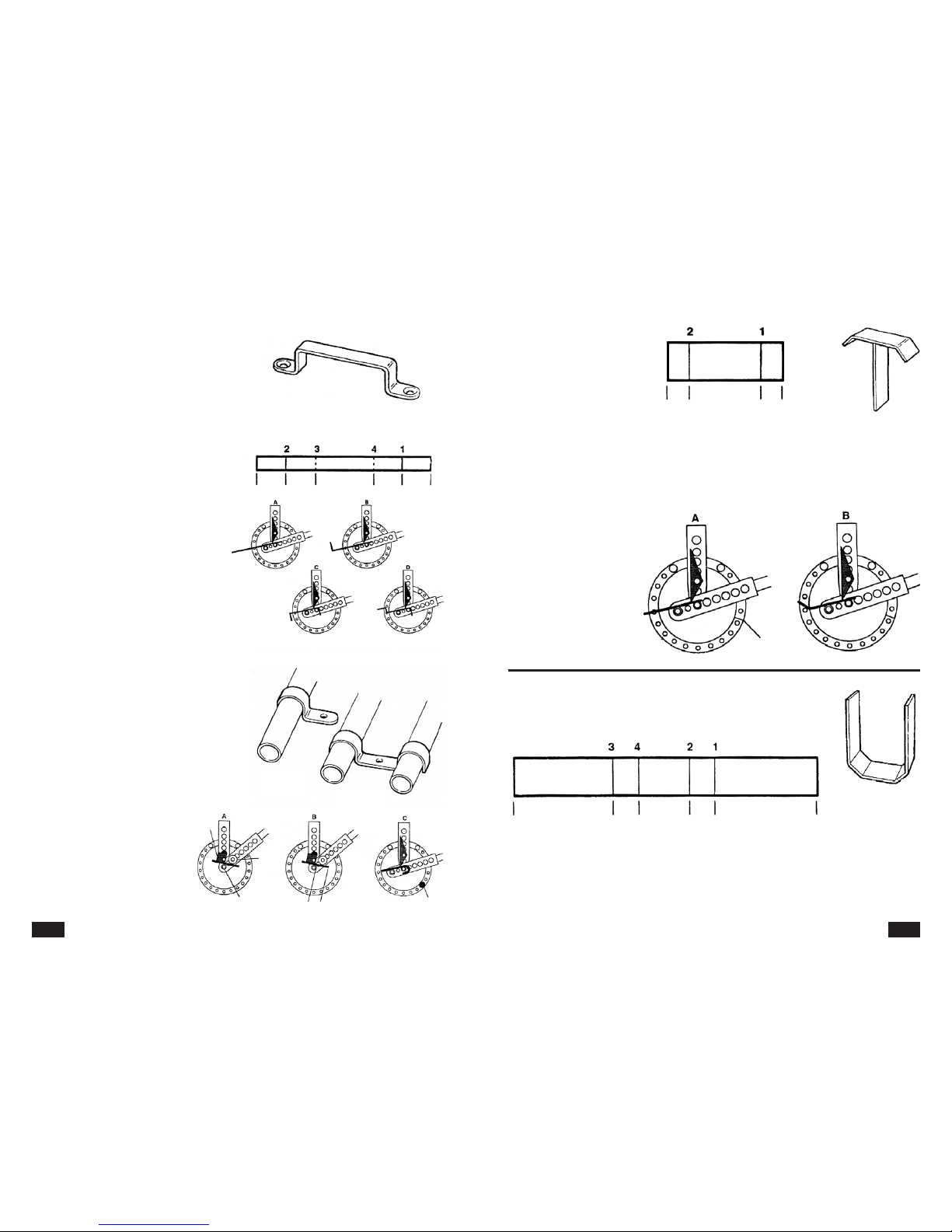

Material suitable for bending:

Hot rolled steel (steel with low carbon content)

You may bend steel with diameter up to 6.5 cm . . . . . . . . . . . . . . . . . . . . . . . . .around the centre stud.

To bend large diameters, place the master die on the centre stud. . . . . . . . . . . . . . . . . . . . . . . . . . . .2"

Maximum dimensions of the work piece

Flat steel straps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 × 50 mm

Round or square steel poles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 × 16 mm

EXCEPTION

Rib-reinforced pole with diameter of 12.7 mm may be bent only around the centre stud

with the 3" master die installed.

