Section 4

Tool Operation and Guidelines

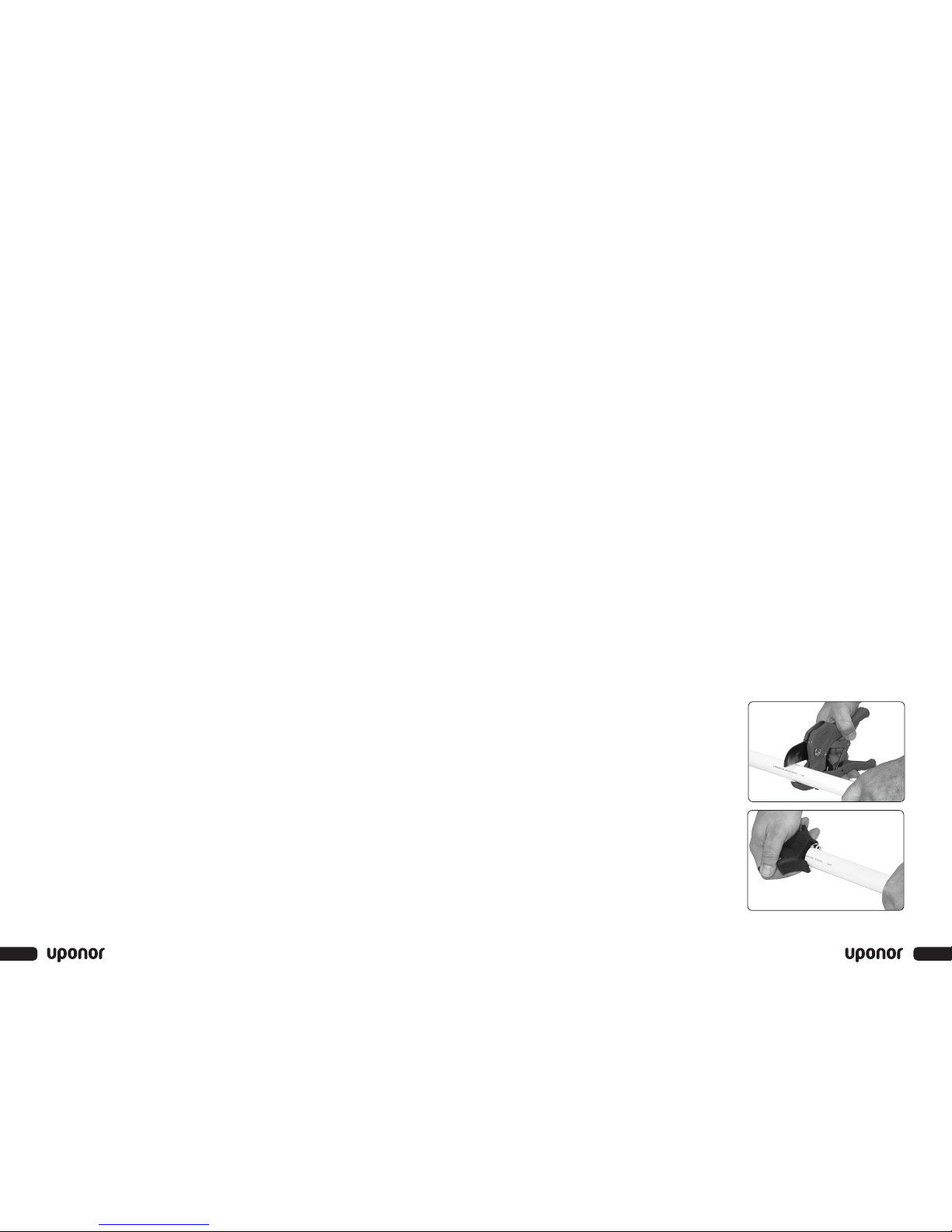

Installing and Changing Press Jaws

Refer to the following instructions to properly

install and change press jaws.

Note: Use only Uponor Mini-Press Battery Tool

Press Jaws on the Mini-Press Battery Tool. Using any

other jaws will void the warranty.

Warning: Prior tochanging the jaws, remove the battery to make

sure the tool doesn’t turn on.

1. Select the proper size press jaw for the application.

Note: Prior to installing the press jaws, check the head and jaws for

damage or excessive wear. Never use a damaged tool or jaws.

2. Disengage the locking pin by simultaneously pushing it in and turning

it counterclockwise.

3. The spring-loaded pin will pop out of its holder.

4. Insert the appropriate press jaw into the head, and push the locking pin

back into its proper position.

Warning: Ensure the locking pin is securely in place. Failure to

do so can cause personal injury or damage to the tool.

