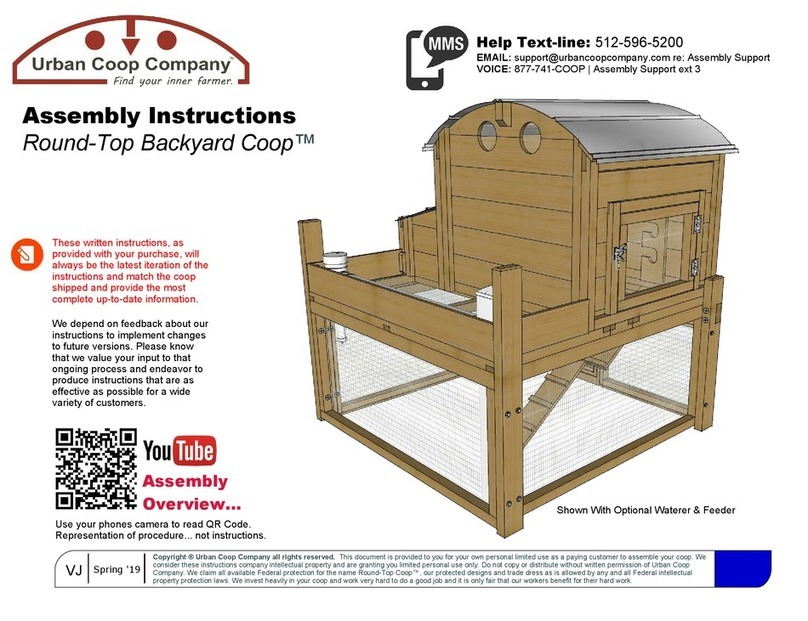

Round-Top Mobile Chicken Coop Assembly Instructions

Parts List:

Coop Comes In 2 Boxes

A. Run Panels

1) Sides 2x (beveled top edge)

2) Back (no door)

3) Front (has door)

B. Roost

1) Sides 2x (has wing panels)

2) End (egg box end)

3) End

4) Roost Bars 2x

5) Eave Boards 2x

6) Roof Panel

C. Egg Box

1) Front (has hole)

2) Bottom Wire (square)

2) Bottom Sides 2X

3) Entry Exit Board

D. Misc. Parts

1) Optional Waterer, Bracket & 2

Green Screws

2) Optional Feeder & Hasp

3) Handhold Brackets 4x

4) Handhold Bars 2x

E. Fasteners

1) 3” Brown T25 Screws

2) 1 5/8” Green T20 Screws

3) Rubber Washer Roof Screws

4) 2 1/2” Gold T-20 Screws

Note: Extra screws are provided in

case you lose one, or we goofed in

counting.

F. Tools Provided

1) T25, T20 Torx Bits

2) Magnetic Bit Holder

3) #2 Phillips Bit

G. Required Tools (not provided)

1) Cordless Drill (recommended)

! If you ordered a run extension,

you will receive a third box. You

will want to read the run extension

section of these instructions to

help identify parts.

Please email your suggestions on

making our instructions more

It’s by feedback that we can make

improvements.

Urban Coop Company

TM

Find your inner farmer

Care:

You can paint or seal your coop with just about any water-based product. Some people don’t want chemicals in contact with their hens.

Unsealed cedar will last outdoors for many years, better than almost any other wood. Painting or sealing can certainly prolong that life and

keep the wood from going naturally grey. An unsealed coop could easily last 10+ years with modest upkeep, and a sealed coop could last

longer than that. Clean wood with mild detergent and water or with a commercially available coop cleaner as needed. Glues used in all

joints are completely waterproof, and all metal parts are galvanized or have exterior-rated coatings. Clean coops make for happy healthy

hens. :)

Placement:

Easy access to water and clear access to egg door is recommended. Flat, level high ground is best. Some sunlight is not all bad. The

Galvalume roof does a good job at not transferring heat and provides shade. Sunlight does a good job at disinfecting the ground under the

coop. Good air movement around your coop is more important than anything else. Since your coop can be easily moved with two people,

make sure the ends are accessible for lifting if you decide to move it around.

Tips:

The welded wire is stronger than almost any predator smaller than a bear. :) If you’re worried about diggers, stack heavy block shaped

rocks around perimeter of coop to make getting under more difficult. You can also attach a strip of wire that extends out from the bottom

rails, and bury it below the surface of the soil. Use pine wood shavings or shredded paper in egg box to make laying eggs more comfy for

your hens.

More About Cedar:

Your coop is built from rough cut North American Western Red Cedar. Wood deemed defective is culled during fabrication (about 5%-10%).

Knots, blemishes, coloring variations, minor surface cracking, slight warping and occasional worm marks are normal parts of rough cedar.

We try to make it to where a reversible part always has a “pretty side” and take care to make the “pretty side” show on all parts. If you’re

unhappy with a piece of wood we fabricated into your coop, send us a picture. We want you to love every piece of your new coop. If there

is a serious problem, we will send out a new part to you at no charge.

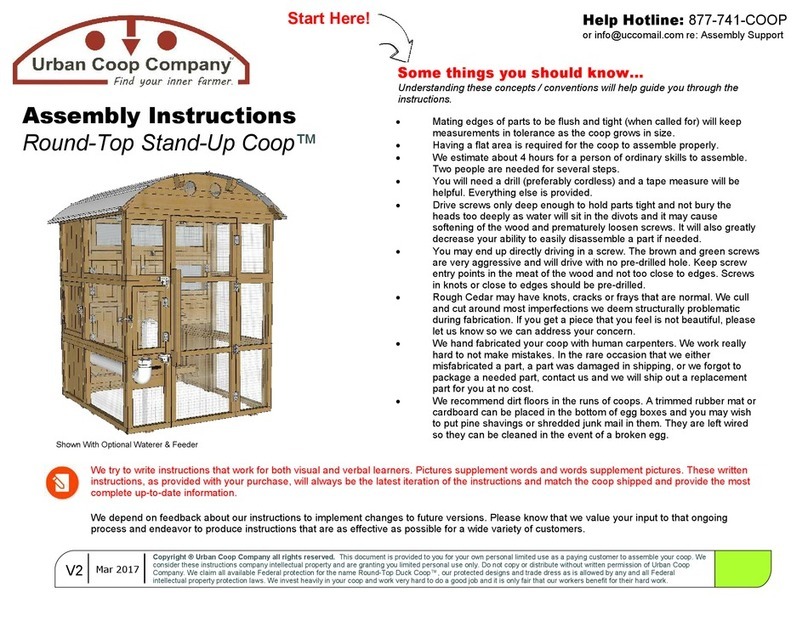

Assembly is easiest with two people and a dry flat area. You will need several hours of time to assemble.

About your new coop!