From the library of: Superior Sewing Machine & Supply LLC

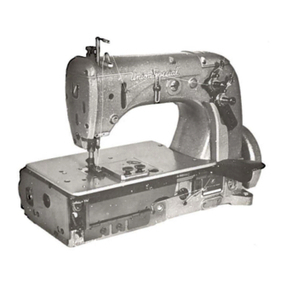

Each

UNION

SPECIAL

machine

is

identified

by

a Style

number,

which

on

this

machine

Class,

is

stamped

into the Style plate affixed to the right front of

machine.

Serial

number

is

stamped

into

bed

casting

at

the

left

rear base of machine.

NOTE:

Instructions

stating

direction or location,

such

as

right,

left,

front or

rear

of

machine, are given

relative

to the operator's position

at

the

machine, unless otherwise noted.

The

handwheel

rotates counterclockwise in

operating direction

when

viewed

from

the

right

end

of

machine.

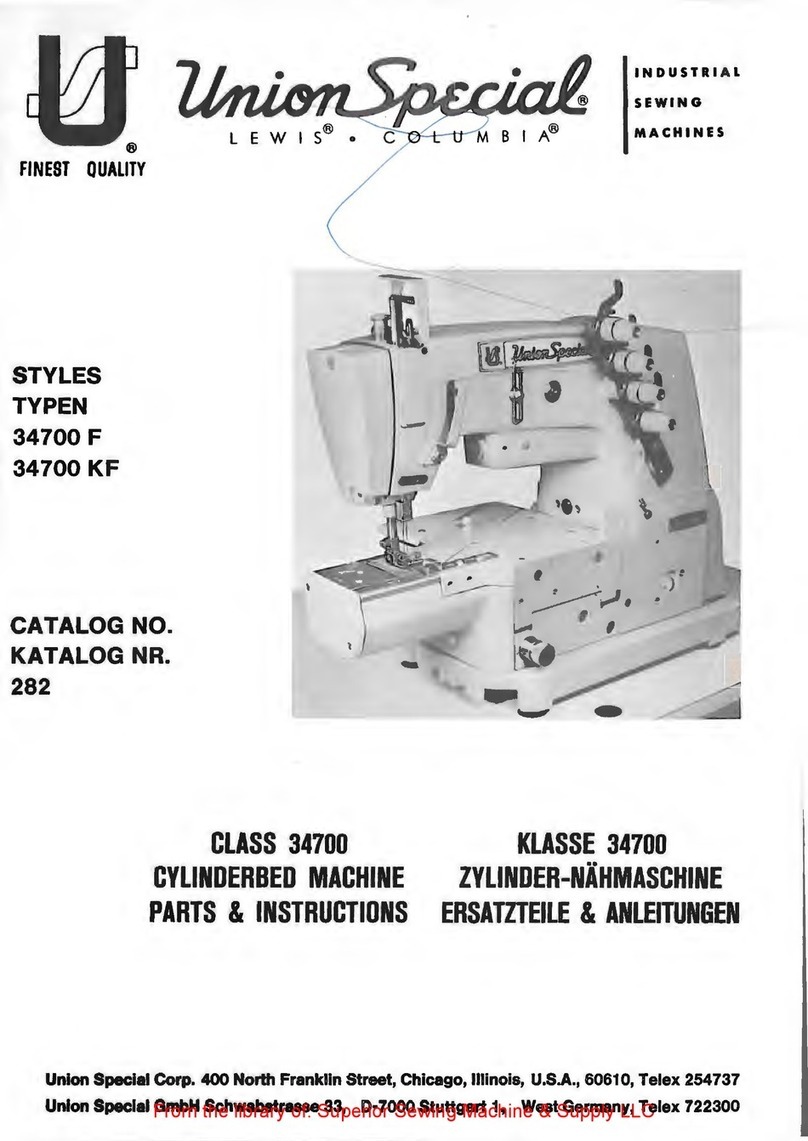

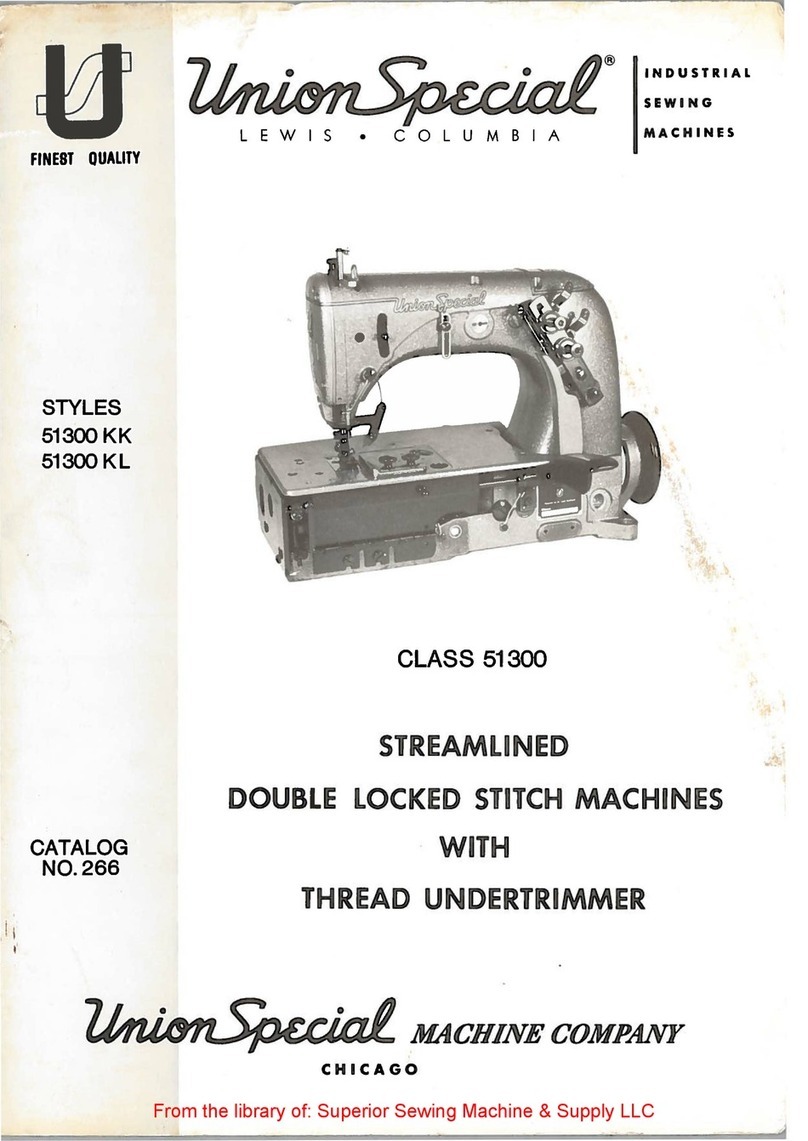

STYLES

OF

MACHINES

High

speed,

maximum

performance, double locked