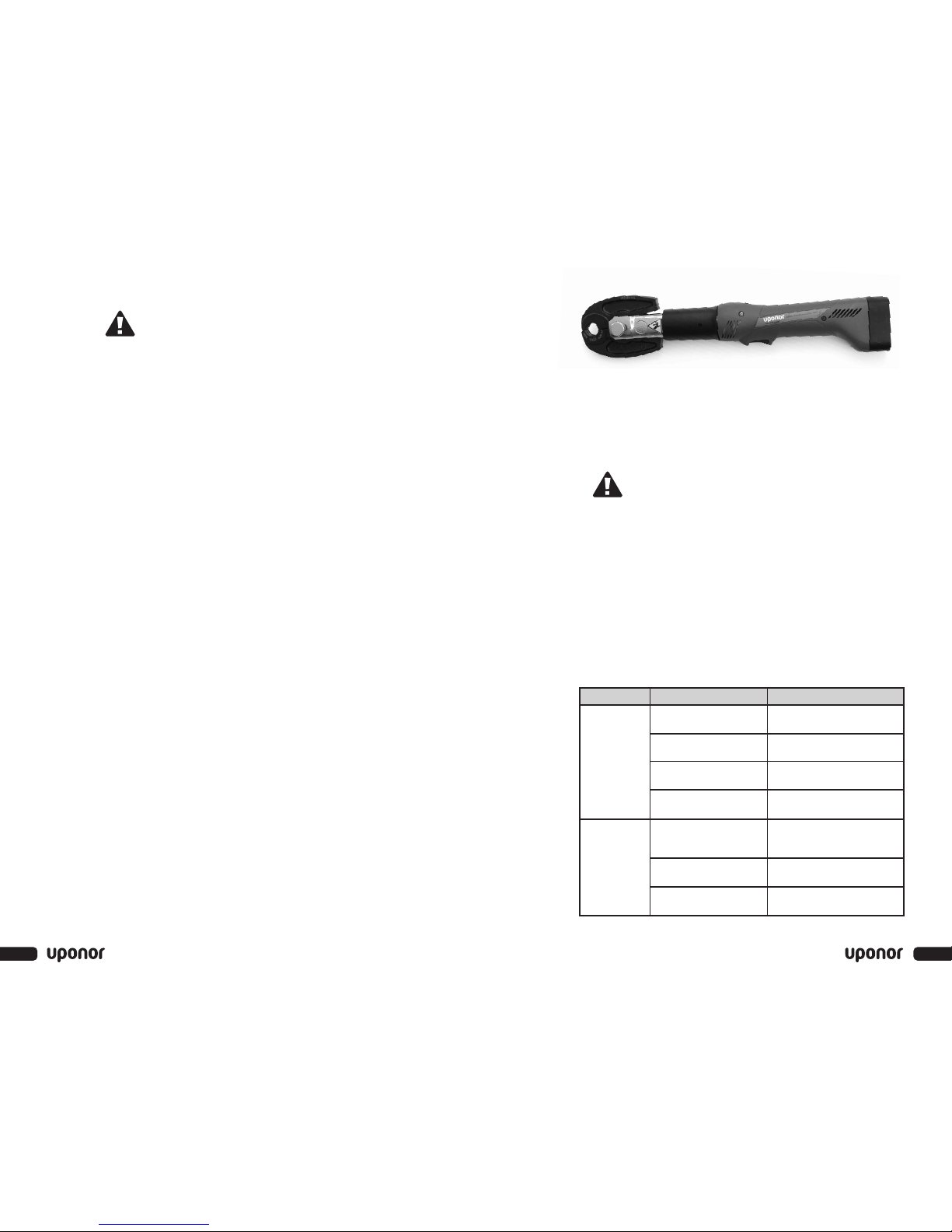

Tool Operation

Refer to the following instructions tooperatethe Mini-Press Battery Tool.

1. Beforeusing the Mini-Press Battery Tool, always perform a test

connection. Ensure the tips of the jaws close completely after

completing the connection. If the jaws do not close properly, refer

to the Troubleshooting section on page 9 for information.

2. After mounting the fitting on the tubing, open the jaws by manually

compressing them at the base near the tool body.

3. Position the jaw on the fitting.

4. Actuate the trigger to start the pressing cycle.

5. Continue holding the trigger until the pressing cycle is complete

(visually check toensure the tips of the jaws are completely closed).

6. Once the pressing cycle is complete, release the trigger.

7

Section 4 – Tool Operation and Guidelines

• Do not allow metal objects (e.g., screws, cutlery, nails) to come in

contact with the battery contacts.

• Use only the provided charger to charge the batteries. Using any other

charger will void the warranty.

• Use only the batteries provided. Using any other battery will void

the warranty.

• Use Uponor-recommended charging procedures. Incorrect use leads

to short circuits, overheating or battery fluid leakage.

• To prolong the battery’s life, avoid overcharging. Do not charge for

more than two days.

• Replace the battery if there is a substantially reduced operating time

after proper charging.

• This symbol, located on the underside of the battery pack,

signifies the battery needs to be disposed of properly in

accordance with local environmental regulations. Do not

incinerate the battery or dispose of the battery in common

waste-removal containers.

Charging Indicators

Two LEDs signal the charger’s status. Refer to Table 3-1 for the

LED definitions.

Table 3-1: LED Definitions

6

www.uponor-usa.com

Left LED (Opposite + Pole) Definition

Solid Red Charger has power and is ready for operation.

Flashing Red Charger is defective.

Right LED (Below + Pole) Definition

Solid Green Batteryis charging.

Solid Yellow Battery is 90% charged.

Flashing Green Battery is completely charged.

Flashing Red and Green Charging stopped due to an extreme

temperature condition.

Solid Red Battery is defective.

Flashing Red Battery is too hot or too cold. Remove

the battery immediately and wait for

battery temperature to reach between

50 and 104°F (10 to 40°C).

LED Off Batterypolarity is reversed or the battery

circuit is open.