Section

i

Contents

AB46 Work Platform I

3.0 Maintenance

3.0 Introduction .......................................................... 3-1

Terminology ................................................... 3-1

General Procedures........................................ 3-1

Special Tools .................................................. 3-1

3.1 Preventative Maintenance..................................... 3-1

Preventative Maintenance Table Key........... 3-2

3.2 Blocking Elevating Assembly ................................. 3-3

Installation ................................................... 3-3

Removal....................................................... 3-3

3.3 Battery Maintenance............................................. 3-4

Battery Inspection and Cleaning..................... 3-4

Battery Charging............................................. 3-4

3.4 Lubrication............................................................ 3-5

Grease Fittings ................................................ 3-5

Hydraulic Oil and Filter.................................. 3-5

Fluid Level ................................................... 3-5

Oil and Filter Replacement.......................... 3-5

3.5 Proportional Controller......................................... 3-6

Joystick Handle............................................... 3-6

Proportional Control Adjustment ................... 3-6

Rotary Control for Boom Functions............. 3-6

Drive Control............................................... 3-7

3.6 Platform Down Limit Switch............................... 3-7

3.7 Tilt Sensor ........................................................... 3-8

3.8 Hydraulic Manifold............................................... 3-8

Removal ......................................................... 3-8

Disassembly.................................................... 3-8

Cleaning and Inspection................................. 3-8

Assembly ........................................................ 3-8

Installation ...................................................... 3-8

3.9 Hydraulic Brakes................................................... 3-10

Removal....................................................... 3-10

Seal Replacement ........................................ 3-11

Installation ................................................... 3-11

3.10 Drive Pump Settings ........................................... 3-12

Pressure Override........................................... 3-12

Main Reliefs.................................................... 3-12

Pump Removal and Installation...................... 3-12

3.11 Front Wheel Bearings ......................................... 3-13

Removal ......................................................... 3-13

Installation ...................................................... 3-13

3.12 Drive Motor Removal ......................................... 3.14

Drive Motor Seal Replacement ...................... 3-14

Disassrmbly .................................................... 3-14

Assembly ........................................................ 3-15

3.13 Torque Hub ........................................................ 3-15

Removal ......................................................... 3-16

Installation ...................................................... 3-16

Seal Replacement........................................... 3-17

Roll Test....................................................... 3-17

Leak Test...................................................... 3-17

Roll and Leak Testing ..................................... 3-17

Disassembly.................................................... 3-17

Assembly ........................................................ 3-17

Main Assembly ............................................... 3-18

Pressing Tools .............................................. 3-20

Table of Contents

Section Page

No. No. Section Page

No. No.