stitch,

plain feed flatbed

machine.

Totally enclosed feed

and

looper drive

mechanism,

fully

automatic forced feed

lubricating system with

easily

replaceable

oil

filter,

quick

stitch

change,

independently driven rear needle guard

and

quick adjustable looper avoid.

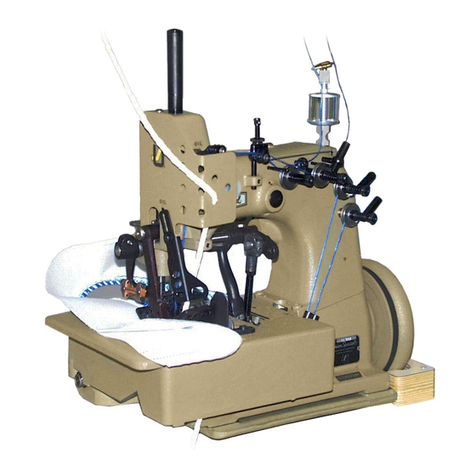

LF611KlOOHM

Single needle,

HIGH

sewing

capacity

machine

with

sewing

parts to

accomodate

Selvage

Edge

Binder -for binding mattress

ticks

made

from

medium

heavy

to

heavy

weight materials.

Uses

selvage

edge

binding 5/8, 3/4

and

7/8 inch (15.8, 19.0

and

22.2mm)

wide

to

produce a 5/16, 3/8

and

7/16 inch (7.9, 9.5

and

11.1mm)

finish.

Standard

recommended

needle

Type

128

GAS,

Size 125/049.

Stitch

range

5-14

S.P.I.

Maximum

recoR111ended

speed

6500

R.P.M.