Dimension of round or square steel rod - sharp bending . . . . . . . . . . . . . . . . . . . . . . . . . . .5 × 50 mm

or . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 × 32 mm

A pole with diameter of 12 mm may be bent around the . . . . . . . . . . . . . . . . . . . . . . . . .3" master die.

Packaging dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .900 × 250 × 270 mm

Gross weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26 kg

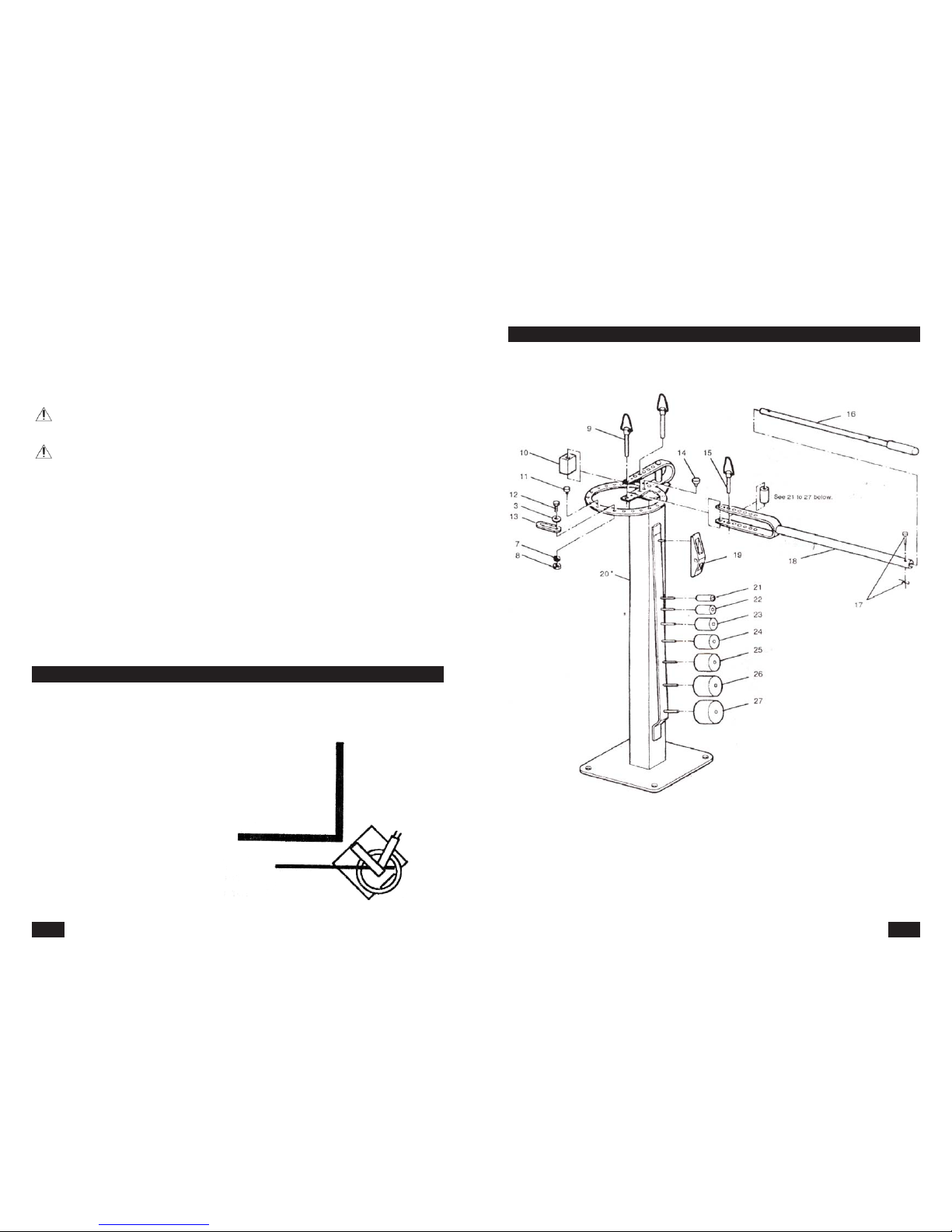

DESCRIPTION

TECHNICAL SPECIFICATION