6.3.1 Removing/dosing feed ................................................................................................................................ 34

6.4 Cleaning........................................................................................................................ 37

6.4.1 Milk Shuttle without dosing pump ............................................................................................................... 37

6.4.2 Milk Shuttle with dosing pump (optional) .................................................................................................... 38

6.5 Moving the MilkShuttle.................................................................................................. 39

6.5.1 Moving on level ground ............................................................................................................................... 39

6.5.2 Moving the MilkShuttle on sloping terrain ................................................................................................... 40

7 Programming and calibrating.........................................................................43

7.1 General settings............................................................................................................ 43

7.1.1 Setting the time and date ............................................................................................................................ 43

7.1.2 Setting the user language ........................................................................................................................... 44

7.1.3 Changing the temperature unit (Celsius or Fahrenheit) .............................................................................. 44

7.1.4 Setting the warning levels for minimum and maximum temperature .......................................................... 45

7.1.5 Display Version and serial numbers ........................................................................................................... 45

7.2 Calibration..................................................................................................................... 46

7.2.1 Calibrate pump (time-controlled) ................................................................................................................ 46

7.2.2 Calibrate the pump with the flow rate controller (optional) .......................................................................... 47

7.2.3 Temperature calibration .............................................................................................................................. 48

7.3 Programming heating and agitating .............................................................................. 49

7.3.1 Overview ..................................................................................................................................................... 49

7.3.2 Operating values ......................................................................................................................................... 50

7.3.3 Programming the start times ....................................................................................................................... 51

7.3.4 Deleting the start times ............................................................................................................................... 52

7.4 Programming feeding.................................................................................................... 53

7.5 Programming the cleaning programs............................................................................ 54

8 What if...............................................................................................................57

8.1 General errors...............................................................................................................57

8.2 Display messages......................................................................................................... 58

8.3 Determining the operating code.................................................................................... 68

9 Maintenance/Repairs.......................................................................................69

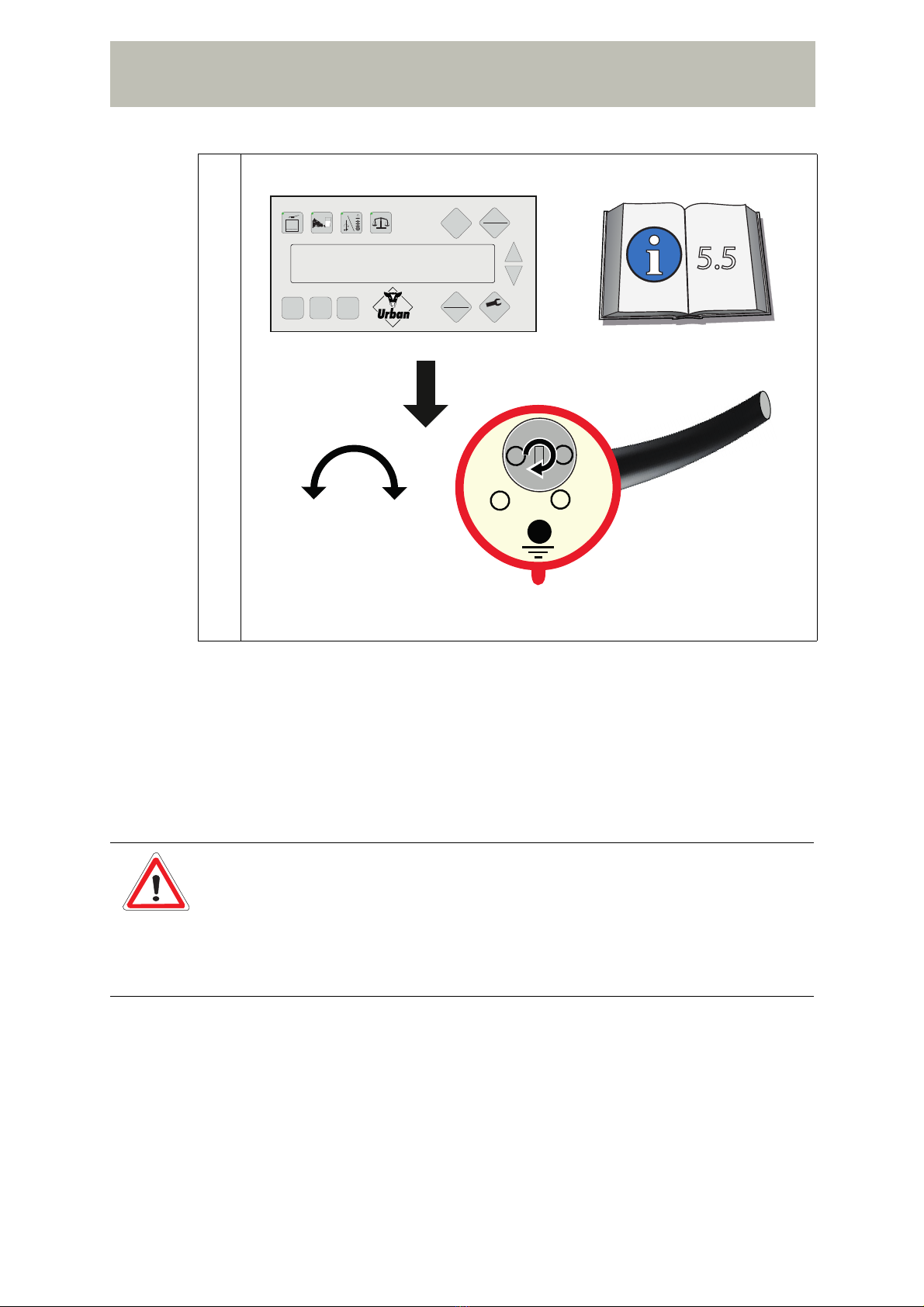

9.1 Replace wearing part set .............................................................................................. 69

9.2 Replacing fuses ............................................................................................................ 72

9.3 Replace batteries .......................................................................................................... 73

9.3.1 Replace main batteries ............................................................................................................................... 73

9.3.2 Replace batteries for date/time ................................................................................................................... 74

9.4 Changing the wheels .................................................................................................... 76

9.4.1 Changing the front wheel ............................................................................................................................ 76

9.4.2 Changing the rear wheel ............................................................................................................................. 77

10 Spare parts.......................................................................................................79

11 Mixing tables....................................................................................................81

11.1 Variant I: water volume given in litres, CMR weight given in kilograms........................ 81

11.2 Variant II: water volume given in litres, CMR weight given in pounds .......................... 82

11.3 Variant III: water volume given in gallons, CMR weight given in pounds...................... 83

Index .................................................................................................................85