Page 2 of 16

For GripSafe®ST patent and trademark information, go to https://usaindustries.com/gripsafe-patents-trademarks/

Copyright ©2022 USA Industries. All rights reserved.

FRM-22.1-Rev.H-SMDBB

2. Safety

Failure to follow proper safety requirements may result in the GripSafe® Plug failing, which could lead to

personnel injury, material loss, and damage to equipment.

Wear proper PPE when performing any task with the GripSafe® Plug as defined by site safety rules. Always

follow site procedure for safely lifting and operating equipment.

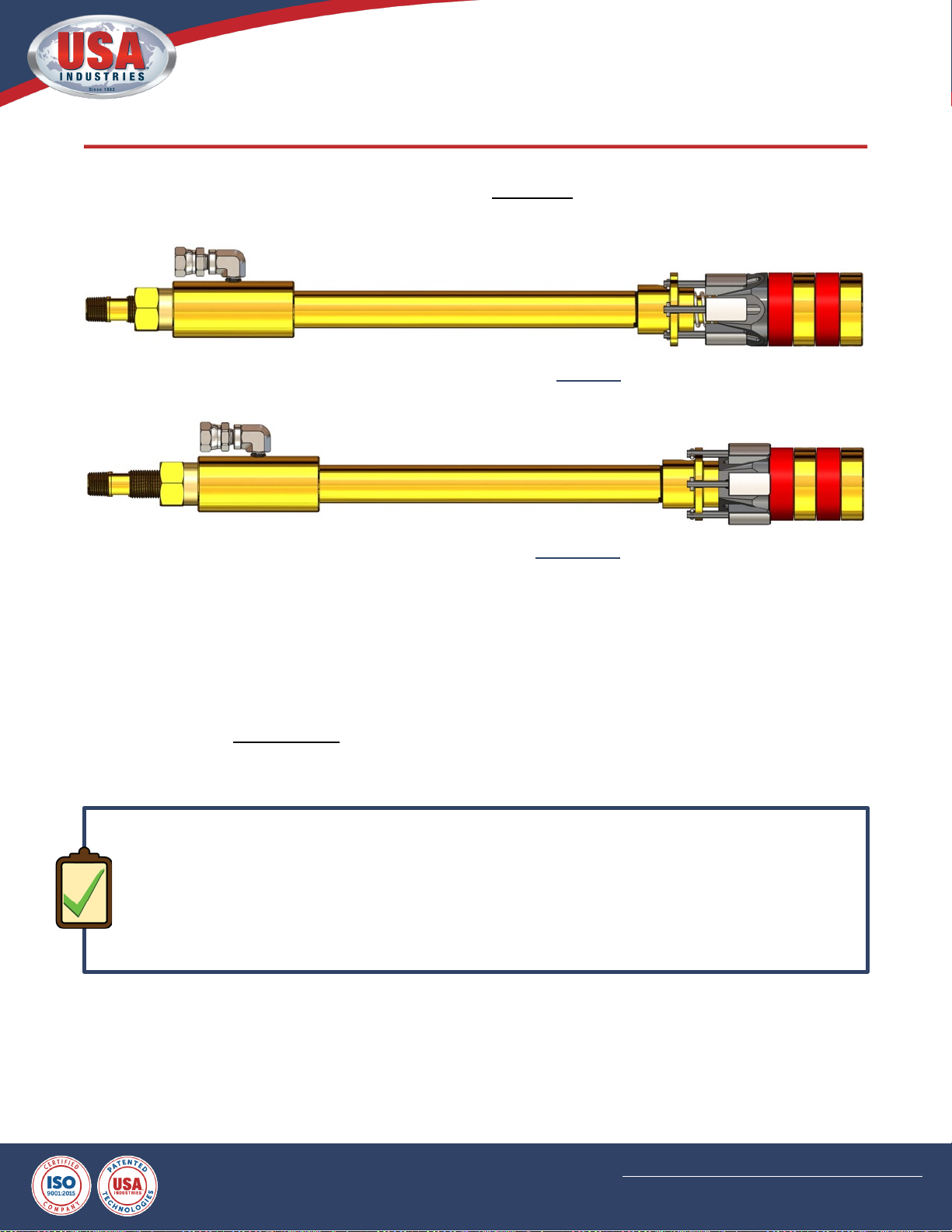

Never install the GripSafe® Plug in a position where the Gripping Wedge would be located over weld droop

or ridge.

Never install the Seals or Gripping Wedge over a section of pipe that is missing its interior wall; e.g. weldolet,

tee, etc.

Use care in the handling of the Wedge Studs. Never beat, hammer, or pry on the Wedge Studs. Never

remove the nut located on the Wedge Studs.

Pressure testing can be an extremely hazardous operation and safety precautions should be strictly adhered

to. Never stand or pass in front of any test plug while installed or while testing is in progress.

Do not make any adjustments to the plug, safety equipment, or vessel while the plug is under pressure.

Do not exceed rated pressure stamped on the plug. Plugs are rated for holding pressure in one direction

only, never apply pressure on the non-rated side of the plug.

Backpressure rating on the plug is in reference to the plugs ultimate holding capacity. Never exceed the

pressure capacity of the weakest component in a pressurized system. It is imperative that a system’s

components be studied prior to beginning a pressure test to confirm the maximum test pressure a system

can be subjected to in accordance with all applicable industry and site-specific standards.

It is recommended that water be used as the test medium. Venting all gases from the vessel being

pressurized is necessary before pressurizing the system.

In the event pneumatic testing is required, all attempts to limit potential damage to any personnel or

equipment must be made. USA Industries recommends Nitrogen as the medium for pneumatic testing as it

does not support combustion. Follow provisions outlined in ASME PCC-2 Repair of Pressure Equipment and

Piping when testing pneumatically.

The Double Block and Bleed GripSafe Plug is designed to hold pressure originating from the vessel side and

Between the Seal area only.

Careful observation is needed at the location of the pipe where the Wedge Grippers make contact while

performing a hydrotest. If any deformation or swelling of the pipe is observed, stop immediately and slowly

release the pressure from the system. Contact USA Industries for further assistance.

At any time during hydrotesting, if a popping or clicking sound is heard, stop immediately and slowly release

the pressure from the system. Popping or clicking sounds during hydrotesting could be a sign of the Wedge

Gripper slipping, cracking, or plug components failing. Remove the plug from the pipe or fitting and inspect

for damage. Contact USA Industries for further assistance.

Ensure plug is clean of debris, fouling, and contaminants before each use. Each Wedge Grippers should

freely slide up and down in its slots with a full range of motion without any resistance. With impeded

movement due to debris, dirt, contaminants, or other fouling will cause the plug to not grip on the pipe’s inner

diameter, which can cause it to eject under pressure, leading to personnel injury or death, material loss, and

damage to equipment.

For any questions or concerns, contact USA Industries for technical assistance.