1.0 Introduction & Specifications

1.0 Introduction .......................................................... 1-1

Purpose .......................................................... 1-1

Scope.............................................................. 1-1

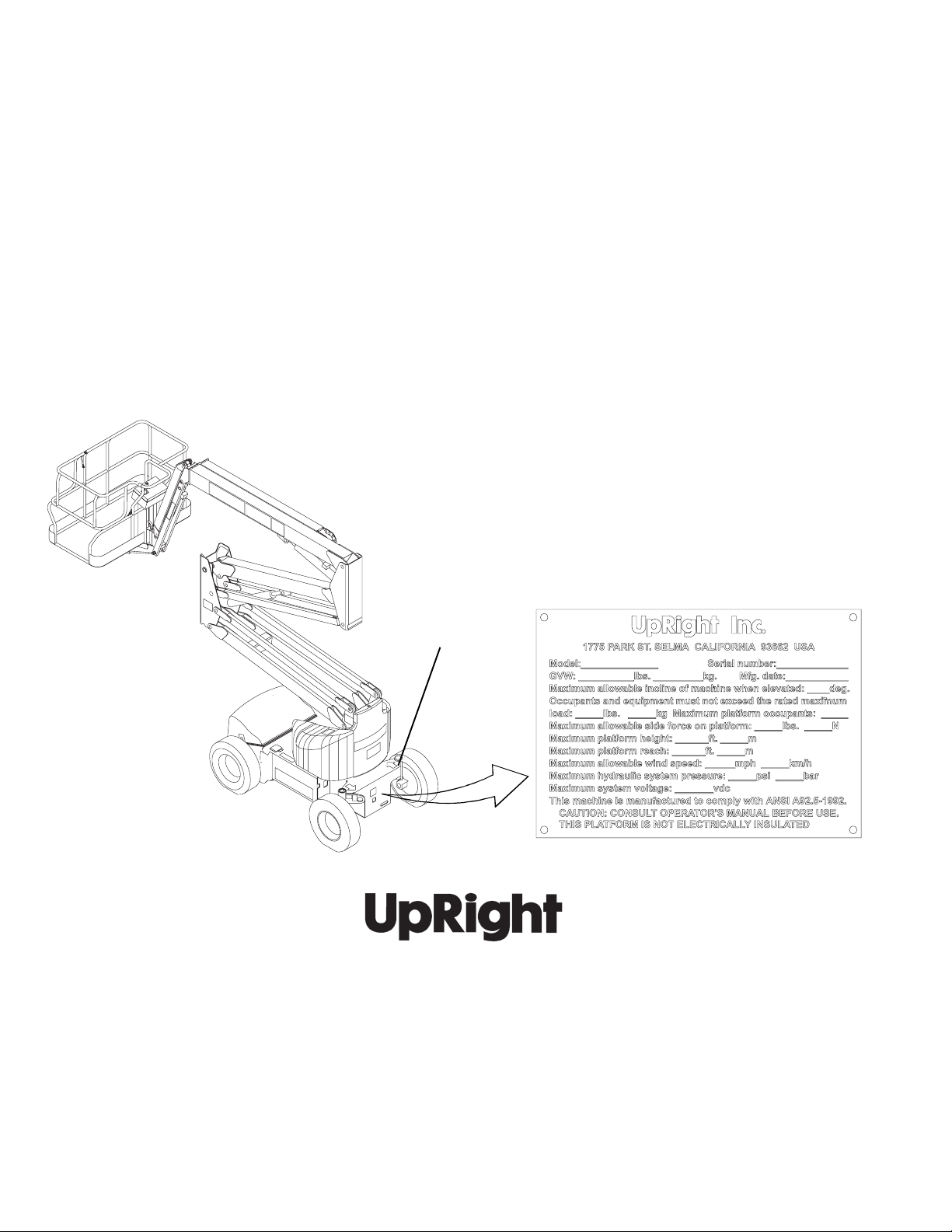

1.1 General Description.............................................. 1-1

Platform ....................................................... 1-1

Controller .................................................... 1-1

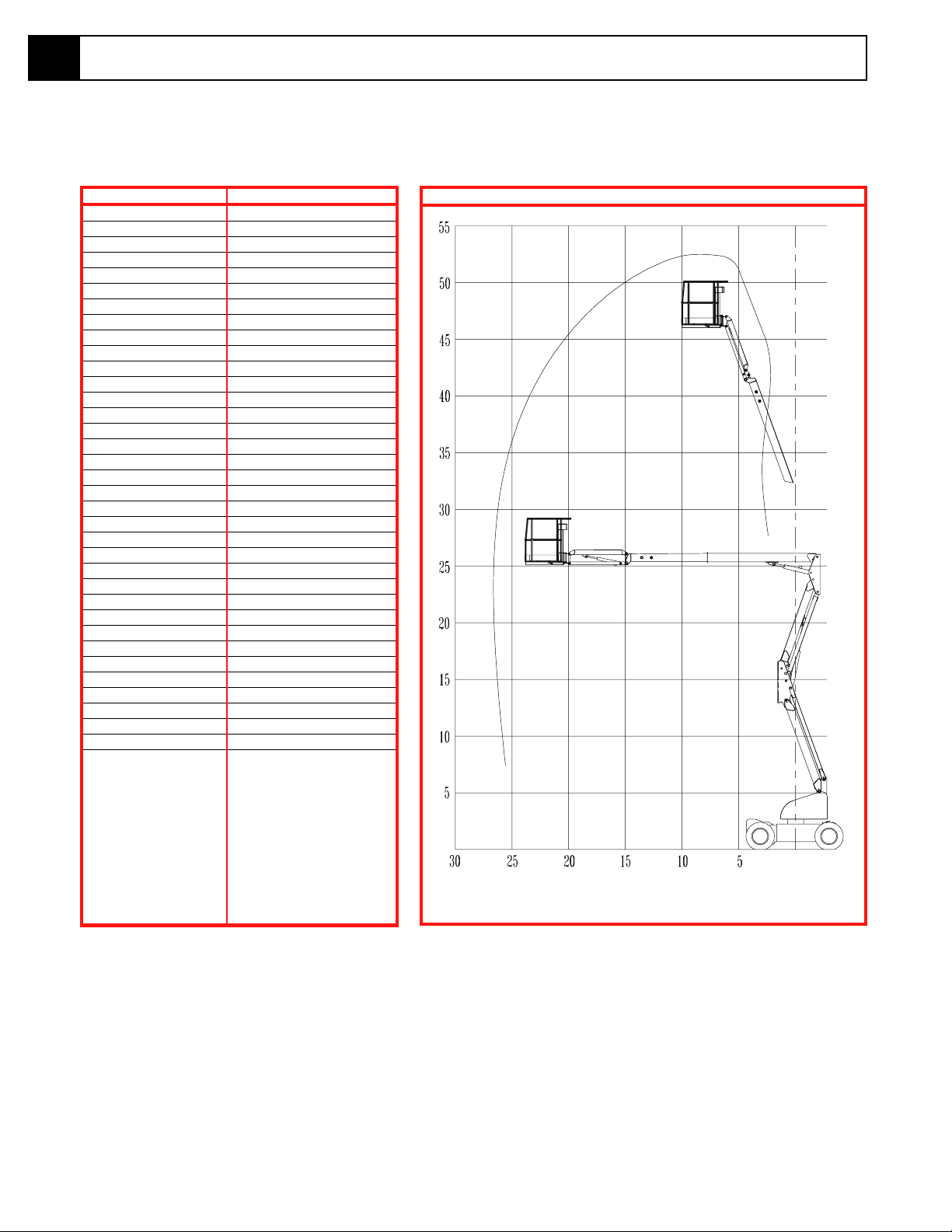

Elevating Assembly....................................... 1-1

Chassis ......................................................... 1-1

Purpose of Equipment .................................... 1-1

Special Limitations.......................................... 1-1

1.2 Specifications ........................................................ 1-2

2.0 Operation

Safety Rules................................................................. 2-1

2.1 Introduction ........................................................ 2-2

Pre-Operation and Safety Inspection.................. 2-2

System Function Inspection............................ 2-2

Controls and Indicators....................................... 2-3

Operation ........................................................... 2-3

Emergency Stop.............................................. 2-3

Service Horn................................................... 2-3

Starting the Engine.......................................... 2-4

Driving............................................................ 2-4

With Boom Lowered................................. 2-4

With Boom Elevated ................................. 2-4

Steering ..................................................... 2-4

Positioning The Platform..................................... 2-4

Multifunction Controls .............................. 2-4

Lower Controls Operation ........................ 2-4

Leveling the Platform...................................... 2-5

Rotating the Turret ......................................... 2-5

Elevating the Riser .......................................... 2-5

Elevating the Upper Boom ............................. 2-5

Extending the Upper Boom............................ 2-6

Elevating the Jib .............................................. 2-5

Rotating the Platform...................................... 2-5

Emergency Operation ......................................... 2-6

Lowering Elevating Assembly.......................... 2-6

Rotating Turret ............................................... 2-6

Emergency Towing.............................................. 2-6

After Use Each Day............................................. 2-6

Transportation.......................................................... 2-7

By Crane............................................................. 2-7

By Truck or Trailer .............................................. 2-7

Maintenance ............................................................ 2-8

Fueling ................................................................ 2-8

Gasoline ......................................................... 2-8

Diesel ............................................................. 2-8

Hydraulic Oil ...................................................... 2-8

Lubrication.......................................................... 2-8

Battery Maintenance........................................... 2-8

Tires .................................................................... 2-8