1

CONTENT

Chapter1Safety...................................................................................3

1Precautionsforsafety......................................................................3

1-1Precautions forsafety.............................................................3

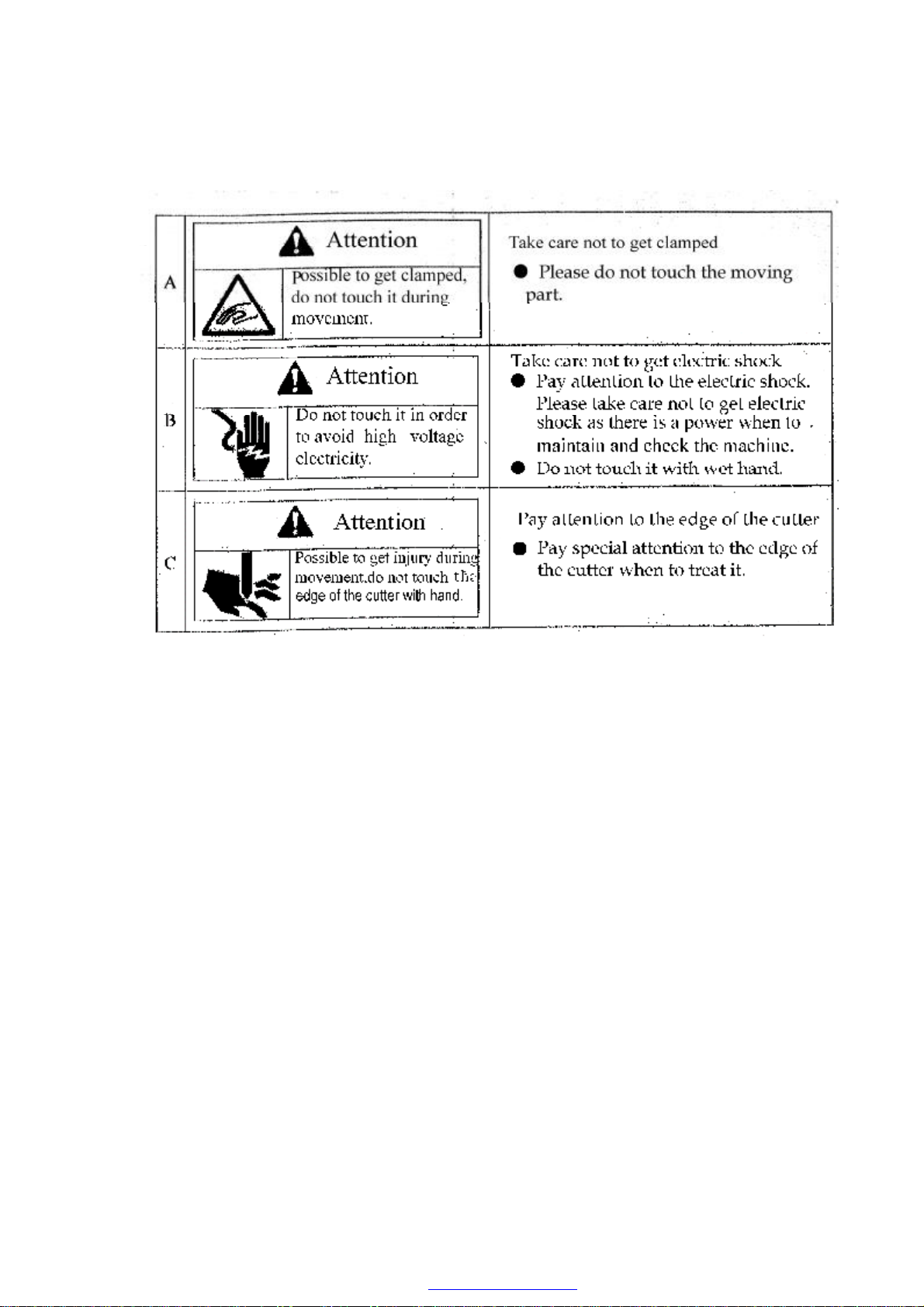

1-2Labelofwarning....................................................................3

2Safetydevice...................................................................................4

2-1Detailrules.............................................................................4

Chapter2General................................................................................6

1Outlineofmechanism.....................................................................6

1-1Purposeofuse........................................................................6