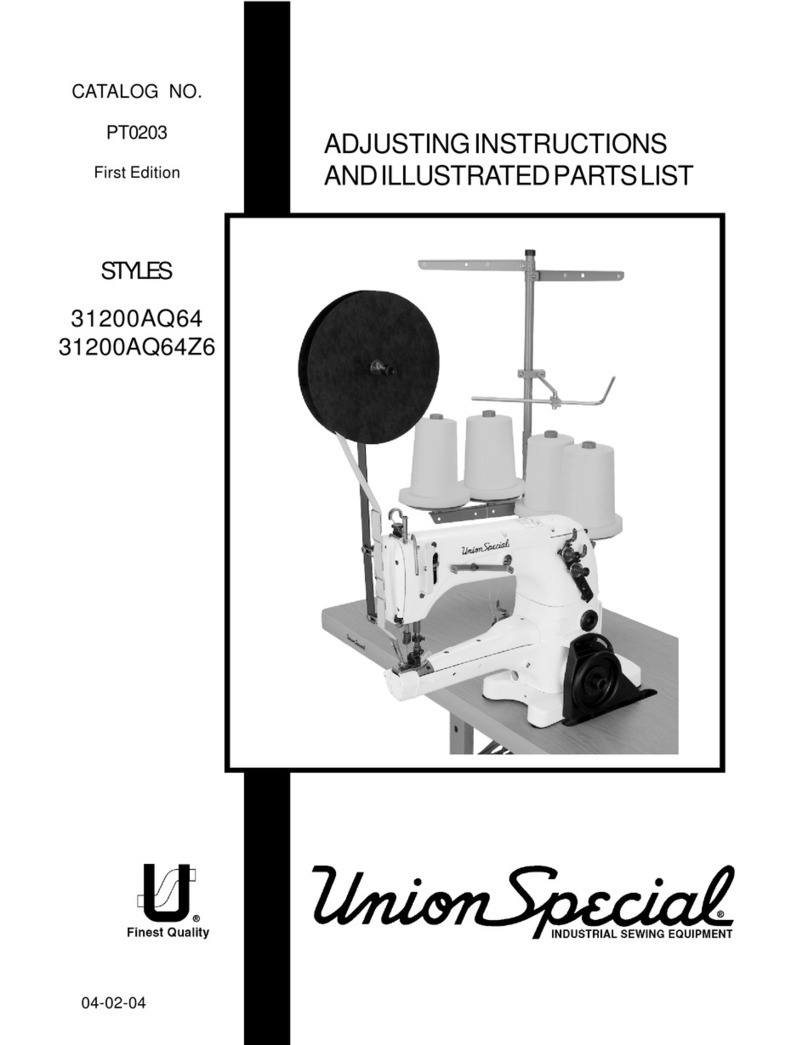

LF611KlOOMF

Single needle,

MEDIUM

sewing

capacity

machine

with

low

inertia

presser foot, permitting 1ight presser foot pressure

for

positive

feeding

and

chaining

at

high speeds -

for

long

seams

on

light

to

medium

weight fabrics

such

as in trousers,

skirts,

coats, jackets,

etc.

Standard

recommended

needle

Type

128

GBS,

Size 90/036. Stitch

range

7-10

S.P.I.

Maximum

recommended

speed

6500

R.P.M.,

depending

on

operation.

LF611K100MG

Single needle,

MEDIUM

sewing

capacity

machine

used

for side

and

inseaming men's

work

and

dress pants

made

from

medium

weight

material. Standard

recommended

needle

Type

128

GBS,

Size 90/036.

Stitch

range

10-14

S.P.I.

Maximum

recommended

speed

6500

R.P.M.,

depending

on

operation.

LF611KlOOMR

Same

as Style

LF611KlOOMF

except -

fitted

with feeding presser foot

with yielding section to

left,

allowing crossing of

seams

and

pockets.

LF611KlOOMW

Same

as Style

LF611KlOOMF

except -

used

for

seaming

cotton, flannel

and

leather

palm

gloves. Standard

recommended

needle

Type

128

GAS,

Size 110/044.

Stitch

range

5-14

S.P.I.

LF611KlOOMAW

Same

as Style

LF611K100MF

except -equipped with

narrow

feeding

presser foot

and

related

sewing

parts for 3/16 inch

(4.8mm)

margin.

LF611K112MF

Same

as Style

LF611K100MF

except -equipped with

Power

"AIR-KLIPP

®"

chain

cutter.

LF611K112MG

Same

as

Style

LF611K100MG

except -equipped with

Power

"AIR-KLIPP"

chain

cutter.

®

"AIR-KLIPP"

is

a registered trademark of

Union

Special Corporation.

3