MTJ MRJ Series

MANUAL

1.000.0

TABLE OF CONTENTS

CONTENTS PAGE

GENERAL INFORMATION _ _ _ _ _ 1.005.0

Used symbols _ _ _ _ _ 1.005.0

Tightening torques _ _ _ _ _ 1.005.0

General safety instructions _ _ _ _ _ 1.005.0

Safe operation _ _ _ _ _ 1.005.0

Modification of the linear unit _ _ _ _ _ 1.010.0

Lables and notices _ _ _ _ _ 1.010.0

Warranty _ _ _ _ _ 1.010.0

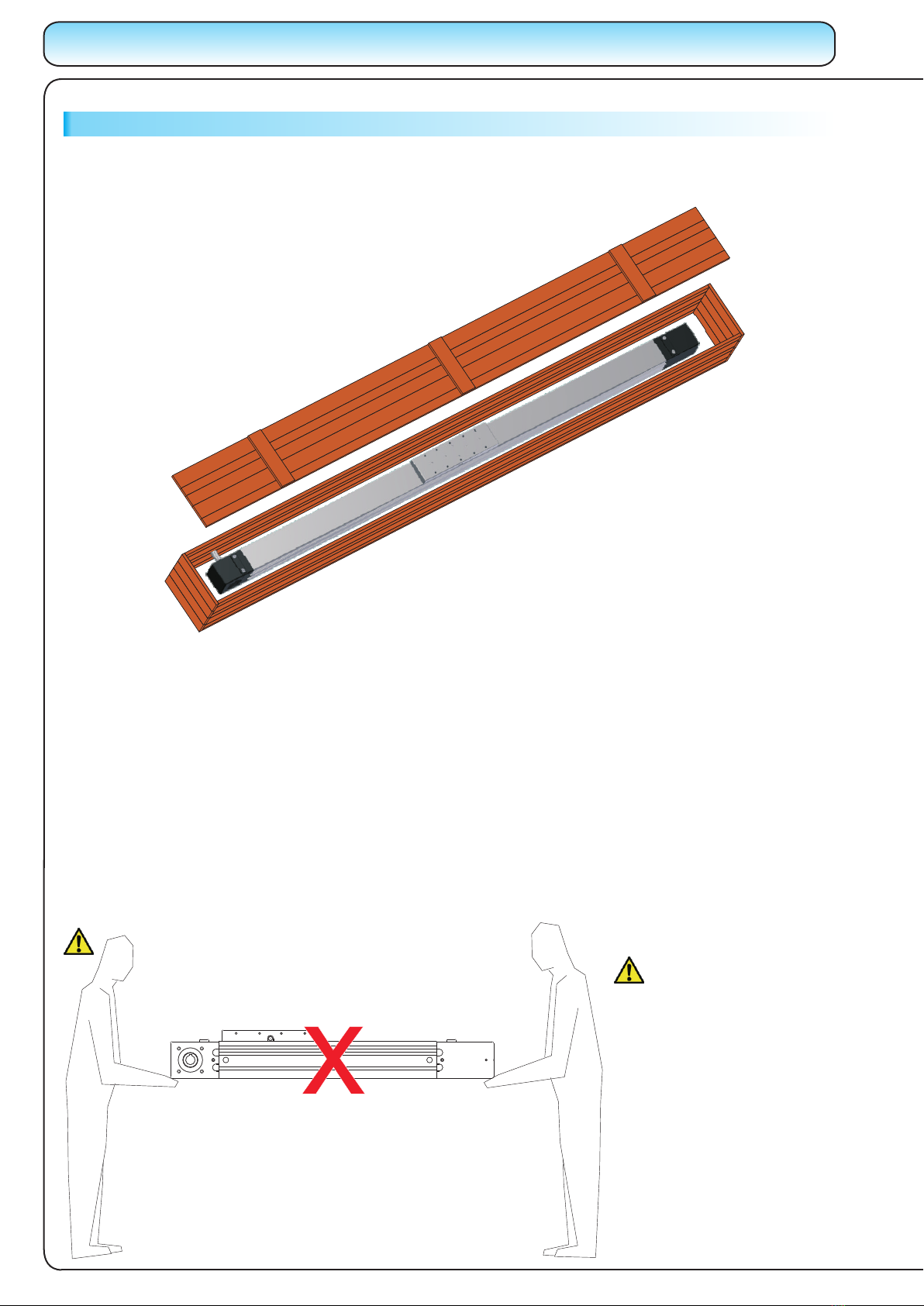

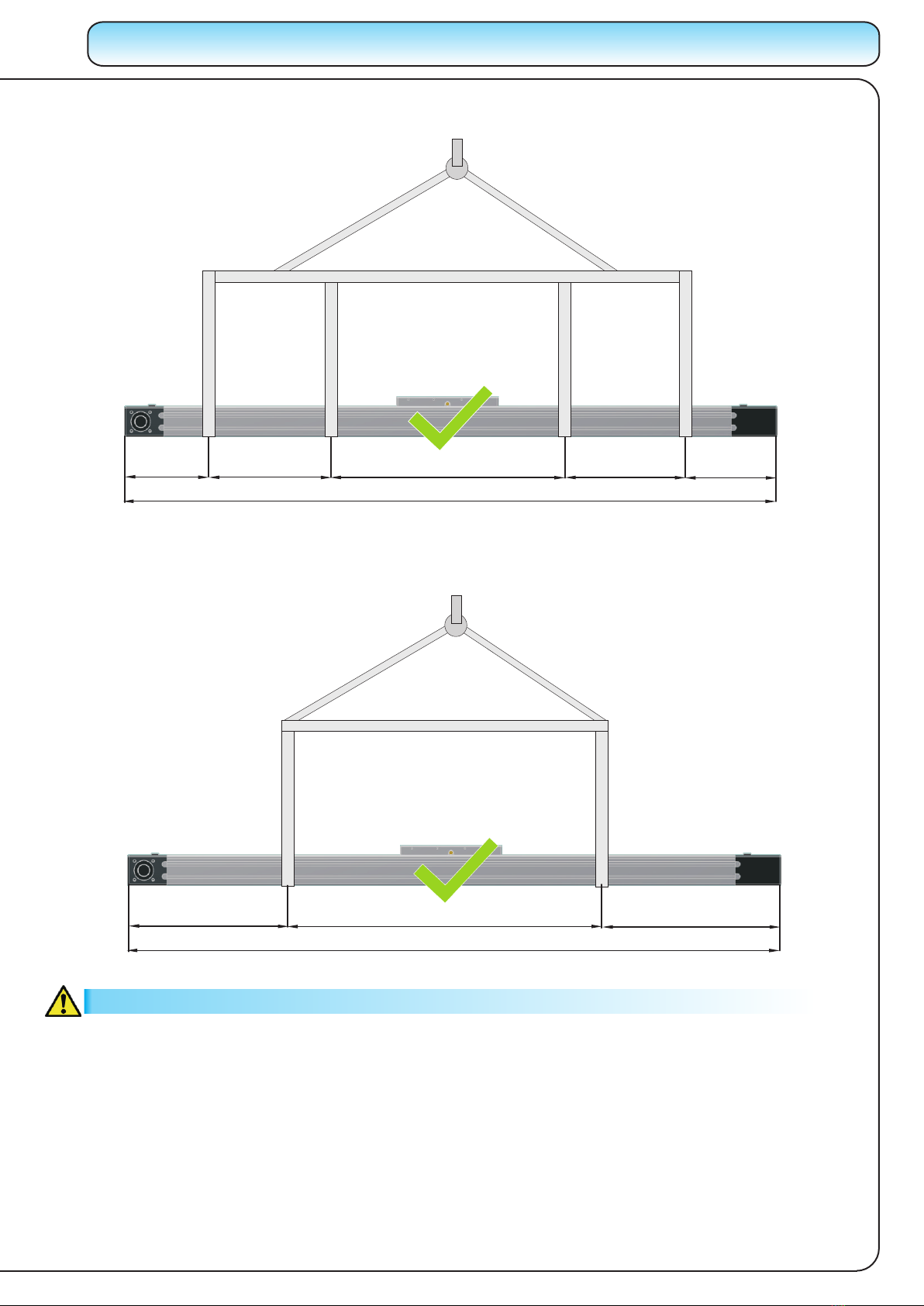

Handling the linear unit _ _ _ _ _ 1.015.0

Product description _ _ _ _ _ 1.025.0

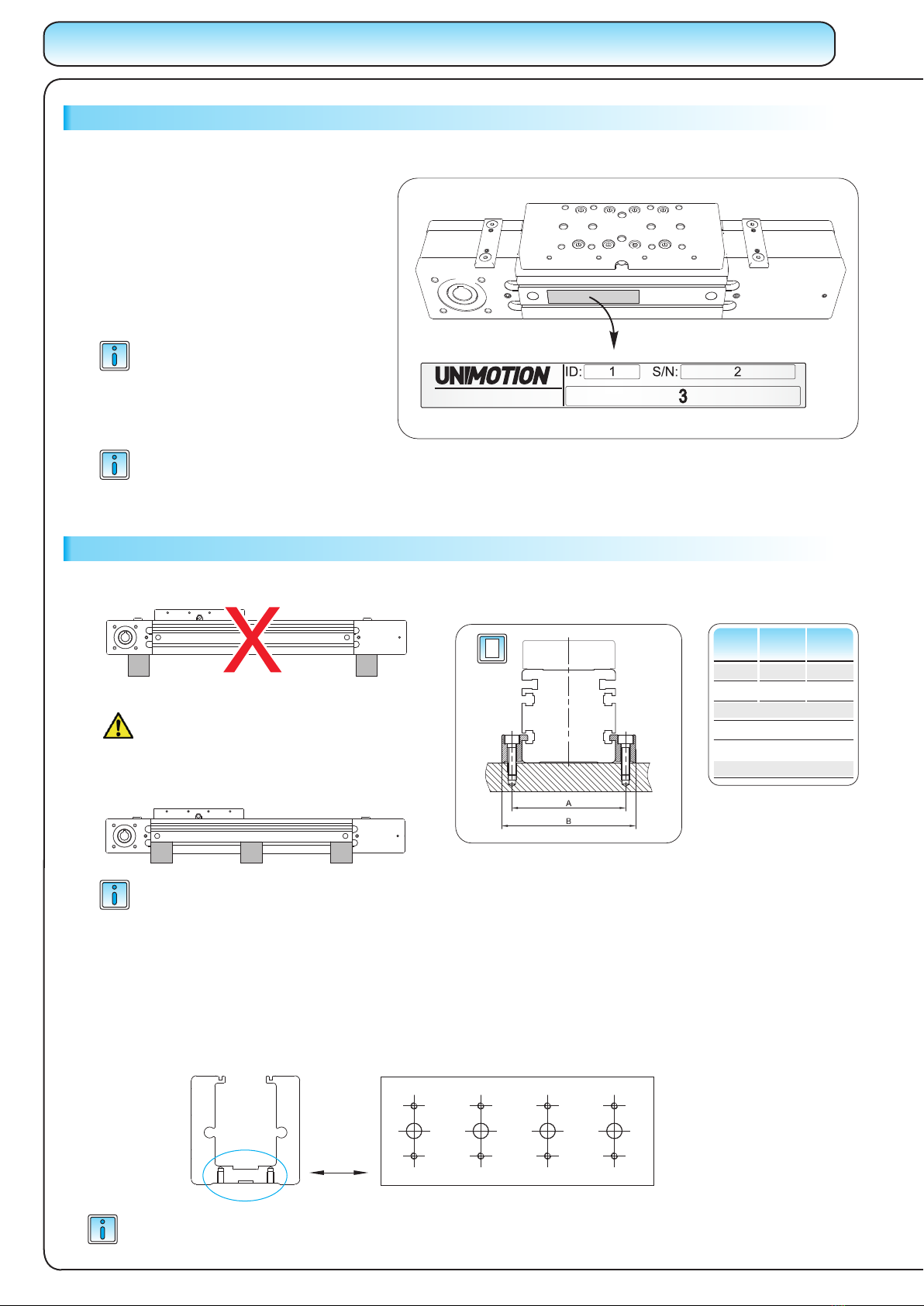

Overview _ _ _ _ _ 1.035.0

MOUNTING _ _ _ _ _ 1.035.0

Fixing system _ _ _ _ _ 1.035.0

Magnetic field sensor _ _ _ _ _ 1.040.0

Mechanical and inductive switch_ _ _ _ _ 1.045.0

Motor with the coupling _ _ _ _ _ 1.050.0

MAINTENANCE _ _ _ _ _ 1.055.0

Lubrication of the carriage _ _ _ _ _ 1.055.0

Lubrication of the cover strip _ _ _ _ _ 1.055.0

Lubricant _ _ _ _ _ 1.055.0

Lubricant quantities and intervals_ _ _ _ _ 1.055.0

Normal operating conditions _ _ _ _ _ 1.060.0

ASSEMBLIES _ _ _ _ _ 1.065.0

MTJ 40 _ _ _ _ _ 1.065.0

MRJ 40 _ _ _ _ _ 1.070.0

MTJ 65 S _ _ _ _ _ 1.075.0

MTJ 65L _ _ _ _ _ 1.080.0

MRJ 65 L _ _ _ _ _ 1.085.0

MTJ 80 S _ _ _ _ _ 1.090.0

MTJ 80 L _ _ _ _ _ 1.095.0

MRJ 80 L _ _ _ _ _ 1.100.0

MTJ 110 S _ _ _ _ _ 1.105.0

MTJ 110 L _ _ _ _ _ 1.110.0

MRJ 110 L _ _ _ _ _ 1.115.0

MTJ ECO 40 S _ _ _ _ _ 1.120.0

MTJ ECO 40 L _ _ _ _ _ 1.125.0

REPLACEMENT OF ASSEMBLIES MTJ/MRJ SERIES _ _ 1.130.0

Removing the cover plate _ _ _ _ 1.130.0

Replacing the protection strip _ _ _ _ 1.130.0

Removing the end blocks _ _ _ _ 1.135.0

Replacing the toothed belt _ _ _ _ 1.135.0

Tensioning the toothed belt _ _ _ _ 1.140.0,

REPLACEMENT OF ASSEMBLIES MTJ 40 ECO SERIES _ 1.145.0

Loosening the toothed belt _ _ _ _ 1.145.0

Removing the end blocks _ _ _ _ 1.145.0

Replacing the toothed belt _ _ _ _ 1.150.0

Tensioning the toothed belt _ _ _ _ 1.150.0

Replacing the end blocks _ _ _ _ 1.155.0

Replacing the carriage _ _ _ _ 1.155.0

Replacing the profile / the rail _ _ _ _ 1.155.0

The specifications in order to improve the products in this catalogue are subject to change without notice.