ARR Series Three Phase, Six Pulse SCR Charger Front Matter

RS-420, Rev. 7 iv

TABLE OF CONTENTS

1. INTRODUCTION..................................................................................................................................... 1-1

1.1 PURPOSE AND USE ................................................................................................................................. 1-1

1.2 IDENTIFICATION ..................................................................................................................................... 1-2

2. INSTALLATION....................................................................................................................................... 2-1

2.1 UNPACKING.............................................................................................................................................. 2-1

2.2 LOCATION................................................................................................................................................. 2-1

2.3 MOUNTING ............................................................................................................................................... 2-1

2.4 POWER SOURCE ...................................................................................................................................... 2-1

2.5 CONNECTIONS (REFER TO DRAWINGS IN BACK OF MANUAL) .................................................. 2-1

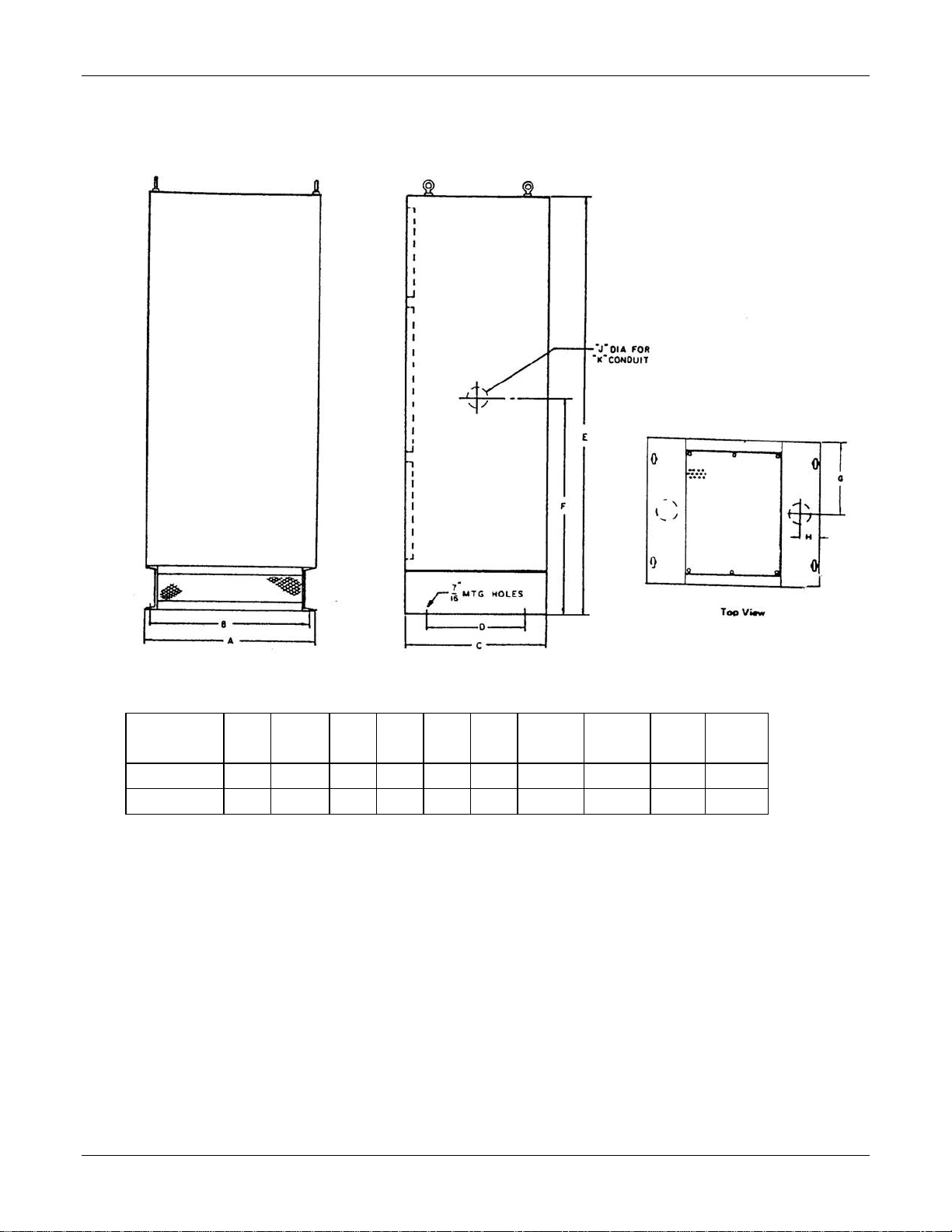

2.5.1 Cabinet Dimensions................................................................................................................................. 2-3

2.5.2 Preliminary Adjustments.......................................................................................................................... 2-5

2.5.3 Float Voltage Adjustment........................................................................................................................ 2-5

2.5.4 Equalize Voltage Adjustment.................................................................................................................. 2-6

2.5.5 Current Limit Adjustment........................................................................................................................ 2-6

2.5.6 High Voltage Shutdown........................................................................................................................... 2-7

3. OPERATION............................................................................................................................................. 3-1

3.1 STARTING AND STOPPING.................................................................................................................... 3-1

3.2 METERS ..................................................................................................................................................... 3-1

3.3 FLOAT-EQUALIZE OPERATION............................................................................................................ 3-1

