Revision date: 10/07/2017 Page 3 of 40

1 GENERAL DESCRIPTION UWI-500TP

Automatic adjustment to any primary voltage between 380 and 440V.

Line Voltage compensation keeps output of the power source constant regardless of fluctuation in

input power from 10% below lowest to above highest rated input voltage.

Safe in use. Touchable open circuit voltage only 9V, providing optimal safety for the operator

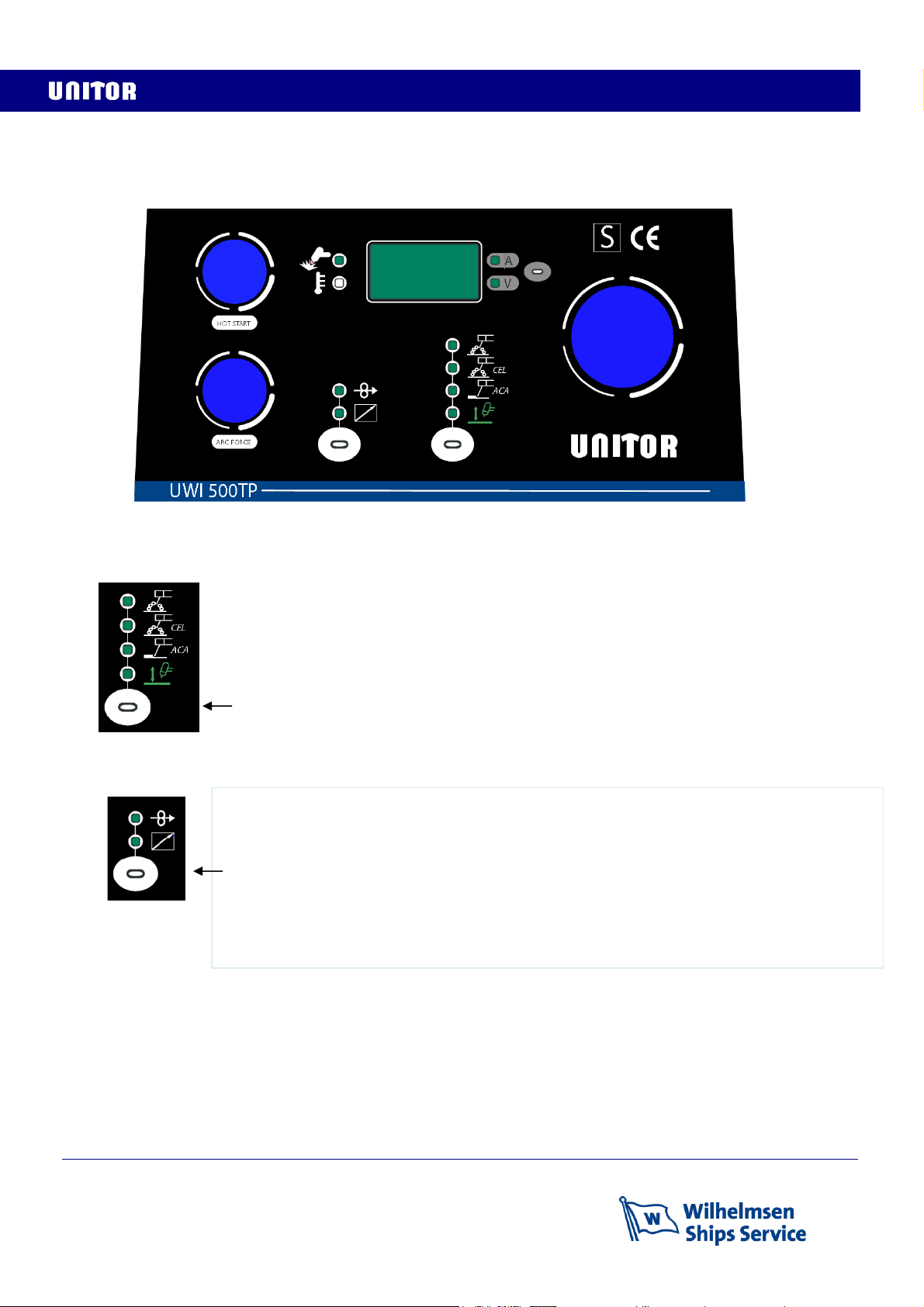

Adjustable Hot Start for MMA provides optimal arc striking for all electrode types and prevents

electrode sticking.

Adjustable Arc Force for stick electrode welding allows the arc characteristics to be changed for

specific applications and electrodes.

Lift-Start in TIG mode provides easy and soft TIG arc start and remote control from 5 amp to max.

ensures total arc control both during welding and for the down-slope finish of the weld.

Casing of high-grade aluminium and industrial plastic to eliminate corrosion damage also contributes

to low weight, which together with compact outer dimensions provides good portability.

Wind tunnel design for the internal cooling airflow protects electrical components and PC boards

from dirt, dust, debris, greatly improving reliability.

Thermal overload protection with indicator lights helps prevent machine damage if the duty cycle is

exceeded or airflow is blocked.

Total Protection function with indicator light prevents machine damage if one phase in the primary

power supply falls out or if over-voltage is supplied to the machine.

Separate characteristics for welding with standard electrodes, for cellulosic electrodes, for TIG, for

Air Carbon Arc gouging and for Wire welding with or without shielding gas ensures optimal properties

for all processes

The remote amperage control can be used for all processes, and also for two machines in parallel for

up to 1000 Amp. for Air Carbon Arc gouging.

Delivered as machine only, with

primary cable (correct plug must be

added) and instruction manual