Copyright® Urban Coop Company all rights reserved. This document is provided to you for your own personal limited use as a paying customer to assemble your coop. We consider these instructions company intellectual property and are granting you limited personal use only.Do not copy or distribute without written permission of Urban Coop Company.

Urban Coop Company

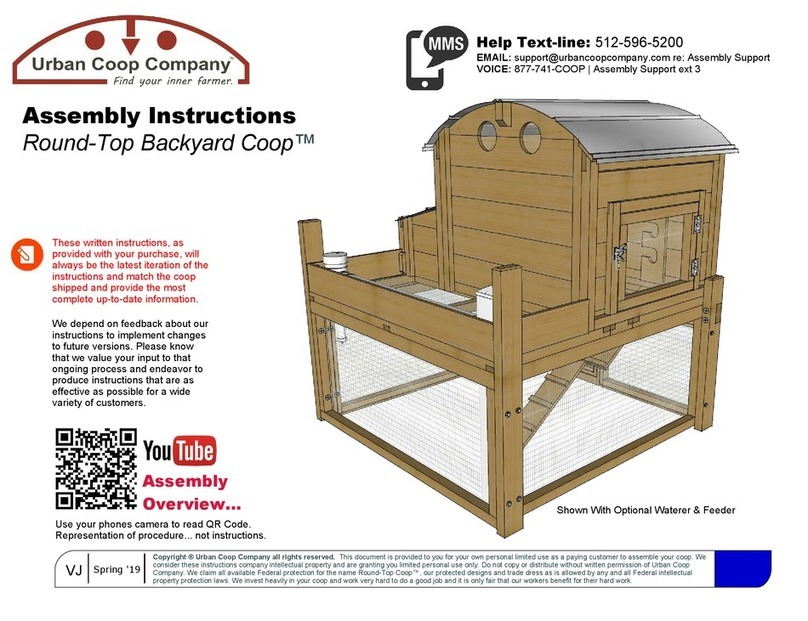

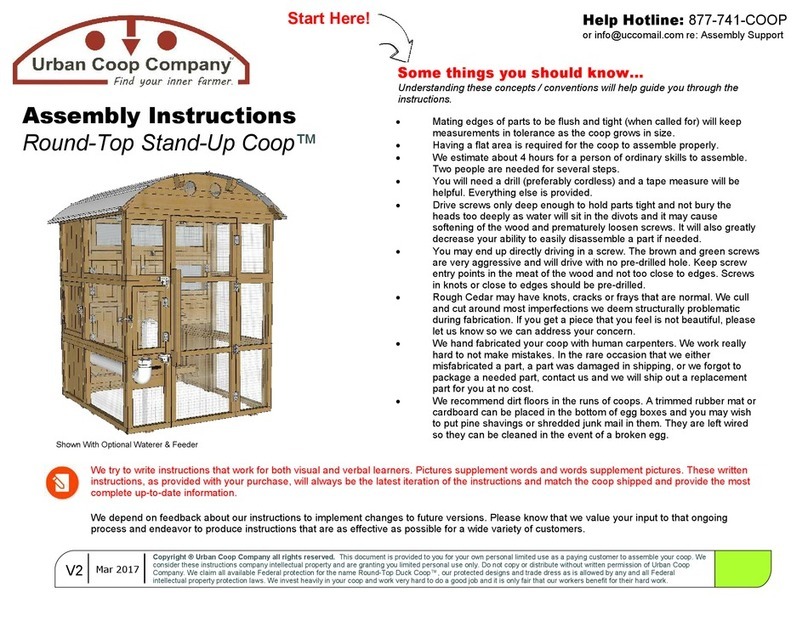

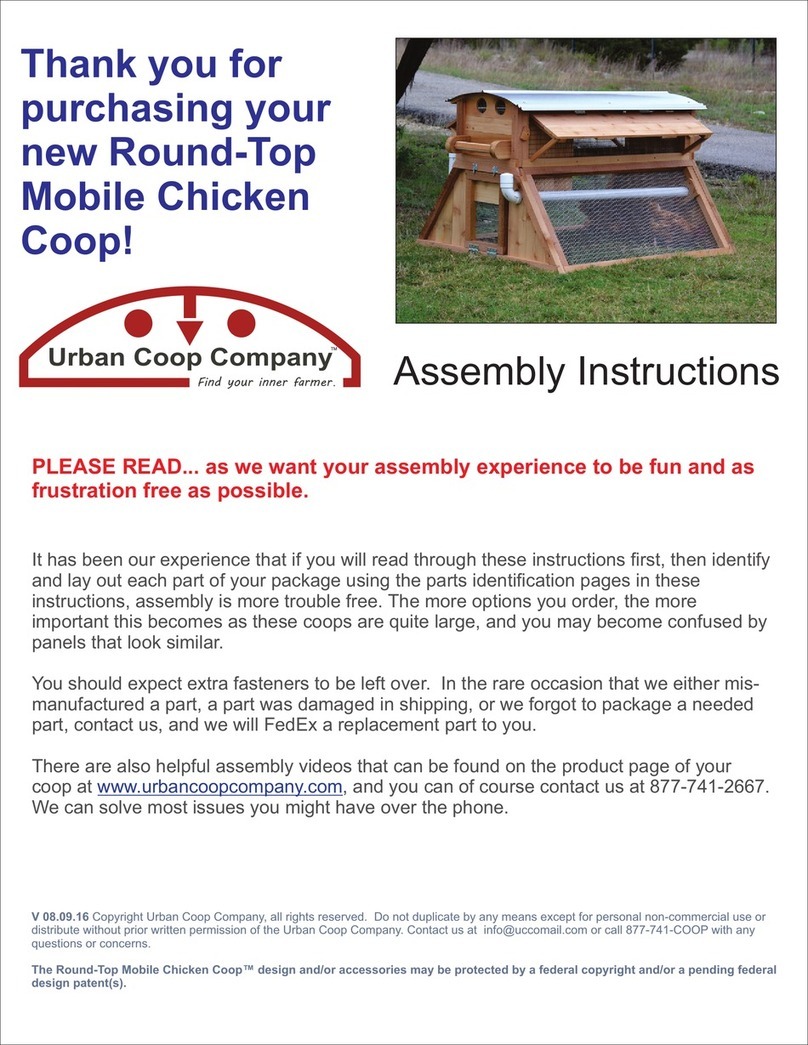

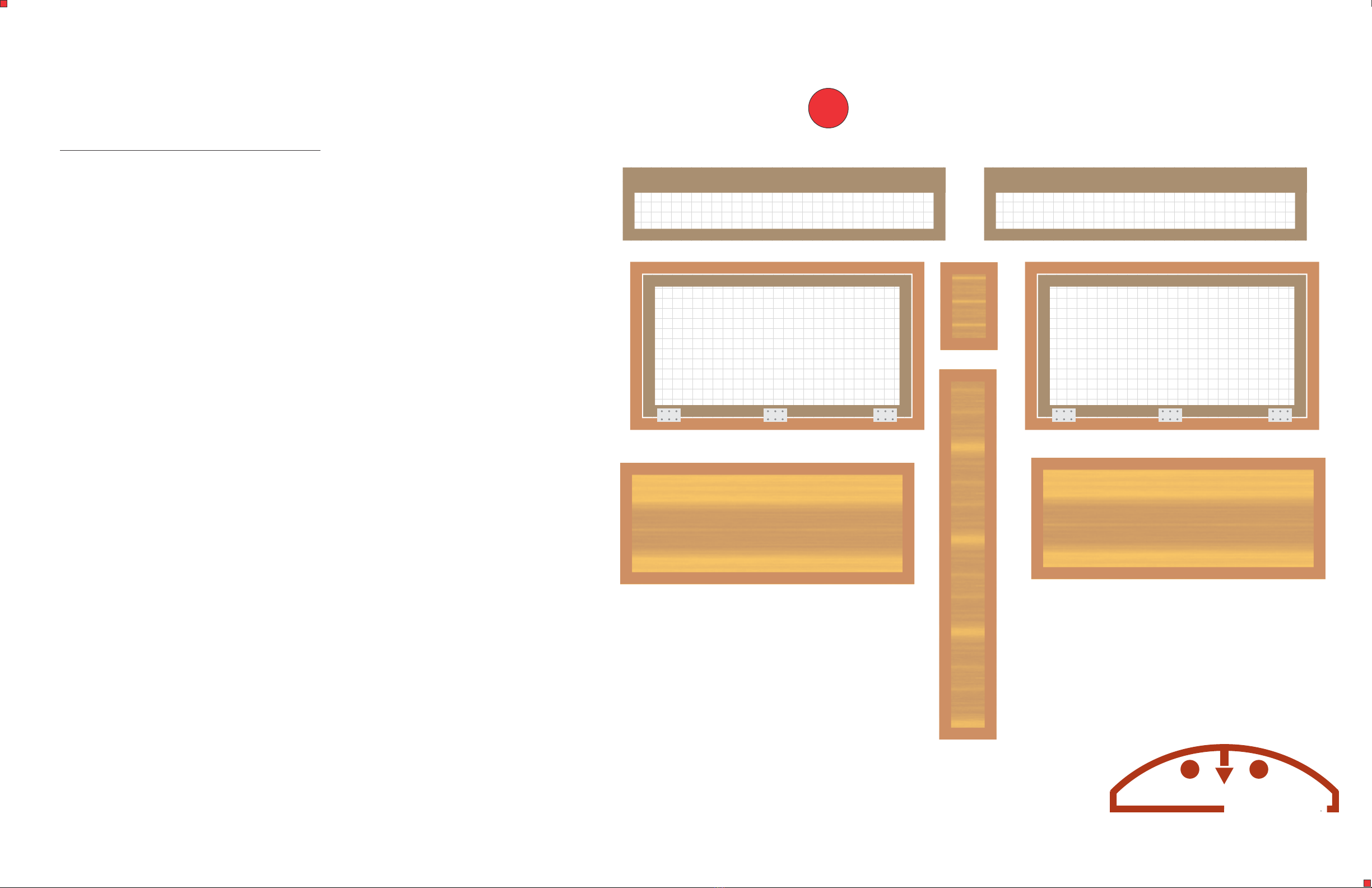

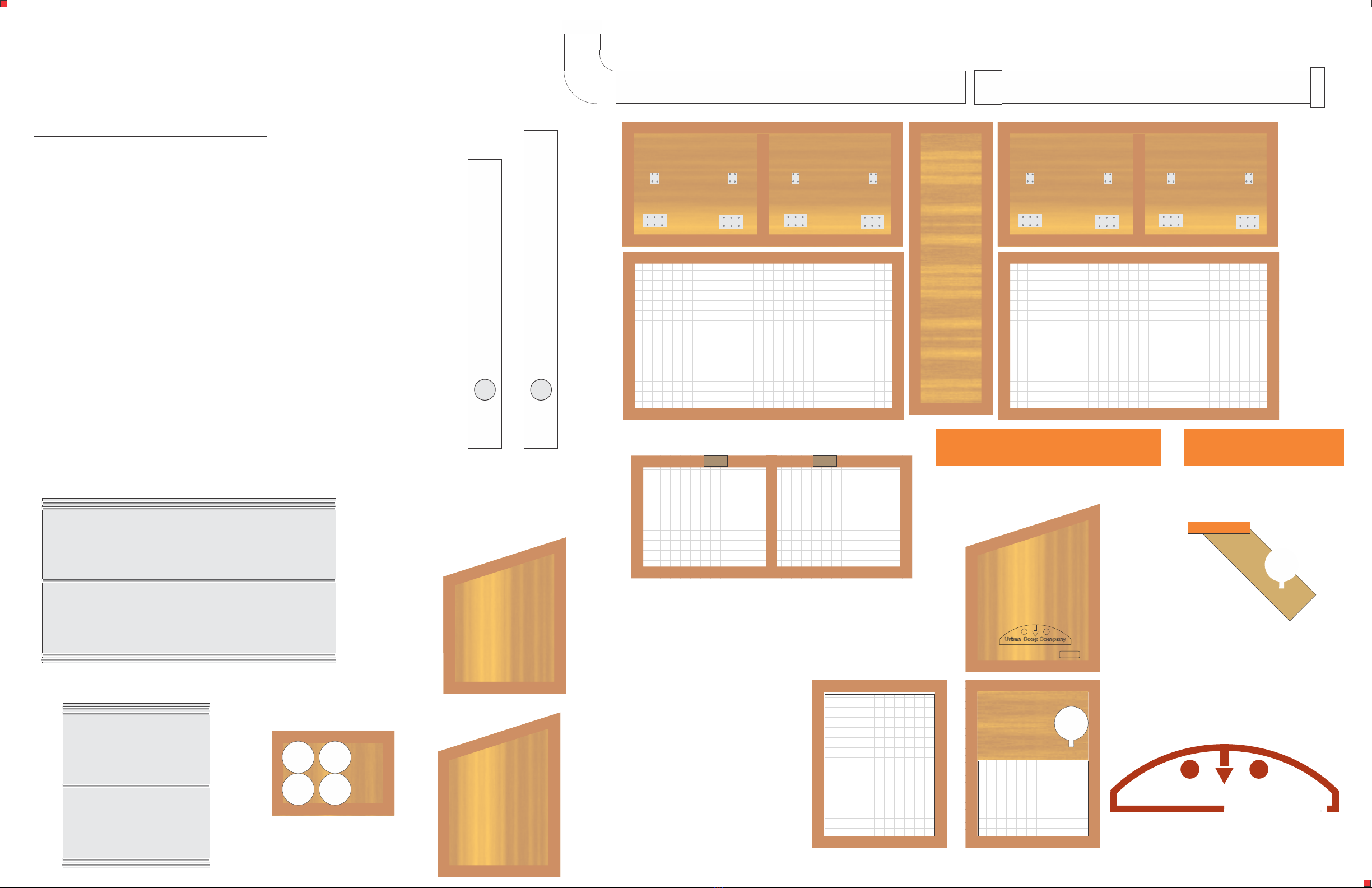

TMFind your inner farmer TMRound-Top Chicken CoopModel: Walk-InAssembly Instructions V1.0 FPlease Read: Understanding these concepts will help guide you through the instructions.ŸThe coop is assembled in three sections (I)Run Assembly (ii) Roost Assembly, and (iii) Egg Box Assembly. Wire side of panels face to the inside of coop.ŸMating edges of parts to be flush and tight will keep measurements in tolerance as the coop grows in size.ŸBrown screws are 3” and use T-25 bit. Green screws are 1 5/8” and use T-20 bit.ŸHaving a flat surface ~ 10’x10’ is required for the coop to assemble well.ŸSeveral steps will require that you work comfortably from a 6’ step ladder. Get help for these steps if needed.ŸWe estimate 8-12 hours for two people of ordinary skills to assemble.ŸYou will need a cordless drill, hammer and a tape measure. All else is provided.ŸDrive screws only deep enough to hold parts tight and not bury the heads too deeply.ŸMany pre-drilled screws holes are driven upside-down so as not to be a place to collect water, look for pre-drilled holes under parts too.ŸThere are some screw holes that must be field drilled. The brown and green screws are very agressive and will drive with no pre-drilled hole. Keep screw entry points in the meat of the wood and not too close to edges. Screws in knots or close to edges should be pre-drilled. A countersink bit is enclosed in case you run into this situation.ŸRough Cedar may have knots or cracks that are normal for this wood. We cull and cut around any imperfections we deem structurally problematic during manufacturing. If you get a piece that you feel is not acceptable, please let us know. We build to ~1/8” tolerance. Cedar expands and contracts considerably and some gaps between boards is to be expected. In any event, they should not be greater than 1/8”.Spending the time up front to identify all the parts and lay them all out will pay off in the long run and make assembly go more smoothly. The instructions are intended to be read in page order as, the information builds in that way, then referenced during assembly. Pre-reading the instructions will help immensely.Search: Round-Top Walk-In Coop