At the end of the initialization, instrument moves to the menu page.

The menu page gives information on the operating mode selection for the specific key activation

as follows:

1. “UP” key ▲Monitoring mode i.e. Start sampling (continuous/batch sampling).

2. “DN” key ▼Switch to Calibration mode.

3. “SET” key ● Enter into parameter setting and to proceed for Instrument OFF page

4. “ENTER” key Access to data logger

4. Operations in Various Modes

4.1 PARAMETER SETTING MODE:

While in the menu page, press the SET Key ●to enter into the parameter set mode.

After successful authentication (Password - 123), user has an access to the following

parameters in this mode.

To change parameter value, follow below procedure.

1.The cursor will blink below the first digit of the Parameter. Use the DOWN Key ▼to move

the cursor horizontally over different digits (i.e. to change cursor position).

2. If any digit is to be changed, move the cursor under the digit and press the UP Key ▲.

Using the UP Key ▲, the digits can be changed from 0 to 9.

3. Press the ENTER Key to confirm the changed digit and to switch over to the next

parameter.

4. If the displayed parameter is not to be changed, press the SET Key ●to switch

over to the next parameter.

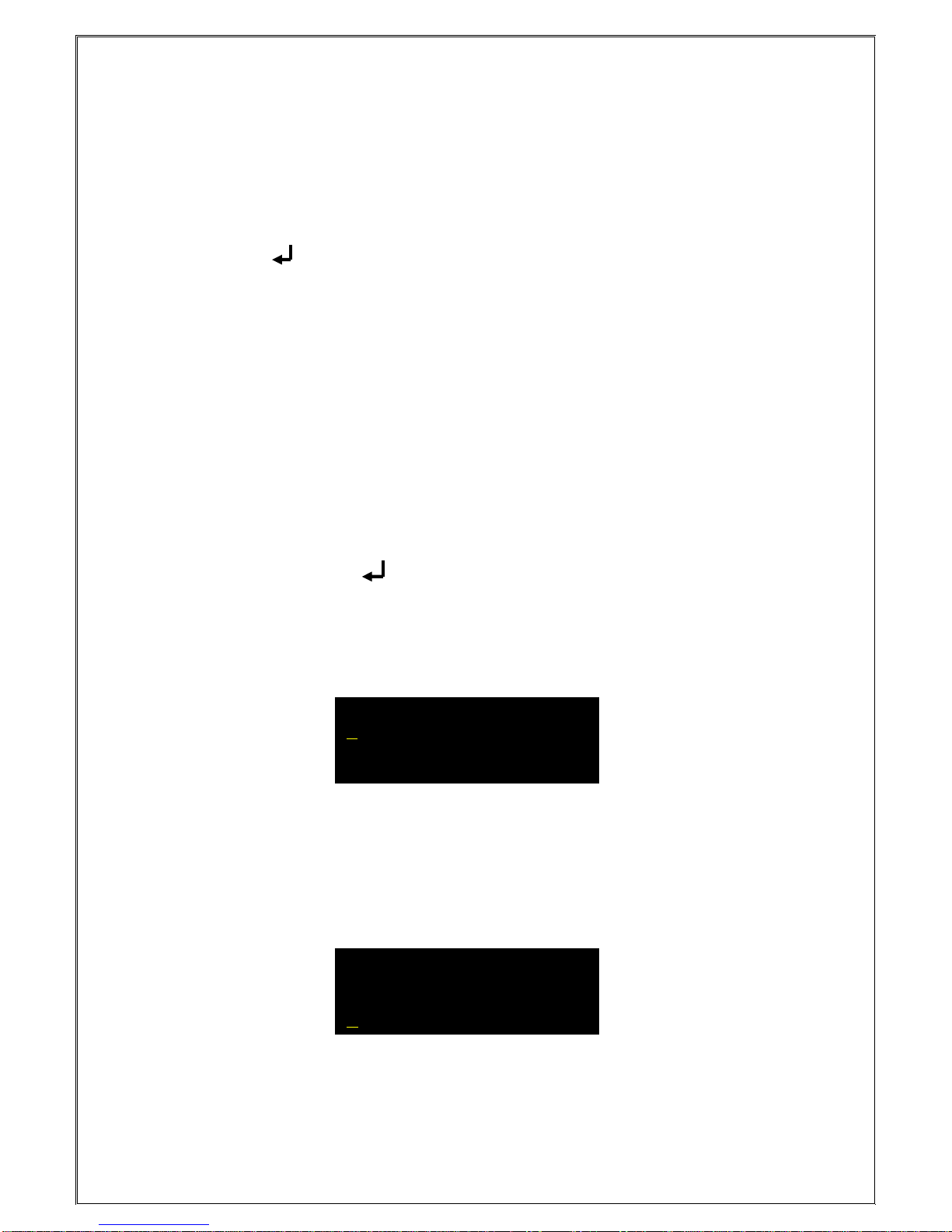

4.1.1 Select Sampling Type & Sampling Time:

1. In this screen, the cursor will blink below “C” of Continuous sampling type. Pressing the

DOWN Key, the cursor will toggle between “Continuous” and “Batch” sampling type.

Select the desired type. Press ENTER key to confirm the type and to move to the next

page.

2. In sampling time setting, the cursor will blink below the first digit of sampling time(only for

BATCH sampling)

As explained above in 4.1, user can input any desired sampling time (between 001-999)

by using UP/DN key and confirm the new value by pressing ENTER key.

Note: At any time, press SET to skip the current data (without saving) and to move to

the next screen.