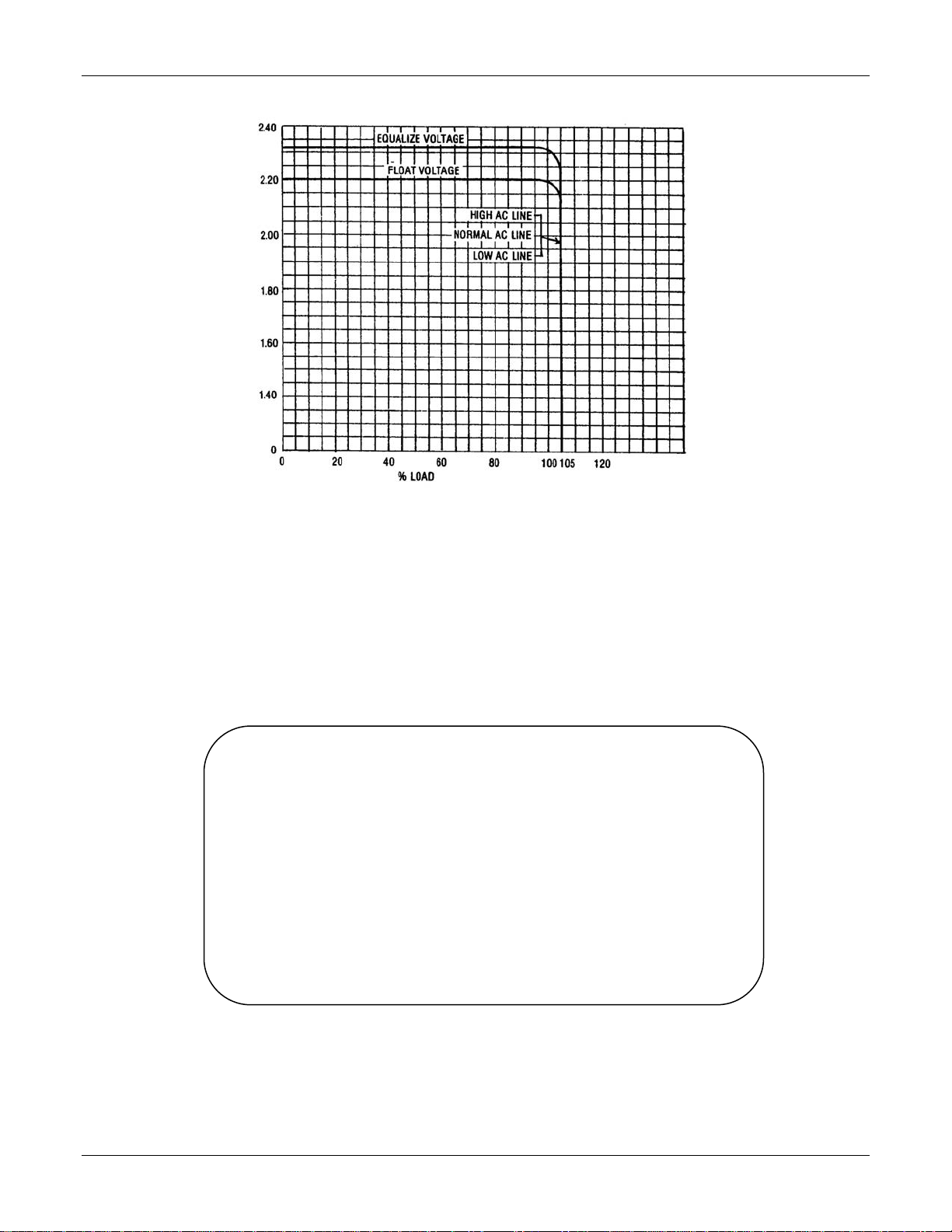

3.4 DESCRIPTION OF OPERATION.............................................................................................................. 3-1

3.4.1 Block Diagram......................................................................................................................................... 3-1

4. ROUTINE MAINTENANCE................................................................................................................... 4-1

5. CORRECTIVE MAINTENANCE........................................................................................................... 5-1

5.1 VOLTAGE CHECKPOINTS...................................................................................................................... 5-1

5.2 BALANCING PROCEDURE..................................................................................................................... 5-1

5.2.1 2010 Series (Refer to Cabinet Dimension section).................................................................................. 5-1

5.2.2 1329 Series (Refer to Cabinet Dimension section).................................................................................. 5-1

5.3 VOLTAGE CHECKPOINT SCHEMATIC (GENERALIZED)................................................................. 5-2

5.4 SPECIFIC PROBLEM CHART.................................................................................................................. 5-3

5.5 INSTRUCTION NOTES............................................................................................................................. 5-5

5.5.1 Checking of Potentiometers..................................................................................................................... 5-5

5.5.2 Checking of Diodes and Silicon Controlled Rectifiers............................................................................ 5-5

5.5.3 Checking the Current Transformer.......................................................................................................... 5-8

5.5.4 Checking the Auxiliary Transformer....................................................................................................... 5-8

5.5.5 Checking DC Filter Capacitors................................................................................................................ 5-8

5.5.6 Checking of Printed Circuit Control Cards.............................................................................................. 5-9

6. CIRCUIT DESCRIPTIONS..................................................................................................................... 6-1

6.1 BASIC CONTROL...................................................................................................................................... 6-1

6.2 CONTROL BOARD SCHEMATICS......................................................................................................... 6-3

6.3 CONTROL BOARD PARTS LIST............................................................................................................. 6-4

6.4 CONTROL BOARD "A" (MBC01970-1) .................................................................................................. 6-6

6.5 CONTROL BOARD “B” (MBC01971-2) .................................................................................................. 6-6

6.6 INTER-PHASE BALANCE BOARD......................................................................................................... 6-7

7. ACCESSORIES AND OPTIONAL EQUIPMENT ............................................................................... 7-1