Magnetic Lock Installation Guide V1.0.0 Internal Use Only

Zhejiang Uniview Technologies Co., Ltd. www.uniview.com 8/ 19

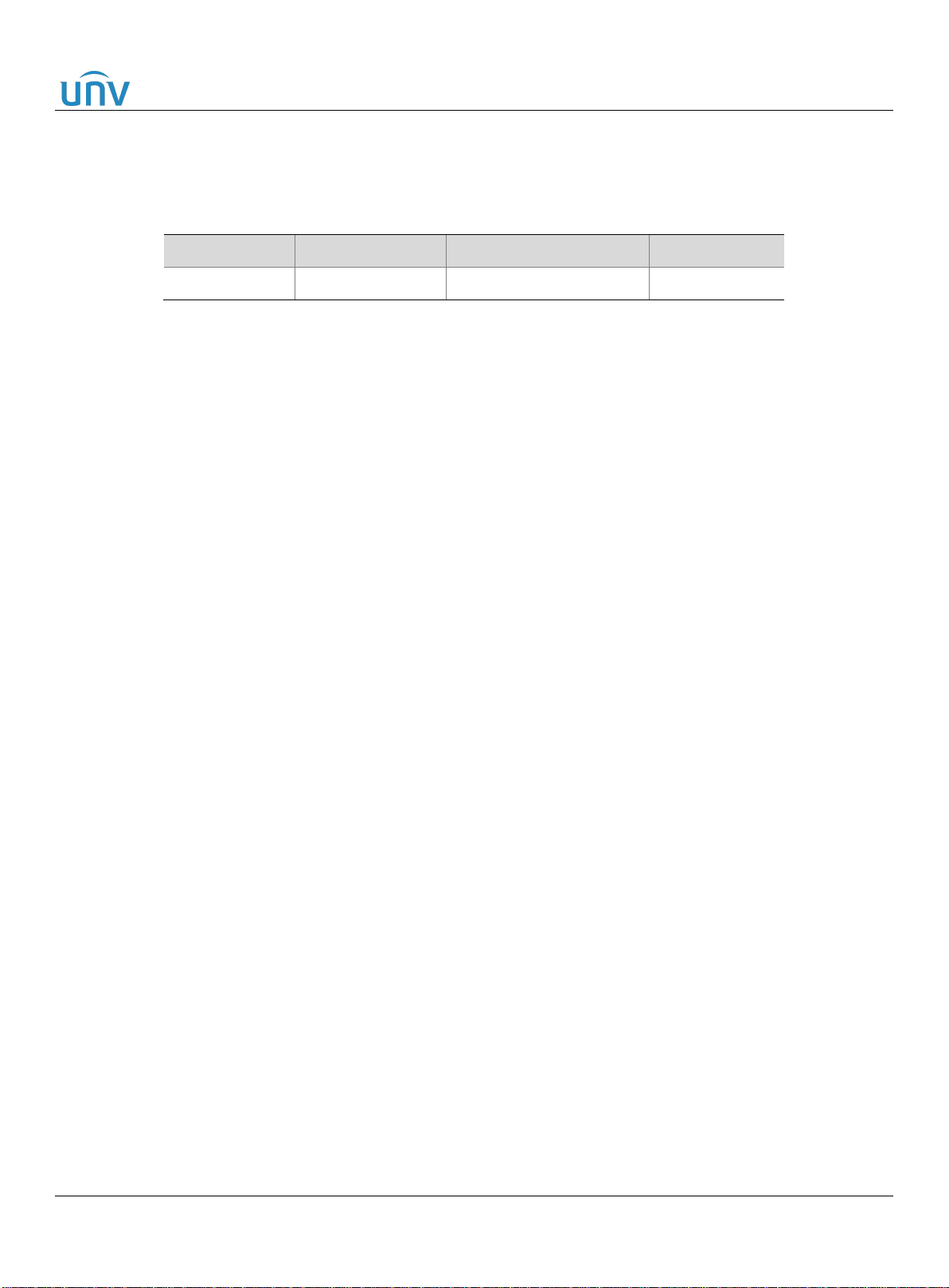

Used to measure the installation height.

Used to drill holes for screws, 8mm drill

bit.

6.8mm drill bit (only required for single-

sided reinforced doors).

Used to tap on a metal sheet, 8mm tap

(only required for single-sided

reinforced doors).

Used to loosen/tighten hex socket

screws.

4 Installation

4.1 Precautions

1. Be sure to wear gloves before installation.

2. OEA-ML12-500 series magnetic lock is heavy, so be sure to check whether the door can hold it before

installation.

3. Check if there is an available power supply (DC12V&DC24V) at the installation site.

4. The supplied rubber ring must be installed between the armature plate and the door for shock

absorption.

5. Do not screw the armature plate too tightly, so that the rubber ring can maintain proper elasticity and

the armature plate can automatically adjust to maximize the pulling force of the lock.

6. Be sure to install the two dowel pins behind the armature plate, and ensure that the dowel pin hole is

not less than 5.5mm, so as to ensure that the armature plate is not offset, and can flexibly adjust to

achieve the maximum effect of suction between the armature plate and the lock body.

7. Be careful to protect the armature plate and the lock body suction surface during installation, otherwise

it will affect the pulling force and normal use of the product.

8. During installation, the center of the armature plate and the center of the lock body shall not deviate by

more than 3mm, otherwise it will affect the pulling force and normal use of the product.