1-2Maintechnicalparameters.....................................................6

1-3Accessories withthemachine.................................................7

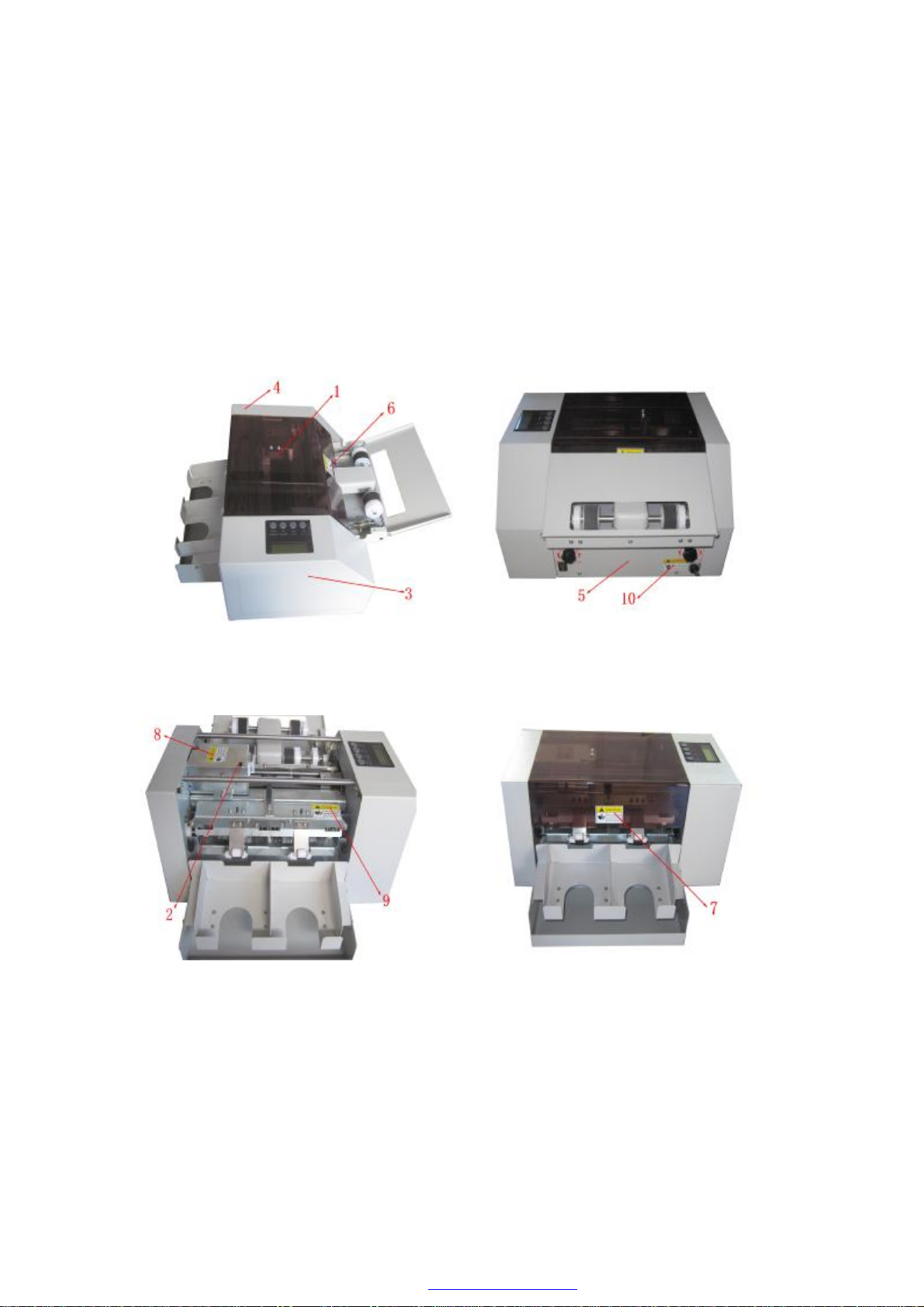

1-4Outlookdrawing....................................................................7

Chapter3Set-up, operation andmaintenance................................9

1Set-up..............................................................................................9

1-1Wayofset-upandflowsequence...........................................9

1-2Place andconditions wherethemachineis placed................10

2. Operation.....................................................................................11

2-1Cuttingflow.........................................................................11

2-2Operationpanel....................................................................12

2-3Datumselection...................................................................13

2-4Cuttingmode.......................................................................14

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn