UniPOS

Gas Detector – 71CNG

UniPOS

i!

Before use, read

the instructions carefully!

Addressable Natural Gas Detector

Type :71CNG

TECHNICAL SPECIFICATION

ENGLISH

GENERAL DESCRIPTION

The 71CNG detector (g.1) is applicable for detection of natural gas (methane) in the protected area. The status of the detector is

indicated with LEDs and sounder.

The 71CNG detector has a signal (communication) and

external

power interface lines.

The signal loop (communication) interface line is compatible with the IFS7002 re control panel through the UniTalk private protocol.

The signal loop (communication) interface power supplies the communication, micro-controller, detection schematics of the device.

In order to be fully functional, the 71CNG device requires additional

external

power supply in the range (18 – 30) Vdc, which supplies

the sounder and Led indication and heating of the sensor.

The signal loop (communication) interface is protected with a short-circuit isolator.

Both power supplies are galvanic-separated and must not be with common ground. The common ground will not damage the

standalone operation of the 71CNG, but will aect the communication between the detector and the IFS7002 control panel.

TECHNICAL DATA

Maximum number of

71CNG detectors

in the IFS7002 signal loop: 125 pcs.

Supply voltage :

- signal loop (15-30) V DC

- external power

supply

(18-30) V DC

Current consumption in Duty mode:

- signal loop < 350µA

- external power

supply

55 mA

Current consumption in Alarm mode :

- signal loop (2±1)mA

- external power

supply

75 mA

Sound level 100dB@1m

Temperature: from minus 5°С to 40°С

Degree of protection IPX2D

Relative humidity resiatance (no condensation) ≤ 95%

Dimensions (134x36x112)mm

Weight 0.115кg.

Construction: ABS

1

02/09.20 02/09.20

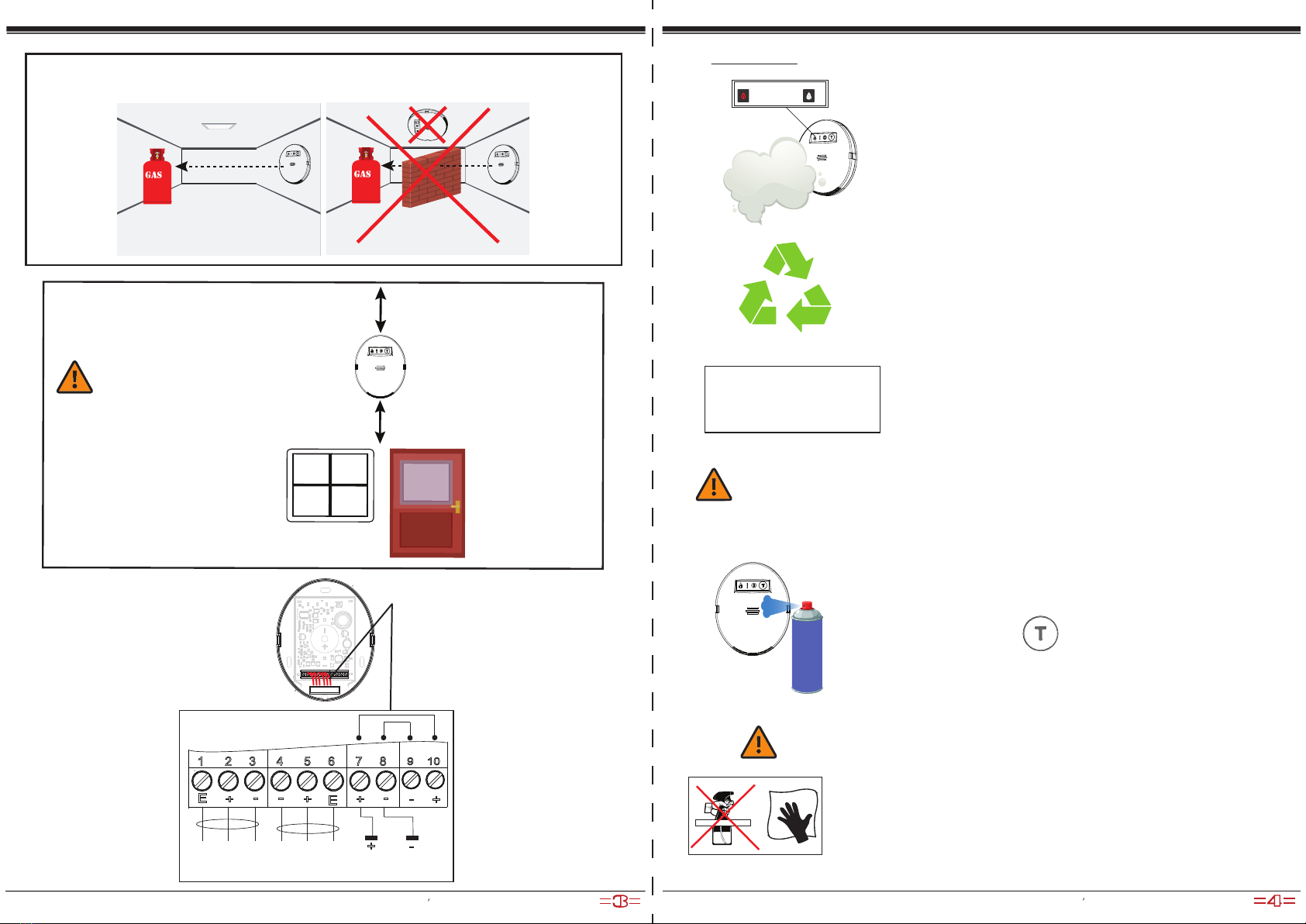

ATTENTION !!! OPERATION TO BE DONE IN CASE OF ALARM:

– Put out any ames.

– Close the gas tap or the cylinder.

– Do not turn any electrical consumers on or o.

– Open all windows and doors to increase ventilation.

– If alarm stops it is necessary to discover the cause and act on consequence.

– If the alarm continues and the cause is not evident or possible to eliminate leave the room

immediately and call the emergency service.

Fig.1

CONTROL AND INDICATIONS

The 71CNG detector's functions are indicated through the following LEDs (g1 pos.1):

green - indicates working power supply status of the detector

- If the green LED is continuous On - there is properly working power supply

yellow – indicates fault and service status.

- If the yellow LED is blinking - the gas sensor is in heating (warm-up) procedure for 120 seconds

- If the yellow LED is continuous On - there is fault in the 71CNG detector

red and yellow – indicates duty and verication mode

- If both LEDs are continuous On - a service command is required in the IFS7002 control panel (Menu setup>Initializa-

tion>Check)

- If both LEDs are blinking simultaneously in a period of 16 sec. - there is fault in the 71CNG detector

red – indicates alarm

- If the red LED is continuous On - the methane level is over the calibrated trigger level in the device

and

INDICATES FUNCTIONS

Gas Detector – 71CNG

INSTALLATION

To mount the 71CNG detector,

please remove front panel.

The detector should be installed vertically at the wall – LEDs indicators are in the top-side

of the cabinet, the inlet openings are on the bottom side of the cabinet.

-5°С +40°С

The gas detector must not be mounted:

– Directly above cooking appliances;

– Directly above a sink;

– Adjacent to extractor fans;

– In any outside location;

– Where the environment conditions are outside

of operational specication.

Manufacturer: UniPOS Ltd., 47 San Stefano Street, Pleven 5800, Bulgaria, http://www.unipos-bg.com Manufacturer: UniPOS Ltd., 47 San Stefano Street, Pleven 5800, Bulgaria, http://www.unipos-bg.com