1

TableofContents

Section1:Safety......................................................................................................................2

SafetyPrecautions(English).............................................................................................................2

SafetyPrecautions(Español)............................................................................................................3

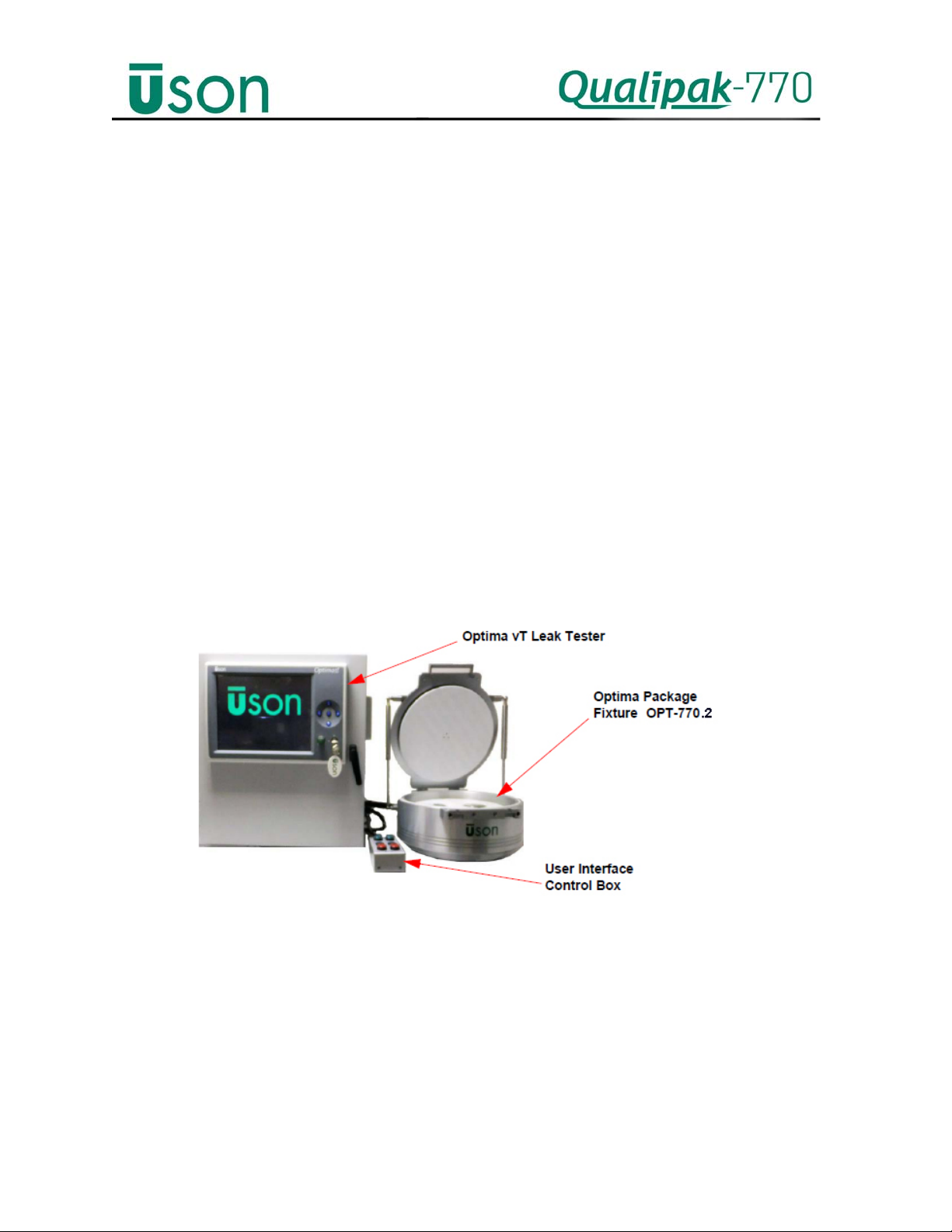

Section2:Introduction............................................................................................................4

Overview.........................................................................................................................................4

Specifications...................................................................................................................................5

HowitWorks...................................................................................................................................5

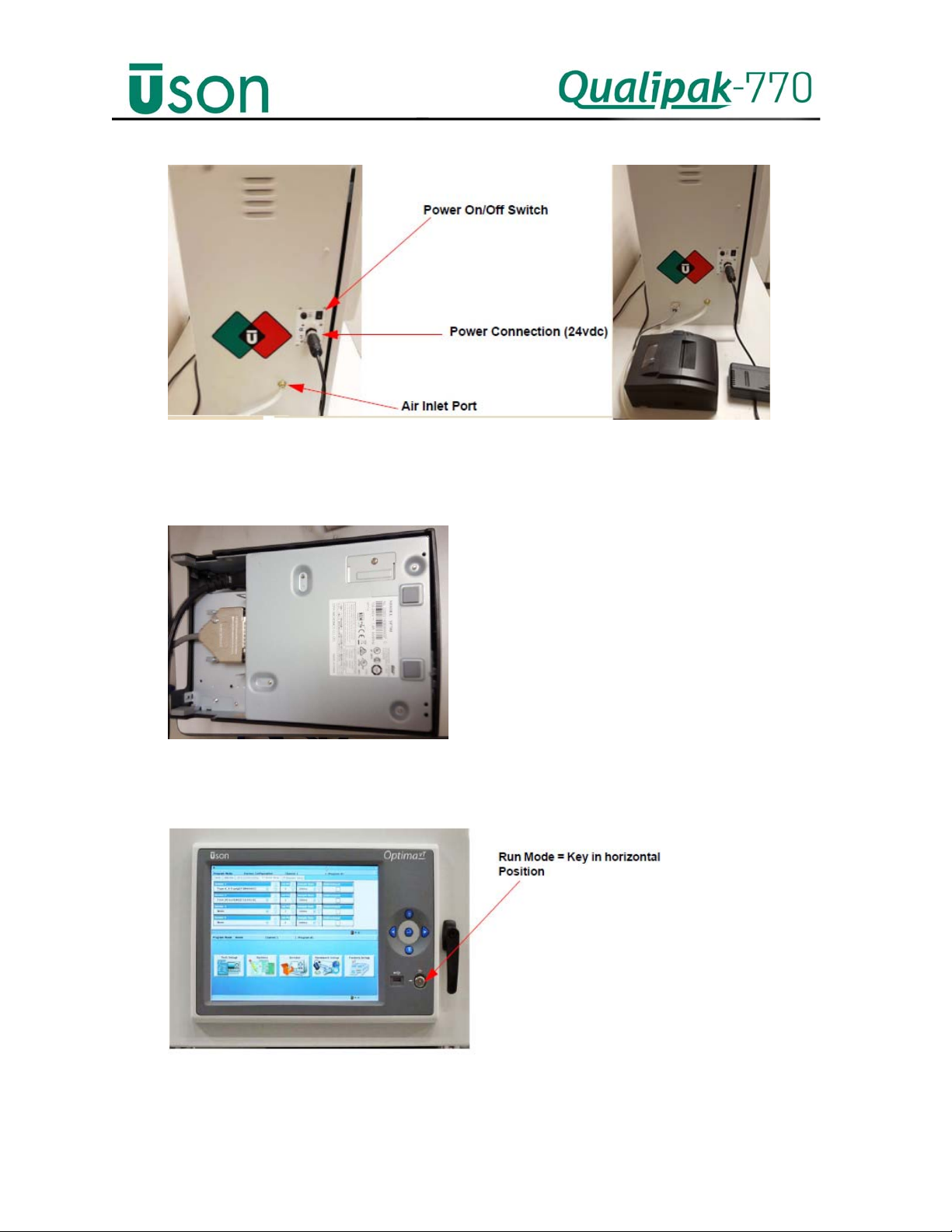

GettingStarted................................................................................................................................6

SystemTest/ChamberSealTest.......................................................................................................9

Section3:Operation..............................................................................................................11

TestingPrinciple.............................................................................................................................11

Testing...........................................................................................................................................12

Pre‐ProgrammedTests......................................................................................................................................13

ProgrammingaNewTest....................................................................................................................................14

SetupScreen...................................................................................................................................................14

SensorsTab.....................................................................................................................................................16

OutputsTab

.....................................................................................................................................................17

StepLimitsTab

................................................................................................................................................18

JumpsTab

........................................................................................................................................................18

DownloadtoTCU............................................................................................................................................19

ChallengeTest.....................................................................................................................................................20

Lidadjustment...............................................................................................................................22

Section4:Maintenance.........................................................................................................24

RoutineMaintenance.....................................................................................................................24

Daily....................................................................................................................................................................24

Weekly................................................................................................................................................................24

SixMonths..........................................................................................................................................................24

Annually..............................................................................................................................................................24

Cleaning..............................................................................................................................................................25

UserchangeableSpareparts..........................................................................................................25